TSO Products TPG PARALLEL GUIDE SYSTEM User manual

USER GUIDE FOR TPG SYSTEM

Publication 699-009 RevH ©2022 TSO Products LLC Page 1 of 2

when changing between narrow cut and standard calibration rods.

Connecting TPG T-Tracks to your

guide rail can be accomplished using

either a GRS-16 Guide Rail Square,

GRS-16 PE Guide Rail Square, or TPG

Adapter. Either two TPG Adapters can

be used; or one TPG Adapter and one

GRS-16 Guide Rail Square; or two GRS-

16 Guide Rail Squares (one of which must be a GRS-16 PE for the

left-hand T-Track, as it is the only square capable of referencing off

the front or back edge of your workpiece).

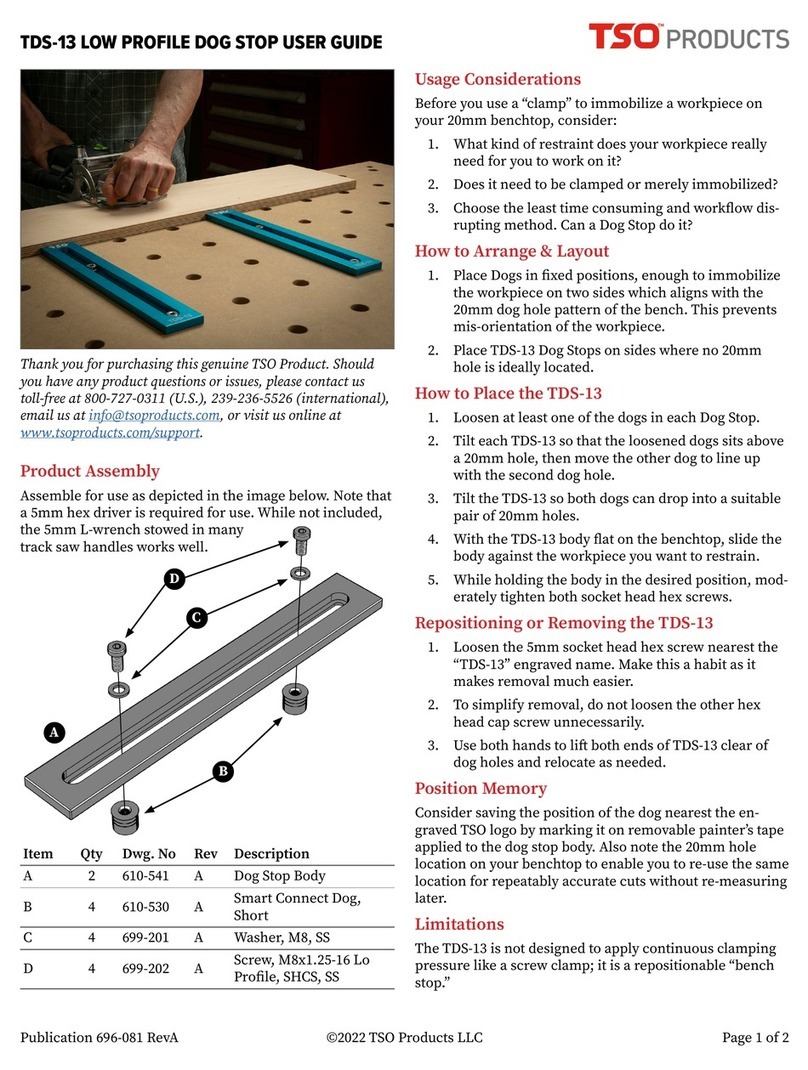

CALIBRATION: FOR FINISHED PARTS WIDER THAN

GUIDE RAIL

1. Mount the TPG Parallel Guide T-Track to the GRS-16 Guide

Rail Square or TPG Adapter using the (2) M6 x 10 mm knobs

provided.

2. Slide the FlipStop onto the TPG Parallel Guide T-Track, cursor

end rst, and tighten (secure) the knob.

3. Attach the GRS-16 Square + Parallel Guide assembly to the Fes-

tool, or Makita or Triton guide rail as shown.

If you own a combination square, skip to step 8.

4. Mark a line on the workpiece at 10 inches (254mm) from the

edge.

5. Place the assembled Guide Rail + GRS-16 Square + Parallel

Guide on the workpiece and set the cursor to the 10-inch

(254mm) mark.

6. Loosen the Screw securing the Calibration Rod and slide the rod

so that it contacts the edge of the workpiece. Then tighten the

screw securely with the 3mm hex driver provided.

7. This calibration should be complete for this saw and guide rail

combination, but cuts should be checked occasionally to con-

rm nothing has changed.

Thanks for purchasing this genuine TSO Product. Should you have

any product questions or issues, please contact us toll-free at 800-727-

0311 (U.S.), 239-236-5526 (international), email us at info@tsoprod-

ucts.com, or visit www.tsoproducts.com/support for the most up-to-date

version of this user guide.

INTRODUCTION

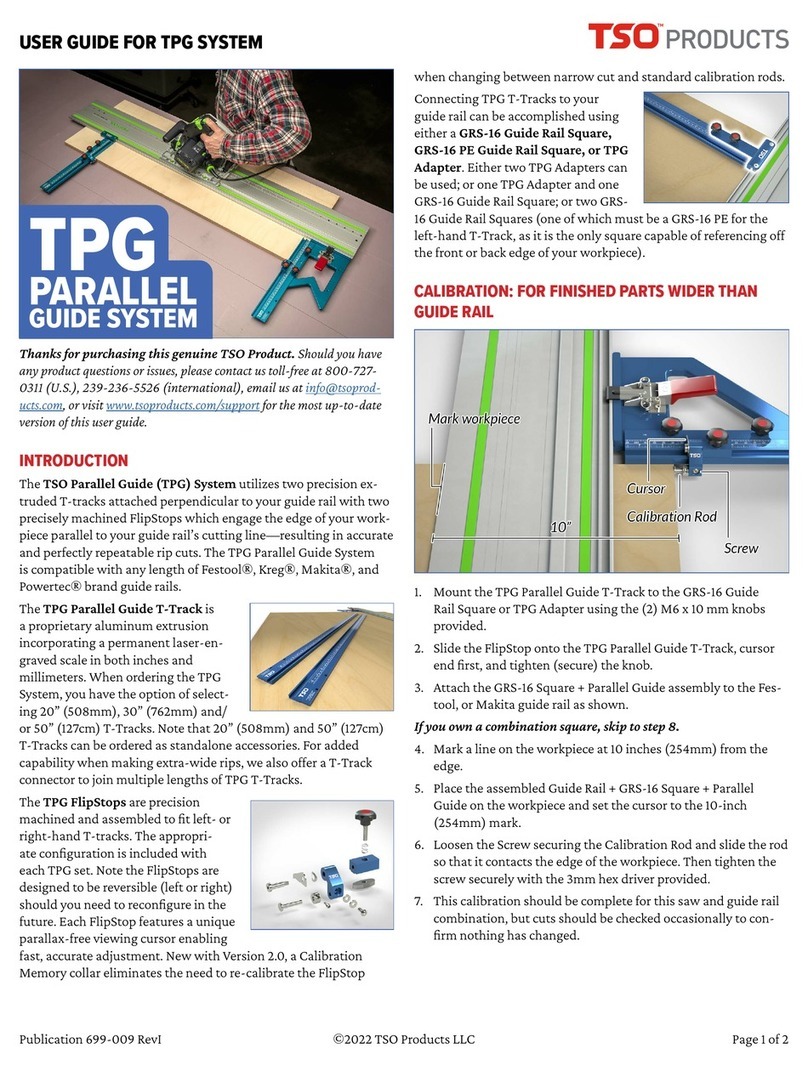

The TSO Parallel Guide (TPG) System utilizes two precision

extruded T-tracks attached perpendicular to your guide rail with

two precisely machined FlipStops which engage the edge of your

workpiece parallel to your guide rail’s cutting line—resulting in

accurate and perfectly repeatable rip cuts. The TPG Parallel Guide

System is compatible with any length of Festool®, Kreg®, Maki-

ta®, Powertec® and Triton® brand guide rails.

The TPG Parallel Guide T-Track is

a proprietary aluminum extrusion

incorporating a permanent laser-en-

graved scale in both inches and

millimeters. When ordering the TPG

System, you have the option of select-

ing 20” (508mm), 30” (762mm) and/

or 50” (127cm) T-Tracks. Note that 20” (508mm) and 50” (127cm)

T-Tracks can be ordered as standalone accessories. For added

capability when making extra-wide rips, we also offer a T-Track

connector to join multiple lengths of TPG T-Tracks.

The TPG FlipStops are precision

machined and assembled to t left- or

right-hand T-tracks. The appropri-

ate conguration is included with

each TPG set. Note the FlipStops are

designed to be reversible (left or right)

should you need to recongure in the

future. Each FlipStop features a unique

parallax-free viewing cursor enabling

fast, accurate adjustment. New with Version 2.0, a Calibration

Memory collar eliminates the need to re-calibrate the FlipStop

TPG

PARALLEL

GUIDE SYSTEM

USER GUIDE FOR TPG SYSTEM

Publication 699-009 RevH ©2022 TSO Products LLC Page 2 of 2

CALIBRATION: FOR FINISHED PARTS WIDER THAN

GUIDE RAIL (CONTINUED)

If you have a combination square…

8. Set your combination square to 10 inches (254mm) and place

the 90° face of the combination square at against the guide

rail splinter guard.

9. Extend or retract the Calibration Rod to touch the tip of the

combination square blade. Ensuring the combination square is

still at against the guide rail splinter guard, secure the Calibra-

tion Rod with the 3mm hex driver provided.

USE: FOR FINISHED PARTS WIDER THAN GUIDE RAIL

1. Conrm that nished part will be wider than the guide rail.

2. Set the cursor on the TPG Parallel Guide to the required width

of cut.

3. Set the saw to the required depth of cut.

4. Position the reference edge of the GRS-16 Guide Rail Square

against the edge of the workpiece perpendicular to the cuT.

5. Move the Parallel Guide + Guide Rail so that the head of the

Calibration Rod rests against the edge of the workpiece which

will be parallel to the cut.

6. It may be helpful to raise the guide rail slightly to ease the fric-

tion caused by its anti-slip strips and make it easier to reposi-

tion.

CALIBRATION: FOR FINISHED PARTS NARROWER

THAN GUIDE RAIL

This calibration process requires use of the supplied Narrow Part

Rod. It is the longer of the two calibration rods included in your

TPG Set.

Although the TPG System, as with all parallel guide devices, can be used

to cut narrow parts (narrower than the guide rail), the preferred method

of making narrow part cuts is with a table saw. Extra care must be used

to make a stable setup. We recommend practicing with scrap material to

perfect your technique.

Cutting narrow parts requires using both the left- and right-hand

parallel guides. Additionally, the workpiece must be supported

with pieces of material under the guide rail of the same thickness

as the workpiece to stabilize the Guide Rail + GRS-16 Square +

Parallel Guide assembly and prevent the workpiece from moving

while being cut. This is even more important when the workpiece

is shorter than the guide rail being used.

1. Mount the TPG Parallel Guide T-Track to the GRS-16 Guide

Rail Square or TPG Adapter using the (2) M6 x 10 mm knobs

provided.

2. Slide the FlipStop onto the TPG Parallel Guide T-Track, cursor

end rst.

3. Attach the GRS-16 Square + Parallel Guide assembly to the right

end of the Festool, Makita, or Triton guide rail.

4. Remove the Standard Calibration Rod (used for wide parts) and

insert the Narrow Part Rod.

5. Place the assembled Guide Rail + GRS-16 Square + Parallel

Guide on the workpiece with the Narrow Part Rod under the

Guide Rail and set the cursor to the 10” (254 mm) mark.

6. Place a piece of material against the Guide Rail splinter guard.

Loosen the screw securing the Narrow Part Rod and slide the

rod so that it contacts the edge of the material in contact with

the splinter guard. Then tighten the screw securely with the 3

mm hex driver provided.

7. With this calibration method, zero-width corresponds to the

10” (254 mm) mark. As an example, to cut material 3” wide, the

cursor would be set to the 13” (330 mm) mark.

8. This calibration should be complete for this saw and guide

rail combination, but cuts should be

checked occasionally to conrm noth-

ing has changed.

For a video walkthrough of calibrating the

TPG System, visit the TPG System product

page at tsoproducts.com.

From the entire TSO Team, we wish you enjoyable use of this

product. Please swing by our website and leave a review if you

get a moment—it really makes a difference.

Other TSO Products Tools manuals