TTC Lifting WA30A User manual

Operation

Manual

Hydraulic

drum

truck

MODEL:WA30A... WA30B

Note

: The ow11er/operator must read carefully and understand

au

the

infonnation presented here before operation.

Content

1 Specification.................................................. 2

2 Part Name..............

..

............

........................

4

3 Installation and Operation........

..........

... ........... 4

4 Warning.......

..

.............................................. 5

5 Operation Instruction....

............

........

..

.

..

.

..

..

..

..

. 5

5.1

Lift drum..............

............

.................. 5

5.2 Transport drum.......

........

..........

..

......

..

6

5.3 Put down drum................

.................

..

6

6 Hydraulic Circuit Diagram....

..

.............

..

............ 7

7 Exploded Vtew &Part List................................ 8

- 1•

I

I

I

I

:

THANK

YOU

FOR

BUYING

THE

0

T300/DT300L

HYDRAULIC

DRUM

TRUCK.

AREFULLY

BEFORE

USING

THE

TRUCK

OPERATING SAFELY

AND

MAINTAIN\NG.

PLEASE

READ THIS

MANUAL

C

IN

ORDER

TO

GET

THE

WAY

OF

NOTE~

All

of

the

information report

ed

her

ein is based

on

data available

at

the

erves

the

rightto modify its

own

products

at

urring

in

any

sanction.

So

it

ts suggestedto

moment

of

printing.

The

factory res

any

moment

without

notice

and

inc

always

verify possjble updates.

This hydraulic drum truck can be used

to

load

or

unload, transport, stack

uitable lifting

the

drum

for

itsspecial design

widely

used

in factories, warehouses

and

the

drum

by clamping it. It is

more

s

of

low fork and high hoisting

and

is

so

on.

1. SPECIFICATION

Mpdel

WA30B WA30A

Suitablefor Drum Diameter (mm) 572 572

Capacity (Kg) 300 300

I

Front

Wheel Diameter d {mm) 64 125

Rear

Whee

l OLameter 0 (mm) 80 125

Minimum Clamp Height

H1(mm)

835

870

MaXimum Clamp Height H2{mm) 1640 1675

Total Height .

H(mm)

1525 1560

Length

L(mm)

866

952

Width

W(mm)

956 956

Net

Weight

(Ko) 68

7?

-2-

WA30B

.

·

-

~

WA30A

_

--.:~'!-

1

S.f1

I

·~

j

..

-

~

- 3 -

2. PART NAME

(1) Front

Wheel

{2)

Front

Wheel ForkAssembly

(3

) Supporting Tube

{4)

Rear

Wheel Connecting Board

(5}

Supporting Clamp Structure

(6)

MastAssembly

3. INSTALLATION

{7)

Mast

Bonnet

(8) Cylinder

Assemb

ly

(9)

Rear

Wheel (Versatile

Wheel

)

00}

Operation Handle

(11)

Pulley

All the parts

of

the hydraulic drum truck have been cased up

when

finished.

You can install it quickly and expediently

as

if

following

the

steps below.

-

4-

3.1 Make sure all

of

the parts are intact contained 2 (Front Wheel Fork

Assembly),

12

(Connecting Bolt), 4 (RearWheel Connecting Board), 3

(Supporting Tube

),

13

(Pad), 14 (Connecting bolt), 8 (CylinderAssembly),

6 (MastAssembly), 5(Supporting Clamp Structure).

3.2 Join 2 (FrontWheel ForkAssembly), 4 (RearWheel Connecting Board). 3

(Supporting Tube) togetherfirmly with 12 (Connecting Bolt) as showed in

picture.

3.3 Join 13 (Pad), 5.6.8(Mast & Supporting Clamp Assembly & Cylinder

Assembly) and 3(Supporting Tube) together finnly with

14

(Connecting

bolt).

3.4 Replace

the

screw plunge on the top

of

8 (Cylinder Assembly) with

(ventilated screw plunge).

3.5 Make suresupporting clamp structure lifts smoothly withoutload.

3.6 Make sure supporting clamp structure lifts smoothly, wheels move agilely,

and brakes are available under

the

rated load.

4. WARNING

4.1 Neveroverload this truck beyond its rated capacity.

4.2 Place

the

drum in a low position when does not

lift

4.3 Raise the drum

just

awayfrom the ground when transportit,

do

notneed

to

lift

it

higher.

5.

OPERATION INSTRUCTION

5.1

Lift

Drum

Move th'e truck until its supporting clamp structure(5) touch the drum,

tighten descending valve lever(15), kick the brake

of

rearwheel(9). Kick

the

P.edal

lever so that

the

upperbiter

of

supporting clamp structure(5) will

screw down to clamp the drum, then continue to kick the pedal lever

to

lift

-5

-

the drum.

S.2 Transport

drum

Loosen brakewhen thedrum

has

been lifted,

co

ntrol operation handle(10)

on the mast assembly(6)

to

transport the drum.(

Just

lift t

he

drum

a little

when

transporting it.)

5.3

Put

down

drum

Loosen descending valve lever(15)

to

descend the drum to the floor

when

reaching

the

destination, then the upper biter

of

supporting

clamp

structure(S) will loosen t

he

drum. Tighten descending valve lever(15) at

la

st

NOTE:

It

is

forb

idden

to

loosen descending

valve

lever (15)

suddenly

in

case

of

danger

.

5.4 Please change the hydraulic oil

if

its

work

time adds

up

to

20

hourswhen

you

us

e

it

for

the

first time.Afterthat, you should changethe oil

when

its

work

time

adds

up

to

300 hours. Change

the

oil every

18

months

if

the

aggregate

work

t

ime

is deficient.

Use

differe

nt

hydrau

lic

oil according to temperature

sca

le

below_

-Temperature HydraulicOil

...

5

"C-+

45

~

I L-HM68 Hydraulic Oil (equivalentto ISO VG68)

-15

"C-

-5

t I L-HM46 Hydraulic Oil (equivalent

to

ISO VG46)

Put

mast

plunge

rod

at

the

bottom

position

when

changing

the

oil.

Keep

adding

the

oU

until

the

level

reaches

the

oil

hole

.

-

6-

I

I

6.

HYDRAULIC CIRCUIT DIAGRAM

1

3

5 t

I N

o.

I

1

2

3

4

5

t

i

2

4

Description

Hydraul

ic

Cylinder

Swivel Discharge Valve

Reliefva

lv

e

Work valve

Work Cylinder

-7

-

I

7. EXPLODED VIEW & PART LIST

7.1

Exploded View

-8-

7.2 Part

List

No.

Description

Qty

No.

Description

Qty

1 Inside

hex

screw 2

23

Chain pin axle 1

2

Copper

washer

2 24 Split ring 6

3 Taperspring 2

25

Adjusting screw 1

4 Steal ball 4 26 Plunger rod 1

5 Screw plunger 2

• 27 IDustproofring 1

6 0 -ring 2

28

0-ring

2

7 Locking screw 1 29 Nylon

washer

1

8 Spring I 1

30

Pump

rod 1

9 Short pin 1 31

Pump

cover . 1

10

Inside

hex

screw 2 32 Pump ring 1

I

11

Hex

nut

4 33 Dustproof ring 1

12 Locating ring 2

34

0-ring

2

13 Torsional spring 1

35

Nylon

washer

1

14 Unitaryvalve rod 1 36 Welding

the

fute tank

body

1

15 Insidehex screw 1

37

0-ring 2

16

Split pin 1

38

Valve

core

1

17

Hex nut 4

39

Spring pin 1

. 18 Chain bolt 1

40

Pfn axle 1

19 Rollercha

in

1 41

Seat

1

20 Chain wheel 1

42

Nut

1

~

43

I

Hex

bolt

21

Bearing 2 1

22 Chain cover 1

44

Hex nut 1

-9-

No.

Description

Qty

No.

Description

Qty

45 Split ring 2 67

Nether

Clamp

Assembly

I 1

46 Bearing 1 68 Spring I 1 I

47

Ring 1 69 Pin

Ax

le 1

48 Pin axle 1

70

Pulley I 1 I

49

Adjusting

screw

1

71

Bearing

1

50

Spring 1

72

Bushing 1

51

Stee

l ball 1

73

Pin

Axle

I 1

52

Sheath

1

74

SupportingStructure

Assembly

I 1

53

Oil

cup

2

75

Pulley

4

54

Split ri

ng

1

FrontWheel<I>64(WA30B)

2

76

55

Lever

1 Frontwheel

<l>

125(WA

3

0A)

2

..

56

Rubber

sheath 3

77

Front

Wheel

Pin

Axle

I 2

57

Hex

Bolt

2

78

Front

Wheel

Fork

Assembly

2

58

Mast

Bonnet

1

79

Supporting

Tube

1

59

Mast

Assembly

1

80

Rear

Wheel Connecting Board 1 2

60

kde

Fender

Ring 2

81

Hex

Bolt

6

61

Pin

Axle

1 82

Hex

Bolt

2

62

Ax

le

Fender

Ring 6 versatile

Wheel

~

ao

(WA30B)

1

83 versatileWheel

<t>

125(WA30A)

I

63

Upper

Clamp

Assembly

1 1

64

Pin

Axle

1 84 Pad I 1

65

Pulley

1 85

Hex

nut

I 8 I

66

Bearing 1 I

-

10-

No.

Description

Qty

No.

Description

Qty

Rear

Wheel

~

60

(WA30B) 1 88 Spring

washer

2

86 I

Rear

Wheel

<1>

125rt'JA30A) 1 89 Washer 2

87

Hex Bolt 8

90

u hoop I 1

-

11

-

This manual suits for next models

1

Table of contents

Other TTC Lifting Lifting System manuals

Popular Lifting System manuals by other brands

High Lifter

High Lifter PGL-KIT-RZRT manual

ShoreDocker

ShoreDocker SD1200 Assembly and operating instructions

StoreYourBoard

StoreYourBoard Hi-Lift PRO quick guide

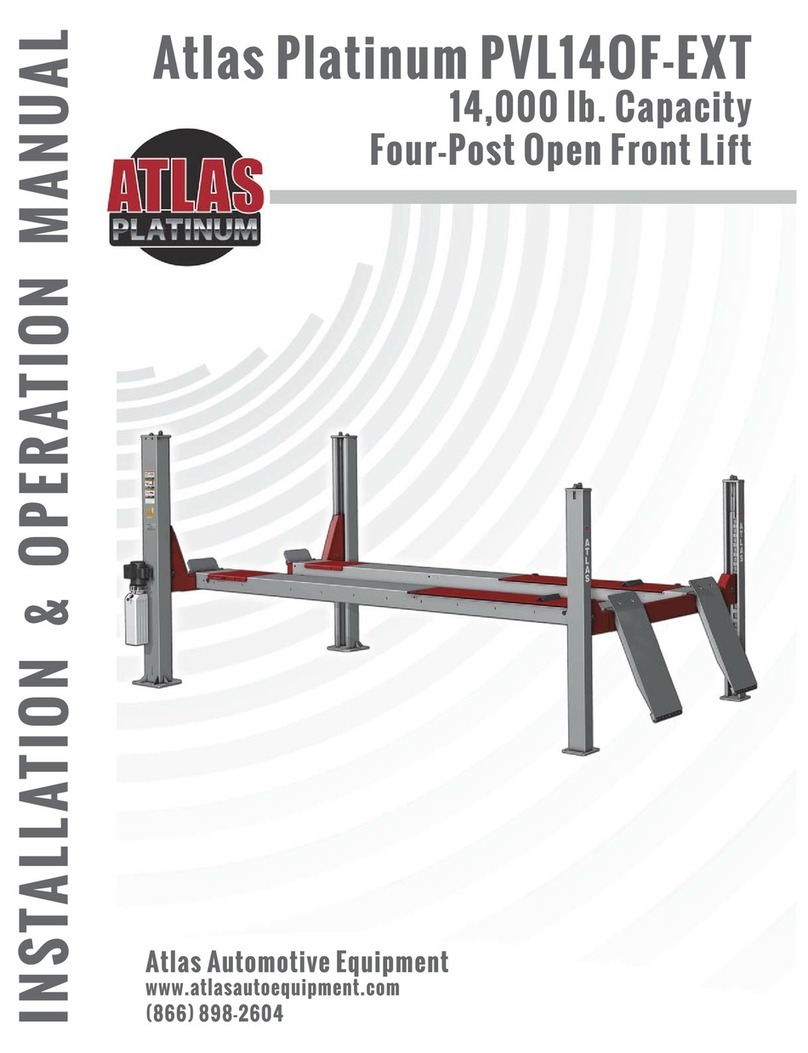

ATLAS PLATINUM

ATLAS PLATINUM PVL140F-EXT Installation & operation manual

Stannah

Stannah 320 General Installation Instructions

IXOLIFT

IXOLIFT 400 Series operating manual

Aqua Creek Products

Aqua Creek Products F-EZPL2 Installation, assembly and operating instructions

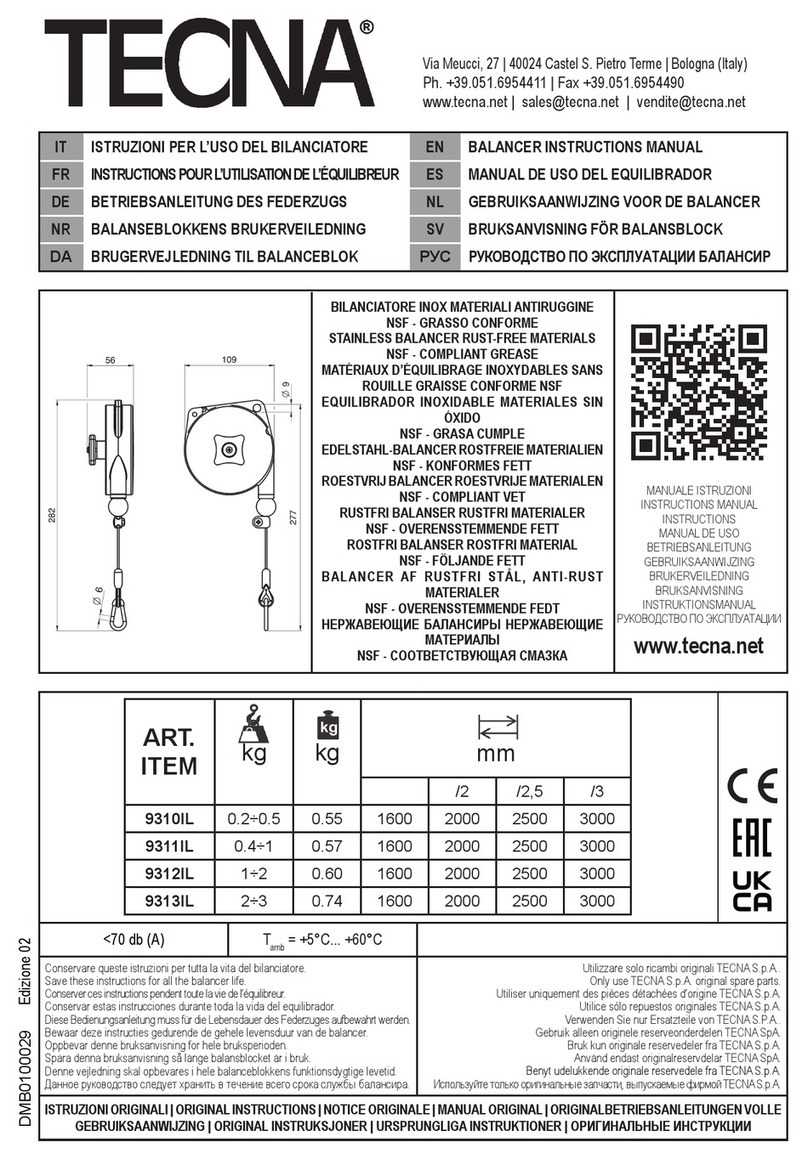

TECNA

TECNA 9310IL instruction manual

Joerns

Joerns Quickfit Deluxe Sling user guide

Ricoh

Ricoh PF4000 Series quick start guide

BAUKER

BAUKER EH300D instruction manual

Braun Corporation

Braun Corporation UVL Series Service manual