2RP07X Tandem Trolley Series: Issue E March 2021

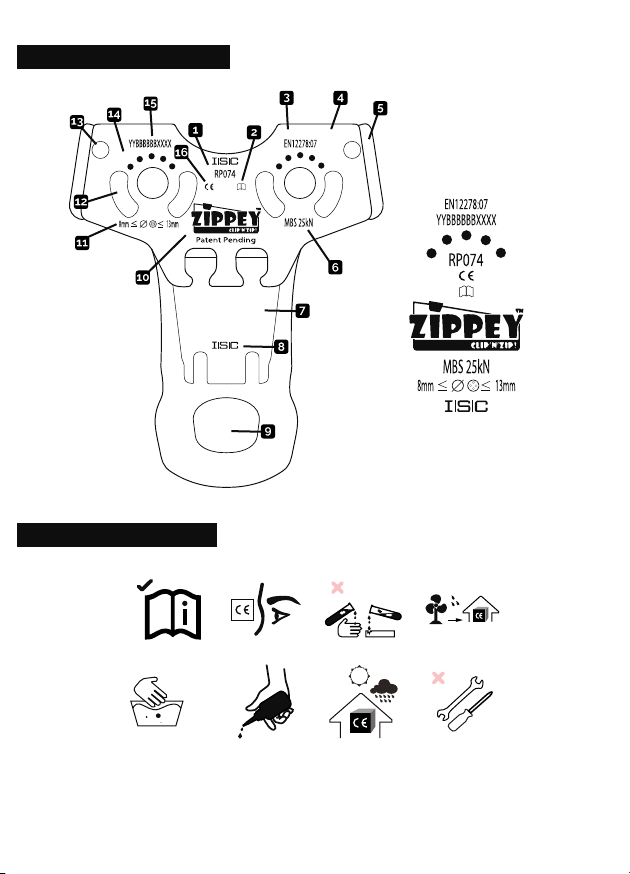

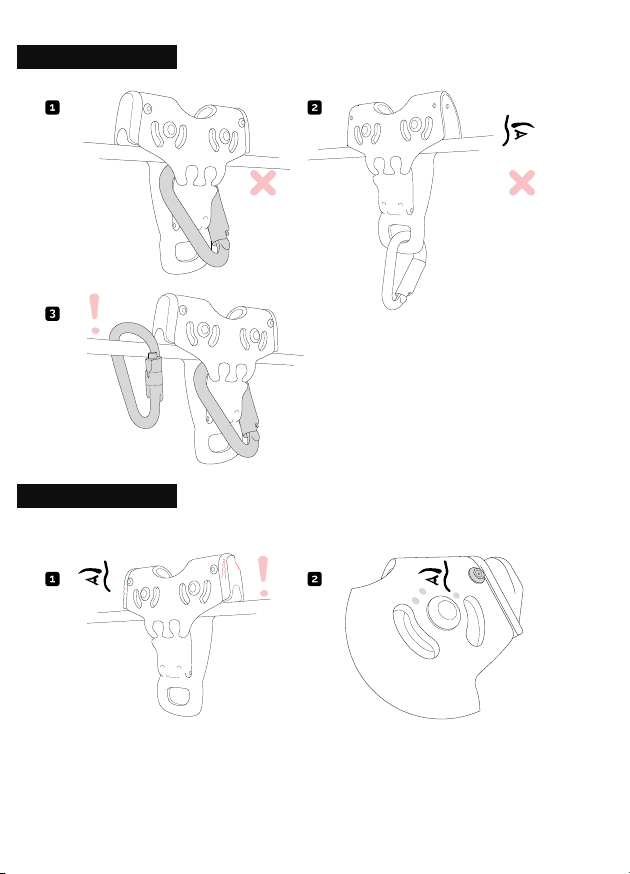

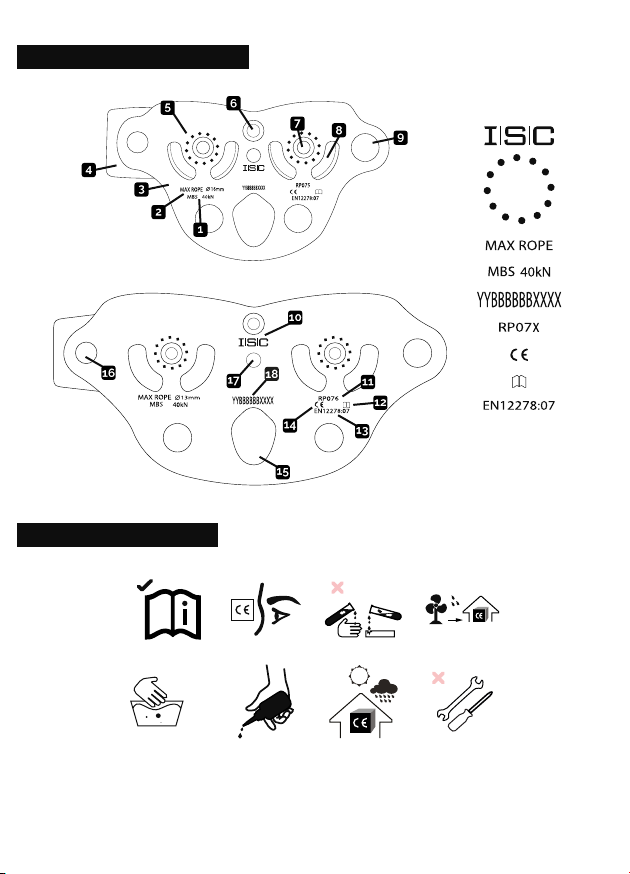

RP074

RP075

RP076

RP079XT

Zippey Trolley

ZipSpeed Trolley (50mm / 2” Wheel Diameter)

ZipSpeed Trolley (75mm / 3” Wheel Diameter)

ZipSpeed Xtreme

TANDEM TROLLEY SERIES

20

23

26

30

34

37

40

44

48

51

54

58

17 General Instructions for Use

Obecné pokyny k použití

Generelle brugerinstruktioner

Allgemeine Bedienungsanleitung

Instrucciones generales de uso

Yleinen käyttöohje

Instructions générales d’utilisation

Istruzioni generali d’uso

Algemene gebruiksinstructies

Generell bruksanvisning

Ogólne instrukcje dotyczące użytkowania

Instruções gerais de utilização

Allmänna användarinstruktioner

English

Český

Dansk

Deutsch

Español

Suomi

Français

Italiano

Nederlands

Norsk

Polski

Português

Svenska