Trulife AEV350 User manual

AEV350, MEV350

TWO PART VALVE HOUSING,

AUTO AND MANUAL EXPULSION

Installation and User Guide

32210-001 REV A

Trulife www.trulife.com Page 1 of 4

INTRODUCTION

The AEV350 and the MEV350 valves are intended for transfemoral prosthetic suction sockets. Both utilize the same two-part valve

housing, which is ideal for use with flexible thermoplastic socket materials.

The AEV350 valve insert has automatic air expulsion function and manual push button to release suction.

The MEV350 valve has a push button used to manually expel air and to release suction.

Both type valve inserts are removable to allow use of a pull-sock for donning the socket.

Both are furnished with valve key and necessary components to form the socket to accept the two-part valve housing.

Product Code Description

AEV350 AUTO EXPULSION VALVE WITH TWO-PART HOUSING

MEV350 MANUAL EXPULSION VALVE WITH TWO PART HOUSING

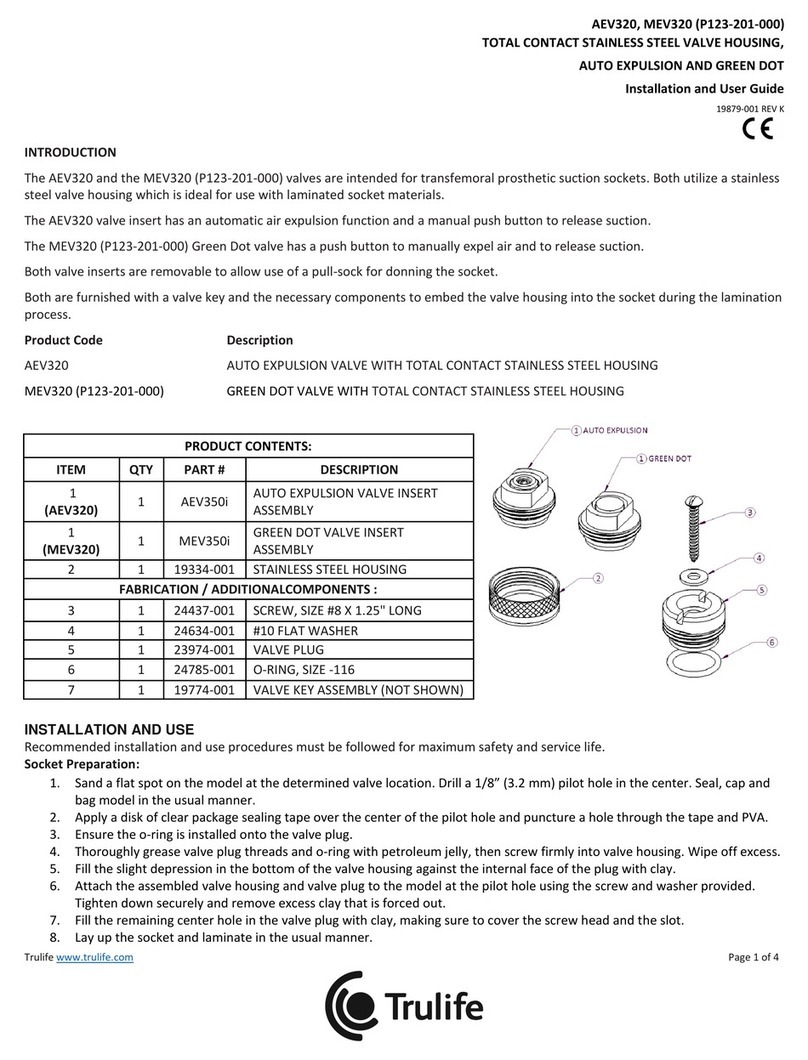

PRODUCT CONTENTS:

ITEM

QTY

PART #

DESCRIPTION

1

(AEV350)

1

32201-001

AUTO EXPULSION VALVE INSERT

ASSEMBLY

1

(MEV350)

1

32213-001

MANUAL EXPULSION VALVE INSERT

ASSEMBLY

2

1

32207-002

SOCKET OUTER HOUSING

3

1

32212-001

O-RING, SIZE -125

4

1

32208-001

SOCKET INNER HOUSING

FABRICATION / ADDITIONALCOMPONENTS :

5

1

24437-001

SCREW, SIZE #8 X 1.25" LONG

6

1

32209-001

FORMING TOOL

7

1

19774-001

VALVE KEY ASSEMBLY (NOT SHOWN)

INSTALLATION AND USE

Recommended installation and use procedures must be followed for maximum safety and service life.

Socket Preparation:

1. Determine valve location on the positive model. Flatten the region so the forming tool is flush. Mark the center hole

location of the forming tool.

2. Drill a Ø3.2mm (Ø1/8”) pilot hole for the supplied screw.

3. Drill a vacuum channel hole 12mm (1/2”) adjacent to the pilot hole with a long drill. This hole must extend through the

model so that vacuum will draw at the forming tool site.

4. Secure the forming tool to the model with the supplied screw, and positioning it so that one of the small holes in the

forming tool is over the vacuum channel hole.

5. Vacuum form the thermoplastic socket. Manually apply the necessary external pressure around the forming tool to help

guide the softened thermoplastic to fully form around the tool.

AEV350, MEV350

TWO PART VALVE HOUSING,

AUTO AND MANUAL EXPULSION

Installation and User Guide

32210-001 REV A

Trulife www.trulife.com Page 2 of 4

6. After the socket has cooled, sand off excess plastic directly above the forming tool until the top surface of the forming tool

is exposed.

7. Remove the socket from model. Use a sanding cone to carefully open up the hole if necessary so that the inner housing fits

snug through the hole.

8. Clean the inside and outside of the formed pocket of anything that could prevent a good seal.

Final Assembly:

9. Make sure the large o-ring is seated in the groove of the flange of the inner housing and place components into the recess

formed inside the socket.

10. On the outside of the socket, screw on the aluminum outer housing, and firmly hand tighten.

Tip: To facilitate a tight fit and a good seal, wet the o-ring and the threads of the housing components with water or

isopropyl alcohol just prior to tightening.

11. Assemble the valve insert (auto expulsion or manual expulsion) by gently hand tightening clockwise until the o-ring on the

outside of the valve insert makes contact with the sealing surface inside the valve housing.

Note: To prevent cross-threading, it is sometimes necessary to initially turn the insert counter-clockwise until the

threads are aligned properly, and then tighten clockwise.

12. A valve key is provided to assist removal of the valve insertfor individuals with limited hand strength or dexterity.

Disassembly and cleaning valve inserts:

Foreign debris such as dust, baby powder, and residue from lotions used for donning the

socket can become lodged in the sealing surfaces of the valve overtime and may cause a

decrease in vacuum performance.

Instruct patients to periodically wipe clean the outer o-ring and threads of the valve insert

and the inner threads and sealing surface of the valve housing. Use water or isopropyl

alcohol.

To disassemble the valve insert for more thorough cleaning, steps 1-4 pertain to both the

auto expulsion and the manual expulsion valve inserts:

1. Remove the valve insert from the housing.

2. Firmly press down on the valve button until the valve cover

snaps off.

3. Maintain downward force of the button, while carefully

removing the inner o-ring.

This is made easier by using a small nut or other object on a

flat, sturdy work surface.

Press the assembly down onto the small object so that the

valve button lifts up from the inner seal surface.

While the valve button is lifted, use a pick to CAREFULLY

remove the o-ring from the button. DO NOT CUT OR

DAMAGE THE O-RING!

4. Remove the button and spring from the valve body. Clean

components with water and mild detergent, or isopropyl

alcohol. Ensure all sealing surfaces are free of debris or

residue.

AEV350, MEV350

TWO PART VALVE HOUSING,

AUTO AND MANUAL EXPULSION

Installation and User Guide

32210-001 REV A

Trulife www.trulife.com Page 3 of 4

Steps 5-7 pertain only to the auto expulsion valve insert:

5. Use a 3mm hex key to remove the set screw.

6. Carefully remove the small inner spring and rubber ball.

7. Clean components with water and mild detergent, or isopropyl alcohol. Ensure

that the rubber ball and inner sealing surface of the button is free of any debris or

residue.

Re-assemble valve inserts, steps 1-3 pertain to the auto expulsion version:

1. Lightly coat the rubber ball with petroleum jelly or synthetic lubricant.

2. Place the ball, followed by the small spring into the valve button.

3. Apply 1 drop of Loctite 242 or 243 (blue) to the threads of the set screw and screw

it in until it stops.

Remaining steps apply to both the Auto-expulsion and the manual expulsion valves:

4. Place the large spring over the valve button, then press and hold it through the valve body while placing the small o-ring

over the lip on the opposite side of the button to retain it in place.

5. Press the button a few times to ensure the o-ring is seated properly.

6. Position the valve cover over the lower opening of the valve and press firmly until it snaps into place.

Warning: Failure to follow the installation and use procedures set forth above may lead to failure of the components subjecting

the user to a risk of serious personal injury.

AEV350, MEV350

TWO PART VALVE HOUSING,

AUTO AND MANUAL EXPULSION

Installation and User Guide

32210-001 REV A

Trulife www.trulife.com Page 4 of 4

QUESTIONS

Contact Customer Service at;

USA

Tel: +1 800 492 1088

Fax: +1 800 245 3765

Email: info-usa@trulife.com

Canada

Tel: +1 800 267 2812

Fax: +1 613 392 4139

Email: infocanada@trulife.com

Visit Trulife online at www.trulife.com.

Trulife has appointed Medical Device Safety Service (MDSS) of Hannover, Germany to act as our EU authorized representative. They

may be contacted at:

MDSS GmbH

Schiffgraben 41

30175 Hannover

Germany

Phone (+49)-511-6262 8630

FAX (+49) -511-6262 8633

LIMITED WARRANTY

Trulife warrants that the PRODUCT will be free from defects in material and workmanship from the date of installation for the

warranty period stated on the PRODUCT warranty card.

This warranty will not apply if the PRODUCT has been damaged by misuse, abuse, neglect, improper care, failure to follow

instructions, abnormal wear and tear, or in the event that the PRODUCT has been modified/repaired by persons unauthorized by

Trulife.

If a defect in material or workmanship is found during the warranty period, Trulife will, at Trulife’s option, either repair or replace

the product. If it is not possible to repair or replace the product, Trulife will be limited to refunding the purchase price.

Trulife will not be liable under any legal theory for any direct, indirect, special, incidental or consequential damages arising from the

use of or inability to use this product.

The application guidelines for this Trulife product are for the use of and by a certified, qualified practitioner only. Patients are not to

attempt to apply or adjust the item unless expressly instructed to do so by the practitioner responsible for the prescription and/or

initial fitting of the device. All patient questions should be referred to the practitioner and not to the manufacturer. The

manufacturer warrants only that the enclosed product has been inspected for quality and can be effective for certain indications,

but final decisions and ongoing monitoring must be made by the medical professional(s) prescribing and/or fitting the device to

determine its effectiveness for an individual patient. Patient compliance is an integral part of the entire protocol and must be

adhered to in order to avoid potential problems and to maximize the effectiveness of the prescribed product.

As a condition of the sale of any Trulife product, this product is restricted to a “Single Patient Use Only” by the originally fitted

patient in order to protect the care provider and the patient against potentially adverse consequences of infectious disease

transmission, material instability in adapting to the configuration of the original user and/or decrease in effectivity. Any express or

implied warranties are voided if the product is reused or fitted to another patient. Additionally, a license of right to use under any

relevant patents pertaining to the product is terminated with the cessation of use by the original patient. As with all Trulife

products, this product must be prescribed and applied by a qualified practitioner to determine it meets the needs of the particular

patient and accomplishes the desired results.

This manual suits for next models

1

Table of contents

Other Trulife Mobility Aid manuals