Introduction

TableofContents

Disclaimers

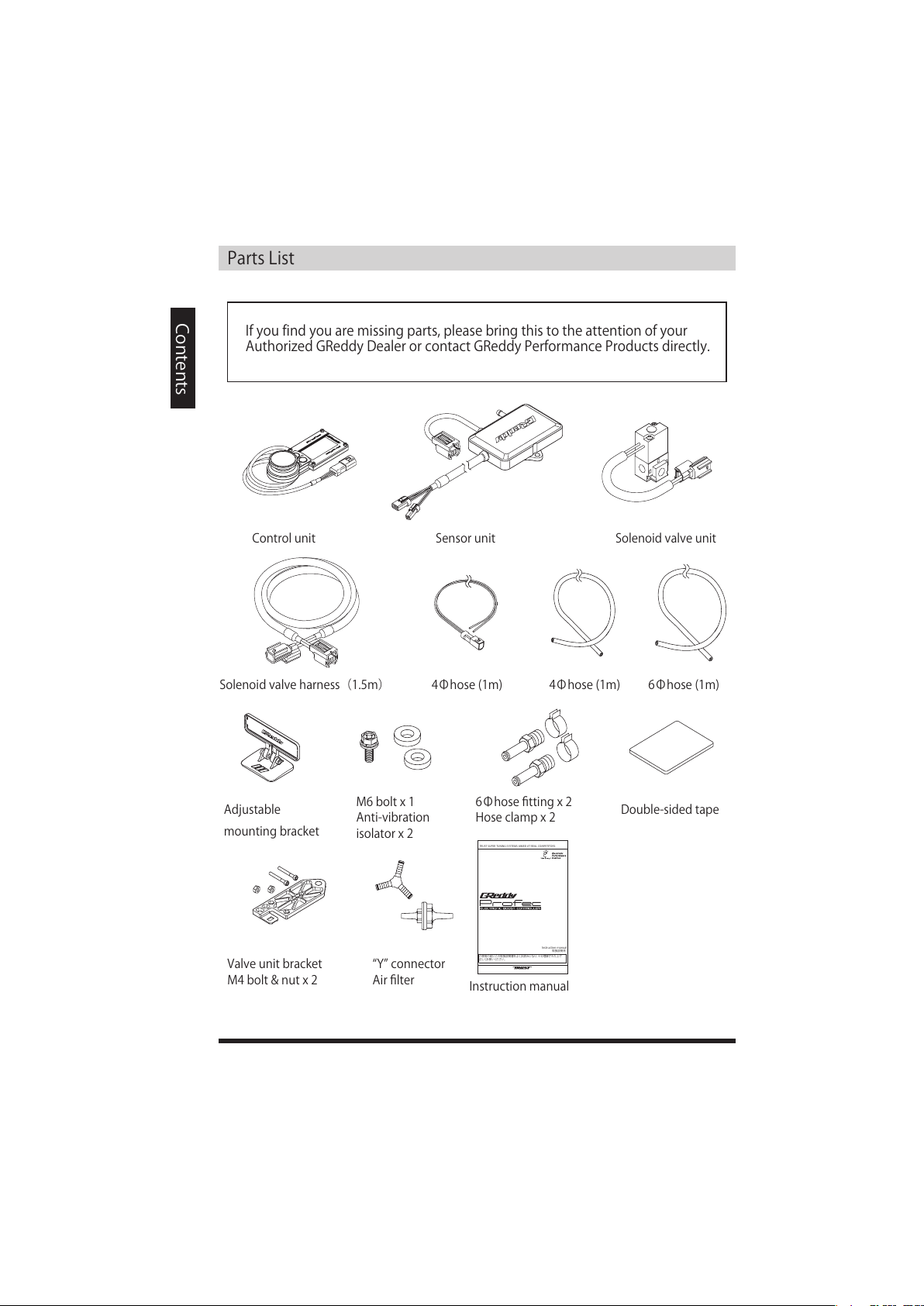

PartsList

ProductFeatures

Productdescription/Beforeinstallation

Installationoverview(Actuatortype)

Powerunitwiringinstructions/Pressuresensorhoseroutinginstructions

Installingthesolenoidvalveunit

Installingthesolenoidvalveunit(Actuatortype)

Installingthesolenoidvalve(Externalwastegatetype)

Controlunitinstallation

Basicoperation

Opearatinginstructions

Quickreferencematrix

SETUPoverview

PATTERN

DIRECTION / BRIGHT

UNIT / ALARM

LASTBOOST

STARTTYPE

DATALOCK

Programmingoverview

SET

GAIN

STARTBOOST

PEAK

WARNING

LIMITER

SCRAMBLE

SWITCHMODE

Shortcutcommands

Troubleshooting/Testmode

Boostsettingtips

Factorydefaultsettings/Troubleshooting

Service

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

P1

P2

P3〜6

P7

P8

P9

P10

P11

P12,13

P14

P15

P16

P17

P17,18

P19,20

P21

P22

P23

P24

P25

P26

P27,28

P29

P30

P31

P32

P33

P34

P35

P36

P37

P38

P39

P40

P41

P42

PleaseRead

PleaseRead

PleaseRead

PleaseRead

TableofContents

Contents Installation Configurations Boostsettings Troubleshooting

Operations

Contents Installation Configurations Boostsettings TroubleshootingOperations