English FG-701 Glassbreak Simulator

- 2 - 5-051-320-00 Rev. D

Detector

Farthest point of glass to be protected by detector

C

RED

Button

FLEX MAN

ACTIVATE TEST

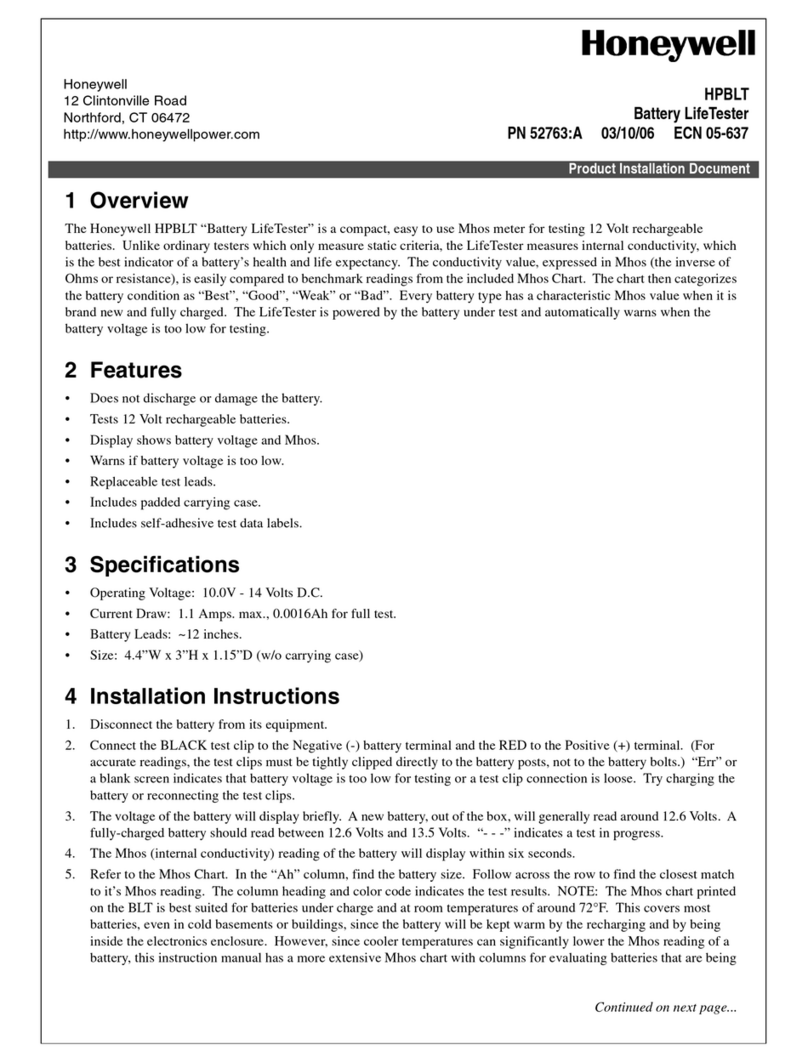

Testing detector range [MAN (manual) mode] (continued):

1. Set the FG-701 to TEST and MAN (manual). See C.

2. Position the FG-701 near the protected glass and point the

speaker directly at the glassbreak detector. Watch the green

LED on the detector.

3. Press the RED button and the FG-701 will generate a burst

of glassbreak

audio

.

Refer to the detector’s installation instructions for details of

green LED function.

BATTERY ANNOUNCEMENT

When the battery is low, the simulator

audio

sound will be

interrupted by the word "BATTERY." The battery must then be

replaced.

Use only 9V alkaline batteries. Do not use carbon-zinc or

rechargeable Ni-Cd batteries because they don’t have

sufficient peak power capacity.

TECHNICAL NOTES

When a window is broken, many things affect the sound

produced, including type of glass, glass size and thickness,

type of mounting, the breaking object, and how much force is

used. The sound will also be modified by absorptive or

reflective surfaces in the room.

No simulator can account for all possible conditions, but the

sound produced by the FG-701 is carefully designed to

represent a worst-case break. The sound is a recording of a

small pane of tempered glass broken in a controlled

environment. The output level of the simulator is correlated

with the original sound to insure an equivalent response in

FlexGuard®detectors. In production, the acoustic output is

factory-calibrated.

Room characteristics greatly affect the range indicated by the

simulator. A room with hard surfaces will increase range,

because hard surfaces reflect the sound back into the room. A

room with absorbing surfaces (carpets, acoustic tiles) and

absorbing materials (curtains and soft furniture) will reduce

range.

Real glassbreak sound is affected in the same way as the

simulator sound because it has the same frequency content

and originates from the same location in the room. So the

audio range indicated by the FG-701 is a good indication of

glassbreak detection range.

A low frequency sound is also produced when a window is

broken. In FLEX mode, the low-frequency signal (

flex

) is

generated by gently thumping the window. The

flex

signal is

detected by the FG-701 which sends a burst of

audio

. If

sufficient

flex

can be generated by a safe, non-breaking thump

to the glass, there is good assurance that a real break will be

detected. Range indicated by the simulator should be

considered the safe detection range for an individual detector.

Because of component tolerances do not assume that a

substitute detector will work at the same range. If a detector is

changed, the replacement should also be tested with the FG-

701.

PRODUCT SPECIFICATIONS

Temperature Range:

Operating:

32ºF to 122ºF (0ºC to +50ºC)

Storage:

-4ºF to +140ºF (-20ºC to +60ºC)

Output Spectral Range:

1.5 - 16 kHz

Estimated Battery Life:

2500 operations [MAN (manual) mode]

Battery Type:

9V Alkaline, Duracell MN1604 or equivalent

Output Level:

Approx. 110dB peak at 1 meter, on axis (Re 20µPa)

Dimensions:

3.25"W x 6.3"H x 0.9"D (83mm x 160mm x 23mm)

Weight:

8 oz. (.23 kg)

Approvals/listings:

CE

C-Tick

To obtain applicable EU compliance Declaration of Conformities for this product,

please refer to our Website,

http://www.security.honeywell.com/hsce/international/index.html.

For any additional information regarding the compliance of this product to any

EU specific requirements, please contact:

Quality Assurance Department,

Honeywell Security & Custom Electronics,

Newhouse Industrial Estate

Motherwell,

Lanarkshire ML1 5SB,

Scotland,

United Kingdom.

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com

Please contact your local authorised Honeywell representative for product warranty information.

Copyright 2009 Honeywell International Inc. Honeywell and FlexGuard are registered

trademarks of Honeywell International, Inc. All Rights Reserved

Made in China