Tsuruga 8505 User manual

#

MODEL 8505

Withstand Voltage & Insulation Tester

Instruction Manual

I-02271

FOR SAFE USE

For safe use of this tester, please observe the following warning and caution.

!Regarding safety symbols

In order to help the users to use the testers safely, the following symbols are used in this manual.

、Place where there is a dangerous high voltage .

!Warning

It shows the content that a dangerous situation is possible which may cause a fatal accident or

severe injury in case the tester is mishandled.

!Caution

It shows the content that a dangerous situation is possible which may cause a minor injury to user

or only material damage in case the tester is mishandled.

!Warning

●This tester is designed to output a high voltage. As there is a danger of an electric s

hock, please follow the directions below:

・Do not touch output terminal, high voltage cables or test samples during the test.

The places marked with on the tester are the dangerous parts where the high voltage is generated.

・Make sure to connect the protective ground terminal to the earth.

・Do not short-circuit the output to the ground or commercial power supply line. It is dangerous as the housing of

the tester is charged with high voltage. It also causes the breakdown of the tester.

・When operating the tester, put on the rubber gloves of an electric operation purpose.

・For the connection to the test specimen, use the enclosed high-voltage cable or an electric cable that confirms to

the operating voltage.

●Place for installation

・Never use or install this tester in the place where explosive or flammable materials as mentioned below are used

or stored. (Occupational Safety and Health Act, Enforcement Regulations Appendix Table 1 Hazardous

Materials )

[Explosive materials], [Ignitable materials], [Inflammable materials], [Flammable gas], [Oxidizing materials]

※This tester uses metal internally. There is a risk of deterioration due to the occurrence of corrosion or rust and

explosion or ignition by an electric spark.

・Do not place objects on top of this tester or use it as a footstool.

※It affects the heat dissipation causing internal temperature rise and break-down.

※There is a risk that the upper part is deformed.

●Storage

・Take care that the water drops like from rain do not wet the tester.

※There is a risk of electric shock or malfunction.

・Do not place the tester sideways. Take care during handling and do not let it fall down due to the vibration etc.

※There is a risk of damage of internal mechanism or malfunction.

!Caution

●Do not use the tester in the following places

Followings can cause the trouble due to break-down or malfunction.

Rain, water drops or direct sunlight places.

Places having high temperature, high humidity , dust and corrosive gas.

Places having external noise, radio waves or static electricity.

Places which are unstable or having lot of mechanical vibrations or shock.

Places where high sensitivity measuring testers or receivers are located nearby.

・Do not open the case or modify the tester as it may cause a danger of an electric shock or other troubles.

・If the operation is abnormal, turn off the power supply switch immediately and unplug the power cord.

・Make sure to stop the use and turn off the power supply during the maintenance or checking.

・Do not use the tester where the ventilation is poor.

Cooling system of this tester is forced air cooling from

the rear panel. Mainly it takes in the air from the bottom

and discharge to the rear side. As heat may be trapped

and become the reason for the fire, always keep space of

more than 10cms between the top, side, rear and the

walls. In between the bottom surface and the floor (the

height of rubber foot is about 14mm), do not place any

object like paper, plastic etc. which can be easily sucked

in.

●Apply the voltage to capacitance load (test sample)

The output voltage may rise higher than the case of no load depending upon the capacitance value of the load.

Also, in case of voltage dependent load (test sample), the waveform distortion may occur.

In case of test voltage 2kV, the influence of capacitance less than 2000pF can be ignored.

●Transportation

・Hold the chassis (bottom plate) during transportation.

Do not carry the tester holding its red bushing of high voltage terminal section (refer to ⑩ of “1. Part

names and functions”).

※The bushing (red) may get damaged and there is a risk of serious injury when this product falls down.

・Minimize the mechanical vibration or shock when transporting the tester.

※There is a risk of damage of internal mechanism or malfunction.

●Regarding Interlock

This tester is provided with interlock function.

No test can be made when interlock function is in operation.

The interlock function can be released by plugging the enclosed remote /out plug into the remote I/O

connector ⑤ and pressing the stop switch ⑫.

Front panel

Exhaust exit

Suction inlet

Content

Preface................................................................................................................................1

Functions ................................................................................................................................................ 1

Confirmation prior to use.................................................................................................2

Inspection at the time of unpacking ....................................................................................................... 2

Cautions for handling ............................................................................................................................. 2

1.Names and functions of each part ..............................................................................3

Front Panel ............................................................................................................................................. 4

Rear Panel .............................................................................................................................................. 7

2.Preparation before use.................................................................................................9

Connection of power cord .................................................................................................................... 10

Connection of the protective earth terminal ......................................................................................... 10

Method of removing and mounting of key cover (option) ................................................................... 10

Connection to the external control equipment ...................................................................................... 11

Connection of the high-voltage cable ................................................................................................... 11

Power on and off .................................................................................................................................. 12

3.Panel operation ..........................................................................................................13

Expression of the panel display of setting operation ............................................................................ 14

Key Lock ............................................................................................................................................. 14

Configuration of the display................................................................................................................. 15

Setting of test conditions ...................................................................................................................... 15

READY state ....................................................................................................................................... 16

Display during the test ......................................................................................................................... 17

Display example of judgment result ..................................................................................................... 17

4.Setting of a single test and an automatic test (ACW→IR, IR→ACW).................19

Types of test ......................................................................................................................................... 20

Selection of test mode .......................................................................................................................... 21

5.Setting of withstand voltage test conditions.............................................................23

Setting of test voltage ........................................................................................................................... 24

Upper limit judgment value ................................................................................................................. 25

Lower limit judgment value ................................................................................................................. 26

Setting of the voltage rise time (rise time) ........................................................................................... 27

Setting of the voltage fall time (fall time) ............................................................................................ 28

Setting of the test time ......................................................................................................................... 29

Setting of test voltage frequency .......................................................................................................... 30

6.Setting of insulation resistance test (IR) conditions................................................31

Setting of test voltage ........................................................................................................................... 32

Setting of resistance range ................................................................................................................... 33

Upper limit judgment and lower limit judgment value ........................................................................ 34

Setting of mask time ............................................................................................................................ 35

Setting of test time ............................................................................................................................... 36

7.Memory operation .....................................................................................................37

Overview .............................................................................................................................................. 38

Call and setting of memory .................................................................................................................. 39

8.Program operation.....................................................................................................41

Overview .............................................................................................................................................. 42

Flow of program operation................................................................................................................... 43

Call of program operation .................................................................................................................... 44

Setting of the program.......................................................................................................................... 45

9.Test method (From the start of the test till the judgment) .....................................47

Method operation of single withstand voltage test ............................................................................... 48

Operation method of single insulation resistance test .......................................................................... 49

Operation method of automatic test ..................................................................................................... 50

Operation method of program operation test ........................................................................................ 51

10.Other functions........................................................................................................53

Double action start ............................................................................................................................... 54

GOOD hold .......................................................................................................................................... 54

Momentary start ................................................................................................................................... 54

FAIL mode ........................................................................................................................................... 54

NG start ................................................................................................................................................ 54

Setting method ..................................................................................................................................... 55

Setting of the buzzer ............................................................................................................................ 56

Interlock ............................................................................................................................................... 57

11.Remote I/O..............................................................................................................59

Test contents depending on remote I/O ................................................................................................ 60

Connector pin array and pin function ................................................................................................... 61

Call Memory No. from remote I/O ...................................................................................................... 62

Combination of Memory No. and MEM SET Signals ......................................................................... 63

I/O control by MEM SET .................................................................................................................... 64

I/O control by REAR MODE ............................................................................................................. 65

I/O Control with combination of REAR MODE and MEM SET ......................................................... 67

I/O Control with separate judgment(During GOOD judgment) ...................................................... 68

I/O Control with separate judgment(During ACW-NG Upper limit judgment) .............................. 69

I/O Control with separate judgment(During IR-NG lower limt judgment) ..................................... 70

Timing Chart: Details from the start to the high voltage output ........................................................... 71

Interlock signal .................................................................................................................................... 72

Protective function operation (PROTECTION) .................................................................................. 72

Input signal .......................................................................................................................................... 73

Output signal and the control power supply ......................................................................................... 74

12.PC remote control....................................................................................................75

RS-232C・USB Interface ...................................................................................................................... 76

13.Error message..........................................................................................................77

Error display ........................................................................................................................................ 78

Coping with error display .................................................................................................................... 78

14.Maintenance.............................................................................................................79

Cleaning ............................................................................................................................................... 80

Problem solving ................................................................................................................................... 80

Calibration ........................................................................................................................................... 80

15.Specifications ...........................................................................................................81

Withstand voltage test .......................................................................................................................... 82

Insulation resistance test ...................................................................................................................... 84

Memory operation ................................................................................................................................ 85

Program operation ................................................................................................................................ 85

Other functions .................................................................................................................................... 86

Input Output signal .............................................................................................................................. 86

RS-232C・USB Interface ...................................................................................................................... 87

General specification............................................................................................................................ 88

Setting of the default value .................................................................................................................. 88

Dimensions .......................................................................................................................................... 90

MEMO ................................................................................................................................................. 91

MODEL 8505 1

Preface

For proper use of this tester, read these instructions carefully before initial operation. Make sure that

this instruction manual is available to the responsible person for the operation. Besides, keep this

manual near the tester so that the operator can read it any time.

Functions

As this tester handles the high voltage, so it is designed with a lot of protective functions and a number

of considerations for the safety of the users.

・The withstand voltage tester has the capability of maximum output of 5kV and output capacity of

100VA.

・Precise test can be made due to upper and lower limit leakage current setting.

・As the insulation tester, this model is provided with 6 ranges of DC25V~DC1000V.

・The displays of test voltage, current and test time are easy-to-read green large LED.

・16 sets of memory are equipped which can write and read the test conditions.

・16 sets of memory are equipped which can program 16 steps of applied voltage of withstand

voltage test and test time.

・It is possible to control input of the start/stop of the test from the outside by remote I/O connector.

Besides, matching with the status of this tester, the output signals like “waiting”, “under test” or

“decision result” etc. are output in open collector.

MODEL 8505 2

Confirmation prior to use

Inspection at the time of unpacking

(1)When unpacking

When the tester is delivered, check whether it has been damaged in transit and unpack it carefully.

In case the tester does not operate as per the specification due to damage, contact the dealer from

where you have purchased or sales office.

(2)Checking of the contents

Check the packing box which contains the main item and the standard accessories as listed below.

List of accessories

Instruction manual (Main document) 1 set

RS-232C・USB Interface manual 1 set

High voltage cable 2m 1 pair

Earth wire 3m 1 piece

Power supply cord 2.5m 1 piece

Remote I/O plug 1 piece(36P)

!Caution

・For external communication RS-232C(D sub 9 pin model 5881-11-020)

When the customer procures it, it is requested to use the inch pitch screw type.

USB cable (Standard A-B model 5881-12-010) is optional.

Cautions for handling

Since this tester deals with high voltage, it is designed paying special attention to the safety. However, it

is still dangerous as it outputs high voltage of max. 5kV. An erroneous handling may cause fatal

accident. In order to avoid any accident, strictly observe the following cautions and take utmost care for

safety.

!Warning

If the earthing is insufficient, there is a risk of electric shock.

(1)Make sure to connect the protective ground terminals (rear panel) to the earth. If the grounding

is insufficient and the output is short-circuited to the earth or power supply line, the tester

housing is charged with high voltage and it is very dangerous when the operator touches the

outer box.

Check if the earthing cable is disconnected or not.

(2)During the test, never touch the output terminals, high voltage cable and test samples.

(3)When making a connection to the test sample, with output OFF , connect the LOW side prior

to other.

(4)When operating this tester, put on rubber gloves for electric shock prevention.

MODEL 8505 3

1.Names and functions of each part

Front Panel............................................................................................................................................. 4

Rear Panel .............................................................................................................................................. 7

1.Names and functions of each part

MODEL 8505 4

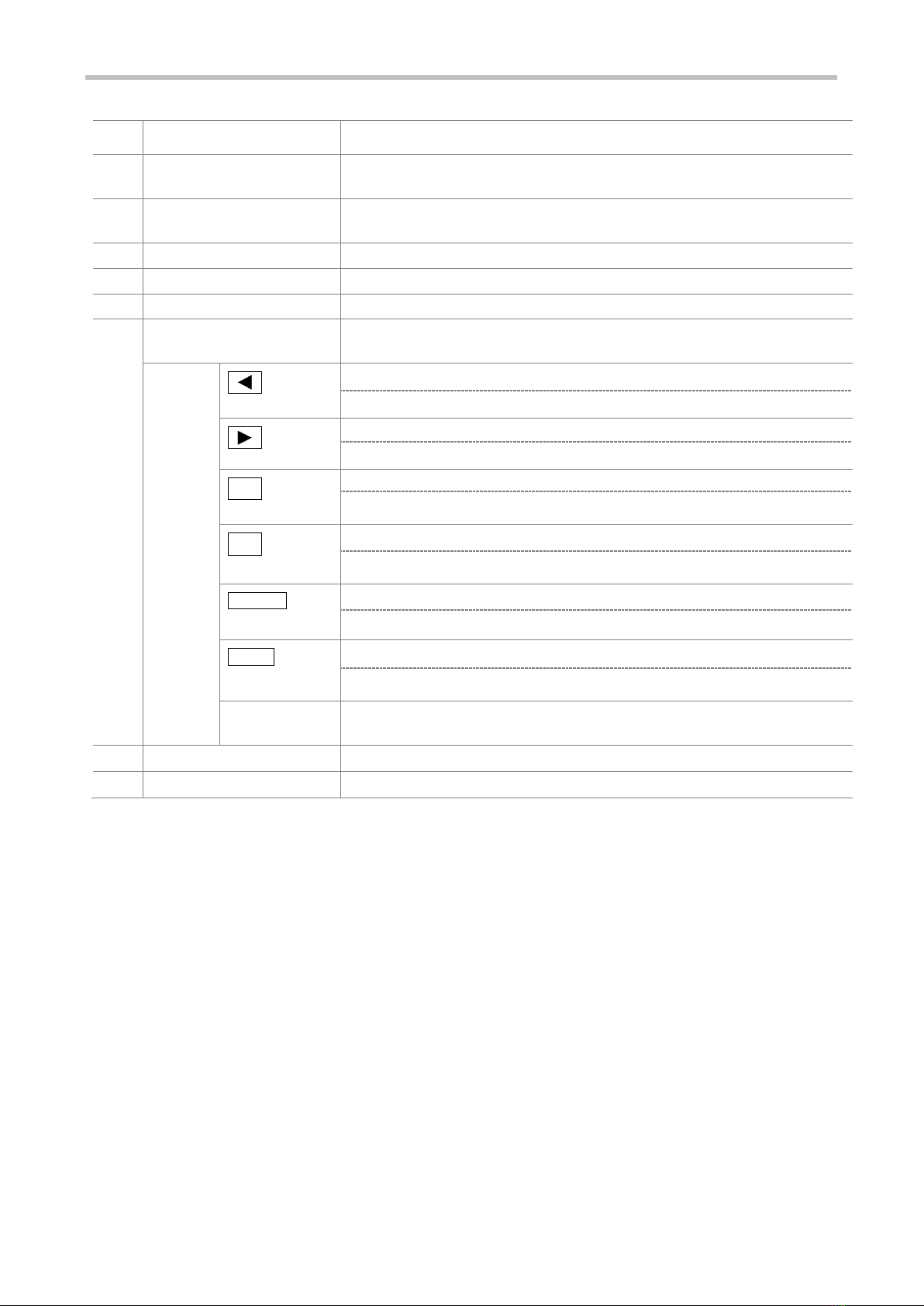

Front Panel

No.

Name

Function description

1

DANGER Lamp

Gives warning lamp when the test voltage is an

output.

Lighting of each lamp, refer

blinking state

2

MEMORY No.

Memory operation, display of memory number and step number of program operation

Memory, Lit up during program operation , blinking during setting up

PROG Lamp

During program operation, Lit up during

setting

Lighting of each lamp, refer

blinking state

3

TEST VOLTAGE

Withstand voltage test : Display of setting of test voltage and value of output voltage.

Program operation : Setting of step off (end) (withstand voltage test only)

Insulation test : Setting of the test voltage

V, kV Lamp

Unit display of test voltage

Lighting of each lamp, refer

blinking state

4

FREQ Display

Display of the frequency setting of the test voltage in regards to withstand voltage test

5

CURRENT

/RESISTANCE

Withstand voltage test : Display of leakage current measurement value and result

value, blinking during setting up

Insulation test : Display of insulation resistance measurement value and result

value, blinking during setting up

HIGH SET Lamp

Lights up when upper limit value is set

Lighting of each lamp, refer

blinking state

LOW SET Lamp

Lights up when lower limit value is set

6

TIME

Withstand voltage test : Display of RAISE、TEST、FALL time

Insulation test : Display of MASK、TEST time

RAISE Lamp

During withstand voltage test RAISE operation,

Lights up during setting

Lighting of each lamp, refer

blinking state

TEST Lamp

During withstand voltage test TEST operation,

Lights up during setting

FALL Lamp

During withstand voltage test FALL operation,

Lights up during setting

MASK Lamp

During MASK time of insulation test, Lights up

during setting

1413129 10

87654321

11

mA

HIGH

LOW

GOOD GOOD

HIGH

L O W

HIGH

L O W

MΩ

15 16

MODEL 8505 5

1

No.

Name

Function description

7

JUDGE

Display of decision result and test status

ACW-TEST Lamp

Lights up during withstand voltage test

Lighting of each lamp,

refer blinking state

IR-TEST Lamp

Lights up during insulation test

GOOD Lamp

Lights up when the decision result of the test is passed

HIGH Lamp

Lights up when the decision result of the test is larger than the

upper limit decision value

LOW Lamp

Lights up when the decision result of the test is less than the

lower limit decision value

8

MODE

Display of test mode and operation mode

ACW-IR Lamp

Withstand voltage test → Lights up in insulation test mode,

blinking during setting

Lighting of each lamp,

refer blinking state

IR-ACW Lamp

Insulation test → Lights up in withstand voltage test mode,

blinking during setting

ACW Lamp

Lights up during withstand voltage test mode , blinking during

setting

IR Lamp

Lights up during insulation test mode, blinking during setting

READY Lamp

Lights up during READY status

REMOTE Lamp

Lights up during remote control status

KEYLOCK Lamp

Lights up during locked status of key operation setting

DISCHARGE Lamp

Blinking during the discharge of insulation test

1.Names and functions of each part

MODEL 8505 6

No.

Name

Function description

9

LOW terminal

Low-voltage side terminal of the test voltage output, the tester case and the same

potential

10

HIGH VOLTAGE terminal

High-voltage side terminal of the test voltage output, the output of the high voltage

during the test

11

Buzzer

Buzzer

12

START switch

Start switch of the test

13

STOP switch

Interruption and judgment return switch of the test

14

Setup key

Key for reading and writing the setting of the test conditions such as test mode, test

voltage, upper and lower limit values, test time etc.

MEM

Key to select each setting after entering the setup mode

Hold down the SHIFT and press the MEM key to switch to the memory operation

PROG

Key to select each setting after entering the setup mode

Hold down the SHIFT and press PROG key to switch to the program operation

▼

SET

Key to change each setting item

Hold down the SHIFT and press SET key for some time to switch to other function

setting

▲

RANGE

Key to change each setting item

Hold down the SHIFT and press RANGE key while setting to switch to the decimal

point

REMOTE

LOCK

Key to set/release remote operation

Hold down the SHIFT and press LOCK key to switch to Key lock set/release

ENTER

EXIT

Stores the set value and exits from the setting operation

Hold down the SHIFT and press EXIT key to interrupt the setting operation and

READY state

SHIFT

Used in combination with other keys

Function that is displayed on the lower side of the key is enabled

15

POWER switch

Switch for the power

16

Key cover

Protect the set up key from being touched (option)

MODEL 8505 7

1

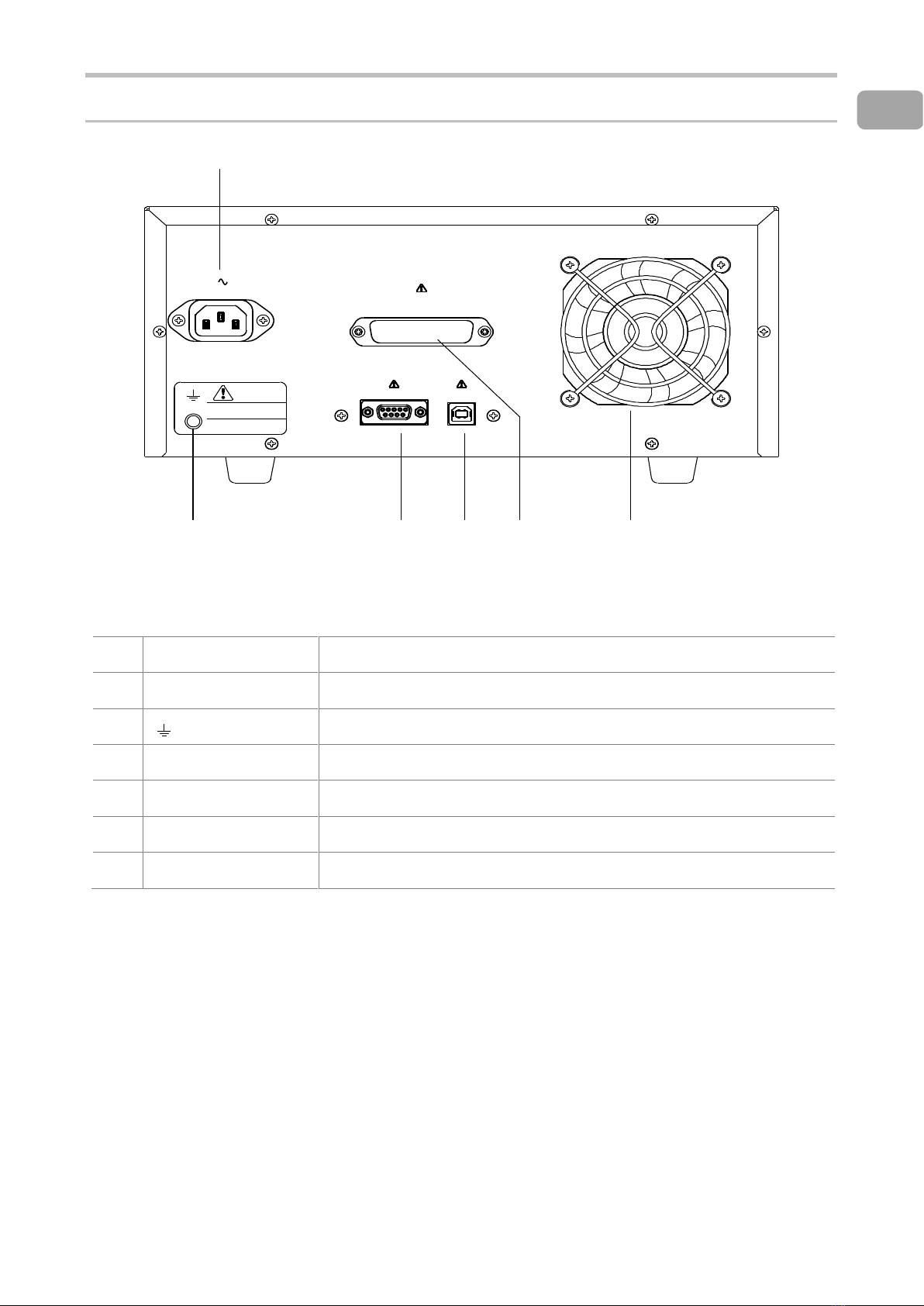

Rear Panel

No.

Name

Function description

1

AC LINE connector

Supply power inlet

2

Protective earth terminal. Terminal for earthing the case of the tester with same

potential

3

RS-232C connector

RS-232C interface

4

USB connector

USB interface

5

Remote I/O connector

Connector for external control

6

Cooling fan

Fan for exhaust

注 意

CAUTION

大 地 ア ー ス し て く だ さ い 。

接 地 端 子 は 確 実 に

ENSURE GROUNDING OF

EARTH TERMINAL.

1

2 3 4 5

REMOTE I/O

RS-232C USB

AC LINE 200VA MAX

100-240V 50-60Hz

6

MODEL 8505 9

2.Preparation before use

Connection of power cord.................................................................................................................... 10

Connection of the protective earth terminal ......................................................................................... 10

Method of removing and mounting of key cover (option) ................................................................... 10

Connection to the external control equipment ..................................................................................... 11

Connection of the high-voltage cable .................................................................................................. 11

Power on and off .................................................................................................................................. 12

2.Preparation before use

MODEL 8505 10

Connection of power cord

1Make sure that the power switch POWER of this tester is turned off.

2Connect the power cord to the inlet for the power supply of the rear face.

The plug of the power cord that comes with this tester is for AC100V. If it exceeds AC125V, use

the power cord suitable for the rating. 200V type power cord with a plug attached (European 2-pole

with earth model name 5880-23-030) is optional.

3Power cord plug (3P) is connected to the earthed outlet.

The plug of the power cord is 3- pin and the round shaped pin of the center is the earthing.

!Warning

Use supply voltage AC100~AC240V (AC90~250V) and power frequency 50/60Hz. Besides,

when you connect the power cord, make sure that the power switch is turned off. Beyond this

range could lead to the failure and incomplete operation of the tester.

Connection of the protective earth terminal

Earth the protective earth terminal ② to the ground using the supplied earthing wire. When the

earthing is imperfect or when the output is short circuited to the ground or power line, the case of the

tester is highly charged and it is dangerous to touch it. Besides, when using the tester, be sure to check

that the earthing wire is not disconnected.

!Warning

If the earthing is imperfect, there is a risk of an electric shock.

Method of removing and mounting of key cover (option)

You can mount the key cover (Model 5858-19) to the set up key as an option.

It is used when the set value is not wanted to be processed. As it is fixed with knurled screws, removing

and mounting can be done easily with your fingers.

MODEL 8505 11

2

Connection to the external control equipment

External control equipment can be connected to the remote I/O connector ⑤

Refer to “11.Remote I/O” for connection method.

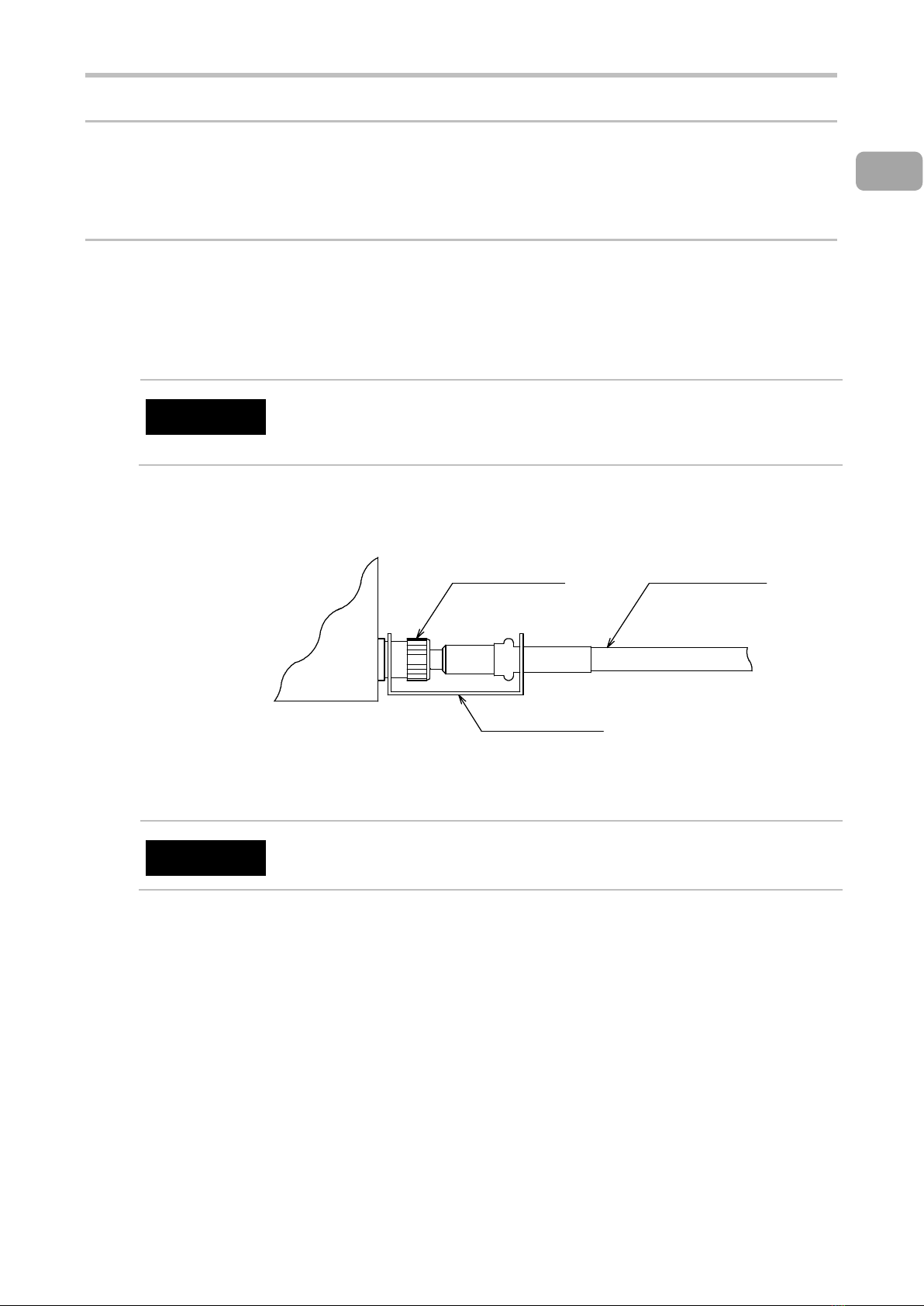

Connection of the high-voltage cable

During the test, the high voltage output terminal is charged to a high voltage. Connect the supplied high

voltage cable with the HIGH VOLTAGE terminal and LOW terminal. For high voltage cable, use the

supplied cable or cable adaptable for the voltage used.

!Warning

・Make sure to confirm the power off before connecting the high voltage cable. There is

a risk of an electrical shock.

・As the vinyl covering part of alligator clip of the supplied high voltage cable is not a

withstand voltage, do not touch during the test. There is a risk of an electric shock.

After connecting the low-voltage side cable to the LOW terminal ⑨, be sure to secure the retaining

bracket to the terminal.

Tighten the low terminal of the main body with the U shaped groove side of the retaining bracket

!Warning

When the low voltage side cable is disconnected, the whole tested equipment gets charged with

high voltage and there is a risk of an electric shock.

8505

MAIN

BODY

LOW TERMINAL ⑨LOW VOLTAGE CABLE

(BLACK)

Retaining bracket

2.Preparation before use

MODEL 8505 12

Power on and off

After purchasing for the first time when POWER switch⑮ is on, the test begins and due to interlock

function, the state becomes PROTECTION state. Connect the supplied remote I/O connector.

Use the supplied remote I/O connector only after the PROTECT state is released easily.

If you do the actual test, use the interlock function for the safety.

To guard the test area against the electric shock, use the interlock function like cut-off etc.

when opening the door or cover.

1Make sure that the power cord, connection cables etc. are connected properly.

2Press “-” side of POWER switch ⑮ of front panel to turn it on.

3After turning on the power switch, all lights on display are on for few seconds (lamp test).

However, TEST VOLTAGE and CURRENT/RESISTANCE display firm version.

After a few seconds, the display would be of test mode when the previous power was turned off.

4Press “○” side of the POWER switch of the front panel to turn it off.

!Caution

Do not turn off the POWER switch ⑮ during the test voltage output. This may cause a malfunction.

However, it excludes in the state of emergency stop when voltage output does not decrease even

when the STOP switch is pressed due to the abnormality of test sample etc.

MODEL 8505 13

3.Panel operation

Expression of the panel display of setting operation ............................................................................ 14

Key Lock ............................................................................................................................................. 14

Configuration of the display ................................................................................................................ 15

Setting of test conditions ..................................................................................................................... 15

READY state ....................................................................................................................................... 16

Display during the test ......................................................................................................................... 17

Display example of judgment result .................................................................................................... 17

3.Panel operation

MODEL 8505 14

Expression of the panel display of setting operation

Depending on the key operation, the state of the display unit LED is expressed as below:

Numerical Indicator

Surface-emitting

LED Lamp

Round LED

Lamp

On state

Blinking state

Off state

!Caution

During setting, if key is not operated for about five minutes, it automatically returns to READY state.

During this time the contents changed will not be stored.

Key Lock

With this operation, the setting key operation is disabled.

At this time, only START switch and STOP switch are enabled in front panel operation.

Setting of Key Lock ① Press LOCK key (pressing the LOCK while holding down the SHIFT) for 3 seconds in the READY

state.

② KEY LOCK lamp is lit and the key lock function is set.

Release of Key Lock ③ Press LOCK key (pressing the LOCK while holding down the SHIFT) for 3 seconds till KEY

LOCK lamp is off.

ACW-IR

ACW-IR

ACW-IR

mA

1

3

HIGH

Table of contents

Other Tsuruga Test Equipment manuals