REFRIGERATED FOOD PREP truemfg.com

TEC_TM_090 REV. A12/17/2020Page 4 of 20

Installation

Ownership

To ensure that your unit works properly from the first day, it must

be installed properly. We highly recommend a trained refrigeration

mechanic and electrician install your TRUE equipment. The cost of

a professional installation is money well spent.

Before you start to install your TRUE unit, carefully inspect it for

freight damage. If damage is discovered, immediately file a claim

with the delivery freight carrier.

TRUE is not responsible for damage incurred during shipment.

Cabinet Specification

This appliance is rated for open food storage.

Cabinet Location

• Appliance tested for IEC to ISO Climate Class 5 [104°F (40°C)

temperature, 40% relative humidity].

• For proper operation, ambient temperatures shall not be less

than 60°F (15.5°C) and no greater than 104°F (40°C).

• Appliance is not suitable for outdoor use.

• Appliance is not suitable for an area where a pressure washer or

hose may be used.

• Ensure the location will provide adequate clearances and

sufficient airflow for the cabinet.

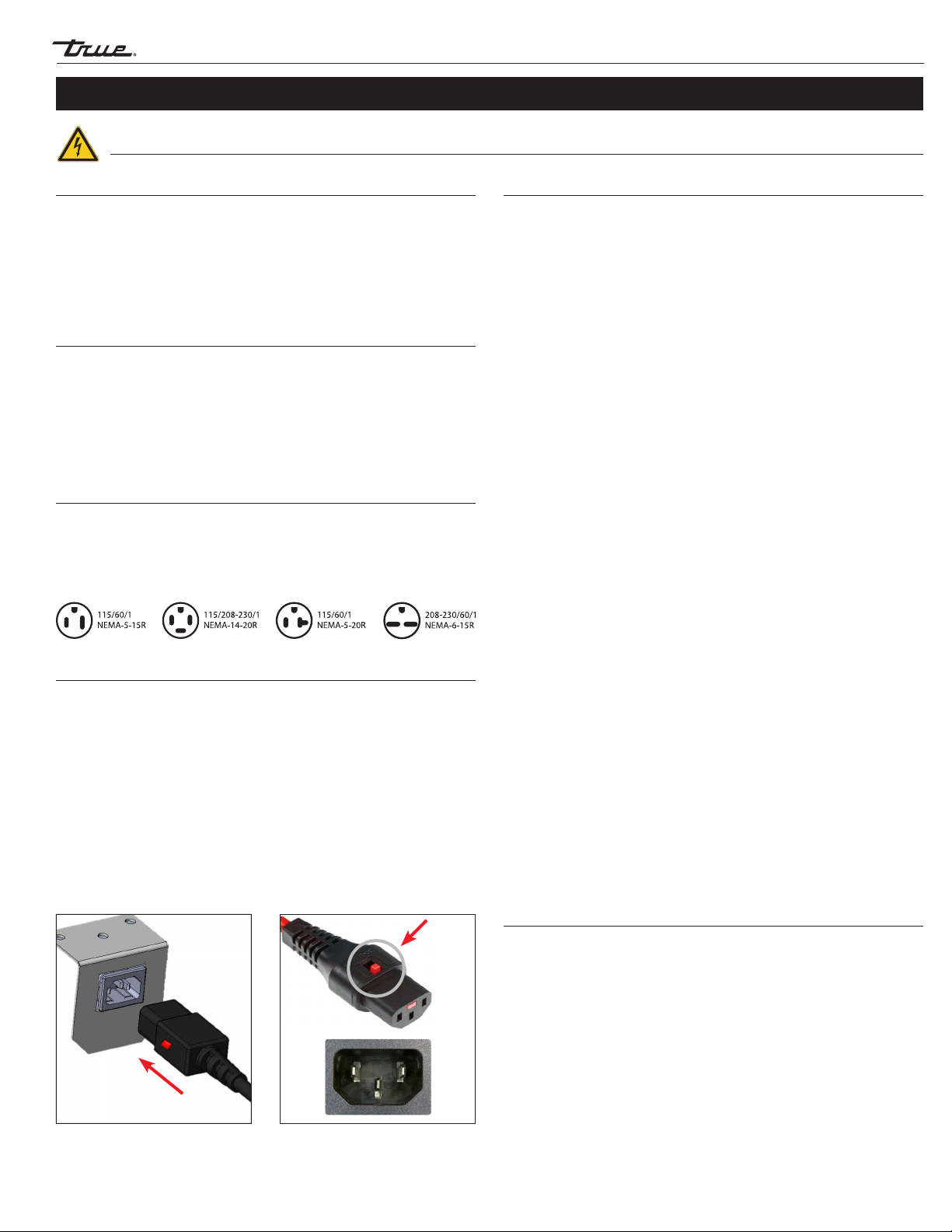

• Ensure the power supply for the cabinet matches the cabinet

specification sheet or cabinet data plate and is within the

rated voltage (+/-5%). Also, that the amp rating of the circuit is

correct and that it is properly grounded.

• The cabinet should always be plugged into its own individual

dedicated electrical circuit. The use of adapter plugs and

extension cords is prohibited.

Notice to Customer

Loss or spoilage of products in your

refrigerator/freezer is not covered

by warranty. In addition to following

recommended installation procedures,

you must run the refrigerator/freezer

for 24 hours prior to usage to verify its

proper operation.

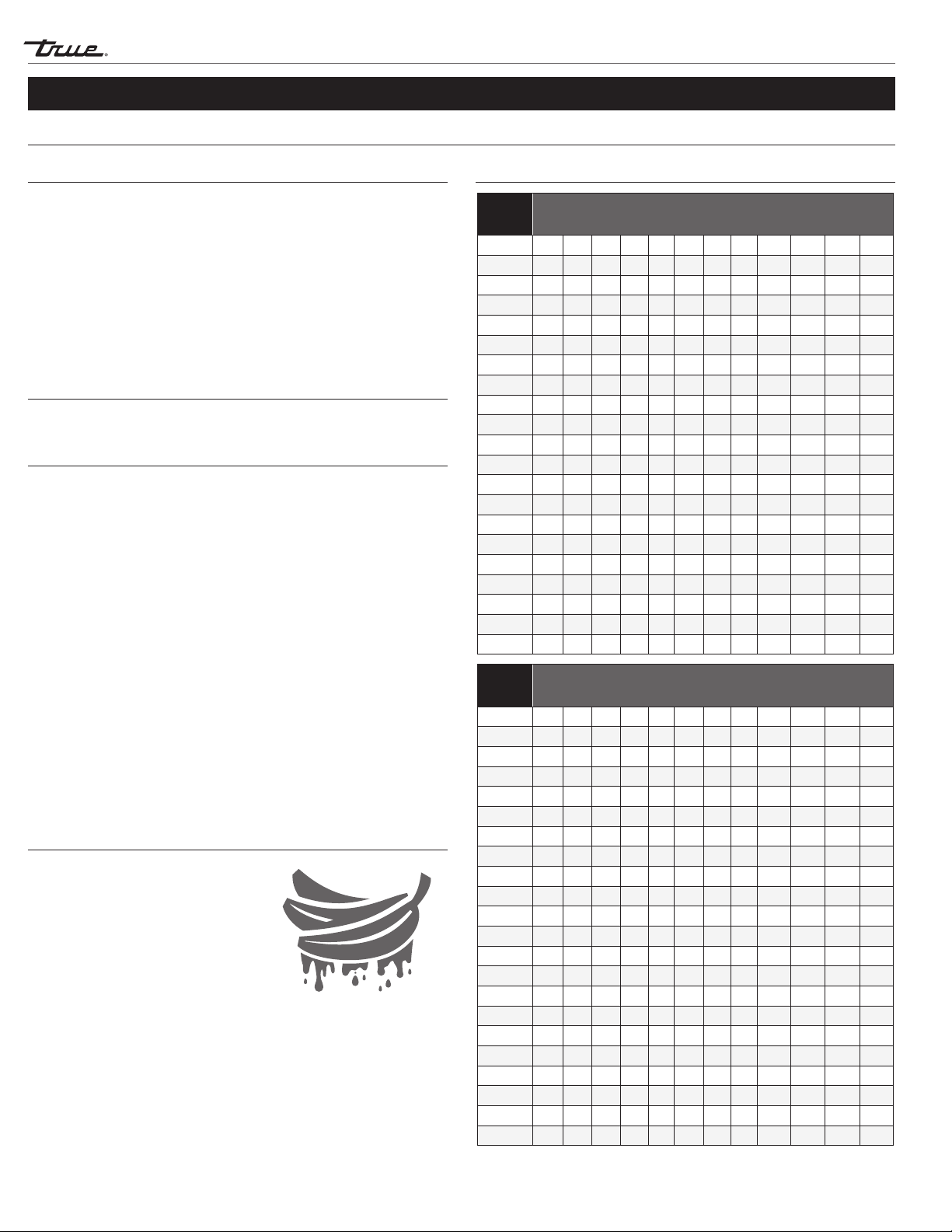

115

Volts Distance In Feet To Center of Load

AMPS 20 30 40 50 60 70 80 90 100 120 140 160

2 14 14 14 14 14 14 14 14 14 14 14 14

3 14 14 14 14 14 14 14 14 14 14 14 12

4 14 14 14 14 14 14 14 14 14 12 12 12

5 14 14 14 14 14 14 14 12 12 12 10 10

6 14 14 14 14 14 14 12 12 12 10 10 10

7 14 14 14 14 14 12 12 12 10 10 10 8

8 14 14 14 14 12 12 12 10 10 10 8 8

9 14 14 14 12 12 12 10 10 10 8 8 8

10 14 14 14 12 12 10 10 10 10 8 8 8

12 14 14 12 12 10 10 10 8 8 8 8 6

14 14 14 12 10 10 10 8 8 8 6 6 6

16 14 12 12 10 10 8 8 8 8 6 6 6

18 14 12 10 10 8 8 8 8 8 8 8 5

20 14 12 10 10 8 8 8 6 6 6 5 5

25 12 10 10 8 8 6 6 6 6 5 4 4

30 12 10 8 8 6 6 6 6 5 4 4 3

35 10 10 8 6 6 6 5 5 4 4 3 2

40 10 8 8 6 6 5 5 4 4 3 2 2

45 10 8 6 6 6 5 4 4 3 3 2 1

50 10 8 6 6 5 4 4 3 3 2 1 1

230

Volts Distance In Feet To Center of Load

AMPS 20 30 40 50 60 70 80 90 100 120 140 160

5 14 14 14 14 14 14 14 14 14 14 14 14

6 14 14 14 14 14 14 14 14 14 14 14 12

7 14 14 14 14 14 14 14 14 14 14 12 12

8 14 14 14 14 14 14 14 14 14 12 12 12

9 14 14 14 14 14 14 14 14 12 12 12 10

10 14 14 14 14 14 14 14 12 12 12 10 10

12 14 14 14 14 14 14 12 12 12 10 10 10

14 14 14 14 14 14 12 12 12 10 10 10 8

16 14 14 14 14 12 12 12 10 10 10 8 8

18 14 14 14 12 12 12 10 10 10 8 8 8

20 14 14 14 12 10 10 10 10 10 8 8 8

25 14 14 12 12 10 10 10 10 8 8 6 6

30 14 12 12 10 10 10 8 8 8 6 6 6

35 14 12 10 10 10 8 8 8 8 6 6 5

40 14 12 10 10 8 8 8 6 6 6 5 5

50 12 10 10 8 6 6 6 6 6 5 4 4

60 12 10 8 6 6 6 6 6 5 4 4 3

70 10 10 8 6 6 6 5 5 4 4 2 2

80 10 8 8 6 6 5 5 4 4 3 2 2

90 10 8 6 6 5 5 4 4 3 3 1 1

100 10 8 6 6 5 4 4 3 3 2 1 1

Wire Gauge Chart

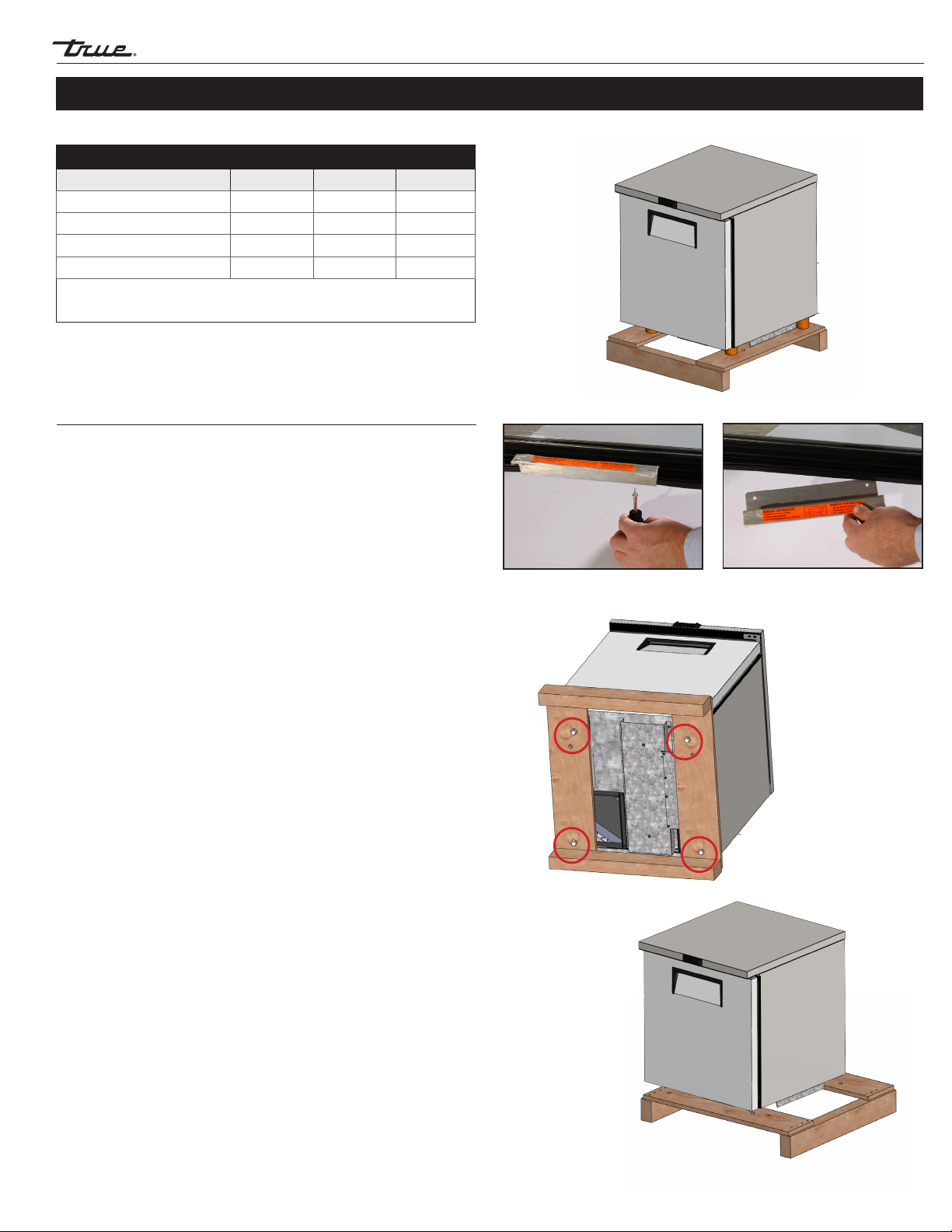

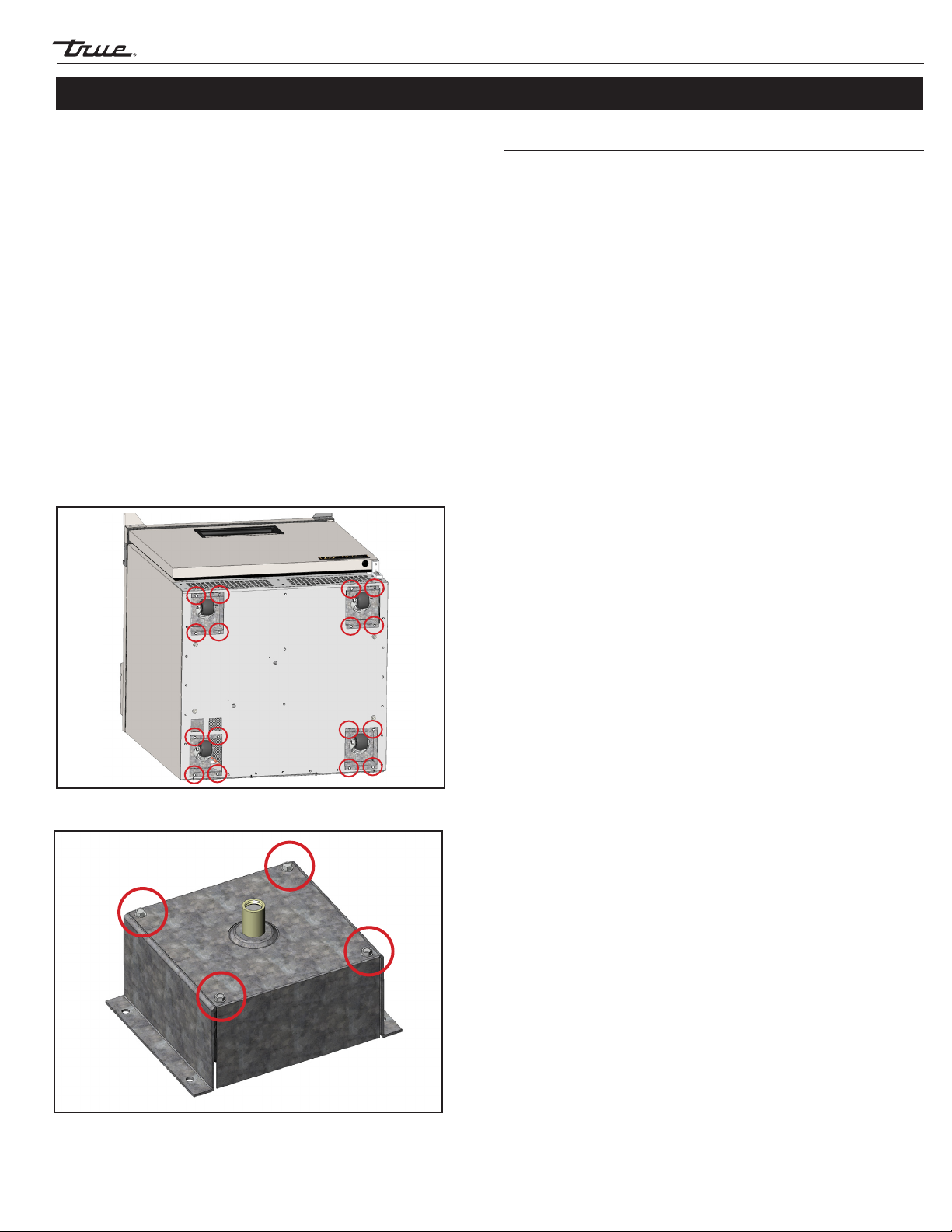

Prior to Installation