Trox Technik TVRK User manual

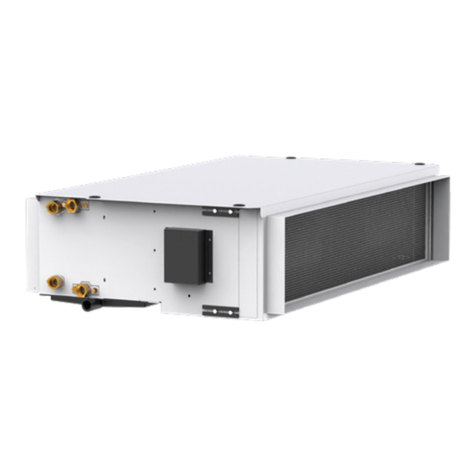

VAV terminal unit

TVRK

Assembly and operating instructions

Read the instructions prior to performing any task!

VARYCONTROL

GB/en

CD10014, 2, GB/en

© TROX GmbH 2023

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn

Germany

Telephone: +49 (0) 2845 202-0

Fax: +49 (0) 2845 202-265

E-mail: [email protected]

Internet: www.troxtechnik.com

01/2024

VAV terminal unit TVRK2

General information

Information about installation and commissioning

instructions

This installation and commissioning manual enables

operating or service personnel to use the variable air

terminal unit (hereinafter also referred to as VAV ter-

minal unit or unit) safely and efficiently.

The manual must be kept near the unit to be available

for use at all times.

The personnel performing work on the device must read

and understand this manual carefully before starting

any work. The basic prerequisite for safe working is to

comply with the safety notes and all instructions in this

manual.

The local regulations for health and safety at work and

the general safety regulations for the area of application

of the ventilation unit also apply.

Illustrations in this manual are mainly for information

and may differ from the actual design.

Other applicable documentation

In addition to these instructions, the following docu-

ments must be observed:

Product data sheets

Instructions for the electrical control components

(assemblies)

Project-specific wiring documents, if any

TROX Technical Support

To ensure that your request is processed as quickly as

possible, please have the following information ready:

Product designation

TROX order number

Delivery date

Issue or fault log

Ä

Chapter 8.1 ‘Troubleshooting’

on page 23

Online www.troxtechnik.com

Phone +49 2845 202-0

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed carefully

to avoid accidents, injuries and damage to property.

DANGER!

Imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not avoided,

may result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Tips and recommendations

Useful tips and recommendations as well as informa-

tion for efficient and fault-free operation.

General information

VAV terminal unit TVRK 3

Safety notes as part of instructions

Safety notes may refer to individual instructions. In

this case, safety notes will be included in the instruc-

tions and hence facilitate following the instructions. The

above listed signal words will be used.

Example:

1. Loosen the screw.

2.

CAUTION!

Danger of finger entrapment when closing

the lid.

Be careful when closing the lid.

3. Tighten the screw.

Specific safety notes

The following symbols are used in safety notes to alert

you to specific hazards:

Warning signs Type of danger

Warning – hand injuries.

Warning – high-voltage.

Warning – danger zone.

General information

VAV terminal unit TVRK4

1 Safety ................................................................ 6

1.1 Correct use ................................................ 6

1.2 Safety signs ............................................... 6

1.3 Dangers when handling the unit ................ 6

1.3.1 Electric shock hazards ........................... 7

1.4 System owner's responsibility ................... 7

1.5 Qualified staff ............................................. 8

1.6 Personal protective equipment .................. 8

1.7 Repair and replacement parts ................... 8

1.8 General safety measures .......................... 8

2 Transport, storage and packaging ................. 9

2.1 Delivery check ........................................... 9

2.2 Transport on site ........................................ 9

2.3 Storage ...................................................... 9

2.4 Packaging .................................................. 9

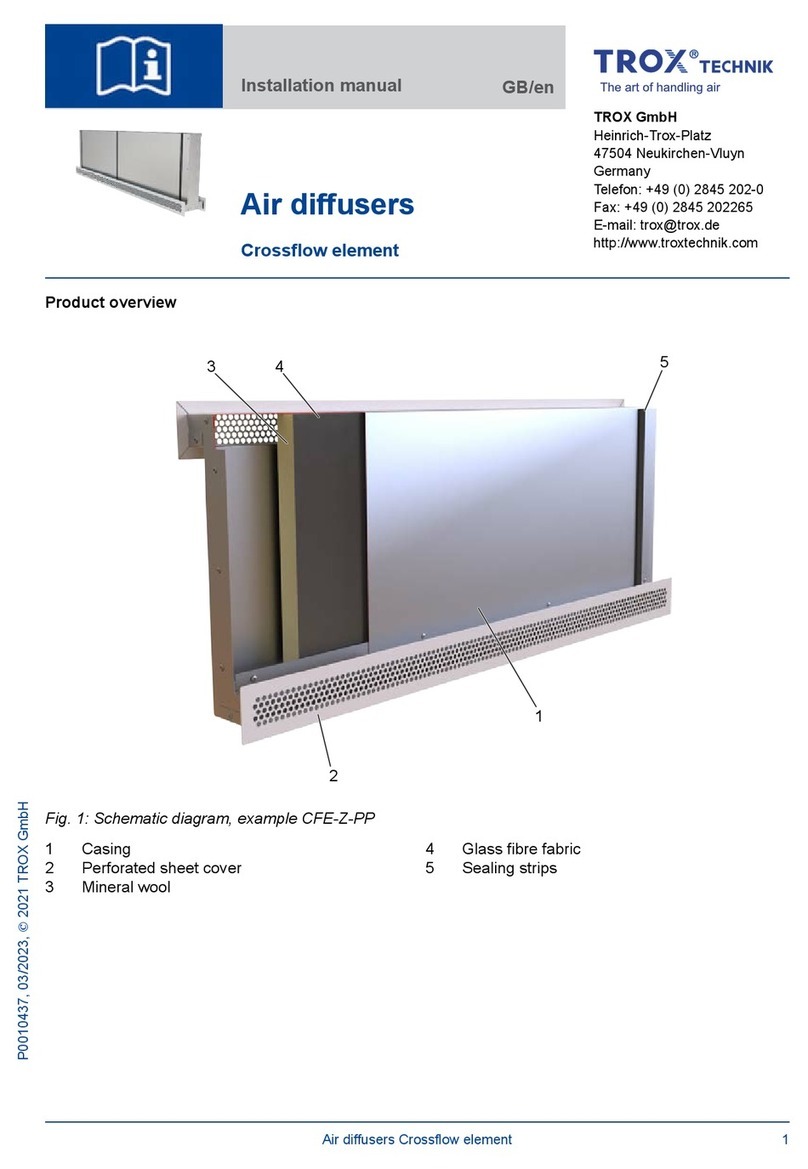

3 Product description ....................................... 10

3.1 Product overview ..................................... 10

3.2 Functional description ............................. 10

3.3 Display of the damper blade position ....... 11

3.4 Labelling on unit ....................................... 11

3.4.1 Rating plate ........................................... 11

3.4.2 Adjustment sticker ................................ 12

3.4.3 CE marking / declaration of incorpora-

tion ........................................................ 12

4 Installation ...................................................... 13

4.1 Safety ...................................................... 13

4.2 General installation information ............... 13

4.2.1 Installation of sound attenuators, fire

dampers and heat exchangers ............. 13

4.2.2 Installation orientation .......................... 14

4.2.3 Airflow direction .................................... 14

4.2.4 Upstream conditions ............................. 15

4.3 Fixing/suspension .................................... 16

4.4 Installation of the circular silencer ........... 16

4.5 Connecting the air duct ........................... 16

5 Electrical connection .................................... 18

5.1 Safety notes ............................................ 18

5.2 Installation instructions ............................ 18

6 Commissioning and operation ..................... 19

6.1 Factory preparation ................................. 19

6.2 Requirement for commissioning .............. 19

6.3 Commissioning ........................................ 19

6.3.1 Installation and connection ................... 19

6.3.2 Parameterisation by others and settings

............................................................... 19

6.3.3 Control components for duct pressure

control ................................................... 19

6.3.4 Control components for room pressure

control ................................................... 20

6.3.5 Functional test ...................................... 20

6.4 Operation ................................................. 20

6.5 Volume flow rate measurement ............... 20

6.5.1 Volume flow rate calculation ................. 21

6.5.2 C values ............................................... 21

7 Maintenance ................................................... 22

7.1 System owner's responsibility ................. 22

7.2 Maintenance ............................................ 22

7.3 Inspection measures ............................... 22

7.4 Repair ...................................................... 22

7.5 Maintenance service ............................... 22

8 Faults .............................................................. 23

8.1 Troubleshooting ....................................... 23

9 Decommissioning .......................................... 26

9.1 Safety ...................................................... 26

9.2 Disassembly ............................................ 26

9.3 Disposal ................................................... 26

10 Technical data ................................................ 27

10.1 General data .......................................... 27

10.2 Control component/attachments ........... 27

11 Index................................................................ 30

Table of contents

VAV terminal unit TVRK 5

1 Safety

1.1 Correct use

The VAV terminal unit from the TVRK type is used for

variable volume flow rate control, throttling or shut-off in

ventilation systems within closed rooms.

If the air is contaminated with dust, fluff, moisture or

sticky particles, only VAV terminal units that use a con-

trol component with a static differential pressure trans-

ducer may be used.

The VAV terminal unit type TVRK is used in particular

in ventilation systems with chemical contamination (e.g.

extract air from fume cupboards). For this application,

only control components with static differential pressure

transducers may be used. We recommend control com-

ponents with static differential pressure transducer and

room air induction.

The VAV terminal unit may only be used in kitchen

extract air systems if it is ensured that the extract air

is cleaned by highly effective aerosol separators (>90

%); observe VDI 2052.

In addition, shortened inspection and cleaning intervals

must be included in the maintenance plan.

Incorrect use

WARNING!

Danger of injury or risk of damage to property

due to unauthorised use!

Incorrect use of the VAV terminal unit can lead to

dangerous situations.

Do not use the VAV terminal unit:

– in areas with potentially explosive atmospheres

(EX)

– in aircraft

– outdoors without sufficient protection against the

effects of weather

– in wet areas

– for areas of application that are not described in

the product brochure

Modifying the unit or using replacement parts that have

not been approved by TROX is not permitted.

1.2 Safety signs

The following symbols and signs are usually found in

the work area. They apply to the very location where

they are found.

WARNING!

Danger due to illegible signage!

Over time, stickers and signs may fade or become

otherwise illegible, meaning that hazards cannot

be identified and necessary operating instructions

cannot be followed. There is then a risk of injury.

– Ensure that all of the safety, warning and oper-

ating information is clearly legible.

– Replace illegible signs or stickers immediately.

Electrical voltage

Only skilled qualified electricians are allowed to work in

areas marked as having electrical voltage.

Unauthorised people must not enter areas, open cabi-

nets or work on components where an electrical voltage

is present and which are hence marked with this

symbol.

1.3 Dangers when handling the unit

The unit is a state-of-the-art product and meets current

safety requirements. Residual risks cannot be excluded,

however, and you should proceed with caution. This

section describes the residual risks that have been iden-

tified in a risk assessment.

Always follow the safety notes in this manual to reduce

health hazards and prevent any hazardous situations.

Safety

Dangers when handling the unit

VAV terminal unit TVRK6

1.3.1 Electric shock hazards

Electric current

DANGER!

Danger of death due to electric current!

Contact with live parts poses an immediate danger

to life due to electric shock. Damaged insulation or

damaged parts are a life threatening hazard.

– Work on the electrical system must only be car-

ried out by skilled qualified electricians.

– If the insulation is damaged, disconnect the

power supply immediately and have the insula-

tion repaired.

– Before you start working on electric systems and

equipment, switch off the supply voltage and

secure it against being switched on accidentally.

Comply with the following safety rules:

– Switch off the supply voltage.

– Secure it against being switched on acciden-

tally.

– Ensure that no voltage is present.

– Connect to the earth; short circuit connection.

– Do not bypass or disable any circuit breakers. Be

sure to maintain the correct current rating when

you replace a circuit breaker.

– Ensure that live parts do not come into contact

with moisture. Moisture can cause a short circuit.

1.4 System owner's responsibility

System owner

The system owner is a natural or legal person who for

commercial or business purposes owns or manages the

ventilation system or component or allows third parties

to use or operate it, but continues to bear legal respon-

sibility for the safety of users, staff or third parties while

the product is in use.

System owner's obligations

The unit is intended for commercial use. The system

owner is therefore subject to the legal obligations of

occupational health and safety regulations.

In addition to the safety notes in this manual, the appli-

cable regulations for safety, accident prevention and

environmental protection must also be complied with.

In particular:

The system owner must be aware of the applicable

occupational health and safety regulations and carry

out a risk assessment to determine any additional

hazards that may exist or result from the specific

working conditions at the installation location. The

system owner has to create operating instructions

for the unit that reflect the results of this risk assess-

ment.

The system owner has to ensure, throughout the

entire operating period of the unit, that these oper-

ating instructions conform to applicable standards

and guidelines; in case of any deviation, the system

owner has to adapt the instructions.

The system owner must secure the unit to prevent

access by unauthorised individuals.

The system owner must clearly define the responsi-

bilities for operation, maintenance, cleaning, trouble-

shooting and removal.

The system owner has to ensure that all individuals

who handle or use the unit have read and under-

stood this manual.

The system owner must provide the employees with

the required personal protective equipment.

The system owner must comply with the local fire

regulations.

Hygiene requirements

The system owner has to comply with the local regu-

lations and harmonised standards for hygiene require-

ments. These include, among other things, compliance

with the corresponding maintenance and test intervals.

Safety

System owner's responsibility

VAV terminal unit TVRK 7

1.5 Qualified staff

WARNING!

Danger of injury due to insufficiently qualified

individuals!

Incorrect use may cause considerable injury or

damage to property.

– Only specialist personnel must carry out work.

The following degrees of qualification are required for

the work described in the operating manual:

HVAC technician

HVAC technicians are individuals who have sufficient

professional or technical training in the field they are

working in to enable them to carry out their assigned

duties at the level of responsibility allocated to them

and in compliance with the relevant guidelines, safety

regulations and instructions. HVAC technicians are indi-

viduals who have in-depth knowledge and skills related

to HVAC systems; they are also responsible for the pro-

fessional completion of the work under consideration.

HVAC technicians are individuals who have sufficient

professional or technical training, knowledge and actual

experience to enable them to work on HVAC systems,

understand any potential hazards related to the work

under consideration, and recognise and avoid any risks

involved.

Skilled qualified electrician

Skilled qualified electricians are individuals who have

sufficient professional or technical training, knowledge

and actual experience to enable them to work on elec-

trical systems, understand any potential hazards related

to the work under consideration, and recognise and

avoid any risks involved.

1.6 Personal protective equipment

Personal protective equipment is equipment that pro-

tects the user against health or safety risks at work.

Personal protective equipment must be worn for var-

ious types of work; the protective equipment required

is listed in this manual together with the description of

each type of work.

Description of personal protective equipment

Industrial safety helmet

Industrial safety helmets protect the head from falling

objects, suspended loads, and the effects of striking the

head against stationary objects.

Protective gloves

Protective gloves protect hands from friction, abrasions,

punctures, deep cuts, and direct contact with hot sur-

faces.

Safety shoes

Safety shoes protect the feet from crushing, falling parts

and prevent slipping on a slippery floor.

1.7 Repair and replacement parts

The devices must be repaired by qualified personnel

using genuine replacement parts only. This particularly

applies to work on the electrical equipment. For safety

reasons, defective devices should therefore be repaired

by the TROX Technical Service,

Ä

‘TROX Technical

Support’ on page 3 .

1.8 General safety measures

Large temperature differences

Be careful when there is a large temperature difference.

If the unit has been kept in an unheated area, wait two

hours before switching on the supply voltage. Conden-

sation may damage the electronic components beyond

repair. Only after about 2 hours will the system have

reached room temperature.

Foreign matter and liquids

Be careful when objects or liquids have got into the

casing, or if the unit emits a smell or smoke. Decommis-

sion the unit and have it checked by the manufacturer.

Safety

General safety measures

VAV terminal unit TVRK8

2 Transport, storage and

packaging

Safety notes on handling the unit

CAUTION!

Danger of injury from sharp edges and sheet

metal parts.

– Always wear protective gloves when handling the

unit.

NOTICE!

Risk of damage to the unit!

– Handle the unit with care.

– Do not lift the unit by its control components, the

damper blade or differential pressure sensor.

– Lift the unit only by lifting the entire casing.

2.1 Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In the case of

any damage or an incomplete shipment, contact the

shipping company and your supplier immediately.

2.2 Transport on site

If possible, take the product in its transport pack-

aging up to the installation location.

Do not remove the protective wrapping until just

before installation.

2.3 Storage

If the product has to be stored temporarily:

Moisture and lack of ventilation can lead to oxida-

tion, even on galvanised components.

Remove any plastic wrapping in order to avoid oxi-

dation.

Protect the product from dust and contamination.

Store the product in a dry place and away from

direct sunlight.

Do not store the product below -10 °C or above +50

°C.

2.4 Packaging

Properly dispose of packaging material.

Transport, storage and packaging

Packaging

VAV terminal unit TVRK 9

3 Product description

3.1 Product overview

Fig. 1: TVRK product overview

1 Sensor tubes

2 Pull-out sensor head section (with sensor tubes)

3 Hoses between sensor tubes and control compo-

nent

4 Actuator

5 Casing

6 Damper blade

7 Electronic control component

Note: When installing the regulating device, ensure that

the hoses are routed without kinks!

3.2 Functional description

To measure the volume flow rate, the differential pres-

sure is measured at the sensor tubes of the VAV

terminal unit TVRK. The differential pressure is then

passed on to the control component via hoses. The

control component consists of a differential pressure

transducer that converts the pressure into an electrical

signal, an electronic control circuit and an actuator to

control the damper blade. With the Compact attach-

ments, all components are integrated together in one

housing. In the case of the Universal or LABCONTROL

attachments, the actuator is a separate component.

In most applications, the setpoint value for a air terminal

unit comes from a ambient temperature or air quality

controller. The controller compares the actual value with

the setpoint value and alters the control signal of the

actuator if there is a difference between the two values.

Notes for regulating devices for duct pressure con-

trol

In order to regulate the duct pressure, VAV terminal

units require a suitable control component, a suitable

pressure tapping point in the duct system and a stable

reference measuring point.

In most applications, the set point value for a differen-

tial pressure controller is stored as a fixed value in the

pressure control component.

In the case of duct pressure control, the control com-

ponent must not be connected to the differential pres-

sure sensors of the VAV terminal unit but to the duct

pressure tapping point and a reference measuring

point.

The accessibility of the connections for the differential

pressure sensors on the regulating device may there-

fore be restricted for differential duct pressure control-

lers depending on the design of the regulating device

and the control component.

For duct pressure detection, a so-called pressure tap-

ping set with pressure tap and hose is supplied, with

which the control component for pressure detection is

connected to the air duct.

The atmospheric pressure at the control component

is generally used as the reference measuring point,

provided that it is stable and is not in a pressure-con-

trolled range.

Product description

Functional description

VAV terminal unit TVRK10

Notes on regulating devices for room pressure

control

To regulate the room pressure, VAV terminal units

require a suitable control component, a pressure tap-

ping point in the room and a stable reference meas-

uring point.

In most applications, the set point value for a differen-

tial pressure controller is stored as a fixed value in the

pressure control component.

In the case of room pressure control, the control com-

ponent is not to be connected to the differential pres-

sure sensors of the VAV terminal unit but to the room

pressure tapping point and the reference measuring

point.

The accessibility of the connections for the differential

pressure sensors on the regulating device may there-

fore be restricted for differential room pressure control-

lers depending on the design of the regulating device

and the control component.

The pressurised rooms must be sufficiently tight to

build up the required pressure. In addition, the rooms

must allow overflow so that the control components

can regulate the pressure (at least 10% of the total

extract air in the room as overflow).

A reference measuring point is a room with constant

atmospheric pressure against which the room pressure

to be controlled is measured.

The reference measuring point should take the fol-

lowing aspects into account:

No room that is surrounded by ventilated rooms

or is ventilated itself

No corridor with elevator

No elevator shaft

No wind load on the reference measuring point

3.3 Display of the damper blade posi-

tion

The damper blade position corresponds to the mark on

the shaft and is thus recognisable from the outside.

Clamping device (frictional connection)

Fig. 2: Display with clamping device

1 Shaft with marking for position indication

2 Damper blade

3.4 Labelling on unit

3.4.1 Rating plate

Fig. 3: Type plate (example)

1 Note on observing the operating instructions

2 Order data commission number – item number; if

necessary, serial number if there are several pieces

in the item

3 Order code

4 Order code detail of the control component

5 Information on devices that deviate from the

standard

6 QR code containing the customer text (11) below in

machine-readable form

7 Barcode with the serial number (for manufacturing

processes at TROX)

8 Manufacturer's address

9 Product and type

10 Arrow indicating the airflow direction

Ä

Chapter

4.2 ‘General installation information’ on page 13

11 Customer text for installation/use (tagging text from

the order)

12 QR code with link in myTrox to individual product

documentation matching the serial number

13 Serial number of the complete product, including the

installed attachment

Product description

Labelling on unit > Rating plate

VAV terminal unit TVRK 11

3.4.2 Adjustment sticker

The adjustment sticker documents the factory setting

and the test steps stored for these variants.

Type and variant information only includes the order

code details required for this process.

Fig. 4: Adjustment sticker example for TVE type with

control components XM0 and XS0

1 Commission number. Item number

2 Type designation of VAV terminal unit

3 nominal size

4 Control component

5 Operating mode

M ð Modbus

F ð constant value

V ð variable

0 or 2 ð characteristic type

6 Characteristics 0 – 10 V or 2 – 10 V

7 Volume flow rate ranges qvmin – qvmax or constant

value

8 Nominal volume flow rate qvnom

9 Hardware type designation

10 Control component:

OF ð equipped at the factory

SP ð replacement part

11 Serial number

12 Test ID number

3.4.3 CE marking / declaration of incorpo-

ration

The TVRK unit complies with the Machinery Directive

2006/42/EC as partly completed machinery, as it does

not fulfil an independent function on its own. A CE mark

and a Declaration of Conformity are therefore not per-

mitted in accordance with the Machinery Directive.

In accordance with the Machinery Directive, partly com-

pleted machinery obtains a Declaration of Incorporation.

This Declaration of Incorporation confirms that the basic

safety aspects of the Machinery Directive and any other

directives are observed.

The Declaration of Incorporation can be accessed via

the QR code on the rating plate. You can download the

document on the Internet at www.troxtechnik.com .

Product description

Labelling on unit > CE marking / declaration of incorporation

VAV terminal unit TVRK12

4 Installation

4.1 Safety

Personnel:

HVAC technician

Protective equipment:

Protective gloves

Safety shoes

Industrial safety helmet

Only specialist personnel are allowed to perform the

described work on the VAV terminal unit.

Only skilled qualified electricians are allowed to work on

the electrical system.

CAUTION!

Danger of injury from sharp edges and sheet

metal parts.

– Always wear protective gloves when handling the

unit.

NOTICE!

Risk of damage to the unit!

– Handle the unit with care.

– Do not lift the unit by its control components, the

damper blade or differential pressure sensor.

– Lift the unit only by lifting the entire casing.

4.2 General installation information

ATTENTION: Pay attention to the arrow indi-

cating the correct airflow direction on the unit!

Ä

3.4 ‘Labelling on unit’ on page 11

Select the installation location such that the VAV ter-

minal unit, inspection accesses and the control com-

ponents remain accessible for the following work:

– Wiring

– Adjustment work (service socket if necessary)

– Servicing and maintenance, e.g. to replace con-

trol components, if necessary in several parts

(controllers, transducers, actuators).

– Cleaning removable sensor tubes

For information on space requirements, see product

data sheets.

Do not swap supply and extract air units.

Do not swap over units that belong together in

command and tracking controls (e.g. supply air and

extract air).

Installation in kitchen extract air systems may only

take place downstream of aerosol separators (>90

%); observe VDI 2052.

4.2.1 Installation of sound attenuators, fire

dampers and heat exchangers

If additional components are arranged upstream of a

regulating device in the airflow direction, the clearances

specified in the table must be observed. Shorter dis-

tances lead to measurement inaccuracies on the ter-

minal unit. The components can be arranged directly

behind the terminal unit.

Distances to other components

Component Clearance in airflow

direction

in front of TVRK

Plastic circular silencer

without core CAK

No clearance

Fire damper At least 3D

Heat exchanger Behind terminal unit only

Installation

General installation information > Installation of sound attenuators, fire damper...

VAV terminal unit TVRK 13

4.2.2 Installation orientation

For terminal units with diaphragm pressure transducers,

the installation orientation of the control component

(TROX Universal or EASYLAB controller) must be taken

into account. The actual installation orientation must be

compared with the variants on the sticker. If necessary,

the position of the membrane pressure transducer must

be adjusted, ( Fig. 5 ).

Fig. 5: Sticker showing installation orientations

The installation orientation of the control component

matches the factory installation position of the dia-

phragm pressure transducer

For the installation orientation of the control compo-

nent, the position of the membrane pressure trans-

ducer must be adjusted according to the figure.

4.2.3 Airflow direction

It is imperative that air terminal units are installed

in their intended airflow direction. An arrow indicating

the correct airflow

Ä

Chapter 3.4.1 ‘Rating plate’

on page 11 is attached to the VAV terminal unit for this

purpose.

Installation

General installation information > Airflow direction

VAV terminal unit TVRK14

4.2.4 Upstream conditions

The volume flow rate accuracy of the unit applies to a straight upstream section of the duct. Bends, junctions

or a narrowing or widening of the duct cause turbulence that may affect measurement. The upstream conditions

explained below must be adhered to in order to achieve the specified volume flow rate accuracy.

Bend Junction from a main duct

A bend with a curvature radius of at least 1D – without

an additional straight duct section upstream of the unit –

has only a negligible effect on the volume flow rate accu-

racy Δqᵥ.

A junction from main duct causes strong turbulence.

The stated volume flow rate accuracy Δqᵥ can only be

achieved with a straight duct section of at least 5D

upstream.

4.2.4.1 Inflow via an open duct (extract air mode)

When flow enters the open end of a duct, the following

conditions must be observed with regard to the posi-

tioning of the air terminal units in order to obtain a lam-

inar flow and thus sufficient measuring accuracy.

Inflow via an open duct

Fig. 6: Upstream conditions at open duct end

The inflow at the open end of a duct causes strong

turbulence.

The stated volume flow rate accuracy can only be ach-

ieved with the following upstream straight duct sections:

At least 5D

Inflow via inflow aid

Alternatively, an inflow aid must be installed at the open

duct end upstream of the VAV terminal unit:

Fig. 7: Upstream conditions with inflow aid

The stated volume flow rate accuracy is achieved when

an inflow aid is connected directly to the VAV terminal

unit.

Fig. 8: Dimensions of inflow aid [mm]

Installation

General installation information > Upstream conditions

VAV terminal unit TVRK 15

4.3 Fixing/suspension

General installation information

When designing and constructing ventilation and air

conditioning systems, take into account the require-

ments of VDI 6022, in particular:

– Hygienic, clean installation of all components

and their air distribution surfaces.

– Planning inspection/cleaning openings in the

ducting system.

– Avoidance of leaks.

Affix the unit proficiently and only to load-bearing

components.

Load suspension systems only with the weight of

the unit. Adjacent components and connecting ducts

must be supported separately.

Only use approved and sufficiently dimensioned

suspensions for fixing. Secure screw connections

against self-loosening, e.g., by locking them. Fixing

material is not included in the supply package.

For fixing, only use drilling screws that are as short

as possible; these must not be screwed into the

movement and sealing area of the damper blade or

the differential pressure sensor.

Fig. 9: Installation example using a VAV terminal unit

TVR-*

1 VAV terminal unit, round, e.g. TVR

2 Air direction arrow e.g., on the scale sticker

3 Drilling screw for fixing to the ducting

4 Pipe clamp

5 Suspension, e.g., with threaded rod

Fig. 10: Examples of fixings for circular units

1 Fixing to pipe clamps

2 Fixing to suspension element

4.4 Installation of the circular silencer

Circular silencers are supplied separately and must be

installed at the installation location between the VAV

terminal unit and the room. Detach the sound attenuator

separately, Ä Installation manual for circular silencers.

4.5 Connecting the air duct

When connecting the ducting, the customer must

ensure that the connection points are installed as air-

tight as possible in order to avoid negative influences

from leakages such as air volume deviations, power

consumption, etc. Unless otherwise stated, the con-

necting material is not included in the supply package.

In the case of one-sided connection of the ductwork,

intervention in the damper blade is to be prevented by

suitable measures (for example, grilles).

Before connecting the ducting:

Check the inside of the unit for damage and loose

parts.

Remove any contamination from the ducting.

Fig. 11: Plastic flanges

Matching flanges, including seal available as acces-

sories

Screw connection M8 (to be provided by others)

Installation

Connecting the air duct

VAV terminal unit TVRK16

Dimensions and number of holes in accordance with

EN 12220.

Position the ducting exactly. Do not pull the dis-

tances together via the flange connection.

Fig. 12: Plastic spigot

Installation on ducting in accordance with DIN 8077

– with clamp connectors

– by plastic welding

Installation

Connecting the air duct

VAV terminal unit TVRK 17

5 Electrical connection

5.1 Safety notes

DANGER!

Danger of electric shock! Do not touch any live com-

ponents. Electrical equipment carries a dangerous

electrical voltage.

– Only skilled qualified electricians are allowed to

work on the electrical system.

– Before working on the electrical system, switch

off the supply voltage and secure it against being

switched on again.

5.2 Installation instructions

The VAV terminal unit was manufactured and configured

on a project-specific basis. The control components are

prewired at the factory. For units with electrical control

components, the supply voltage must be connected,

and, if necessary, also signal or bus lines must be con-

nected.

The connection is made according to the information on

the control components or connection diagrams in the

product data sheet or commissioning instructions for the

respective control component, www.troxtechnik.com .

The voltage ranges and terminal connections specified

on the control components must be observed!

Personnel:

Skilled qualified electrician

Observe the following during installation:

Legal and official regulations, in particular VDE

guidelines.

Observe the technical connection rules (TCR) of the

local grid operator.

Wiring work for supply voltage and signal lines on

site.

The rating and manufacturing of customer-side con-

nections and wiring must be carried out in accord-

ance with the recognised rules of electrical engi-

neering.

The responsibility for design, dimensioning and

sizing of the electrical and network installations

as well as their execution by others lies with the

specialist consultant, HVAC contractor and commis-

sioning engineer appointed by the system owner.

This includes, in particular, the dimensioning of the

power supplies as well as cable types and cross

sections.

For network installations, the specification of the

respective network variant must be observed. For

information, see here:

– BACnet MS/TP or BACnet/IP ð BACnet.org

– Modbus RTU or Modbus TCP ð Modbus.org

– KNX bus ð KNX.org

– MP-Bus technology - project planning informa-

tion ð www.belimo.com

Observe wiring guidelines and project-specific circuit

diagrams.

The electrical connection may only be made after

complete installation of the unit.

For units with a 24 V supply voltage, observe the

following:

– Electrical connection only with safety trans-

former

– Make sure that all connected units have the

same GND reference point for the supply

voltage.

Suitable wire clamping brackets must be provided

for all connecting cables.

Electronic components contain no parts that can be

replaced or repaired by the user and may only be

opened by the manufacturer!

Electrical connection

Installation instructions

VAV terminal unit TVRK18

6 Commissioning and opera-

tion

6.1 Factory preparation

TROX VAV terminal units are prepared, calibrated and

tested at the factory. The commissioned operating

parameters are set and the volume flow controller is

tested with regard to air distribution technology.

The following exceptions apply:

For special versions, parameterisation by others

may be necessary.

The factory adjustment is documented on the silver

adjustment sticker,

Ä

Chapter 3.4.2 ‘Adjustment

sticker’ on page 12 .

6.2 Requirement for commissioning

Contamination, e.g. dust, can adversely affect the func-

tionality of the VAV terminal unit.

Therefore, the ventilation and air conditioning system

and its components may not be put into operation for

the first time until the rooms connected to the ventila-

tion system have been cleaned of any contamination

resulting from construction work. Contamination of the

ventilation system by construction dust and sucked-in

dirt particles must be eliminated. In the case of systems

that are heavily contaminated due to construction activ-

ities, the system may need to be cleaned before com-

missioning.

6.3 Commissioning

Code of good practice for commissioning

Commissioning is governed by the standard "DIN

EN 12599 Testing and measuring procedures for the

transfer of installed ventilation and air conditioning

systems", and, if applicable, contractually agreed

services between HVAC contractors, system owners

and installation engineers. The standard describes

the essential commissioning steps of the complete-

ness check, function check, function measurement

as well as report generation and handover.

6.3.1 Installation and connection

Once the electrical or pneumatic connections have been

correctly installed and made, the VAV terminal unit is

ready for operation.

6.3.2 Parameterisation by others and set-

tings

Subsequent adjustment of settings

Subsequent adjustments to the volume flow rate oper-

ating range may require manufacturer-specific adjust-

ment devices or PC software, depending on the control

component.

Network integration

Bus-compatible control components may require inte-

gration into the building's network infrastructure to be

performed by others (network commissioning, e.g. set-

ting the subscriber address and communication param-

eters). Manufacturer-specific tools such as adjustment

devices or software packages and associated interface

adapters may be required for this.

Special constructions

VAV terminal units without standardised control compo-

nents (e.g. special versions) may require parameterisa-

tion or network integration to be performed by others.

Manufacturer-specific tools such as adjustment devices

or software packages and associated interface adapters

may be required for this.

6.3.3 Control components for duct pres-

sure control

with integrated differential pressure transducer:

– Prepare the duct pressure sampling point (duct

pressure sampling set) and establish the tubing

to the control component.

with separate differential pressure transducer (only

with TROX UNIVERSAL or EASYLAB):

– Install differential pressure transducer for duct

pressure measurement. Prepare duct pressure

sampling point (duct pressure sampling set)

and establish tubing to the differential pressure

transducer.

– Connect the duct pressure actual value signal of

the differential pressure transducer to the control

component.

– During commissioning, carry out the character-

istic setting in order to inform the pressure con-

trol circuit of the characteristics of the external

transducer, e.g. nominal pressure/working range

and signal characteristics. The EasyConnect

software is required for setting.

Commissioning and operation

Commissioning > Control components for duct pressure control

VAV terminal unit TVRK 19

6.3.4 Control components for room pres-

sure control

with integrated differential pressure transducer:

– Carefully select the measuring point for room

pressure and connect the tubing to the control

component.

with separate differential pressure transducer (only

with TROX UNIVERSAL or EASYLAB):

– Install differential pressure transducer for room

pressure measurement. Carefully select the

measuring point for room pressure and connect

the tubing to the differential pressure transducer.

– Connect the room pressure actual value signal

of the differential pressure transducer to the

control component.

– During commissioning, carry out the character-

istic setting in order to inform the pressure con-

trol circuit of the characteristics of the external

transducer, e.g. nominal pressure/working range

and signal characteristics. The EasyConnect

software is required for setting.

6.3.5 Functional test

Prerequisites for the functional test

VAV terminal unit has been correctly installed in the

ducting system:

– Airflow direction, according to airflow direc-

tion arrows

Ä

Chapter 3.4.1 ‘Rating plate’

on page 11

– Upstream conditions correct,

Ä

Chapter

4.2 ‘General installation information’

on page 13

– Correct installation orientation,

Ä

Chapter

4.2 ‘General installation information’

on page 13

Electrical or pneumatic connections have been cor-

rectly installed and tested.

Ventilation and air conditioning system is in opera-

tion (fans running).

Air circulation is guaranteed (shut-off dampers and

fire dampers are open).

Supply voltage or the compressed air supply is

switched on.

Measuring hoses between differential pressure

sensor and control component or pressure trans-

ducer are undamaged and kink-free.

1. Check installation orientation and carry out zero

point correction, see instructions for the control

component.

Installation orientation and zero point

correction

Only required for control components with

static diaphragm pressure transducer. Control

components with static diaphragm pressure

transducers can be identified by the installation

orientation sticker,

Ä

Chapter 4.2.2 ‘Installa-

tion orientation’ on page 14 .

2. Compare volume flow rate actual value signal with

setpoint value signal. The setpoint value signal

can be variable or constant, depending on the

intended application.

3. Check damper blade positions:

Damper blade in control position

Door open

Door closed

4. Check override control functions

5. Further function tests on the VAV terminal unit can

only be carried out if it is known which control

component has been fitted.

Information on this can be found in the documen-

tation of the TROX control components or in

the product information of the control component

manufacturer.

6.4 Operation

Once commissioning has been completed, the VAV ter-

minal unit will operate in a self-powered manner and

require no intervention from the system owner.

Depending on the area of application of the VAV ter-

minal unit, test specifications and intervals may have

to be observed; for example, when used on fume cup-

boards, an annual functional test must be carried out

and documented.

In case of a malfunction, decommission the VAV ter-

minal unit and have it repaired before commissioning it

again.

6.5 Volume flow rate measurement

For testing the volume flow rate or differential pressure-

transducer, the differential pressure ∆pw (differential

pressure) can be measured directly at the differential

pressure sensor of the VAV terminal unit by means of a

pressure gauge.

Attention: During the measurement, the actuator of the

control component must be switched off, e.g. via a spe-

cial function of a service tool or by switching off the

supply voltage. Otherwise, a comparison measurement

will be influenced by changing blade positions from the

control process.

Commissioning and operation

Volume flow rate measurement

VAV terminal unit TVRK20

Table of contents

Other Trox Technik Industrial Equipment manuals

Trox Technik

Trox Technik CFE User manual

Trox Technik

Trox Technik QL-WF-EO User manual

Trox Technik

Trox Technik FKT-EU User manual

Trox Technik

Trox Technik X-AIRCONTROL FAM-RD User manual

Trox Technik

Trox Technik EK-JZ-FF User manual

Trox Technik

Trox Technik JS User manual

Trox Technik

Trox Technik TFCU Series Specification sheet