Manual Supplement

Project:

Date:

Page 2 of 23 Released 2/15/02

Pressure Control Sequence:

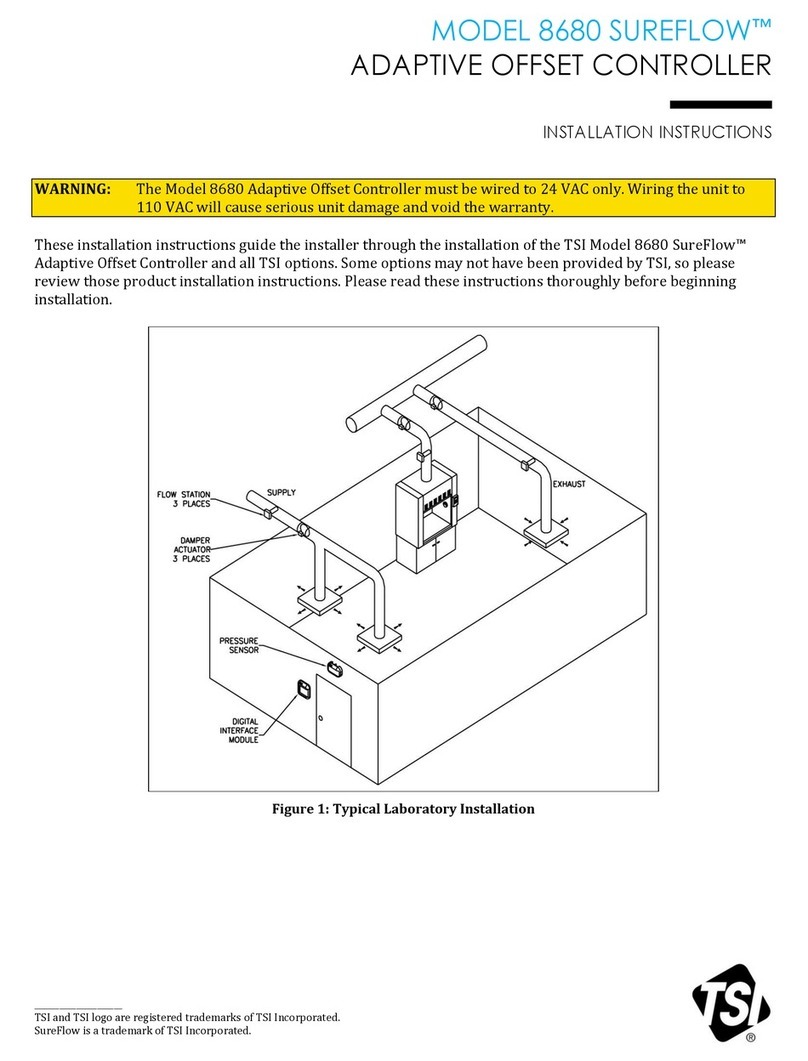

The Model 8682-KF1 receives the pressure differential signal from the pressure sensor. If

pressure is at set point, the control algorithm maintains the offset. If pressure is not at set

point, the offset value is changed until pressure is maintained, or the minimum or maximum

offset value is reached. If the offset value:

Increases, the supply air is reduced until one of 3 events occur:

• Pressure set point is reached. The Model 8682-KF1 maintains the new offset.

• The offset range is exceeded. The offset will be at maximum attempting to reach

pressure set point. An alarm will trigger to inform the user pressure differential

is not being maintained.

• Supply air minimum is reached. The general exhaust begins to open (was

closed) to maintain pressure differential.

Decreases, the supply air increases until one of 3 events occur:

• Pressure set point is reached. The Model 8682-KF1 maintains the new offset.

• The offset range is exceeded. The offset will be at minimum attempting to reach

pressure set point. An alarm will trigger to inform the user pressure differential

is not being maintained.

• Supply air maximum is reached. The alarm will trigger to inform the user

pressure differential is not being maintained.

NOTE: The pressure differential is a slow secondary control loop. The system initially starts

with a calculated offset value and then slowly adjusts the offset value to maintain

pressure differential.

The Model 8682-KF1 continuously monitors and displays pressure differential between the

laboratory and corridor (reference space). When the pressure differential is adequate, a green

light indicates a safe pressure differential is being maintained. Room pressure alarm set

points, configured into the controller, activate a red light and audible alarm when the room

pressure becomes insufficient or too great. In addition to a local indication of room pressure,

alarm contacts and RS 485 communications may be used to provide extensive information to a

building management system.

Temperature Control Sequence:

The 8682-KF1 receives a temperature input from a 0-10 volt (50-85°F) thermostat. The Model

8682-KF1 controller maintains temperature control by:

(1) Controlling supply and general exhaust for ventilation and cooling

(2) Controlling the reheat coil for heating