© Trynex International 2009 L1188

GR4 — 20

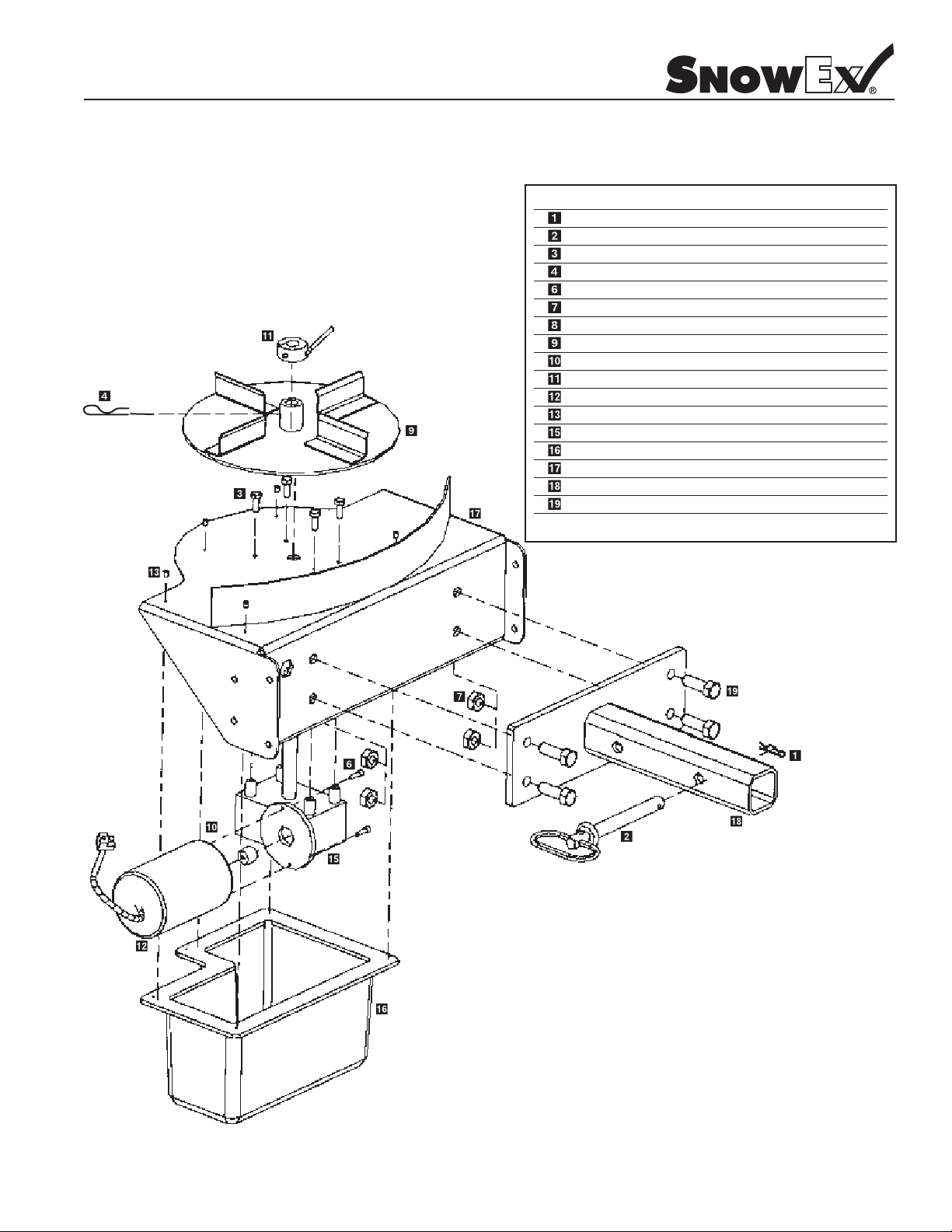

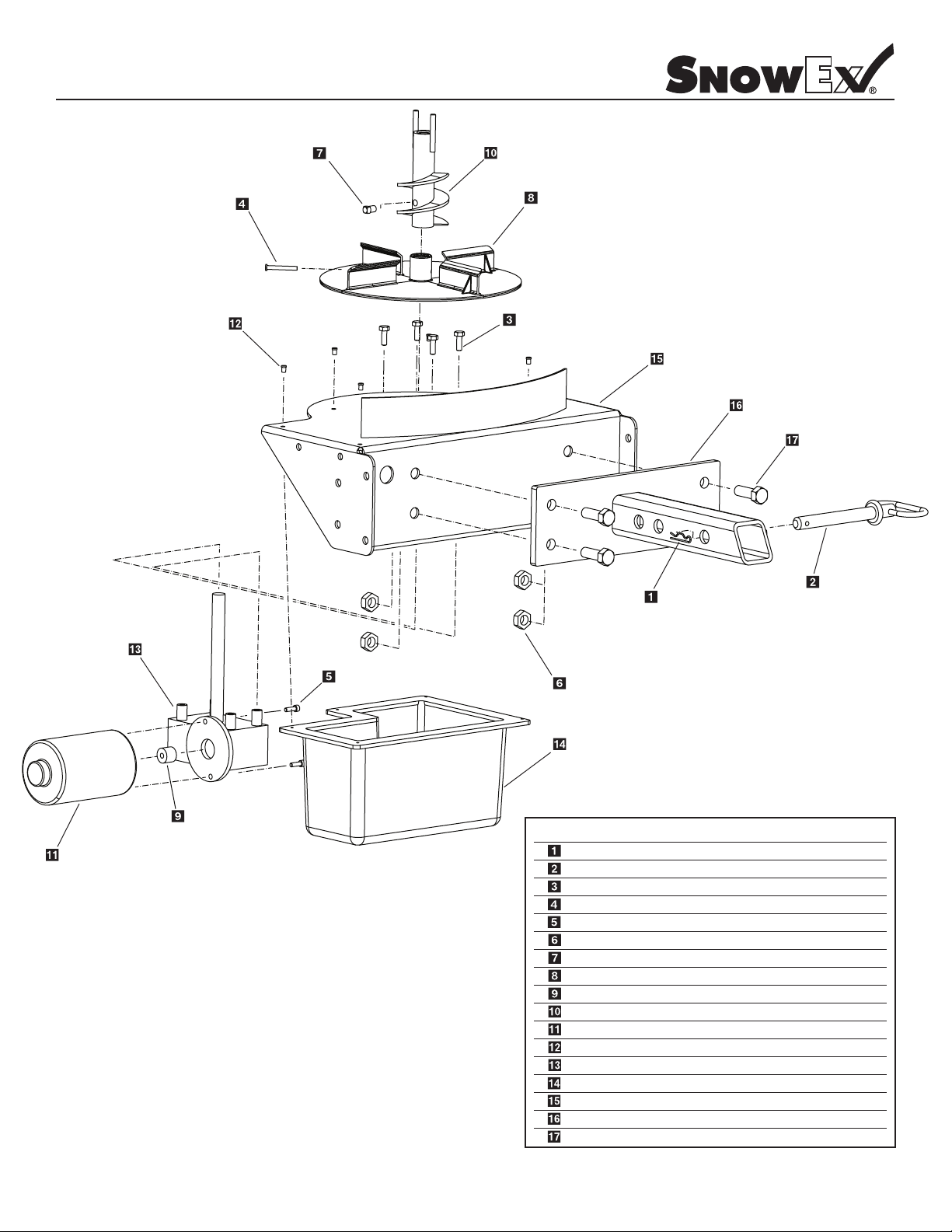

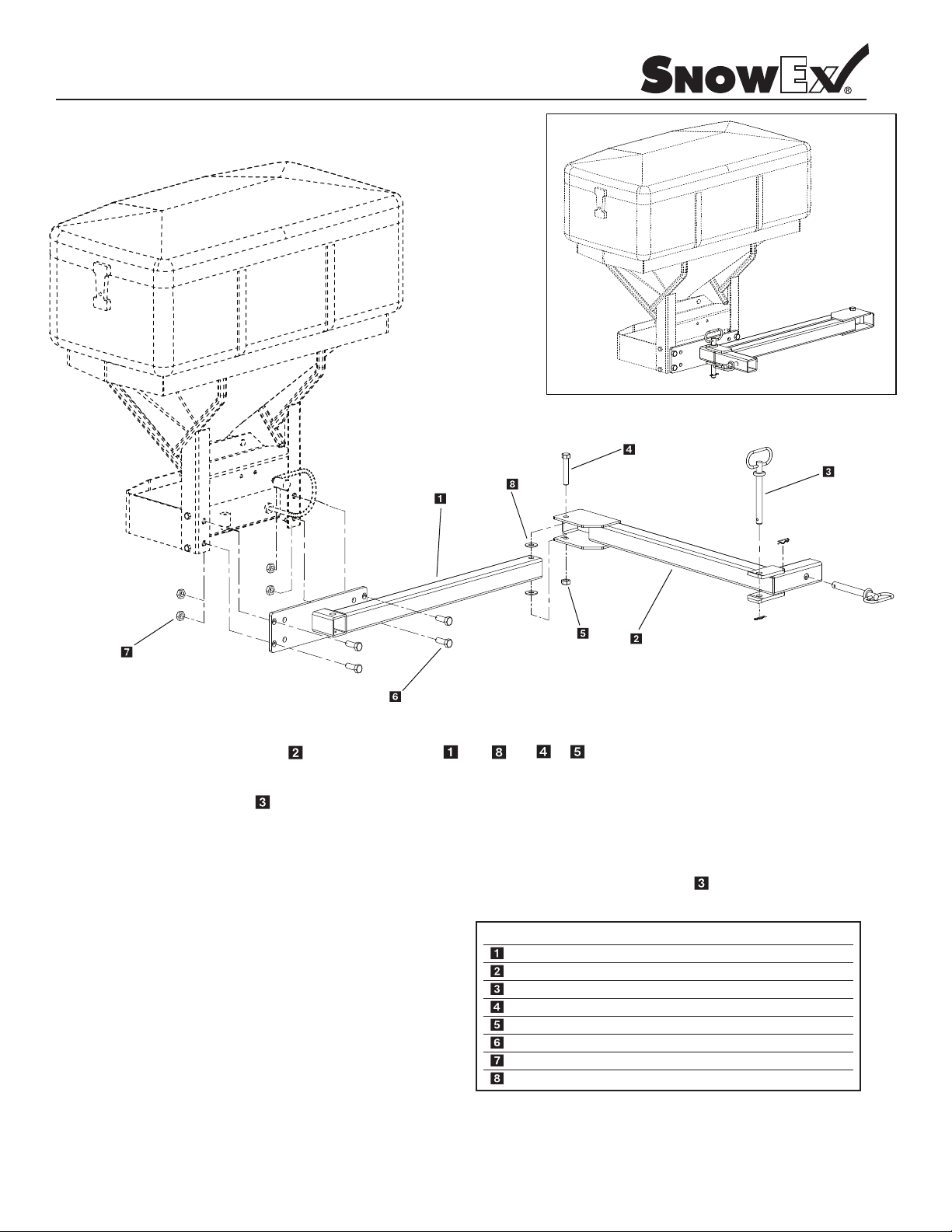

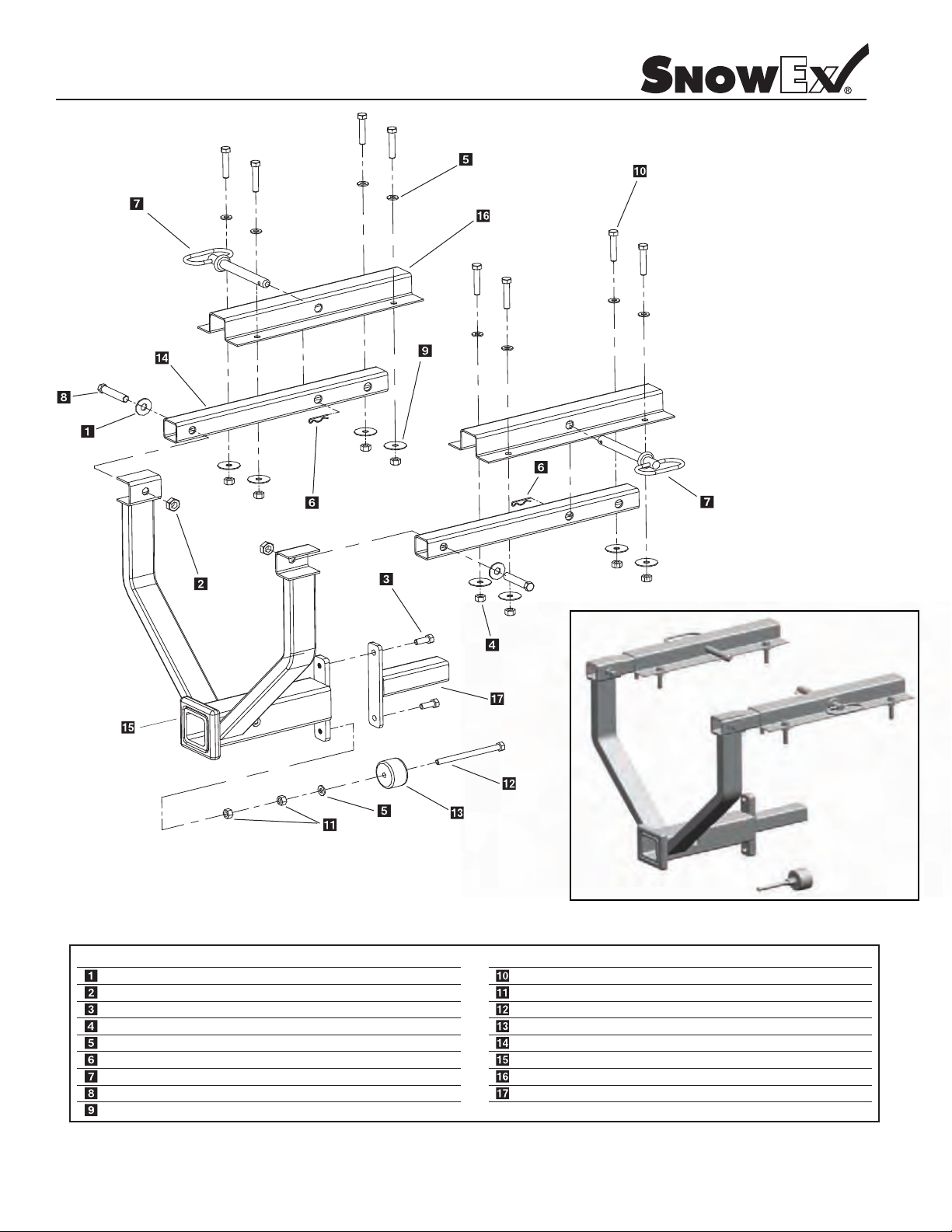

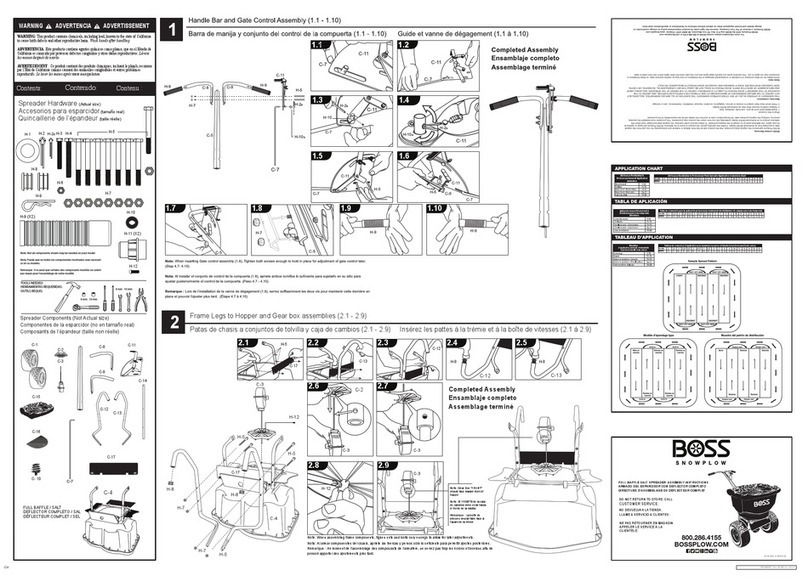

Drop Utility Mount Installation Instructions

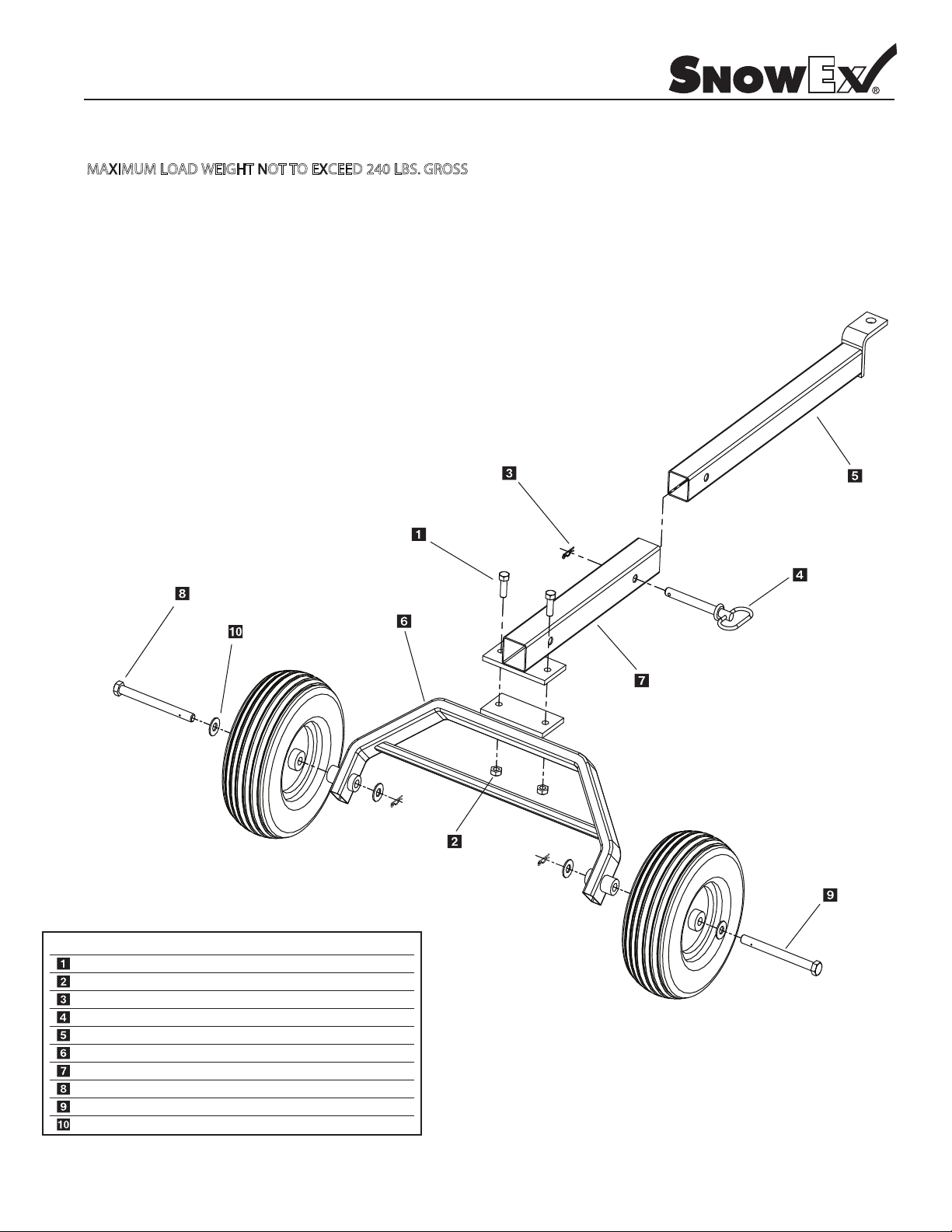

CAUTION: MAXIMUM WEIGHT NOT TO EXCEED 240 LBS.

MULE 550

Step 1: Temporarily remove the tailgate. Remove the bed liner if equipped.

Step 2: Bolt support rails to spreader mount with 1/2” bolts. Install 1/2” hex bolt with washer through rail first then

spreader mount. Install 1/2” locknut and tighten. Avaid over tightening to avoid potentially crushing tube.

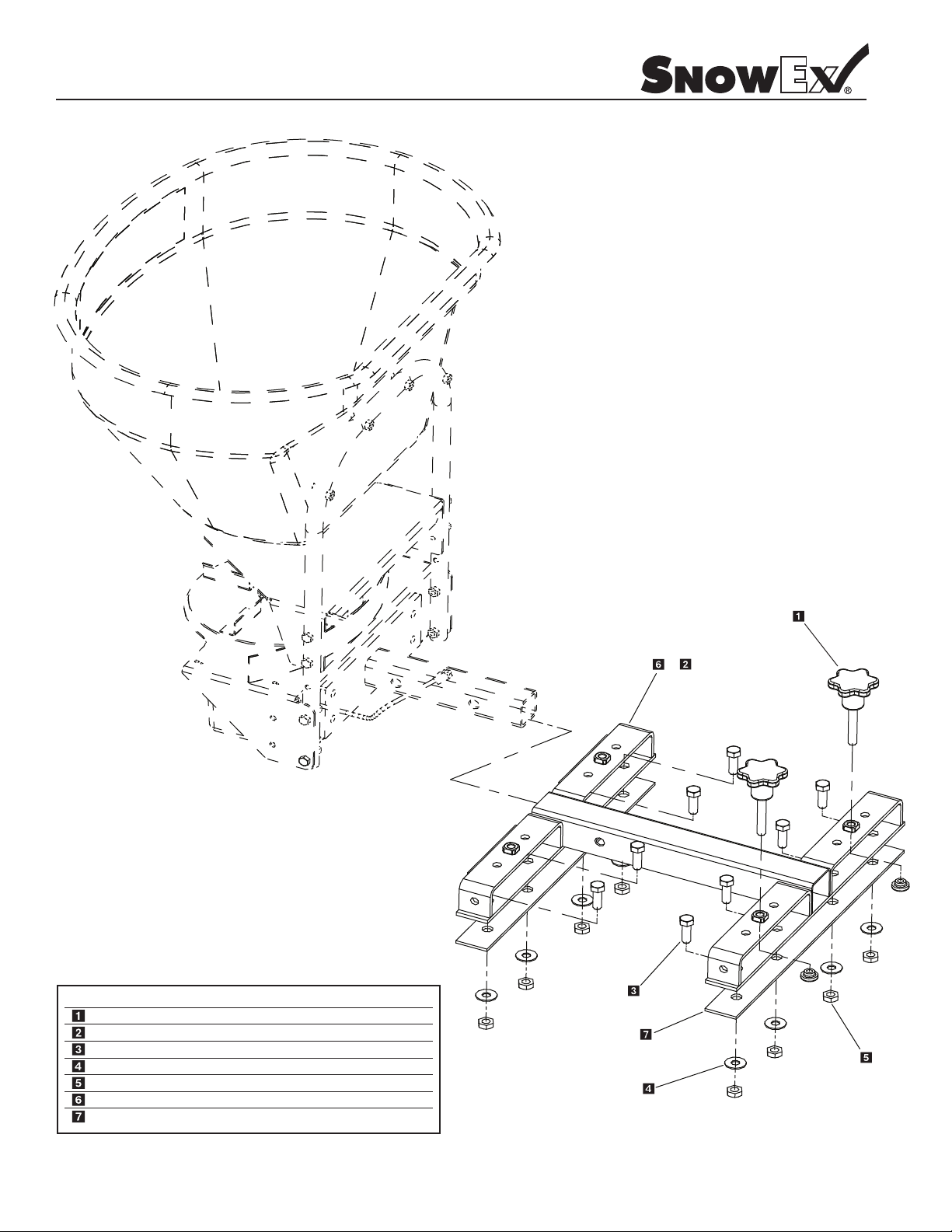

Step 3: Place spreader mounting rails over spreader mount support rails and install pins. Locate the spreader bracket

mounting rails on top of the bed by centering left to right and positioning the rear edge of the rails 5/8” beyond the

rear of the bed. Transfer mounting holes to bed and drill 7/16” holes.

Important: Check for proper clearance underneath bed before drilling holes.

Step 4: Bolt rails under belt with truss head bolts, fender washers, SAE washers and nylock nuts. Install the spreader

Step 5: Install 550 anti dump bracket with (2) 3/8” bolts provided.

Step 6: Install gate control cable per attached instructions.

Step 7: Route Cables at your discretion and install switch.

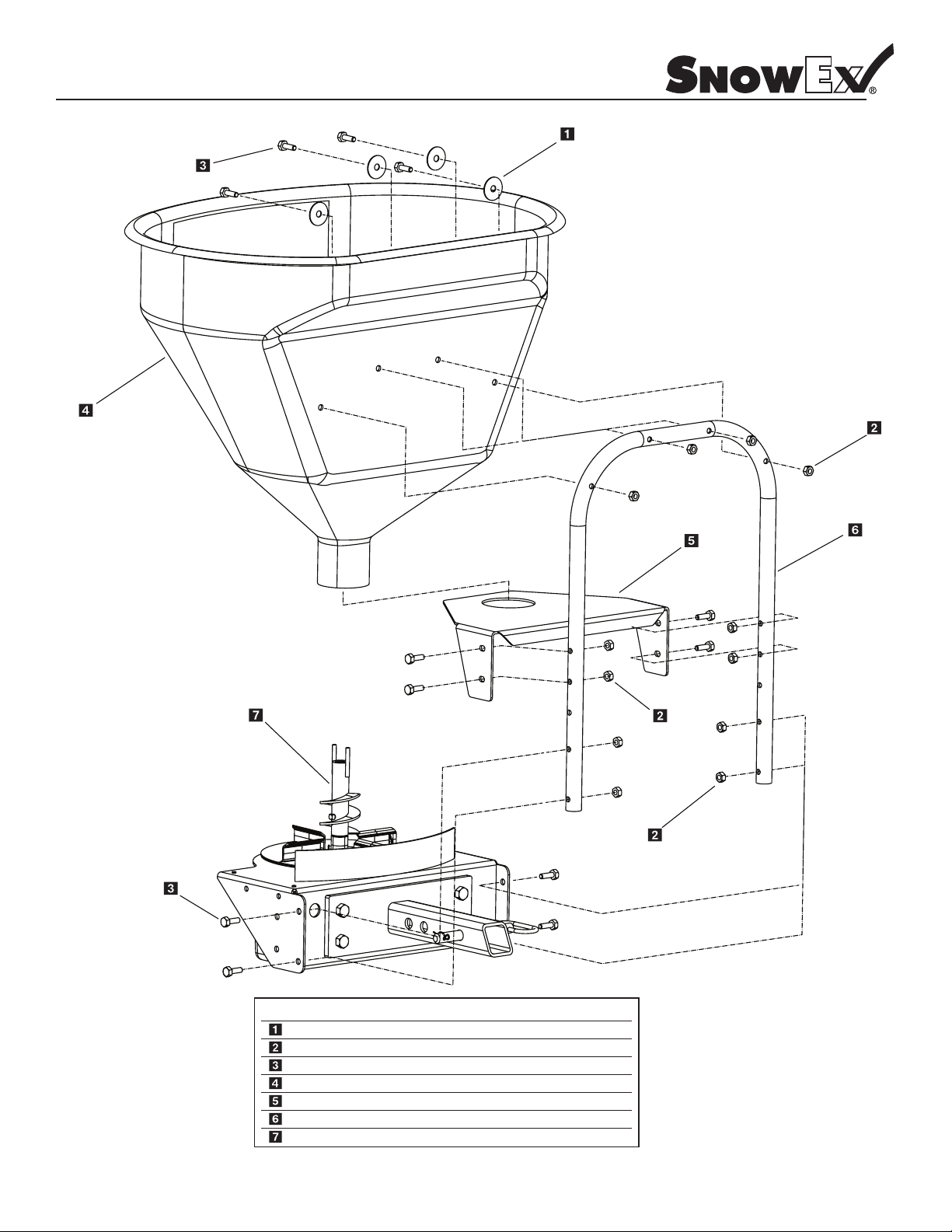

MULE 2500

Step 1: When positioning the mounting rails, the end of the rail should be 1/2” forward of the rear edge of the bed.

Step 2: The universal anti dump threads into the lower weld nut on the spreader bracket assembly. Adjust rubber

CLUB CAR CARRYALL

Step 1: Remove the bed tailgate and bottom angle trim. Also remove the two rear carriage bolts from the floor of the bed.

Step 2: Place spreader mounting rails over spreader mount and install pins.

Step 3: Install truss head bolts, fender washers, SAE washers and nylock nuts in the carriage bolt holes. Transfer the

JOHN DEERE GATOR

Step 1: Remove the bed tailgate.

Step 2: Place spreader mounting rails over spreader mount and install pins.

Step 3: Locate the spreader bracket mounting rails on top of the bed by centering left to right, push main mount flush

Step 4:

Step 5: The universal anti dump threads into the lower weld nut on the spreader bracket assembly. The rubber bumper

bracket before tightening hardware. The tailgate and bed liner may be reinstalled now.

The installation of the spreader on the 2500 is the same as the 550 with the following exceptions.

bumper to be 1/2” to 3/4” behind the rear axle-receiver hitch assembly.

Locate the two front outside mounting rails over the holes from the carriage bolts and remove.

remaining mounting rail holes and bolt rails into bed.

up against rear of bed to locate mounting rails. Transfer mounting holes to bed.

Install truss head bolts, fender washers, SAE washers and nylock nuts in the 1/2” mounting holes.

should be adjusted to rest against the frame of the vehicle. The trailer hitch bracket may need to be relocated

depending on the configuration.

Model # DRM-175