TRW Easycheck User manual

operating instructions

bedieningshandleiding

manuel de l’utilisateur

bedienungsanweisung

istruzioni per l’uso

instuções de utilização

manuel de instrucciones

Çalıs

¸tırma talimatları

TRW – Safety

Part number I317289 (EN)

- Issue 10

Operating instructions

Part number I317 289 (EN)

Issue 10

2

TRW – Safety

i

Contents Introduction

Overview .................................................................. 1

Display screen .......................................................... 6

Keypad ...................................................................... 6

Connection................................................................ 7

Safety precautions .................................................... 8

Communication problems......................................... 8

Scan function - EOBD

What is EOBD?......................................................... 9

Identifying compliant vehicles ................................ 10

Diagnostic Trouble Codes....................................... 11

Interpreting EOBD fault codes................................ 12

Using scan function ................................................ 13

Menu options.......................................................... 15

FastCheck

Introduction............................................................. 18

Safety instructions .................................................. 19

FastCheck ABS ....................................................... 21

FastCheck Airbag.................................................... 25

FastCheck Climate.................................................. 30

FastCheck EMS ...................................................... 33

Manufacturer Applications - EMS........................... 34

FastCheck EPB ....................................................... 83

FastCheck SAS ..................................................... 101

FastCheck Service ................................................ 106

FastCheck TPMS .................................................. 123

Diagnostic connector locations............................. 131

User menu

Overview .............................................................. 148

Security................................................................. 150

CAN Converter (Firmware update) ....................... 151

Multiplexer Cable (Firmware update).................... 152

General information

Cleaning ................................................................ 154

Software updates ................................................. 154

Specification ......................................................... 155

ii

Contents Declaration of Conformity ..................................... 155

Appendix A: Glossary

Glossary of terms.................................................. 156

Appendix B: Cables

Cable identification................................................ 160

Appendix C: Manufacturer compatibility

Scan function ........................................................ 168

FastCheck functions ............................................. 169

Appendix D: Manual service reset

Service Reminder Indicator (SRI) .......................... 170

Alfa Romeo ........................................................... 170

Audi....................................................................... 171

BMW..................................................................... 172

Citroen .................................................................. 173

Fiat ........................................................................ 180

Ford....................................................................... 181

GM Vauxhall/Opel ................................................. 182

Lancia.................................................................... 183

Land Rover............................................................ 184

Mercedes.............................................................. 185

Peugeot................................................................. 186

Renault.................................................................. 192

Smart .................................................................... 198

Volkswagen........................................................... 199

Volvo ..................................................................... 200

Introduction

1

Introduction

Overview

Nearly every new road vehicle, and many older vehicles, have multiple control

modules that monitor and control different aspects of the vehicle (e.g. Engine,

Transmission, Body, Suspension, etc.). The TRW easycheck service tool has been

specifically designed to connect to, and communicate with, a number of these

control modules and allow the user to extract information (e.g. Diagnostic Trouble

Codes) which may aid in the diagnosis of system problems.

The functions available on the TRW easycheck service tool are dependent on the

number of functions that have been purchased. Additional functions can be

purchased separately. For further details, please contact the Product Support Team

by calling freephone 00800 2002 8282 or visit www.trwaftermarket.com/

easycheck.

Scan

The EOBD (European On-Board Diagnostic) Scan function allows you to access

the vehicles emission related data through the OBD functionality. This includes

MI (Malfunction Indicator) status, read and clear faults, live data, O2 sensor tests,

freeze frame data and more.

EMS

FastCheck EMS allows you to read and clear fault codes stored by the selected

system. Additional functions may be available such as live data, actuator tests,

maintenance and injector programming depending on the selected system.

Brakes

FastCheck ABS allows you to read and clear any fault codes stored by the

selected system.

OM0947

Introduction

2

FastCheck EPB (Electronic Parking Brake) allows you to read and clear any fault

codes stored by the selected system, and in addition can be used during brake

operation checks or brake pad replacement.

SRS

FastCheck Airbag allows you to read and clear any fault codes stored by the

selected system.

Climate

FastCheck Climate allows you to read and clear any fault codes stored by the

selected system.

SAS

FastCheck SAS (Steering Angle Sensor) allows you to read and clear any fault

codes stored by the selected system, and in addition can be used to calibrate the

steering angle sensor.

Service

FastCheck Service allows you to reset, dependant upon vehicle, the oil service

interval indicator, service and inspection warning lights.

TPMS

The ‘TPMS’ (Tyre Pressure Monitoring System) function can be used to

re-program TPMS tyre valves to the control module.

If you are using the service tool for the first time, it is recommended that you read

these instructions and safety guidelines fully, prior to commencing any testing on a

vehicle.

Getting started

Connect the Multiplexer cable (YTD965) or the EOBD cable (YTD950) to the service

tool and the vehicle's diagnostic connector. Once connected, the current software

version number is displayed.

Registration and unlocking of units

A new or updated service tool requires a security key to unlock the specific

functions. To register the service tool, log on to

www.trwaftermarket.com/easycheck

and select the link to the administration centre.

Auto-activation is possible using the website if an update cable is available.

Alternatively, after obtaining your security key from the web site, use the following

procedure to unlock your service tool:

1. Select 'User Menu' from the main menu.

2. Select 'Security' from the user menu.

Introduction

3

3. Select 'Enter Security Key' from the security menu.

4. Using the and keys, scroll through the alpha/numerical character list.

5. Confirm each character by pressing the key.

If you make a mistake use the key and enter the correct character. To re-

enter the code from the beginning, press the key.

6. When prompted to verify the security key, press to confirm.

7. Power down the service tool by disconnecting the power source.

8. Reconnect the power supply to restart the service tool. The screen should now

show a list of the functions included.

Further support can be obtained by calling freephone 00800 2002 8282.

Introduction

4

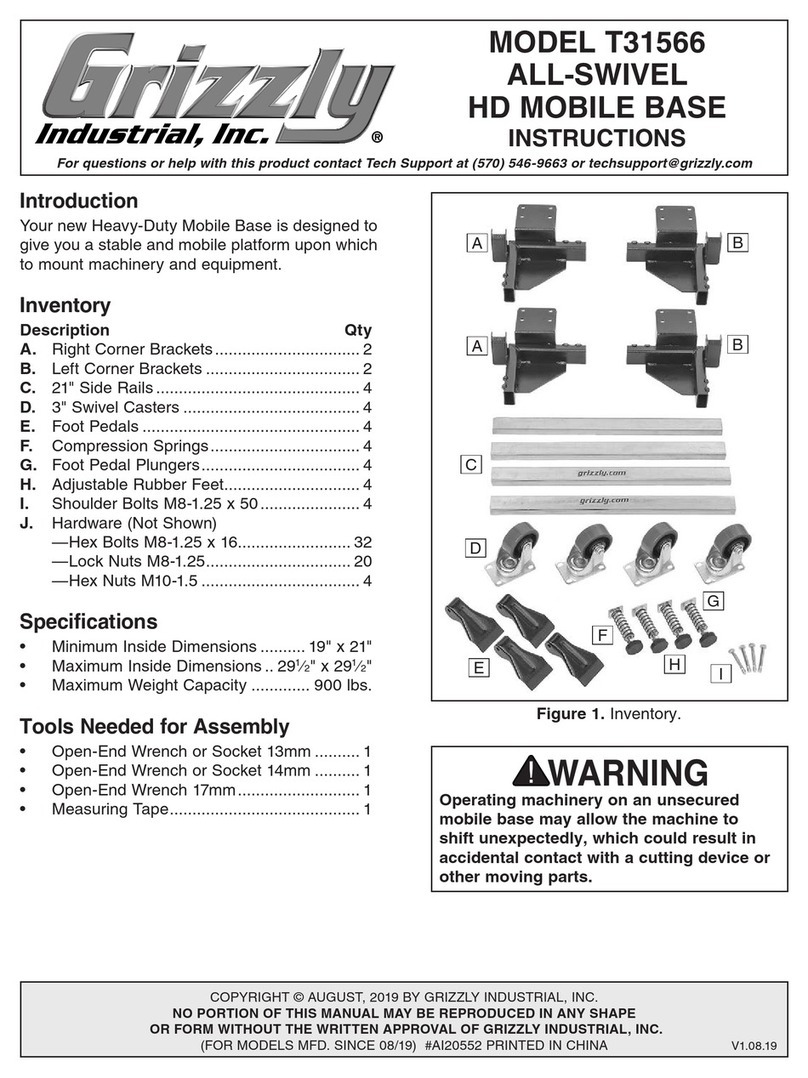

Kit contents

TRW easycheck kit (YTD700, YTD701)

1. Service tool

2. EOBD cable

3. Carry case

4. CD ROM containing operating instructions

5. EOBD pin-switchable cable

OM1386

1

2

3

4

5

112

4

32

10

11 AL

D

CB

I

J

K

Introduction

5

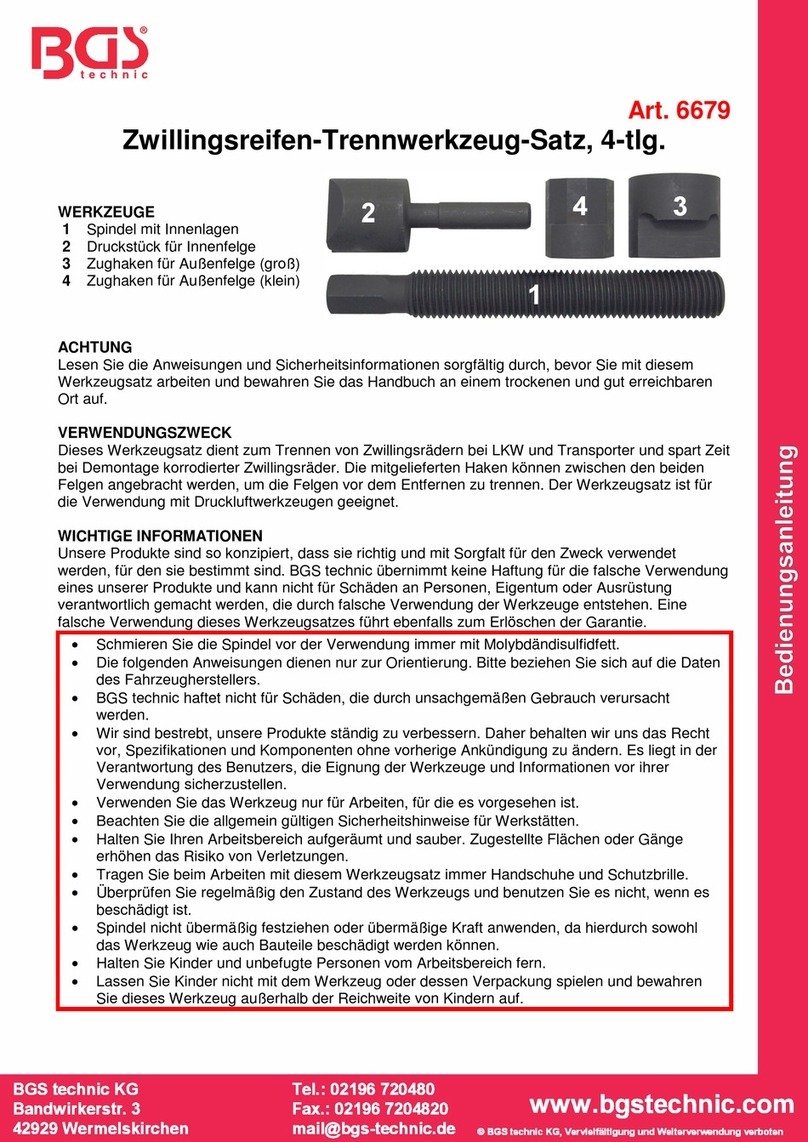

TRW easycheck kit (YTD702, YTD703, YTD704)

1. Service tool

2. Carry case

3. CD ROM containing operating instructions

4. Multiplexer cable

TRW0045

1

2

4

3

Introduction

6

Display screen

The service tool screen is a backlit LCD capable of displaying four rows of text

containing up to twenty characters.

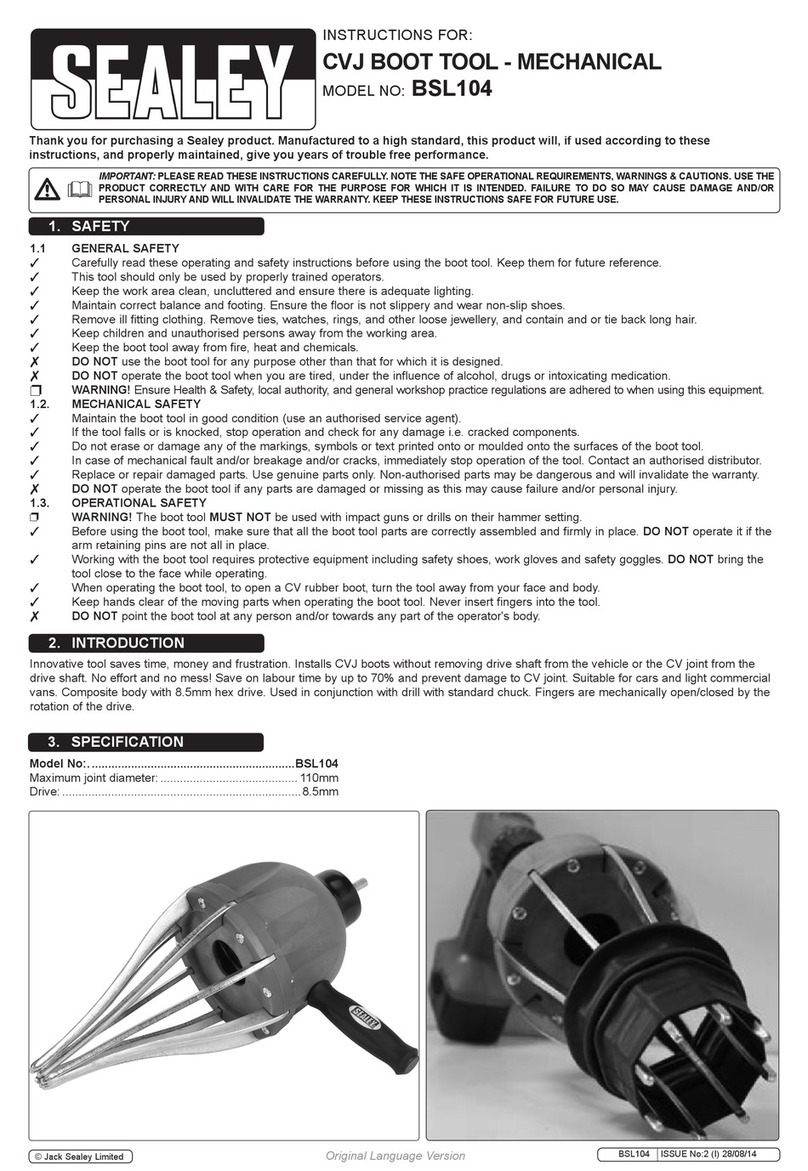

Keypad

The service tool is operated via the 6-button keypad.

The table below details the keypad buttons and their functionality.

Key Function

Select a menu option, Continue or Yes.

Exit a menu or No.

Scroll up within a menu or text.

Scroll down within a menu or text.

Scroll left and right.

Provide context sensitive help (where available).

OM0941

Introduction

7

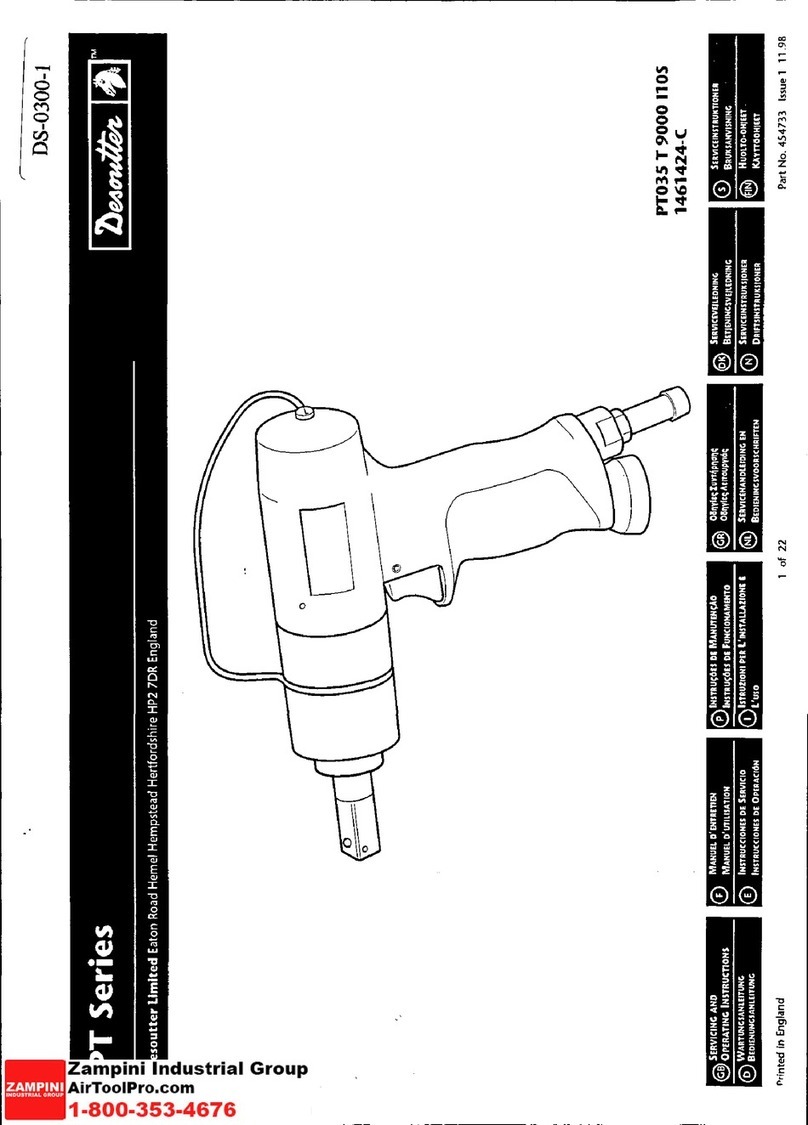

Connection

The service tool has a 15-way connector through which it can communicate to the

vehicle via various interface cables. Connection to the specific system is via either

the vehicle's EOBD (J1962) diagnostic socket or by a system specific connector.

Refer to the 'Vehicle Application List' to determine the correct cable.

When connecting the cable to the service tool, always secure the cable with the

fixing screws to prevent accidental disconnection of the service tool during use.

OM0948

Introduction

8

Safety precautions

The following guidelines are intended to ensure the safety of the operator whilst

preventing damage to the electrical and electronic components fitted to the vehicle.

Equipment - prior to commencing any test procedure on the vehicle, ensure that the

service tool, its harnesses and connectors are in good condition.

Polarity - always observe the correct polarity when connecting the service tool to the

vehicle battery

Before carrying out testing on a vehicle, the following procedure should always be

observed:

Check the handbrake/parking brake is ON.

Check that neutral or park is selected.

Keep test equipment and harnesses away from HT leads.

Be aware of moving engine parts.

Do not run engine in a confined space without adequate ventilation.

Communication problems

If communications cannot be established with the vehicle, follow the procedure

below:

1. Check the correct system was selected from the menu.

2. Check the correct cable was used against the application list.

3. Disconnect both ends of the cable and ensure that no pins are bent or snapped.

4. Reset the control module on the vehicle by turning the ignition OFF and ON,

reconnect the service tool and try again.

If communications still cannot be established, contact the Product Support Team

desk for further assistance.

Scan function - EOBD

9

Scan function - EOBD

What is EOBD?

The American Environmental Protection Agency and the European government

have set targets for reducing the levels of pollution produced by passenger and

commercial vehicles. In order to ensure that these targets can be met,

manufacturers are required to build new vehicles which meet increasingly stiff

emissions standards. The manufacturers must further maintain these emission

standards for the useful life of the vehicle. In order to meet and maintain these

standards the vehicles are fitted with On-Board Diagnostic systems which monitor

the integrity and effectiveness of all emission related components.

As vehicles are becoming more and more complex, many of the systems fitted to

them are being controlled by electronic control modules. Most vehicles now have

multiple control modules (e.g. Engine, Transmission, Body, Suspension, etc.)

located at different locations on the vehicle. The On-Board Diagnostic systems are

integrated into the vehicle control modules.

With so many different vehicle and component manufacturers, a common interface

was required to communicate with these control modules. In 1988, the SAE

(Society of Automotive Engineers) created a standard that defined a standard

diagnostic socket (J1962) and a set of diagnostic test signals.

With the diagnostic socket and diagnostic signals agreed, another standard was

produced that defined a universal inspection and diagnosis method to ensure that a

vehicle is performing to Original Equipment Manufacturer (OEM) specifications.

This standard is known as EOBD (European On-Board Diagnostics).

The fundamental requirement for an EOBD system is that in the event of an

emissions related component fault, a DTC (Diagnostic Trouble Code) will be stored

in the memory of the control module responsible for that component, and a

Malfunction Indicator Lamp (MIL) will illuminate on the vehicle's instrument pack to

alert the driver. The DTC can then be retrieved using diagnostic equipment to

determine the type and status of the fault.

Scan function - EOBD

10

Identifying compliant vehicles

All petrol engine vehicles manufactured since 2000 should be EOBD compliant.

Some manufacturers began incorporating On-Board Diagnostic systems as early as

1994, however not all are 100% compliant. All diesel engine vehicles are expected

to have support from 2004. This means that diagnostic information, related to

vehicle emissions, may be extracted from the vehicle via the J1962 diagnostic

socket using the service tool.

The service tool can communicate with any EOBD compliant vehicle using one of

the five diagnostic communication protocols defined in the standard.

These are

ISO 9141.

Keyword 2000 (originally a European protocol).

J1850 PWM (pulse width modulated) protocol used by Ford.

J1850 VPW (variable pulse width modulated) used by General Motors in USA

designed vehicles.

CAN (controller area network) currently being legislated for and likely to be a

principle diagnostic communication system in the future. A European protocol.

It is normally possible to tell which is used on a specific vehicle by examining the

diagnostic socket (as below), however the service tool's software will automatically

detect the protocol used on the vehicle to which it is connected.

NOTE: Although there are different EOBD electrical connection protocols, the

command set is fixed according to the SAE J1979 standard.

If the diagnostic socket has a pin in the '7' or

'15' position, then the vehicle uses either the

ISO 9141 or Keyword 2000 protocol.

If the diagnostic socket has a pin in the '2' or

'10' position, then the vehicle uses one of the

SAE J1850 protocols.

If the diagnostic socket has a pin in the '6' or

'14' position, then the vehicle uses the CAN

protocol.

Scan function - EOBD

11

Diagnostic Trouble Codes

Diagnostic Trouble Codes (DTCs) are divided into mandatory and voluntary codes.

Mandatory codes are allocated by the ISO (International Standards Organisation) /

SAE (Society of Automotive Engineers). Voluntary codes are allocated by various

vehicle manufacturers and are manufacturer specific and in some instances, vehicle

specific.

ISO/SAE controlled diagnostic trouble codes are those codes where industry

uniformity has been achieved. These codes were felt to be common enough across

most manufacturer's applications that a common number and fault message could

be assigned. All unspecified numbers in each grouping have been reserved for

future growth. Although service procedures may differ widely amongst

manufacturers, the fault being indicated is common enough to be assigned a

particular fault code. Codes in this area are not to be used by manufacturers until

they have been approved by ISO/SAE.

Areas within each of the fault code blocks have been allocated for manufacturer

controlled DTCs. These are fault codes that will not generally be used by the

majority of the manufacturers due to basic system differences, implementation

differences, or diagnostic strategy differences.

Scan function - EOBD

12

Interpreting EOBD fault codes

Use the following rules to determine the basic meaning of an EOBD fault code.

The first character indicates which area of the vehicle the code applies to.

The second character specifies the type of code:

If the first character was 'P' (Powertrain) then the third character identifies the

specific Powertrain system concerned:

The last two characters identify the specific fault as seen by the on-board systems.

P Powertrain

B Body

CChassis

UNetwork

0 Standard (SAE) code

1 Manufacturer's own code

1 Fuel and air metering

2 Fuel and air metering, specifically injector circuit

3 Ignition system and misfire detection

4 Auxiliary emission controls

5 Vehicle speed control and idle control system

6 Computer output circuit

7 Transmission related faults

8 Transmission related faults

Scan function - EOBD

13

Using scan function

Connection and basic operation

1. Connect the Multiplexer cable (YTD965) or the EOBD (J1962) cable (YTD950)

to the service tool and secure the fixing screws.

2. Ensure the vehicle's ignition switch is in the '0' (fully OFF) position.

J1962 Diagnostic socket

3. Connect the service tool to the vehicle via the J1962 diagnostic socket. This

socket is usually located inside the passenger compartment in the vicinity of the

driver's footwell. Refer to vehicle manufacturer's information for the exact

location.

Power for the service tool is provided by the diagnostic socket. When

connected to the diagnostic socket, the service tool will perform an internal self

test and then the screen will display the date of the current software version

before displaying the main menu.

4. Use the and keys to select the EOBD menu function.

Press to confirm the selection.

5. Turn the ignition ON when prompted, then press the key to confirm. The

service tool will then attempt to establish communication with the vehicle's On-

Board Diagnostics.

MAIN MENU

1. E O B D

2. FastCheck ABS

3. FastCheck Airbag

4. FastCheck Climate

5. FastCheck EMS

6. FastCheck EPB

7. FastCheck SAS

8. FastCheck Service

9. FastCheck TPMS

10. User Menu

Scan function - EOBD

14

6. If the vehicle system is not EOBD compliant or there is a connection problem,

the "Please Wait" screen will be replaced with help screens.

If communication with the On-Board Diagnostics is successful, then the display

will report that the service tool is checking the vehicle's ‘System Readiness’

tests.

NOTE: The vehicle’s ignition MUST be ON for successful communication with

the vehicle control modules.

7. The service tool checks to see which of the ‘System Readiness’ tests have

been run and successfully completed and then the screen will inform you of the

status. Press the key to continue.

NOTE: The service tool will always check the status of the ‘System Readiness’

tests before displaying the EOBD Operations menu.

8. The screen will then give you the option of viewing the status of the tests

performed on the emission related systems and their components.

Press the key to display the results.

Press the key to bypass the results and go to the EOBD Operations menu.

9. Use the and keys to select the required function and press to confirm

the selection.

Easy reset facility

To reset the service tool without disconnecting from the vehicle, hold down the ,

, & keys simultaneously.

Establishing Data

Link with Vehicle CMs -

Please Wait......

EOBD OPERATIONS

1. M I S t a t u s

2. View DTCs

3. Erase DTCs

4. Live Data

5. O2 Sensor Tests

6. View Freeze Frame

7. Non-Continuous

8. Continuous Tests

9. System Control

10. Vehicle Info

11. OBD Status

12. System Readiness

13. General Info

14. Tester Setup

Other manuals for Easycheck

1

Table of contents

Popular Tools manuals by other brands

Westfalia

Westfalia 803630 instruction manual

Sealey

Sealey VS7233 instructions

Pro-dig

Pro-dig X12K5 instruction manual

Haussmann

Haussmann PNT210-B Operator's manual

Cornwell Tools

Cornwell Tools CTGCSGGA Operating instructions, warning information, parts breakdown

Macnaught

Macnaught Retracta R3 owner's manual