Trox Technik EK-JZ-FF User manual

Connecting Frame

EK-JZ – FF

Installation manual

Read the instructions prior to performing any task!

for smoke control damper EK-JZ

Promaseal-LW gasket (by others)

to the face of the connecting frame

GB/en

A00000085701, 1, GB/en

Original document

Valid from 12/2022

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn, Germany

Germany

Phone: +49 (0) 2845 2020

Telefax: +49(0)2845 202 265

E-mail: [email protected]

Internet: http://www.troxtechnik.com

12/2022

Connecting Frame EK-JZ – FF2

General information

About this manual

This operating and installation manual enables oper-

ating or service personnel to correctly install the TROX

product described below and to use it safely and effi-

ciently.

This operating and installation manual is intended for

use by fitting and installation companies, in-house tech-

nicians, technical staff, instructed persons, and qualified

electricians or air conditioning technicians.

It is essential that these individuals read and fully under-

stand this manual before starting any work. The basic

prerequisite for safe working is to comply with the safety

notes and all instructions in this manual.

The local regulations for health and safety at work and

general safety regulations also apply.

This manual must be given to the system owner when

handing over the system. The system owner must

include the manual with the system documentation. The

manual must be kept in a place that is accessible at all

times.

Illustrations in this manual are mainly for information

and may differ from the actual design.

Copyright

This document, including all illustrations, is protected

by copyright and pertains only to the corresponding

product.

Any use without our consent may be an infringement

of copyright, and the violator will be held liable for any

damage.

This applies in particular to:

Publishing content

Copying content

Translating content

Microcopying content

Saving content to electronic systems and editing it

TROX Technical Service

To ensure that your request is processed as quickly as

possible, please keep the following information ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxtechnik.com

Phone +49 2845 202-400

Limitation of liability

The information in this manual has been compiled with

reference to the applicable standards and guidelines,

the state of the art, and our expertise and experience of

many years.

The manufacturer does not accept any liability for dam-

ages resulting from:

Non-compliance with this manual

Incorrect use

Operation or handling by untrained individuals

Unauthorised modifications

Technical changes

Use of non-approved replacement parts

The actual scope of delivery may differ from the infor-

mation in this manual for bespoke constructions, addi-

tional order options or as a result of recent technical

changes.

The obligations agreed in the order, the general terms

and conditions, the manufacturer's terms of delivery,

and the legal regulations in effect at the time the con-

tract is signed shall apply.

We reserve the right to make technical changes.

Warranty claims

The provisions of the respective delivery terms apply

to warranty claims. For purchase orders placed with

TROX GmbH, these are the regulations in section "Vl.

Warranty claims" of the Delivery and Payment Terms of

TROX GmbH, see www.trox.de/en/ .

General information

Connecting Frame EK-JZ – FF 3

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed carefully

to avoid accidents, injuries and damage to property.

DANGER!

Imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not avoided,

may result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Tips and recommendations

Useful tips and recommendations as well as informa-

tion for efficient and fault-free operation.

Safety notes as part of instructions

Safety notes may refer to individual instructions. In

this case, safety notes will be included in the instruc-

tions and hence facilitate following the instructions. The

above listed signal words will be used.

Example:

1. Loosen the screw.

2.

CAUTION!

Danger of finger entrapment when closing

the lid.

Be careful when closing the lid.

3. Tighten the screw.

Specific safety notes

The following symbols are used in safety notes to alert

you to specific hazards:

Warning signs Type of danger

Warning – danger zone.

General information

Connecting Frame EK-JZ – FF4

1 Safety ................................................................ 6

1.1 General safety notes ................................. 6

1.2 Qualified staff ............................................. 6

2 Classification ................................................... 7

3 Installation ...................................................... 10

3.1 Installation side ........................................ 11

3.2 Operating side ......................................... 18

Table of contents

Connecting Frame EK-JZ – FF 5

1 Safety

1.1 General safety notes

Sharp edges, sharp corners and thin sheet metal

parts

CAUTION!

Danger of injury from sharp edges, sharp cor-

ners and thin sheet metal parts!

Sharp edges, sharp corners and thin sheet metal

parts may cause cuts or grazes.

– Be careful when carrying out any work.

– Wear protective gloves, safety shoes and a hard

hat.

1.2 Qualified staff

WARNING!

Danger of injury due to insufficiently qualified

individuals!

Incorrect use may cause considerable injury or

damage to property.

– Only specialist personnel must carry out work.

Specialist personnel

Specialist personnel are individuals who have sufficient

professional or technical training, knowledge and actual

experience to enable them to carry out their assigned

duties, understand any potential hazards related to the

work under consideration, and recognise and avoid any

risks involved.

Safety

Qualified staff

Connecting Frame EK-JZ – FF6

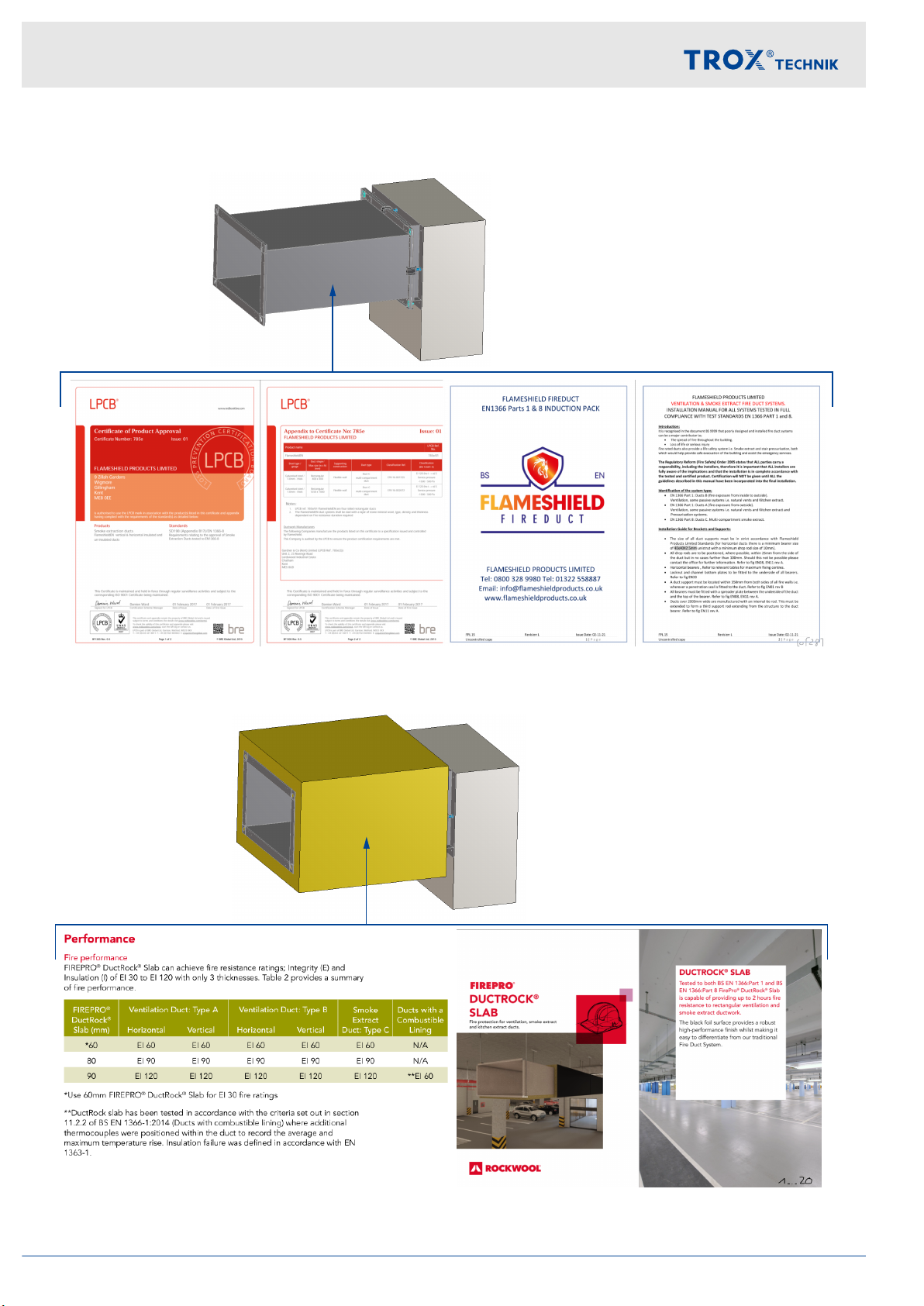

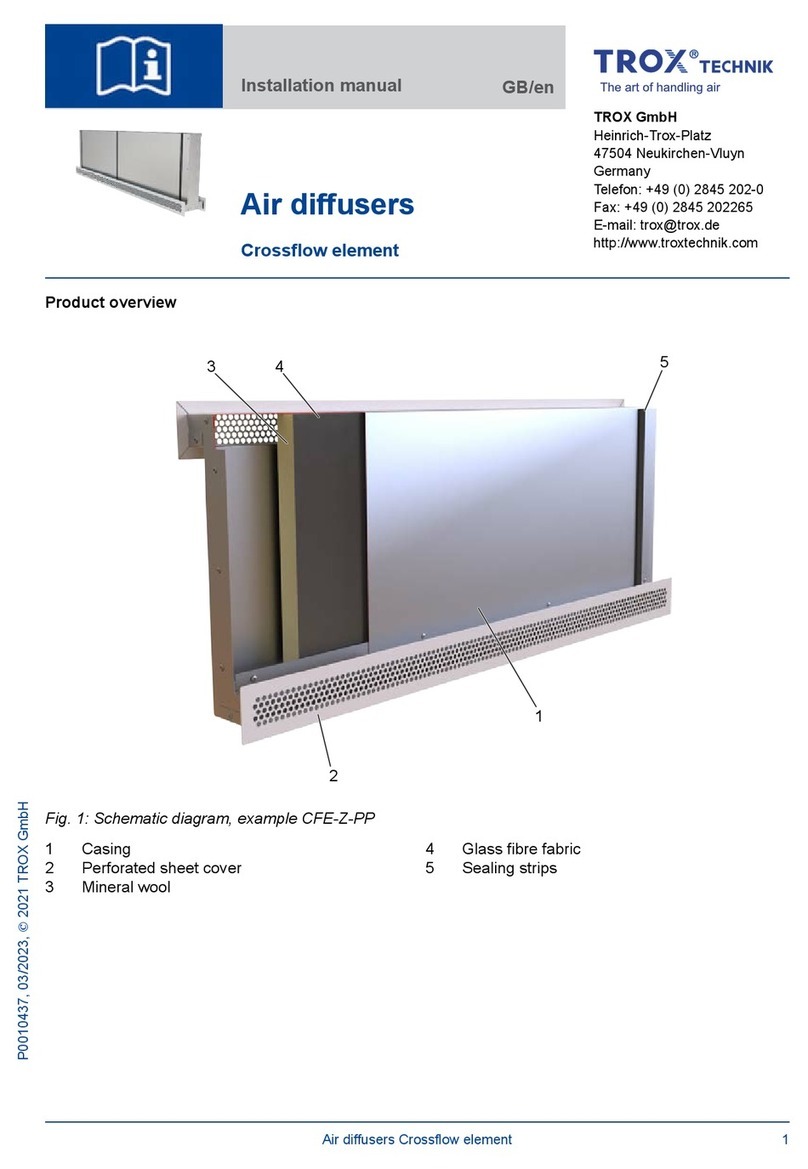

2 Classification

This guide covers the tested solution for TROX type EK-JZ dampers, installed in combination with FF connecting

frames and metal, multi-compartment smoke control ducts insulated with Rockwool FirePro® DuctRock® Slab.

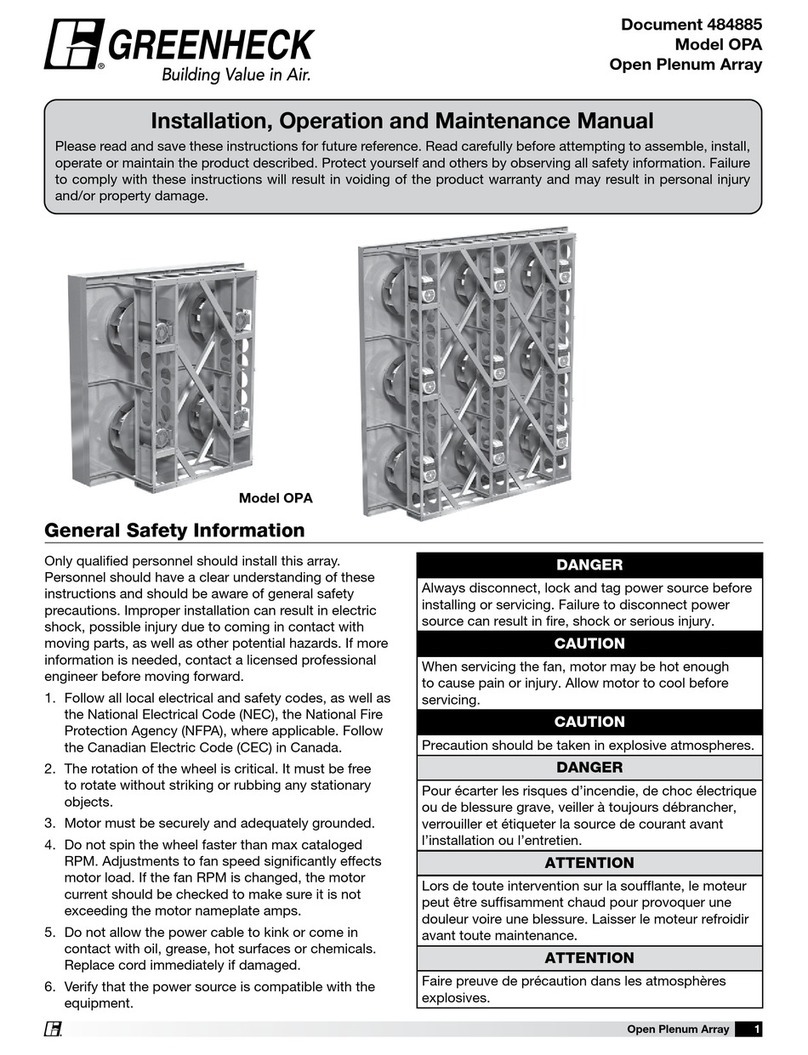

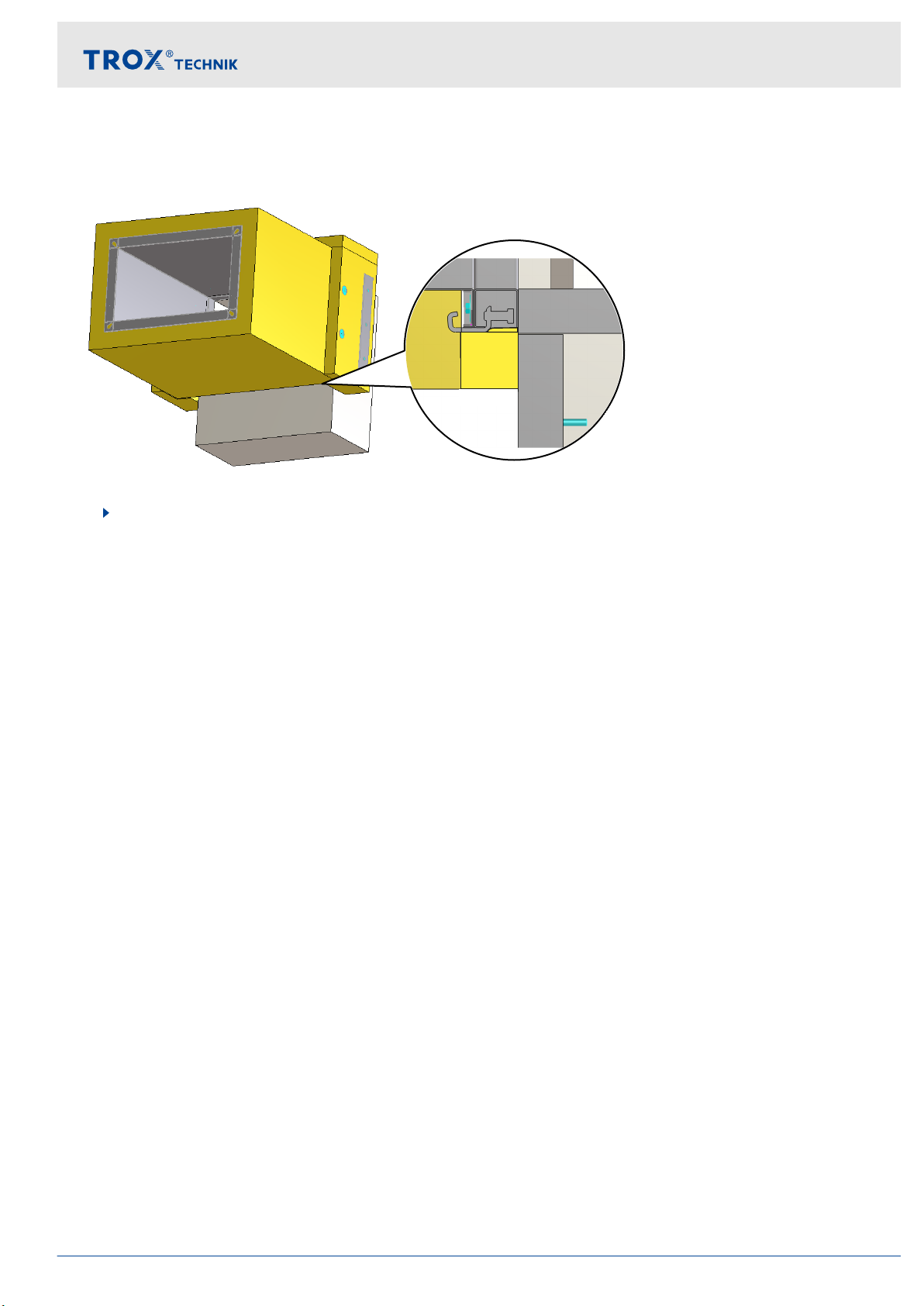

Fig. 1: EK-JZ-FF Test setup

When insulated in accordance with this guide, the classification of TROX type EK-JZ can be assured against the

Declaration of Performance (DoP) and is supported by independent testing by our Notified Body.

The following guide supports classifications upto EI 120 (ved, i↔o) S 1000 Cmod HOT400/30 MA multi

Please Note

The images contained within this guide are rotated for ease of instruction. Application in duct is only certified for

horizontal blade.

INSTALLATION DETAILS ARE SUBJECT TO CHANGE Before commencing any works, check with TROX that

you have the latest version of this guide.

Classification

Connecting Frame EK-JZ – FF 7

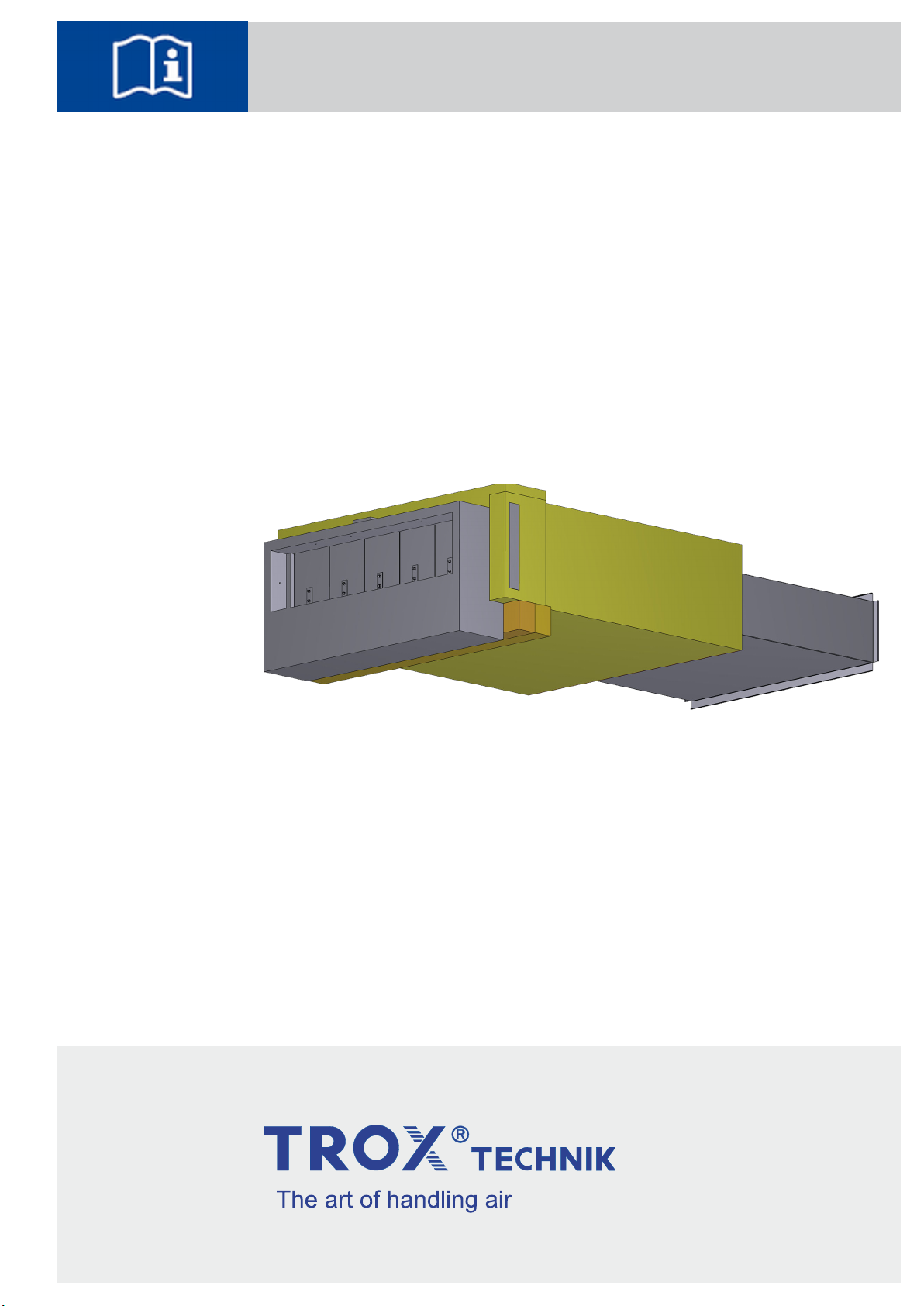

Ventilation & smoke extract fire duct system

DUCTROCKâ SLAB

Classification

Connecting Frame EK-JZ – FF8

Connecting frame

Classification

Connecting Frame EK-JZ – FF 9

3 Installation

Please Note

The images contained within this guide are rotated for ease of instruction. Application in duct is only certified for

horizontal blade.

INSTALLATION DETAILS ARE SUBJECT TO CHANGE Before commencing any works, check with TROX that

you have the latest version of this guide.

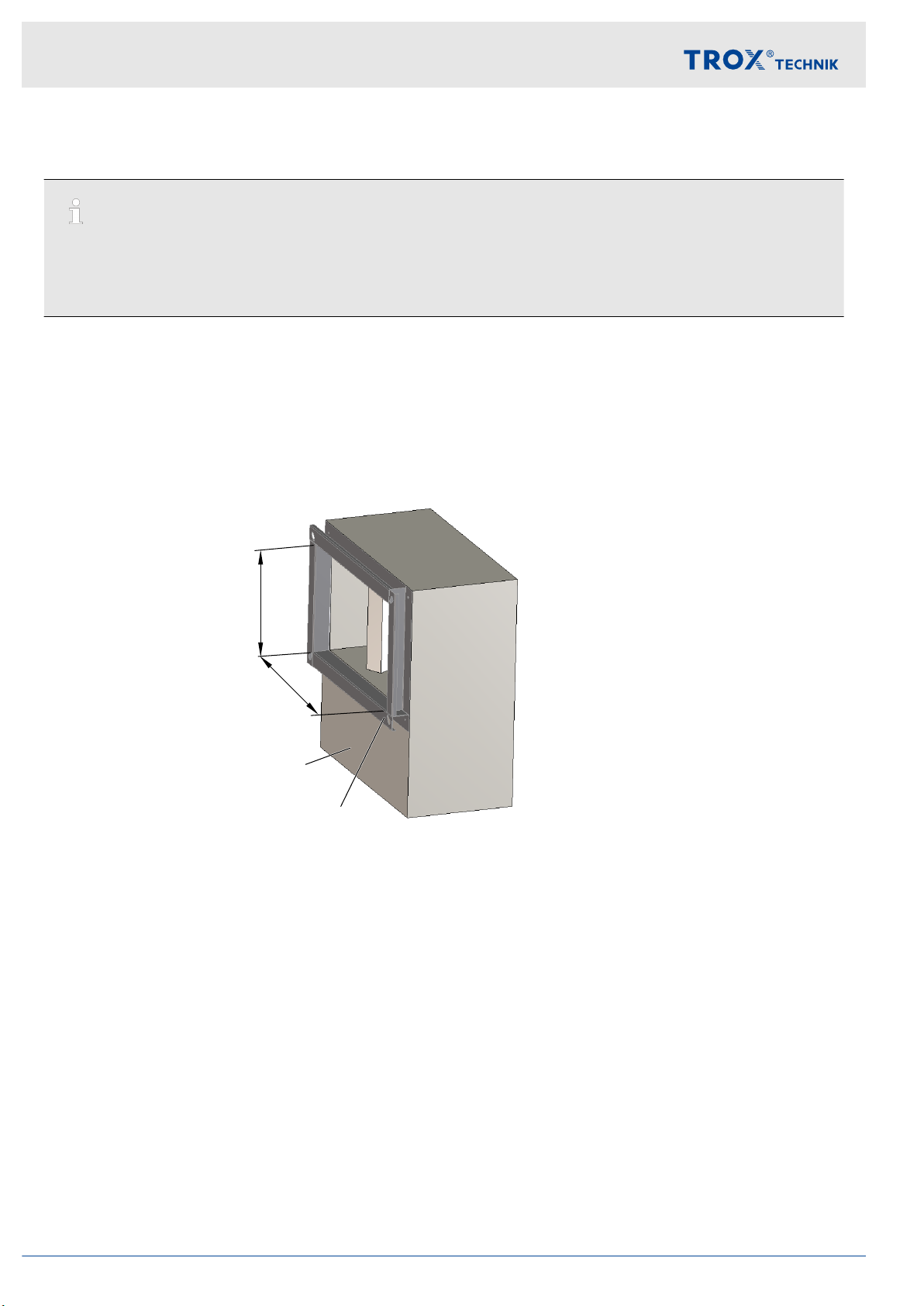

Note during installation

If EK-JZ is installed with multi-compartment ductwork connected to both sides, this insulation detail

must be applied to both sides of the damper.

The “installation side” is the side of the EK-JZ damper without access to the controls enclosure.

The damper may be installed as shown (controls enclosure at the bottom or top: EK-JZ-*-V with vertical blades

within walls only) or with the controls enclosure on the side (with horizontal blades within walls and ducts).

For clarity on the following instructions, the breadth (width) ‘B’ is the nominal damper size parallel to the blade and

the height ‘H’ is the nominal damper size perpendicular to the blades.

B

H

③

①

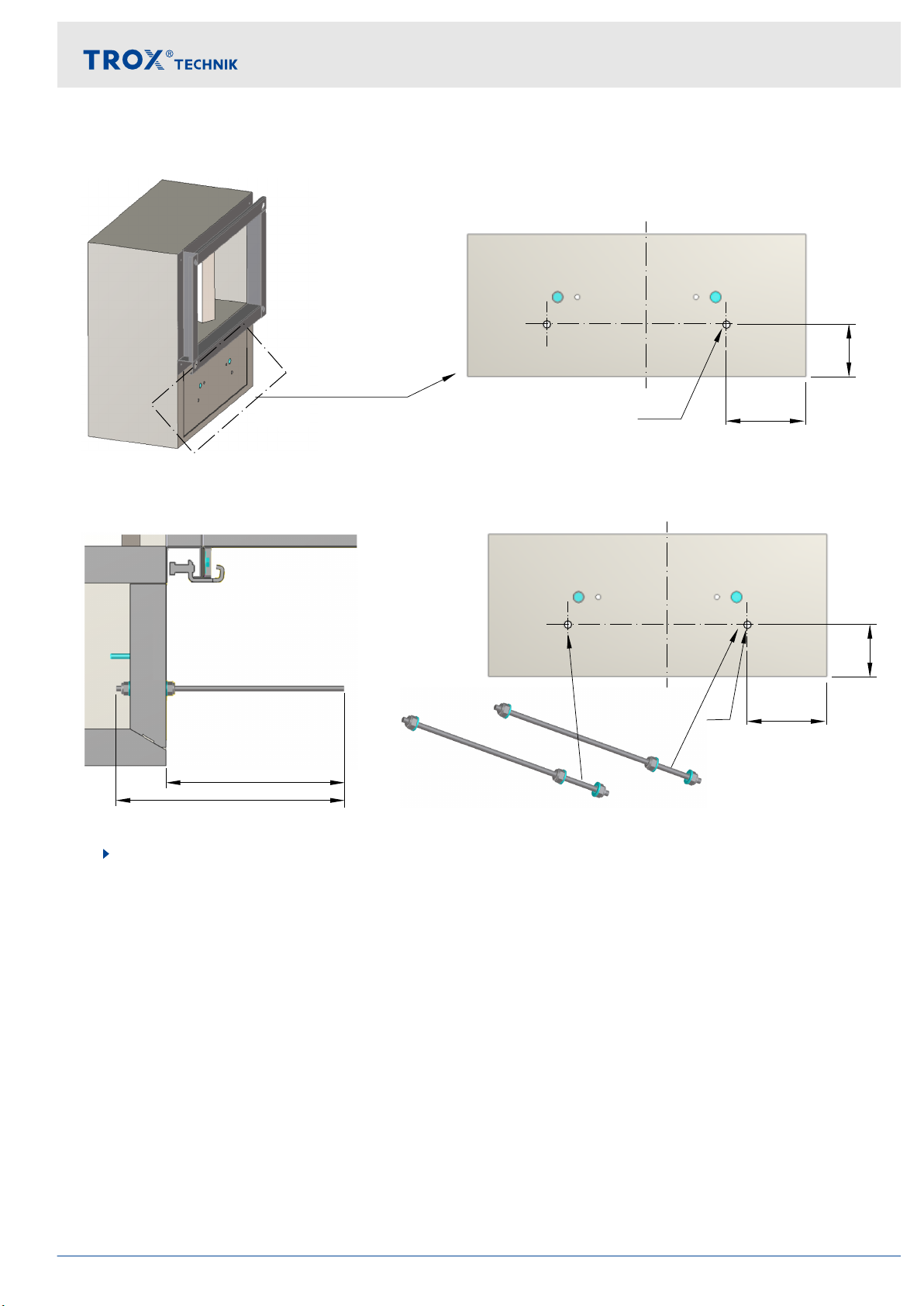

Fig. 2: EK-JZ with conneting frame

Personnel:

Specialist personnel

Installation

Connecting Frame EK-JZ – FF10

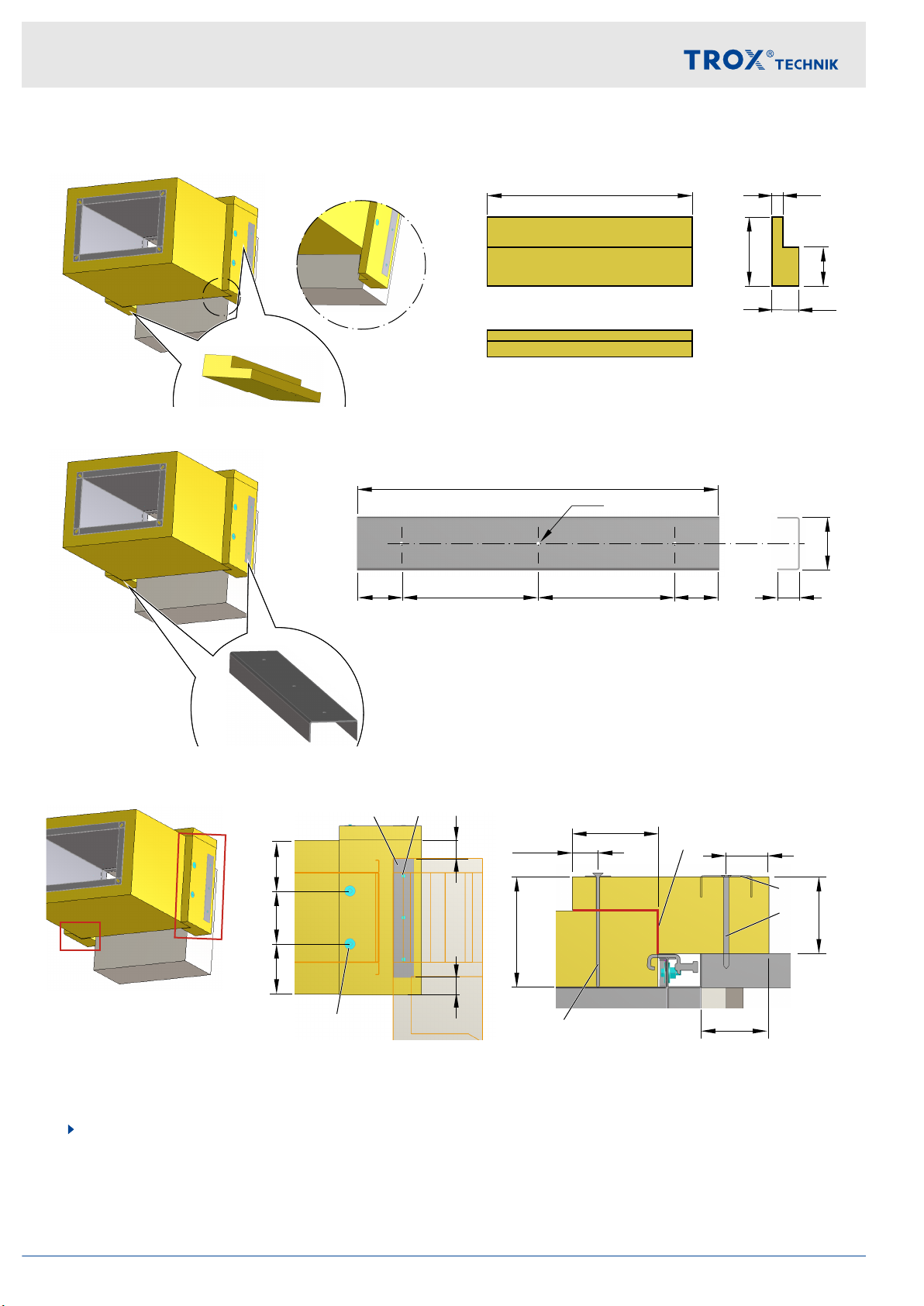

3.1 Installation side

Preparing the damper connecting frame

handle

②

①

③

②

③

installation side operating side

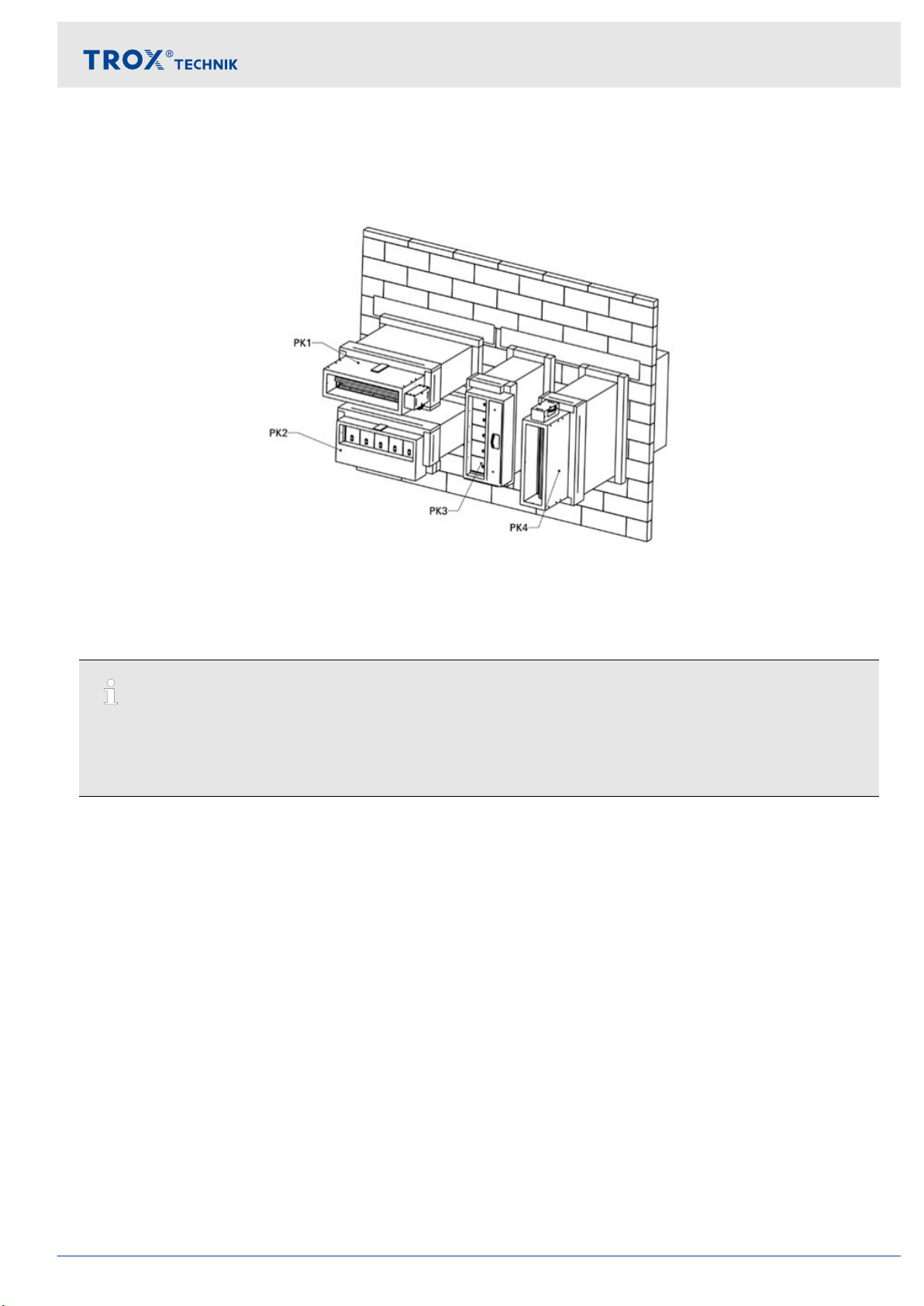

Fig. 3: EK-JZ frame mount

1. If EK-JZ damper ( Fig. 3 /1) is delivered with loose connecting frame ( Fig. 3 /3), this should be installed to

the damper using the screws provided according to TROX IOM. If the gasket ( Fig. 3 /2) is supplied loose, this

must be applied to the face of the connecting frame before installation to the damper.

Installation on Operating side see

Ä

Chapter 3.2 ‘Operating side’ on page 18

③

①

④

④

Fig. 4: EK-JZ Attach gasket

2. Attach 15 mm x 1,8 mm Promaseal-LW gasket ( Fig. 4 /4, by others) to the face of the connecting frame

( Fig. 4 /3).

Installation

Installation side

Connecting Frame EK-JZ – FF 11

Connect the ductwork to the TROX FF connecting frame

⑥

⑤

③

⑦

Fig. 5: Connect the duct

3. Corners: Attach the duct ( Fig. 5 /5) to the connecting frame ( Fig. 5 /3) with the use of M8 screws ( Fig. 5 /6),

washers and nuts.

Sides: Attach the duct to the subframe with the use of duct clamps ( Fig. 5 /7) or alternatively drill and bolt

together (≤150 mm spacing)

Insulate the ductwork

⑧

t = 90 mm

Fig. 6: Insulate the ductwork

4. Insulate the ductwork according with DUCTROCKâ SLAB ( Fig. 6 /8) to the manufacturers detail. Insulation

should finish at the end of the ductwork (Arrow).

Installation

Installation side

Connecting Frame EK-JZ – FF12

Insulating the FF connecting frame

H + 260

EK-JZ

H + 80

EK-JZ

40

90

130

230

Fig. 7: Insulation block

HEK-JZ

50 50

60

25

≤200 ≤200

-20

∅6

t=1.5

Fig. 8: U-Profile

180

180

140

≤200≤200

140

130

100

30...65 50

80

90

⑪

⑨

⑩

⑨⑩

⑪

⑫

Fig. 9: Install insulation

9 U-Profil

10 5x120 chipboard screw

11 Welding pins

12 Rockwool FIREPRO® Glue

5. Prepare 1x profiled insulation block using Rockwool FirePro® DuctRock® Slab, Fig. 7

Prepare 1x U-Profile (60 mm x 25 mm x 1.5 mm), Fig. 8

Note: Alternative option to use plate washers (≥ 25 mm dia.) in lieu of U-profile.

Install insulation to the damper, Fig. 9

Installation

Installation side

Connecting Frame EK-JZ – FF 13

L₂: B+ 180 + 120

EK-JZ

L₁: B+ 180

EK-JZ 40

90

130

230

L₁L₂

Fig. 10: Insulation block, Note: for Operating side only L2 !

B +80

EK-JZ

50 50

60

25

≤200 ≤200

∅6

t=1.5

Fig. 11: U-Profile

140

140

50

≤200

50

130

100

30...65 50

80

90

⑪

⑨

⑩

⑨

⑩

⑪

⑫

Fig. 12: Install insulation

9 U-Profil

10 5x120 chipboard screw

11 Welding pins

12 Rockwool FIREPRO® Glue

6. Prepare 2x profiled insulation blocks using Rockwool FirePro® DuctRock® Slab, Fig. 10

Prepare 2x U-Profile (60 mm x 25 mm x 1.5 mm), Fig. 11

Note: Alternative option to use plate washers (≥ 25 mm dia.) in lieu of U-profile

Install insulation on the top an bottom of the damper, Fig. 12

Installation

Installation side

Connecting Frame EK-JZ – FF14

Fig. 13: Infilling the Gaps

7. Infill all gaps between the duct insulation and the damper body with rockwool ensuring no gaps

Installation

Installation side

Connecting Frame EK-JZ – FF 15

H + 260

EK-JZ

90

150

Fig. 14: Insulation block

180180 ≤200≤200

~10

⑪

⑪

⑫

⑩

⑩

Fig. 15: Fixing the Insulation

10 6x180 chipboard screw + washer

11 Welding pins

12 Rockwool FIREPRO® Glue

8. Prepare 1x profiled insulation block using Rockwool FirePro® DuctRock® Slab, Fig. 14

Fixing the Insulation to the damper side, Fig. 15

IMPORTANT: Ensure all rockwool parts are glued together

Installation

Installation side

Connecting Frame EK-JZ – FF16

Fig. 16: Installation side Job completed

9. Insulation process for Installation side completed

Note: Orientation of butt joint between additional insulation layers can be switched to allow sides to cover top /

bottom panels.

Installation

Installation side

Connecting Frame EK-JZ – FF 17

3.2 Operating side

1. For the insulation on the Operating side, perform steps 1-6 according to installation side

Ä

Chapter

3.1 ‘Installation side’ on page 11 .

Prepare the control panel lid

Fig. 17: Control panel lid

2. Remove the handle and the type label

Note: For ease of the following steps, it is recommended to remove the access panel from the damper and

complete works at ground level.

Installation

Operating side

Connecting Frame EK-JZ – FF18

∅9

65

100

Fig. 18: Additional holes in the control panel lid

∅9

65

100

195

250

Fig. 19: M8 threaded rod, washer, nut

3. Drill 2 x Ø9 mm holes in the control panel lid

Install insulation retaining bolts and re-install control panel lid

Installation

Operating side

Connecting Frame EK-JZ – FF 19

Fig. 20: Infilling the Gaps

4. Infill all gaps between the duct insulation and the damper body with rockwool ensuring no gaps

Installation

Operating side

Connecting Frame EK-JZ – FF20

Table of contents

Other Trox Technik Industrial Equipment manuals

Trox Technik

Trox Technik X-AIRCONTROL FAM-RD User manual

Trox Technik

Trox Technik TFCU Series Specification sheet

Trox Technik

Trox Technik TVRK User manual

Trox Technik

Trox Technik FKT-EU User manual

Trox Technik

Trox Technik CFE User manual

Trox Technik

Trox Technik QL-WF-EO User manual

Trox Technik

Trox Technik JS User manual

Popular Industrial Equipment manuals by other brands

schmersal

schmersal AZM201Z-SK-T-1P2PW-A-DU instructions

schmersal

schmersal AZM201Z-I2-CC-T-1P2PW Instructions for operation

Bosch

Bosch rexroth Sytronix SvP 7020 PFC 03 operating instructions

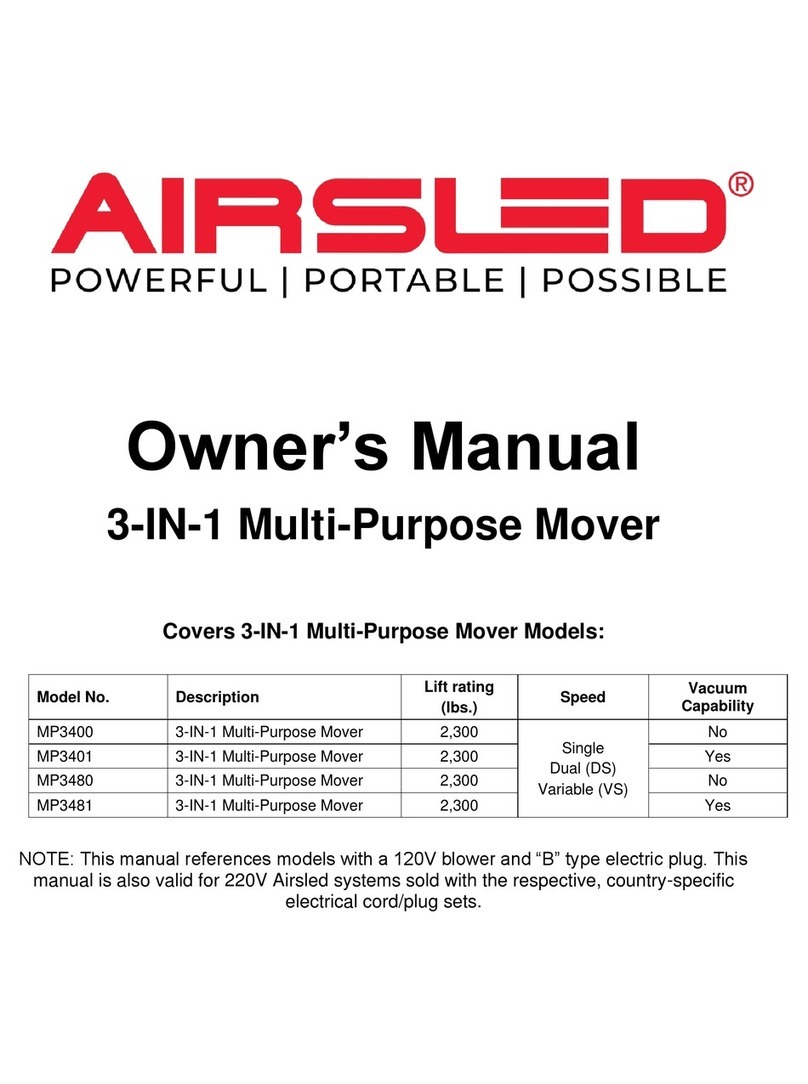

AIRSLED

AIRSLED MP3400 owner's manual

Rockwell Automation

Rockwell Automation Allen-Bradley 194U Series installation instructions

Wey

Wey MF instruction manual