TSI Instruments SUREFLOW 8681 User manual

Other TSI Instruments Controllers manuals

TSI Instruments

TSI Instruments SUREFLOW 8670 Operation manual

TSI Instruments

TSI Instruments PRESSURA 8631-CRM Operation manual

TSI Instruments

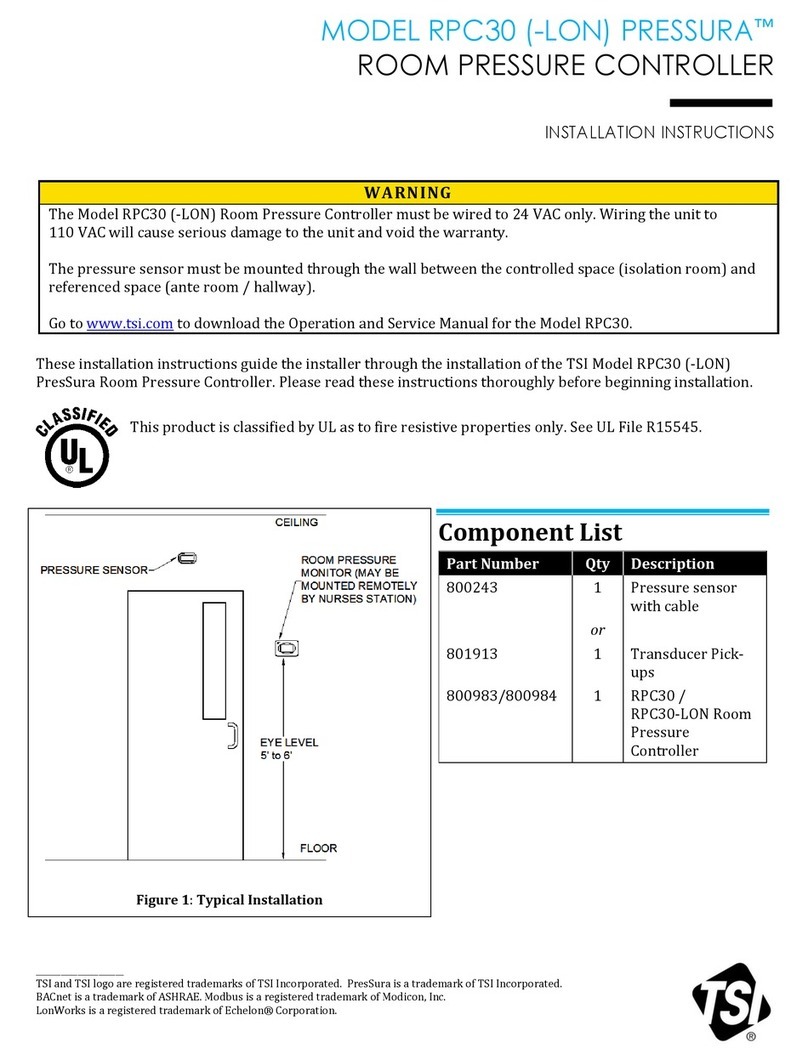

TSI Instruments PRESSURA RPC30 Operation manual

TSI Instruments

TSI Instruments MSP TURBO 2950 User manual

TSI Instruments

TSI Instruments 8682-KF1 Configuration guide

TSI Instruments

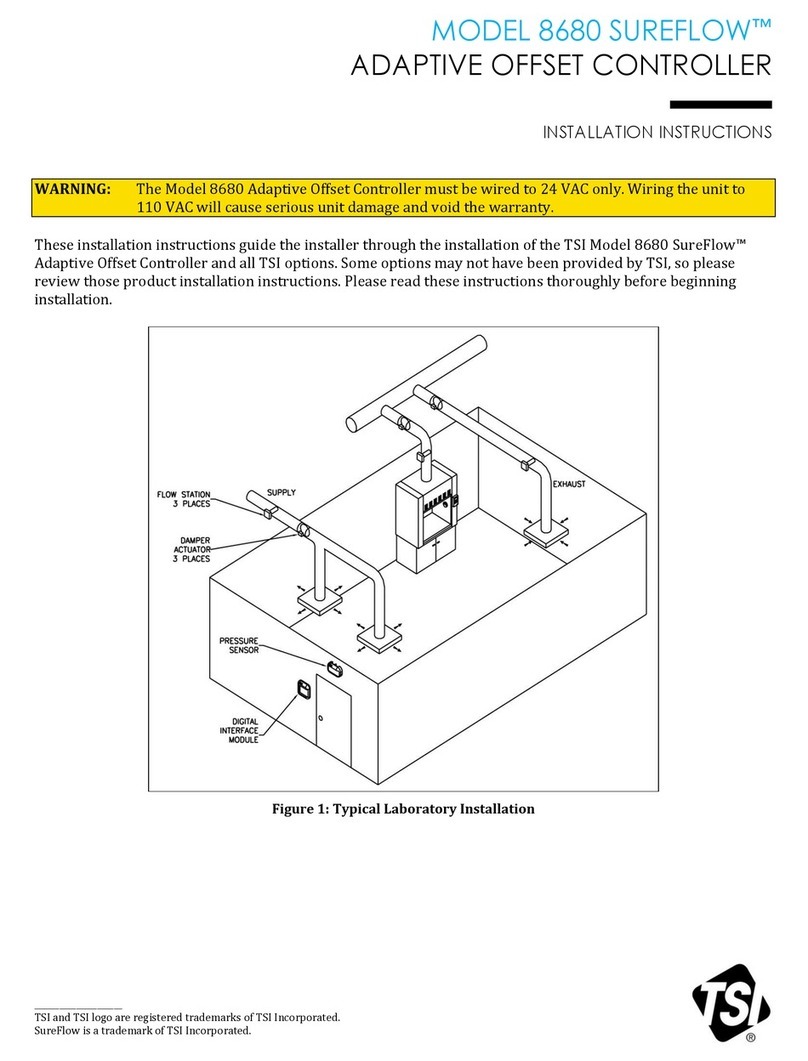

TSI Instruments 8680 SUPERFLOW User manual

TSI Instruments

TSI Instruments FHC50 Operation manual

TSI Instruments

TSI Instruments PRESSURA RPC30 User manual

TSI Instruments

TSI Instruments 8636-N2 Configuration guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions