Truper ROU-MN User manual

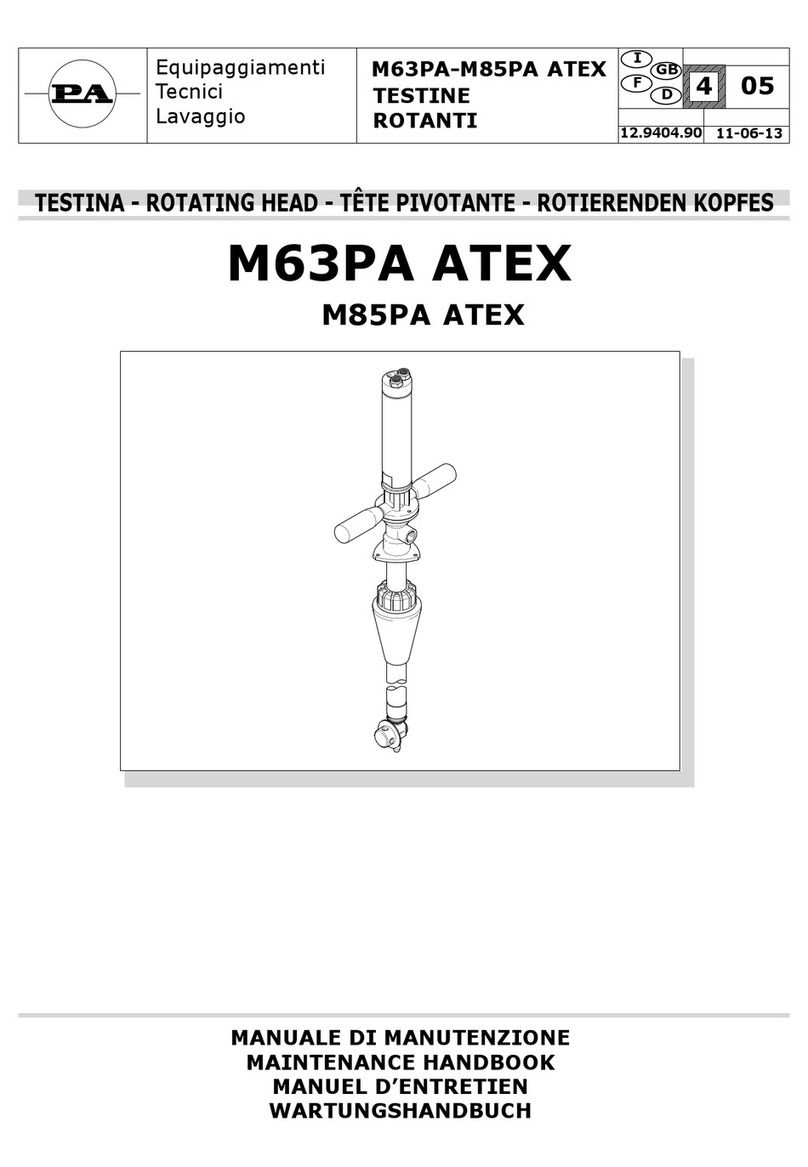

ROU-MN

Manual

Compact Router

ModelCode

ROU-MN

Applies for:

102315

Power

0.95 HP

ENGLISH

ESPAÑOL

CAUTION Read this manual thoroughly

before using the tool.

2

Technical data

Power requirements

General power tool safety warnings

Safety warnings for the use of routers

Parts

Set up

Start up

Operation

Maintenance

Troubleshooting

Authorized service centers

Warranty policy

3

3

4

5

6

7

9

10

14

14

15

16

ROU-MN

ENGLISH

CAUTION

Contents

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

Power requirements

3

ROU-MN

102315

Class II

60 Hz

Compact Router

18 AWG x 2C with insulation temperature of 221 °F

5.6 A 0.95 HP

Code

Description

Voltage Frequency

PowerCurrent

10000 RPM - 30000 RPM

For drills with 1/4” shanks

Speed

Collar clamps

3 1/2” 1 1/8”

Base diameter

1 3/8”

Maximum cutting depth:

Maximum drill diameter

Conductors

Insulation IP 20

IP Grade

El cable de alimentación tiene sujeta-cables tipo: Y

La clase de construcción de la herramienta es: Aislamiento reforzado.

La clase de aislamiento térmico de los devanados del motor: Clase E

127 V

Technical Data

ENGLISH

Tools with double insulation and reinforced insulation are built with a

polarized plug (one prong is wider than the other) This plug fits in any polarized outlet

and can only be connected one way. If the plug does not fit completely into the outlet,

reverse the plug. If it is not fitting, call a qualified electrician or install a polarized outlet.

Do not alter the plug in any way. Double insulation eliminates the need of a three-prong

grounded power plug or a grounded electric system.

When using an extension cable, make it has sufficient gauge to

carry the current your tool will draw. A lower gauge cable will cause voltage drop in the line, resulting in power loss and

the motor will overheat. The following table shows the right size to use depending on cable’s length and the ampere

capability shown in the tool’s nameplate. When in doubt use the next higher gauge.

WARNING

WARNING

From 0 and up to 10 A

From 10 and up to 13 A

From 13 and up to 15 A

From 15 and up to 20 A

18 AWG

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3 (one grounded)

From 6 ft to 49 ft | Higher than 49 ft

Ampere

Capacity Number of

Conductors Extension Gauge

When using power tools outdoors use grounded extension cable labeled “Outdoors

Use”. These extension cables are specially manufactured for outdoors use and reduce the risk of electric shock.

WARNING

WARNING

WARNING Avoid the risk of electric shock or severe injury. When the power cable gets damaged

it should only be replaced by the manufacturer or at a Authorized Service Center.

The build quality of the electric insulation is altered if spills or liquid gets into the tool while in use.

Do not expose to rain, liquids and/or dampness.

Before gaining access to the terminals all power sources should be disconnected.

*It is safe to use only if the extensions have a built-in artifact for over current protection.

AWG = American Wire Gauge. Reference: NMX-J-195-ANCE

4ENGLISH

This tool is in compliance with

the Official Mexican Standard

(NOM - Norma Oficial Mexicana).

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned or

stuck. There should not be broken parts or other conditions that

may affect its operation. Repair any damage before using the

tool.

Most accidents are caused due to poor maintenance to the tools.

Keep the cutting accessories sharp and clean.

Cutting accessories in good working conditions are less likely to bind and are

easier to control.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

General power tool

safety warnings

WARNING! Read carefully all safety warnings and instruction listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

5

Safety warnings for

the use of routers

• Keep hands away from cutting area and

cutting bit. When operating the tool, hold it firmly by the

non-slip handle to avoid accidental injury and prevent

loss of control.

• Accidental contact with a rotating

cutting bit can result in serious personal injury.

• NEVER hold the workpiece with your

hands or on one leg. Hold the workpiece properly to

avoid body contact with the cutting bit, binding of the bit,

or loss of control of the tool or workpiece.

• Do not attempt to remove scrap

material when the cutting bit is rotating.

• Never put your hand under the

workpiece while the tool is running.

• Before each use check all parts for

proper operation, if something is not working give service

before operating the tool.

• Before transporting the tool remove the

cutting bit.

• Operating the tool while holding it by its

insulated parts avoids shocks to the operator in case the

blade contacts hidden electrical wiring.

• Before servicing, removing or

installing bits, parallel guide or dust extractor adapter, you

must disconnect the tool from the power supply.

• ALWAYS keep the power cord away from the cutting

area. The power cord should NEVER hang over the

workpiece when cutting.

• Always wear safety glasses with side shields. If dust is

produced also wear a dust mask.

Dusts from cutting certain materials contain chemicals

known to cause health hazards. To reduce exposure to

these chemicals, work in well-ventilated areas, and use

appropriate safety equipment, such as dust masks

specifically designed to filter out microscopic particles.

Toxic materials

• RISK OF KICKBACK. Kickback refers

to the sudden, forceful movement of the tool away from

the workpiece that can cause the operator to lose control

or even cause injury. It is usually caused when the cutting

bit gets stuck in the workpiece or by poor operation. To

avoid this, the following precautions should be taken:

• Use cutting bits in good condition and

make sure they are properly installed. Poorly installed,

damaged, dull or worn bits tend to get stuck in the

material causing kickback.

• When operating the router, hold the

router firmly by the non-slip handle. Keep your body well

balanced and in a stable position with both feet on the

floor to resist the force of a possible kickback.

• To make a cut, wait for the drill bit to

reach full speed before starting to cut. Do not start the

tool with the drill bit resting on the workpiece, it may

cause kickback.

• To restart work within a cut, center the drill bit in the cut.

• If cutting is interrupted during router

operation, turn the switch off and hold the tool inside the

workpiece until the motor comes to a complete stop. Do

not attempt to remove the bit while the motor is still

running, it may cause kickback.

• To minimize the risk of the bit binding

and causing kickback, remove all nails before cutting a piece

of wood. Wet, warped or pressure-treated wood requires

special attention during cutting. The gum and resin in the

wood that hardens on the cutting bits slows the router. Use

gum and resin remover, hot water or kerosene to remove

these buildups. DO NOT use gasoline.

• Before starting any cut, the depth of

cut adjustment knobs must be tightened and secured. If

they move during the cut, kickback may result.

• Excessive depth cuts and/or the use of

large diameter bits increase the load on the unit and the

possibility of kickback. Make several passes with the

router at progressive depths when the job requires

removal of a lot of material or when using large diameter

bits.

ENGLISH

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

0 in mm 0

1

2

6

Parts

Fine height

adjustment knob

Splinter

guard

Parallel and circle

cutting guide

Edge

guide

Hex

keys

Copying guide

1/2” and 7/8”

wrenches

Carbon

cover

Handle with

anti-skid

cover

Graduated

cylinder

Switch

Knob for securing

the splinter guard Knob to secure accessories

(cutting guides)

Power

cord

Power cord

protector

Base

guard

Base

Shaft

lock

Locking lever

Vacuum

port Collar

Speed

control

6ENGLISH

7

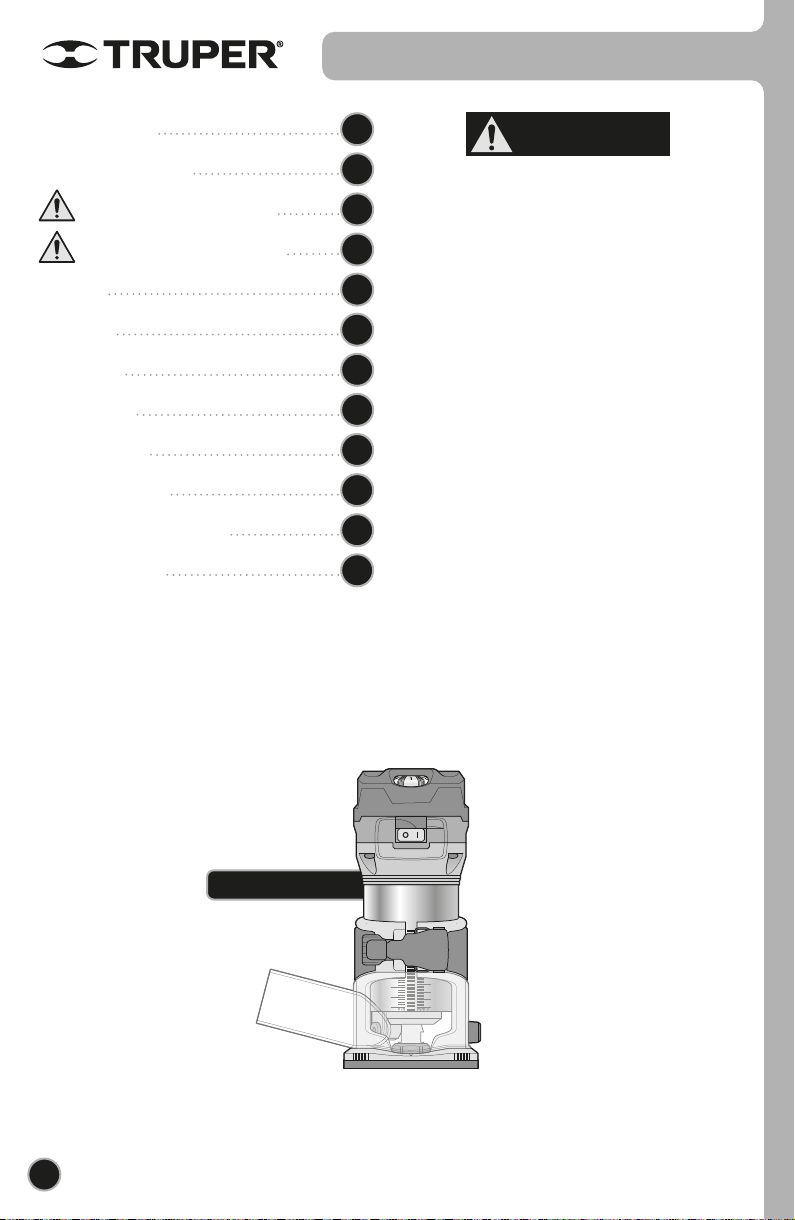

Set up

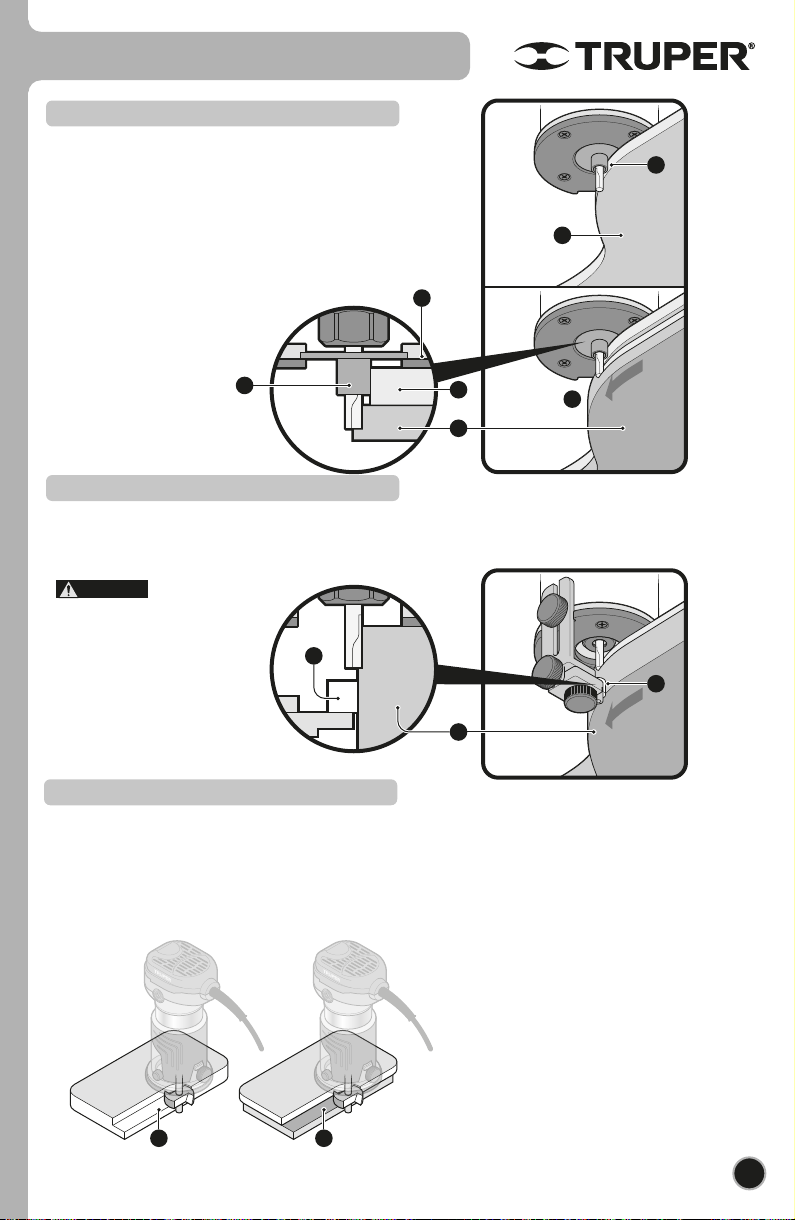

• Before installing or removing a drill bit,

turn off and disconnect the router from the power source.

You can perform drill bit installation and demounting in two

ways:

1. By removing the cylinder.

• Remove the cylinder (A) from the fixed base as described

in the previous section and rest the motor head on a flat

surface with the cylinder pointing up.

• Depress the shaft lock (G) to prevent the shaft from

rotating.

• Without releasing the shaft lock, loosen the collar nut (H)

with the 7/8” wrench ( I).

• Place the drill bit ( J) in the collet, the shank must enter at

least 19/32" to ensure that the drill bit does not accidentally

come out.

• Tighten the collet nut firmly with the wrench to secure the

drill bit.

• Release the spindle lock (G) and make sure that the drill

bit is securely in place.

• To remove the drill bit, depress the spindle lock and

loosen the collet nut with the wrench provided.

2. Without removing the cylinder.

• Remove the drill bit as explained in the previous section.

• Use the 1/2” wrench (K) to secure the shaft to prevent it

from turning.

• Hold the collar (H) with the 7/8” wrench ( I) and turn the

nut counterclockwise.

• Place the 7/8” wrench on the collar and the 1/2” wrench

on the motor shaft.

• Hold the 1/2” wrench and loosen with the 7/8” wrench.

• Place the drill bit in the collet the shank must go in at least

19/32" to ensure that the drill bit does not accidentally come out.

• Replace the 1/2” wrench and tighten firmly with the 7/8” wrench.

• To remove the bit, follow the reverse of the installation procedure.

Drill bit installation or disassembly

• The router motor is housed in the vertical cylinder (A)

which raises or lowers inside the fixed base (B) to adjust

the drill bit to the proper height for the work to be

performed.

• Before installing a drill bit or changing

the collet or clamp, the cylinder must be removed from

the fixed base.

• Before disassembling or assembling

the cylinder, turn off and disconnect the router from the

power supply.

• To remove the cylinder, release the lever (C) from the

fixed base clamp.

• Lift the motor head (D) until the cylinder is removed

from the fixed base.

• To reassemble the cylinder, make sure to align the

toothed groove (E) with the base sprocket (F).

• Insert the cylinder into the fixed base.

• Push the lever (C) to close the clamp.

Disassembly and assembly of the cylinder

J

C

A

E

A

D

F

K

I

I

G

H

H

B

Loosen

Tighten

ENGLISH

CAUTION

CAUTION

CAUTION

E

G

F

D

BA

8

Set up

• Slide the parallel guide slot (C) into the screw on the

back of the router and secure it in place by tightening

the knob (D).

• Depending on the work to be performed, the router

accepts different types of auxiliary guides: parallel

guide, edge guide or copying guide.

Parallel guide installation

• Slide the edge guide slot (E) into the screw on the

back of the router and secure it in place by tightening

the knob (D).

Edge guide installation

• Attach the chip cover (also vacuum port) (A) to the

front of the router base.

• To secure it in place, tighten the knob (B).

• The cover must be mounted and

secured before operating the router.

Splinter shield assembly

• Loosen the screws and remove the base protector (F).

• Put the copying guide (G) on the base and replace the

base protector. Then fasten the base protector by

tightening the screws.

Assembly of the copying guide

C

D

ENGLISH

CAUTION

1

2

1

2

6

• Before adjusting the height of cut, turn

off and disconnect the router from the power source.

• Rest the router base on a flat, level surface with the front

of the router facing you.

• Open the lever (F) on the stationary base.

• With the cutter bit already installed, push down on the

cylinder until the bit is very close to the surface on which

the outer is resting (1).

• Turn the fine height adjustment knob (G) until the drill

bit barely touches the surface on which the router is

resting. This point should be considered as 0 penetration.

• Place the router on two pieces of scrap work that are

level and position it so that the drill bit can be lowered

underneath the base of the router (2).

• Rotate the fine height adjustment knob (G) to lower the

drill bit to the desired depth of cut. Turn in the opposite

direction to raise the bit.

• Once you determine the depth of cut, close the lever (F)

on the fixed base.

Cutting height adjustment

9

Start up

F

A

G

• Connect the router to the power source.

• Use the switch (A) to turn the router motor on or off. To

turn on press the switch to the "O" mark, to turn off press

the switch to the "I" mark.

• When turning the motor on, wait until

the drill bit reaches full speed to make contact with the

workpiece.

• When turning the motor off, wait for

the drill bit to come to a complete stop before removing

the drill bit from the workpiece.

• The motor is configured to minimize torque by limiting

its speed during start-up, which increases its life.

• The motor features electronic feedback control that

maintains constant speed under load to provide proper

control and ensure a smooth finish.

Start-up and operation control

ENGLISH

CAUTION

CAUTION

CAUTION

1

2

6

• It is important to perform test cuts on scrap material

before making the cut on the final material. Test cuts allow

the operator to rehearse the cut for speed and depth

adjustments, as well as to get a feel for material response,

cutting direction, and optimal router setup.

• Rest the base of the router on the workpiece before

turning it on. Make sure the bit is not in

contact with the workpiece until you have control of the

router by firmly gripping the non-slip handle (A) and the

motor has reached the maximum speed set for the job.

• Guide the router at a constant speed through the work

piece without exerting too much pressure on the bit,

allowing sufficient time for the bit to cut the material.

C

A

B

Operation

10

• When cutting along an edge, be sure to

guide the bit in the same direction as the direction of

rotation of the bit (B). Otherwise, the router may be

triggered unexpectedly and also produce faulty cuts.

Cutting direction

• With the speed control (C) it is possible to determine the speed of the router.

• The control can be adjusted from 1 (lowest speed) to 6 (highest speed).

• The speed can be adjusted with the motor running; however, do not change the speed when the drill

bit is in contact with the workpiece, otherwise loss of control due to sudden vibration may occur.

• This allows the ideal speed to be chosen for optimum processing of the material, i.e., the speed can be adjusted

correctly to match the material and diameter of the cutter. Refer to the table for the relationship between the numerical

settings of the rotary control and the approximate tool speed.

Speed control

Number RPM

1

2

3

4

5

6

10000 RPM

12 000 RPM

17 000 RPM

22 000 RPM

27 000 RPM

30 000 RPM

ENGLISH

CAUTION

CAUTION

CAUTION

E

D

A B C

Operation

11

Parallel guide

• It is not advisable to make deep single-cut cuts. Small diameter bits break easily due to excessive load

and torque; while larger bits produce coarse cuts and are difficult to guide and control. To make a deep cut, make

successive cuts by increasing the depth of the bit up to 1/8” per pass until the desired depth is reached.

Cutting depth

• Install the parallel guide (D) on the router base (page 8),

and rest it on the edge of the workpiece to make straight

cuts.

• If the distance between the cut and the edge of the

workpiece is greater than the opening of the parallel

guide, or if the edge of the workpiece is not straight, use at

least two clamps to hold a straight piece of wood (E) as a

guide. Make the cut by resting the side of the router base

against the piece of wood.

• The speed at which the bit is pushed with the router determines the finish of the cut and depends on several factors:

hardness and moisture content of the workpiece, depth of cut and bit diameter. Usually, shallow cuts in soft woods can be

made with fast movements, while deep cuts in hard woods are made more slowly. To determine the ideal speed, tests on

scrap material are essential. Too fast cutting movements (A) cause the bit to take out very large chunks of material, as well

as overloading the motor. Proper cutting motions (B) cause the bit to take small bites and clean cuts. Too slow cutting

movements (C) generate too much friction in the material, resulting in scratches that expose the material fibers and cause

a scorched cut.

Thrust speed

Parallel

guide

ENGLISH

CAUTION

F

12

Operation

Circle cutting guide

• The parallel guide can be configured to cut circles of different

size ranges.

• The radius of the circle is the distance from the anchor (A) of

the guide to the center of the drill bit.

• To cut circles from 2-1/2” to 4-3/4“ radius, place the wing nut

in the hole closest to the router (B).

• To cut circles from 4-3/4” to 8-11/16“ radius, place the wing

nut in the hole farthest from the router (C).

• This guide cannot cut circles with radii from 6-3/4”

to 7-5/16”.

Circle cutting

guide

NOTE

ENGLISH

• Use a template (A) between the router base (B) and the

workpiece (C).

• Rest the copying guide bushing (D) on the edge of the

template.

• Make the cut without separating the bushing around the

perimeter of the template (E).

Copying guide

• Rest the edge guide roller (F) on the edge of the

workpiece (G).

• Make the cut without separating the roller around the

perimeter of the workpiece.

• Before cutting,

test a scrap piece to determine the

position of the roller. Tighten the

knobs before cutting.

Edge guide

• Drill bits with built-in stops are ideal for working edges.

The workpiece itself can serve as a guide when its

thickness is greater than the height of the drill bit (I). If the

thickness of the work piece is less than the height of the

drill bit, use a guide (K) to make the cut.

A

B

AE

C

G

D

F

D

F

I K

Operation

13

Drill bits with guide stop

ENGLISH

CAUTION

Carbon cover

• Ensure that the machine's ventilation slots are kept free of sawdust/chips, etc.

• Keep the guides clean and lubricated with a light multi-purpose oil.

• Tool repair service should always be performed by a Authorized Service Center. If machine repair

services are performed by personnel not authorized by , the product warranty will be invalidated.

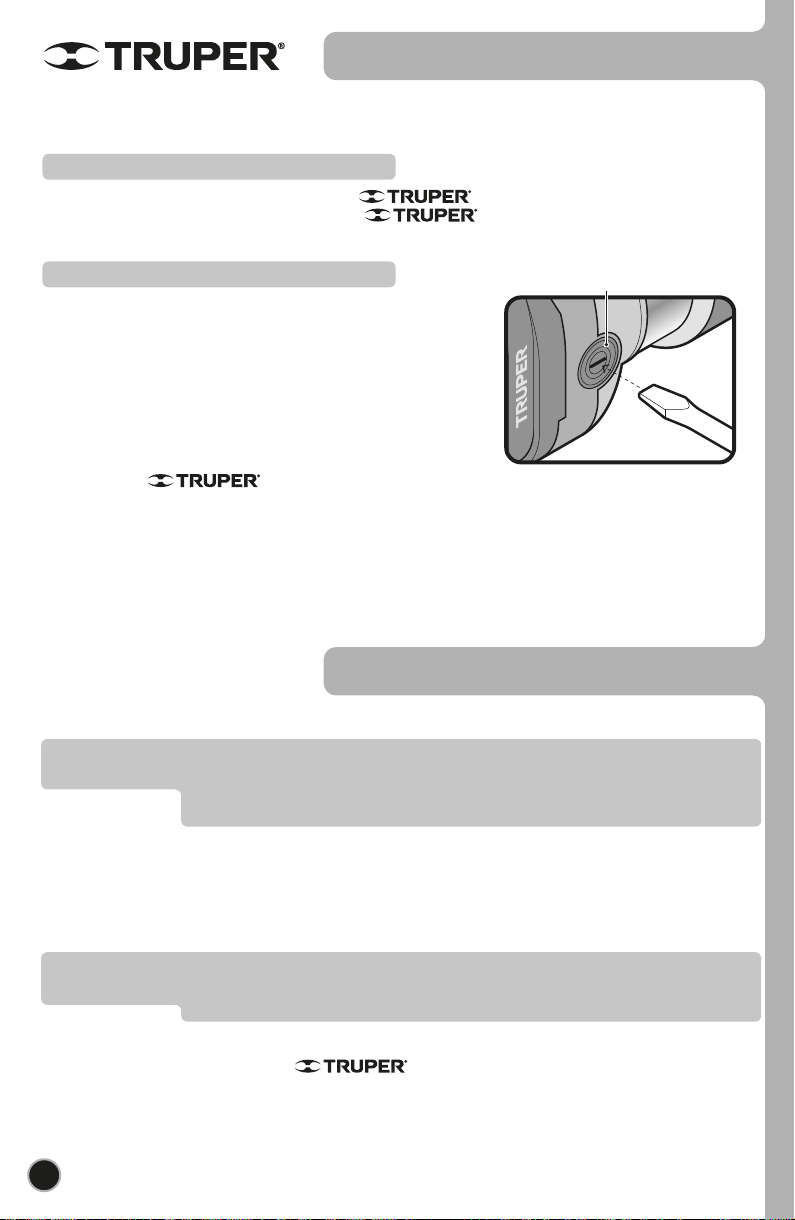

Carbon brush replacement

Repair service

• It is necessary to replace worn out carbon brushes (burnt, broken or less than

5 mm long) with new carbon brushes.

• When replacing the carbon brushes, always replace both carbon brushes.

• Use a screwdriver to remove the cover of the carbons, remove the worn

carbons from the carbon holder and remove the accumulated dust with

compressed air.

• Insert the new carbons in reverse order. The carbons should fall into the

holders easily.

• After inserting the new carbons, allow the grinder to run for a few minutes

without a workload to give the carbons a better fit.

• Only genuine replacement carbons, specifically designed

with the proper hardness and electrical resistance for each type of motor,

should be used. Out of specification carbons can damage the motor.

14

Maintenance

Troubleshooting

Problem Cause Solution

If problems persist despite performing the recommended corrective actions,

contact a Authorized Service Center.

• Connect the cord to the power supply.

• Turn the switch to the “ON” position.

• Remove the covers from the coals and replace

the old coals with new ones.

• Attach a cutting bit with a sharp cutting edge.

• Select an appropriate speed for the cutting bit

that is suitable.

• Perform test cuts on scrap material to

determine the proper thrust speed (see page

10).

• Use 1/4” shank bits with 1/4” chuck

The router is not

working.

Work piece surface is

not smooth after

cutting.

Unable to install the

cutting bit.

• Cord disconnected from power supply.

• Switch is in the “OFF” position.

• The carbons are completely worn out.

• The drill bit has no cutting edge.

• The speed of the drill bit slows down to an

inappropriate speed.

• The speed at which the drill bit is pushed is

inadequate.

• The drill bit size is not correct for the collet.

ENGLISH

15

Authorized service centers

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

MEXICO

CITY

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

In the event of any problem contacting a Authorized Service Center, please see our

webpage www.truper.com to get an updated list, or call our toll-free numbers 800 690-6990 or 800 018-7873

to get information about the nearest Service Center.

ENGLISH

16

102315

www.truper.com

06-2022

Code

ROU-MN

Model Brand

3

YEARS

Warranty

policy

Stamp of the business. Date of purchase:

Warranty. Duration: 3 year. Coverage: parts, components and workmanship against manufacturing or

operating defects, except if used under conditions other than normal; when it was not operated in

accordance with the instructive; was altered or repaired by personnel not authorized by Truper®.

To make the warranty valid, present the product, stamped policy or invoice or receipt or voucher, in the

establishment where you bought it or in Corregidora 22, Centro, Cuauhtémoc, CDMX, 06060, where you

can also purchase parts, components, consumables and accessories. It includes the costs of transportation of

the product that derive from its fulfillment of its service network. Phone number 800-018-7873.

Made in China. Imported by Truper, S.A. de C.V. Parque Industrial 1, Parque Industrial Jilotepec, Jilotepec,

Edo. de Méx. C.P. 54257, Phone number 761 782 9100.

ENGLISH

ROU-MN

Instructivo de

Rebajadora

compacta

ModeloCódigo

ROU-MN

Este instructivo es para:

102315

Potencia

710 W

ESPAÑOL

ENGLISH

Lea este Instructivo por completo

antes de usar la herramienta.

ATENCIÓN

Í

ndice

2

Especificaciones técnicas

Requerimientos eléctricos

Advertencias generales de seguridad

para herramientas eléctricas

Advertencias de seguridad

para uso de rebajadoras

Partes

Preparación

Puesta en marcha

Operación

Mantenimiento

Solución de problemas

Centros de servicio autorizados

Póliza de garantía

Guarde este instructivo para futuras referencias.

Los gráficos de este instructivo son para

referencia, pueden variar del aspecto real de la

herramienta.

3

3

4

5

6

7

9

10

14

14

15

16

ROU-MN

Para poder sacar el máximo

provecho de la herramienta,

alargar su vida útil, hacer válida

la garantía en caso de ser

necesario y evitar riesgos o

lesiones graves, es fundamental

leer este instructivo por

completo antes de usar la

herramienta.

ATENCIÓN

ESPAÑOL

Requerimientos eléctricos

de 0 A hasta 10 A

de 10 A hasta 13 A

de 13 A hasta 15 A

de 15 A hasta 20 A

18 AWG(*)

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3 (uno a tierra)

de 1.8 m a 15 m | mayor de 15 m

Capacidad en

Amperes Número de

conductores Calibre de extensión

Las herramientas de doble aislamiento y aislamiento reforzado

están equipadas con una clavija polarizada (una pata es más ancha que la otra). Esta

clavija cabe en cualquier enchufe polarizado y sólo puede conectarse de una forma. Si la

clavija no cabe en el enchufe, voltéelo. Si aún así no cabe, póngase en contacto con un

electricista calificado o instale un enchufe polarizado. No altere la clavija en forma alguna.

Ambos tipos de islamiento eliminan la necesidad de un cable de corriente de tres partes

con conexión a tierra o de un sistema de corriente eléctrica con conexión a tierra.

Al usar un cable de extensión, asegúrese de usar el calibre suficiente para transportar la corriente que

consumirá su herramienta. Un cable de un calibre inferior ocasionará caídas de tensión en la línea, teniendo como resultado

pérdida de potencia y sobrecalentamiento del motor. La siguiente tabla muestra el tamaño correcto que debe usarse

dependiendo de la longitud del cable y de la capacidad de amperes indicada en la placa de datos de la herramienta. Si tiene

dudas use el siguiente calibre más alto.

*Se permite utilizarlo siempre y cuando las extensiones mismas cuenten con un artefacto de protección contra sobrecorriente.

AWG = Calibre de alambre estadounidense (American Wire Gauge). Referencia: NMX-J-195-ANCE

3

ROU-MN

102315

Clase II

60 Hz

Rebajadora compacta

18 AWG x 2C con temperatura de aislamiento de 105 °C

5.6 A 710 W (0.95 HP)

Código

Descripción

Tensión Frecuencia

PotenciaCorriente

10000 r/min - 30000 r/min

para brocas con zancos de 1/4” (6.5 mm)

Velocidad

Mordaza de collarines

3 1/2” (90 mm) 1 1/8” (28.5 mm)

Diámetro de la base

1 3/8” (35 mm)

Máxima profundida de corte:

Máximo diámetro de la broca

Conductores

Aislamiento IP 20

Grado IP

El cable de alimentación tiene sujeta-cables tipo: Y

La clase de construcción de la herramienta es: Aislamiento reforzado.

La clase de aislamiento térmico de los devanados del motor: Clase E

127 V

Especificaciones técnicas

Si el cable de alimentación se daña, éste debe ser reemplazado por el fabricante o Centro de Servicio

Autorizado , con el fin de evitar algún riesgo de descarga o accidente considerable.

La construcción del aislamiento eléctrico de esta herramienta es alterado por salpicaduras o

derramamiento de líquidos durante su operación. No la exponga a la lluvia, líquidos y/o humedad.

Antes de obtener acceso a las terminales, todos los circuitos de alimentación deben ser desconectados.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

ESPAÑOL

Al operar herramientas eléctricas en exteriores, utilice una extensión

aterrizada marcada como “Uso exterior” marca . Estas extensiones son

especiales para el uso en exteriores y reducen el riesgo de sufrir una descarga eléctrica.

ADVERTENCIA

4

Esta herramienta cumple

con la Norma Oficial

Mexicana (NOM).

Área de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las áreas desordenadas y obscuras son propensas a accidentes.

No maneje la herramienta en ambientes explosivos, como en

presencia de líquido, gas o polvo inflamables.

Las herramientas eléctricas producen chispas que pueden encender

material inflamable.

Mantenga alejados a los niños y curiosos cuando opere la

herramienta.

Las distracciones pueden hacer que pierda el control.

Seguridad eléctrica

La clavija de la herramienta debe coincidir con el tomacorrien-

te. Nunca modifique una clavija. No use ningún tipo de

adaptador para clavijas de herramientas puestas a tierra.

Clavijas modificadas y enchufes diferentes aumentan el riesgo de

choque eléctrico.

Evite el contacto del cuerpo con superficies puestas a tierra

como tuberías, radiadores, cocinas eléctricas y refrigeradores.

Hay un mayor riesgo de choque eléctrico si el cuerpo está puesto a tierra.

No exponga la herramienta a la lluvia o condiciones de humedad.

El agua que ingresa en la herramienta aumenta el riesgo de choque eléctrico.

No fuerce el cable. Nunca use el cable para transportar,

levantar o desconectar la herramienta. Mantenga el cable

lejos del calor, aceite, orillas afiladas o piezas en movimiento.

Los cables dañados o enredados aumentan el riesgo de choque eléctrico.

Cuando maneje una herramienta en exteriores, use una

extensión especial para uso en exteriores.

El uso de una extensión adecuada para exteriores reduce el riesgo de choque

eléctrico.

Si el uso de la herramienta en un lugar húmedo es inevitable,

use una alimentación protegida por un interruptor de circuito

de falla a tierra (GFCI).

El uso de un GFCI reduce el riesgo de choque eléctrico.

Seguridad personal

Esté alerta, vigile lo que está haciendo y use el sentido común

cuando maneje una herramienta. No la use si está cansado o

bajo la influencia de drogas, alcohol o medicamentos.

Un momento de distracción mientras maneja la herramienta puede

causar un daño personal.

Use equipo de seguridad. Use siempre protección para los ojos.

El uso de equipo de seguridad como lentes de seguridad, mascarilla antipolvo,

zapatos antideslizantes, casco y protección para los oídos en condiciones

apropiadas, reduce de manera significativa los daños personales.

Evite arranques accidentales. Asegúrese de que el interruptor

está en posición “apagado” antes de conectar a la fuente de

alimentación y/o a la batería o transportar la herramienta.

Transportar herramientas eléctricas con el dedo sobre el interruptor o

conectar herramientas eléctricas que tienen el interruptor en posición de

“encendido” puede causar accidentes.

Retire cualquier llave o herramienta de ajuste antes de arrancar

la herramienta eléctrica.

Las llaves o herramientas que quedan en las partes rotativas de la

herramienta pueden causar un daño personal.

No sobrepase su campo de acción. Mantenga ambos pies bien

asentados sobre el suelo y conserve el equilibrio en todo

momento.

Esto permite un mejor control de la herramienta en situaciones inesperadas.

Vista adecuadamente. No vista ropa suelta o joyas. Mantenga

su pelo, su ropa y guantes alejados de las piezas en

movimiento.

La ropa o el pelo suelto o las joyas pueden quedar atrapados en las piezas en

movimiento.

En caso de contar con dispositivos de extracción y recolección

de polvo conectados a la herramienta, verifique sus conexiones

y úselos correctamente.

El uso de estos dispositivos reduce los riesgos relacionados con el polvo.

Uso y cuidados de la herramienta

No fuerce la herramienta. Use la herramienta adecuada para el

trabajo a realizar.

La herramienta adecuada hace un trabajo mejor y más seguro cuando

se usa al ritmo para el que fue diseñada.

No use la herramienta si el interruptor no funciona.

Cualquier herramienta eléctrica que no pueda encenderse o

apagarse es peligrosa y debe repararse antes de ser operada.

Desconecte la herramienta de la fuente de alimentación

y/o de la batería antes de efectuar cualquier ajuste,

cambiar accesorios o almacenarla.

Estas medidas reducen el riesgo de arrancar la herramienta

accidentalmente.

Almacene las herramientas fuera del alcance de los niños y no

permita su manejo por personas no familiarizadas con las

herramientas o con las instrucciones.

Las herramientas eléctricas son peligrosas en manos no entrenadas.

Dele mantenimiento a la herramienta. Compruebe que las

partes móviles no estén desalineadas o trabadas, que no

haya piezas rotas u otras condiciones que puedan afectar su

operación. Repare cualquier daño antes de usar la herramienta.

Muchos accidentes son causados por el escaso mantenimiento de las

herramientas.

Mantenga los accesorios de corte afilados y limpios.

Los accesorios de corte en buenas condiciones son menos probables de

trabarse y más fáciles de controlar.

Use la herramienta, sus componentes y accesorios de acuerdo

con estas instrucciones y de la manera prevista para el tipo de

herramienta, en condiciones de trabajo adecuadas.

El uso de la herramienta para aplicaciones diferentes para las que

está diseñada podría causar una situación de peligro.

Servicio

Repare la herramienta en un Centro de Servicio Autorizado

usando sólo piezas de repuesto idénticas.

Para mantener la seguridad de la herramienta.

Advertencias generales de seguridad

para herramientas eléctricas

¡ADVERTENCIA! Lea detenidamente todas las advertencias de seguridad y todas las instrucciones que se

enlistan a continuación. La omisión de alguna de ellas puede dar como resultado un choque eléctrico, incendio y/o

daño serio. Conserve las advertencias y las instrucciones para futuras referencias.

ESPAÑOL

This manual suits for next models

1

Table of contents

Languages:

Other Truper Tools manuals