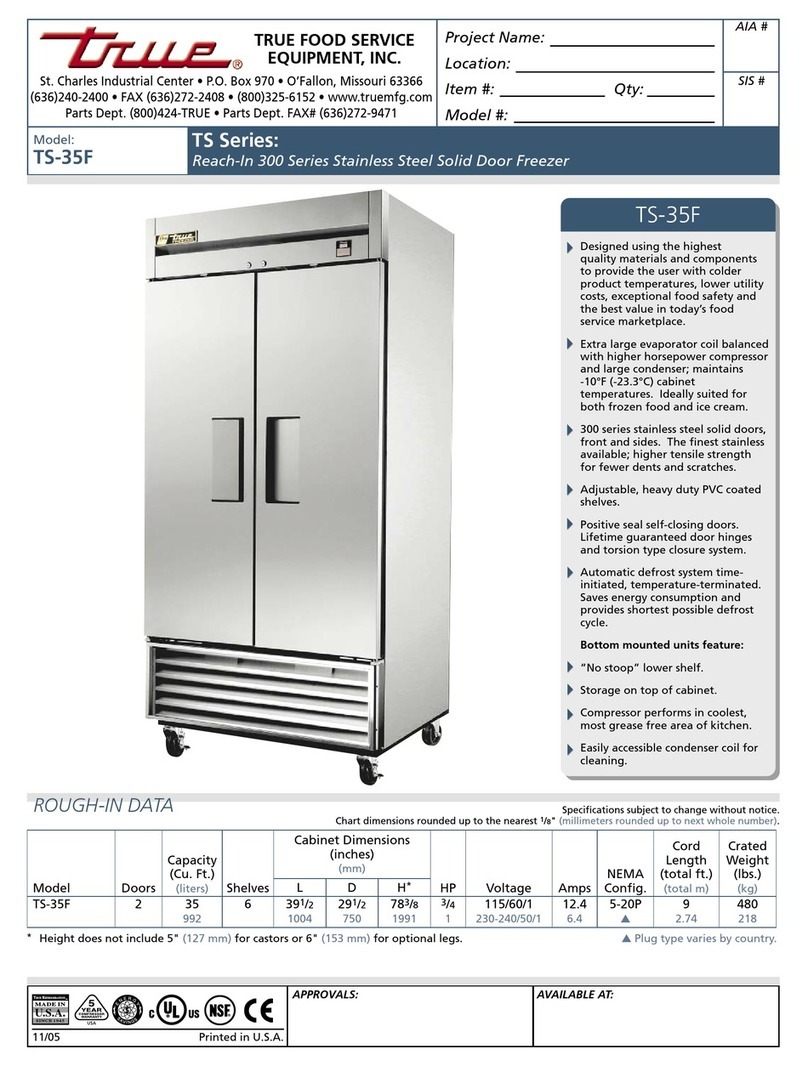

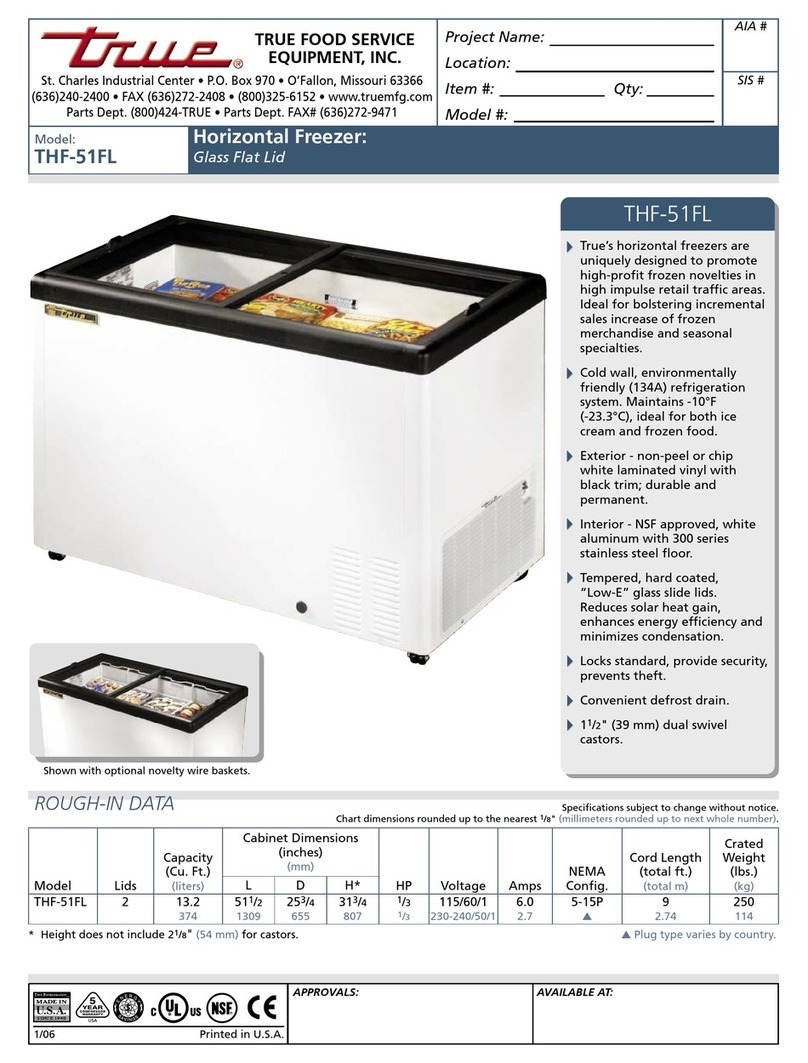

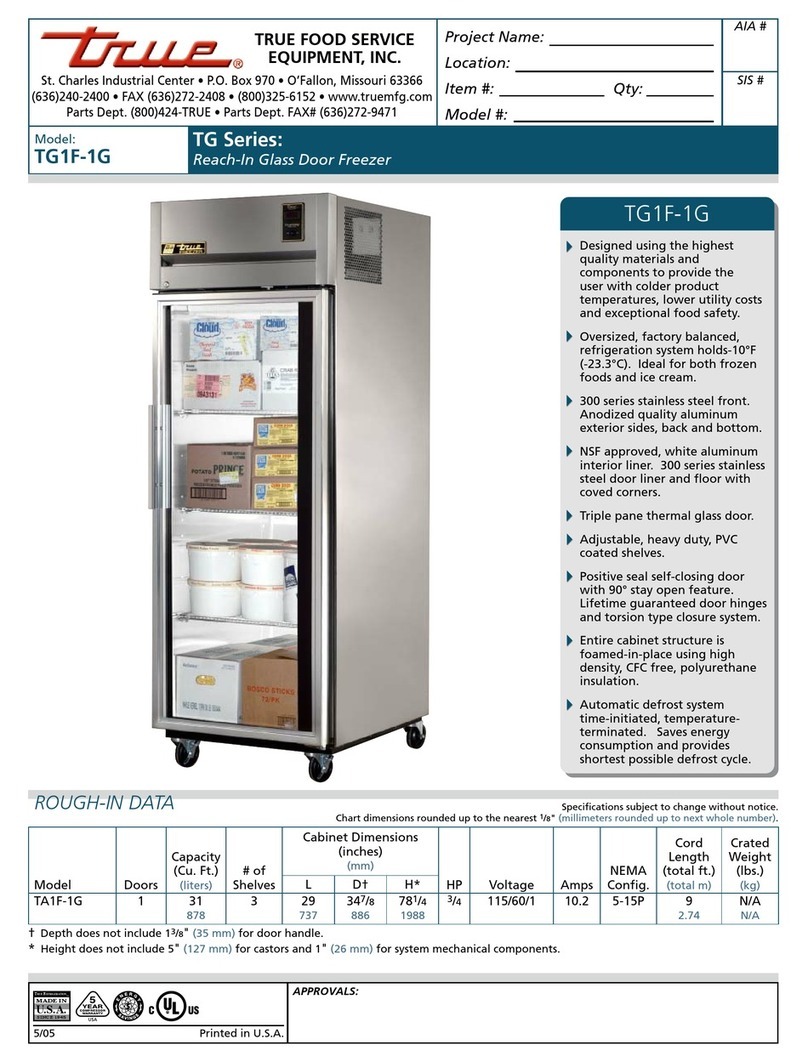

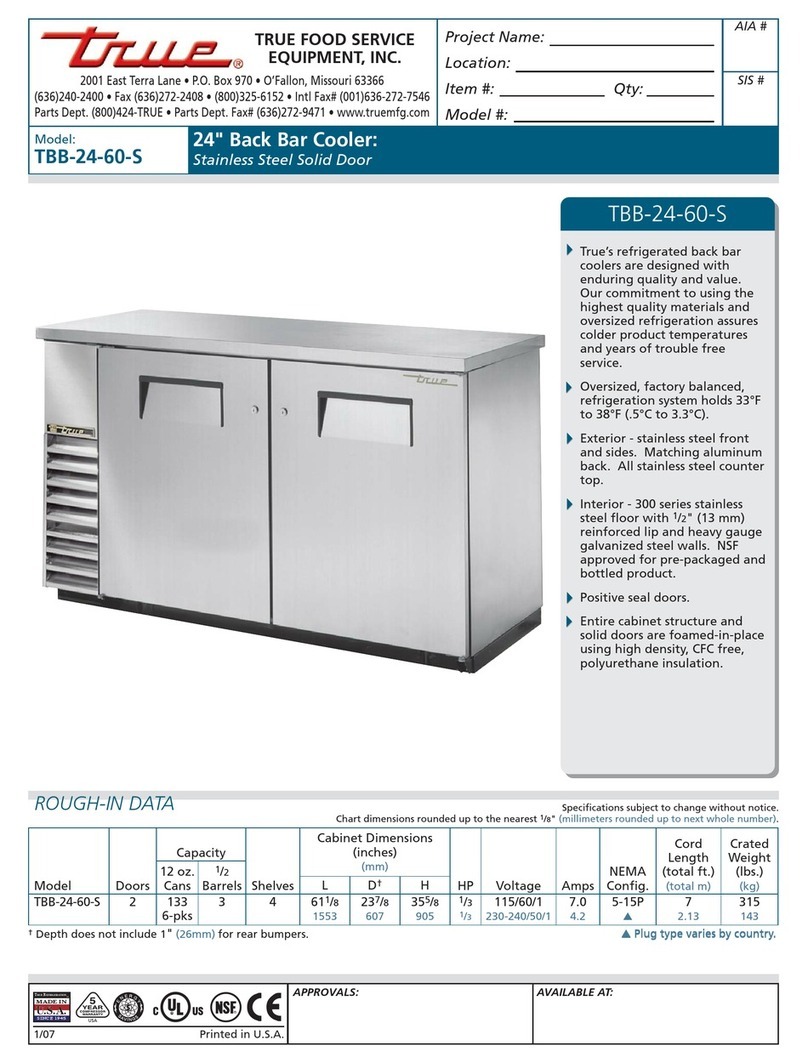

STANDARD FEATURES

Model:

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

WARRANTY

One year warranty on all parts

and labor and an additional 4

year warranty on compressor.

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

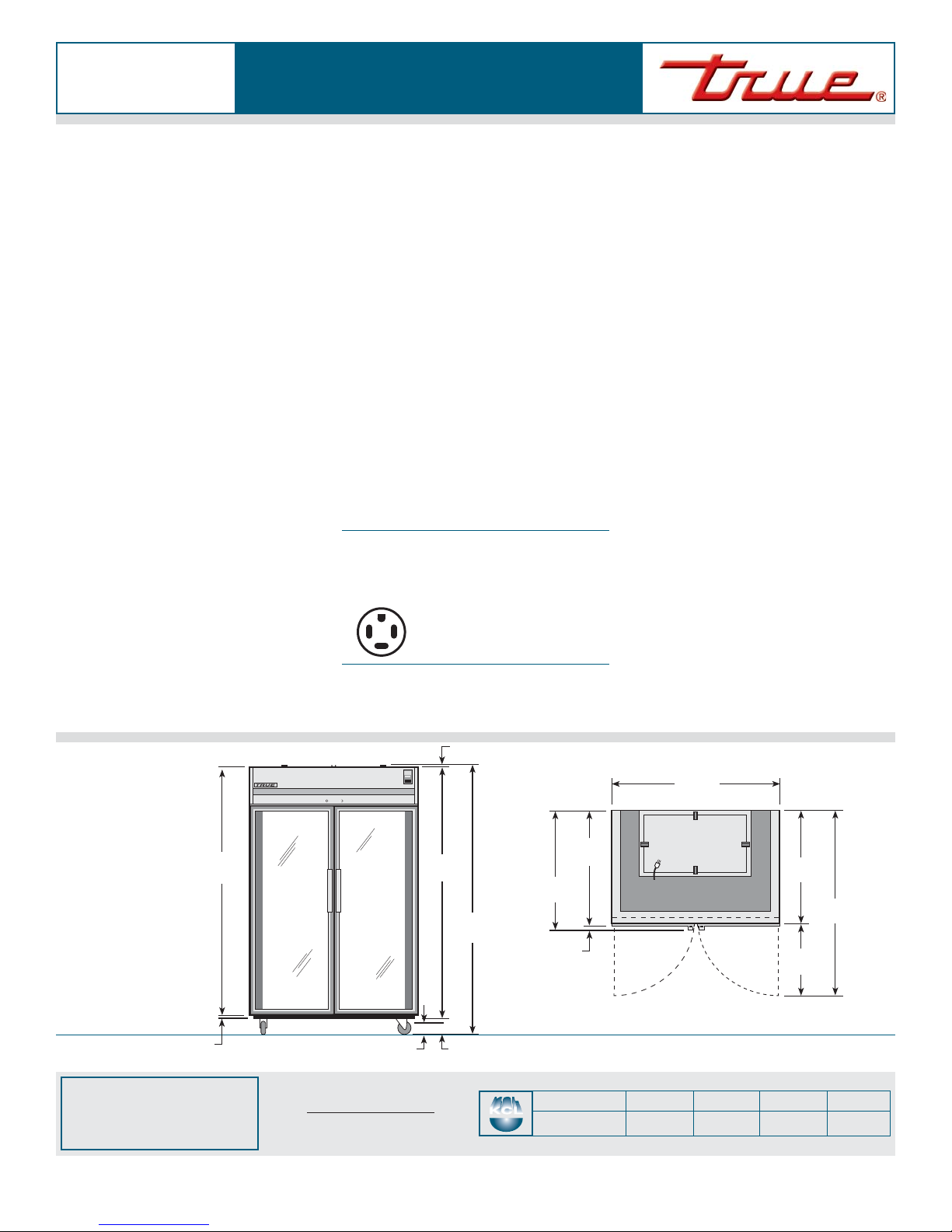

Model Elevation Right Plan 3D

PLAN VIEW

KCL

TR2F-2G TFQY99E TFQY99S TFQY99P TFQY993

TR2F-2G

DESIGN

• True’s glass door reach-in’s are designed with

enduring quality that protects your long term

investment.

• Designed using the highest quality materials

and components to provide the user with colder

product temperatures, lower utility costs and

exceptional food safety.

REFRIGERATION SYSTEM

• Factory engineered, self-contained, capillary tube

system using environmentally friendly (CFC free)

404A refrigerant.

• Extra large evaporator coil balanced with higher

horsepower compressor and large condenser

maintains -10°F (-23.3°C) cabinet temperature.

Ideal for both frozen foods and ice cream.

• Sealed, cast iron, self-lubricating evaporator fan

motor(s) and larger fan blades give True reach-

in’s a more efficient low velocity, high volume

airflow design. This unique design insures faster

temperature recovery and shorter run times in the

busiest of foodservice environments.

• Top mounted refrigeration system with evaporator

positioned out of food zone to maximize capacity.

• Automatic defrost system time-initiated,

temperature-terminated. Saves energy

consumption and provides shortest possible defrost

cycle.

• Automatic evaporator fan motor delay during

defrost cycle.

CABINET CONSTRUCTION

• Exterior - 300 series stainless steel front, sides, back

and bottom.

• Interior - 300 series stainless steel liner and floor.

• Insulation - entire cabinet structure is foamed-in-

place using high density, CFC free, polyurethane

insulation.

• Welded, heavy duty galvanized frame rail dipped

in rust inhibiting enamel paint for corrosion

protection inside and out.

• Frame rail fitted with 4" (102 mm) diameter stem

castors - locks provided on front set.

DOORS

• Triple pane thermal insulated glass assemblies with

extruded aluminum frames. Doors open within

cabinet dimension.

• Door locks standard.

• Each door fitted with 15" (381 mm) long extruded

aluminum handle.

• Positive seal self-closing doors with 120º stay open

feature. Lifetime guaranteed door hinges.

• Magnetic door gaskets of one piece construction,

removable without tools for ease of cleaning.

SHELVING

• One (1) factory installed, interior kit option per full

section. Four (4) different interior kits available

(see Kit Options). Pilasters and tray slides are

factory installed at no charge.

LIGHTING

• Fluorescent interior lighting. Doors utilize full-

length, patented, integrated door light (IDL)

system. Safety shielded.

MODEL FEATURES

• Exterior digital temperature display, available with

either °F or °C display.

• Evaporator is epoxy coated to eliminate the

potential of corrosion.

• Backguards improve airflow.

• Minimum wattage heater in cabinet frame and

doors.

ELECTRICAL

• Unit completely pre-wired at factory and ready

for final connection to a 115/208-230/60Hz single

phase, 3 pole, 4 wire - 20 amp dedicated outlet.

Cord and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❒6" (153 mm) standard legs.

❒6" (153 mm) seismic/flanged legs.

❒6" (153 mm) stainless steel legs.

❒Stainless steel rail skirt for use with legs (field

installed).

❒Electronic temperature control (factory installed).

❒Curb mountable units.

❒Remote cabinets (condensing unit supplied

by others; system comes standard with 404A

expansion valve and requires R404A refrigerant).

Consult factory technical service department for

BTU information.

KIT OPTIONS

❒Kit #1: Nine (9) sets of #1 type tray slides and

pilasters (factory installed), bottom support of one

(1) 18"L x 26"D (458 mm x 661 mm) pan or two (2)

14"L x 18"D (356 mm x 458 mm) pans.

❒Kit #2: One (1) set half-section #2 steel rod tray

slides and pilasters (factory installed), rim support

of one (1) 18"L x 26"D (458 mm x 661 mm) pan.

❒Kit #3: Six (6) sets of universal type tray slides and

pilasters (factory installed), bottom support of one

(1) 18"L x 26"D (458 mm x 661 mm) pan, two (2)

14"L x 18"D (356 mm x 458 mm) pans or two (2)

12"L x 20"D (305 mm x 508 mm) pans

❒Kit #4: Three (3) chrome shelves 231/2"L x 273/4"D

(597 mm x 705 mm). Four (4) shelf supports

included per shelf (factory installed). Shelves

adjustable on 6” (153 mm) increments.

❒Additional kit option components available

individually.

115/208-230/1

NEMA-14-20R

TR Series:

Reach-In Glass Door Freezer

ELEVATION

783/16"

(1986 mm)

843/16"

(2139 mm)

5"

(127 mm)

1"

(26 mm)

PLAN VIEW

77"

(1956 mm)

13/16"

(31 mm)

345/8"

(880 mm)

239/16"

(599 mm)

583/16"

(1478 mm)

513/8"

(1305 mm)

13/8"

(35 mm)

365/32"

(919 mm)

3425/32"

(884 mm)

4"

(102 mm)