TTI TG501 User manual

TG501

Function Generator

Service Manual

Book Part Number 48591-0130 - Issue 5

Table of Contents

General 1

Specification 2

Functional Description 4

Circuit Descriptions 6

Calibration 13

Parts List 17

General

Service Handling Precautions

Service work should only be carried out by skilled engineers. Please note that the tracks on the

printed circuit board are very fine and may lift if subjected to excessive heat. Use only a miniature

temperature controlled soldering iron and remove all solder with solder wick or suction before

attempting to remove a component.

Dismantling the Instrument

WARNING!

Opening the instrument is likely to expose live parts. The instrument shall be disconnected from all

voltage sources before any adjustment, replacement or maintenance and repair during which it shall

be opened. If afterwards any adjustment, maintenance or repair of the opened instrument under

voltage is inevitable, it shall be carried out only by a skilled person who is aware of the hazards

involved.

1. Remove the 8 side screws and lift off the case upper and lower.

2. Access to all components is now possible, further dismantling is not necessary.

3. All small knobs are push on types. To remove the dial, remove the cap in the centre of the

knob using a knife blade, then loosen the nut about 1 turn. The knob and dial can then be

pulled off.

4. Transistors Q32, Q34 and Q39 and IC22 are insulated from the rear panel.

5. Reassemble in reverse order.

Operating Voltage

See the Power Supply section for details of changing the operating voltage from 220/240 to 110/120

and vice-versa.

1

Specification

(All specifications apply after warm-up in an ambient temperature range 18oC-28oC.)

OPERATING RANGE

Frequency Range: .005Hz to 5MHz in 7 overlapping decade ranges with fine

adjustmentby calibrated vernier.

Internal Mode

Vernier Range: 1000:1 within each range.

Vernier Accuracy: Better than ±5% of full scale.

External (Sweep) Mode:

Sweep Range: 1000:1 within each range.

FUNCTIONS

(Specifications apply for vernier between 0.5 and 5.0 and output 10V peak-to-peak into 50Ohm

termination).

Sine

Distortion: Less than 0.5% to 50kHz, less than 1% to 500kHz; all harmonics

>30dB below fundamental on 1M range.

Amplitude Flatness: ± 0.2dB to 500kHz; ±1dB to 5MHz.

Triangle

Linearity: Better than 99% to 500kHz.

Squarewave

Rise and Fall Times: <45ns.

Mark: Space Ratio: 1:1 ±1% to 100kHz; ± 5% to 5MHz

DC

Range: ±10V from 50 Ohm.

OPERATING MODES

Run

Generator runs continuously at the selected frequency.

Triggered

Generator is quiescent until triggered by an external input at TRIG IN or by pressing MANUAL. One

complete cycle is then generated at the selected frequency, starting and stopping at the phase set

by the START/STOP PHASE control.

Gated

Generator is quiescent until gated by an external signal at TRIG IN or by pressing MANUAL.

Generator then runs continuously at the selected frequency for duration of gate signal, starting and

stopping at the phase set by the START/STOP PHASE control. Last waveform started is

completed.

Manual

Manually operates generator as described in Triggered and Gated sections.

Start/Stop Phase

The START/STOP PHASE control varies the triggered and gated signal start/ stop point from

approximately -90oto +90oup to 500kHz.

2

Symmetry

When SYM is selected the SYMMETRY control varies the duty cycle from 1:19 to 19:1 to produce

sawtooth and variable pulse-width waveforms. The indicated frequency is divided by 10 with SYM

selected.

INPUTS

Sweep Input

Input Impedance: 10kOhm

Input Sensitivity: 0 to 4V for 1000:1 sweep

Maximum Allowable Input

Voltage:

±10V

Sweep Linearity: Better than 1%

Maximum Slew Rate of

Input Voltage:

0.1V/us

Trigger Input:

Frequency Range: DC - 5MHz.

Signal Range: TTL compatible levels; maximum input 20V.

Minimum Pulse Width: 50ns.

Input Impedance: Typically 2kOhm.

OUTPUTS

50 Ohm

Amplitude Control: >20dB vernier control within each attenuator range. Maximum output

20V peak-to-peak from 50Ohm (10V into 50Ohm).

Attenuator: Additional switch-selectable attenu- ation of 0, -20 or -40dB. Minimum

output <20mV peak-to-peak from 50Ohm (<10mV into 50Ohm).

DC Offset Control Range: ±10V from 50Ohm. DC offset plus signal peak limited to ±10V (±5V

into 50Ohm). DC offset plus waveform attenuated proportionally in -

20dB and -40dB positions.

TTL

Amplitude: Fixed TTL level output at frequency and symmetry of main output.

Capable of driving 20 TTL loads.

GENERAL

Power Requirements

Input Voltage: 110/120V AC nominal 50/60Hz or 220/240V AC nominal 50/60Hz,

adjustable internally. The TG501 will operate safely and meet

specification within normal AC supply variations viz. 100-130V AC

and 200-260V AC respectively.

Power Consumption: 30VA Max.

Environmental Operating

Range: +5oC to +40oC, 20% to 80% RH.

Storage Temperature Range: -40oC to +70oC.

Size: 300mm wide x 100mm high x 230mm deep

Weight: 3.4kg

3

Functional Description

The relationships between the major circuit elements are shown in the block diagram opposite.

The summing amplifier sums the voltages from the dial and from the sweep input, and its output

controls the magnitude of the complementary current source and current sink. This current varies

from approximately 5.2uA to 5.2mA for a 1000:1 frequency change (.005-5.0).

The symmetry control adjusts the ratio between current source and current sink.

The diode gate steers current into or out of the range multiplier capacitor and is controlled by the

comparator output. When the comparator output is high the charge on the capacitor will rise,

linearly, producing the positive going triangle slope. When the comparator output is low the charge

on the capacitor will fall linearly producing the negative going triangle slope. The triangle amplifier

has unity gain and buffers the triangle wave on the multiplier capacitor to drive the comparator and

output circuits.

The comparator operates as a window detector with fixed limit points set to the triangle peaks. One

of its two outputs drives the TTL circuit and is also level shifted to drive the diode gate. The other

output drives the squarewave shaper. When the comparator output to the diode gate is high, the

triangle wave is positive going until this reaches approximately +1.2V, the comparator output then

switches low. When the comparator output is low the triangle wave is negative going until this

reaches approximately -1.2V, when the comparator output goes high, and the cycle is repeated.

4

This is the basic function generator loop in the Run mode and is shown by the double arrows in the

block diagram. Triangle and squarewave are generated simultaneously as shown.

The control logic determines Trig, Gate or Run modes. In Trig or Gate modes the waveform is

clamped by the -2I+ current sources and the diode gate, at a point determined by the Start/Stop

Phase control. A signal applied to Trig In releases the clamp and a single cycle is produced in the

Trig mode or a burst in the Gate mode, the waveform is then clamped again.

To achieve the 1, 10 and 100 ranges the 1k range capacitor is multiplied by 1000, 100 or 10 by the

capacitor multiplier circuit.

The TTL circuit buffers one of the comparator outputs to drive the TTL output socket.

The squarewave shaper converts the comparator output to a current signal and applies it to the

squarewave function switch. The sinewave converter uses the non-linear characteristics of a

transistor pair to convert the triangle wave into a sinewave, which is applied to the sinewave

function switch. The selected function is sent to the pre-amplifier where it is inverted and buffered

and applied to the output amplitude control. The signal is summed with the voltage from the DC

offset control at the output amplifier. This amplifier inverts and amplifies the signal up to 20V peak

to peak to drive the 50 Ohm output socket.

The power supply converts the incoming AC line voltage to the DC rails required by the instrument.

5

Circuit Descriptions

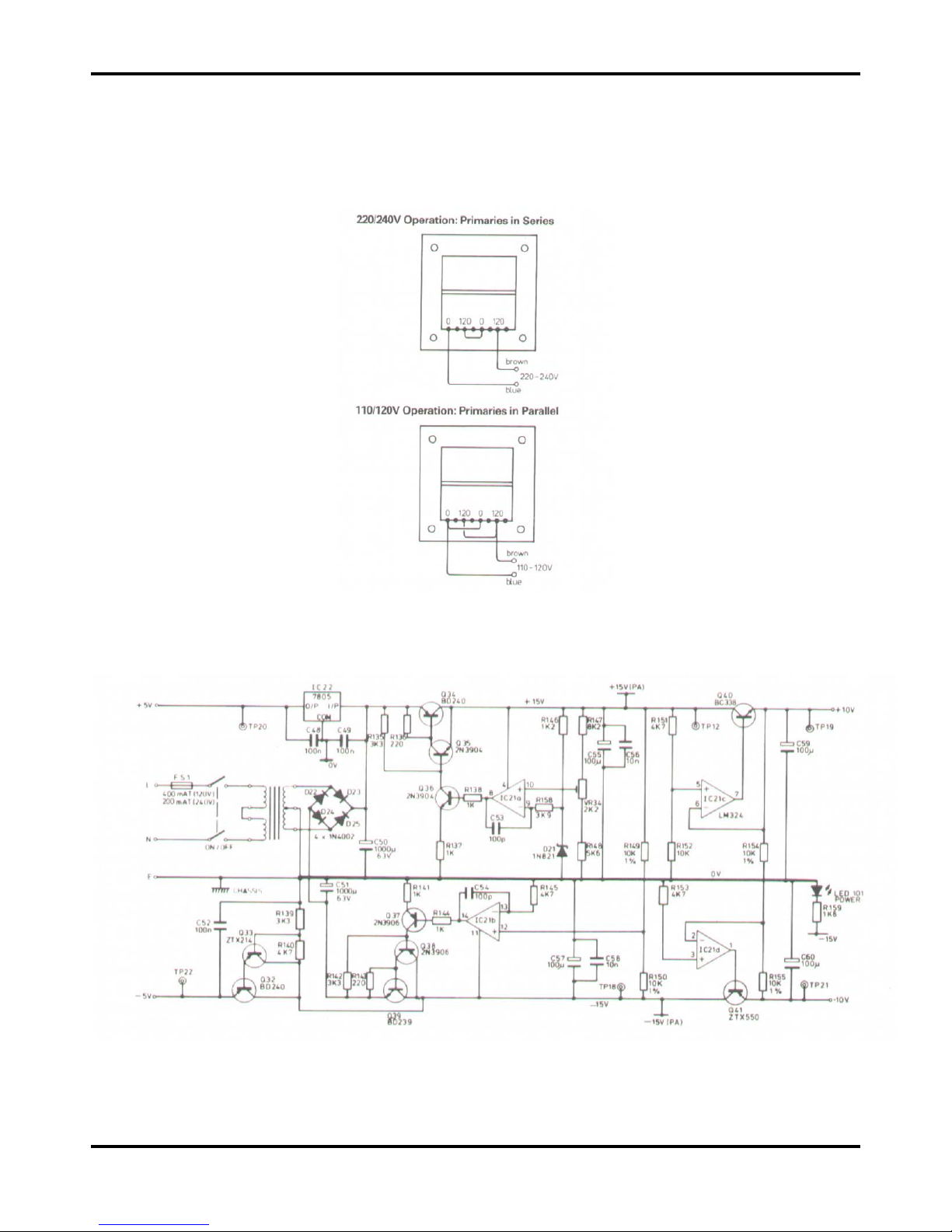

Power Supply - Mains connections

The operating voltage of the instrument is shown on the rear panel label. Should be it necessary to

change the operating range from 220/240V AC to 110/120V or vice-versa, change the transformer

connections following the appropriate diagram below.

If a change is made, the operating voltage label and fuse should also be changed.

For 220/240V operation use 200mA 250V time-lag

For 110/120V operation use 400mA 250V time-lag

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the protective conductor inside or outside the instrument or disconnection of the

protective earth terminal is likely to make the instrument dangerous. Intentional interruption is

prohibited.

6

Power Supply - DC Regulation

Diodes D22 to D25 rectify the transformer output and C50 and C51 are the reservoir capacitors of

the unregulated DC rails.

Q34, Q35, Q36 and IC21a form the +15V regulator, Q34 and Q35 form the compound series pass

element and Q36 its driver. IC21a is the error amplifier and a temperature compensated zener D21

provides the reference (6V2). The +15V output is set by VR34.

The -15V regulator is made up of Q37, Q38, Q39 and IC21b and complements the +15V regulator.

The -15V tracks the +15V by sensing the voltage at the junction of R149, R150 at the input of

IC21b.

The +10V rail is derived by dividing down the +15V rail; R151 and R152 provide the reference from

the +15V for the regulator IC21c and Q40.

The -10V regulator is formed by Q41 and IC21d and is the complement of the +10V regulator. The -

10V tracks the +10V by sensing the voltage at the junction of R154,R155 at the input of IC21d.

The +5V rail uses a standard 3 terminal regulator IC22.

The -5V rail is divided down from the -15V by R139, R140 and buffered by a darlington emitter

follower Q32 and Q33.

Waveform Generation - Summing Amplifier and Current Sources

The dial and sweep voltages are summed by IC1, the gain of which is set by VR3. VR3 is, in fact,

used to calibrate the high end of the dial. The output range of the amplifier is approximately -4mV

(with the dial at .005) to -4V (with the dial at 5.0). This voltage is used to drive the complementary

current source and current sink as follows.

The emitter of Q1 is held at pseudo ground by IC2. If the dial is at 5.0, the -4V at the output of IC1

is forced at the emitter of Q2 by IC4. This -4V is also halved by R6, R7 and IC3 forces this voltage

(-2V) at the junction of R9, R10. A voltage dependant current is therefore set up through R8, R9,

R10 and R11.

IC5 is a current source controlled by the voltage on the collector of Q1 and IC6 is a current sink

controlled by the voltage on the collector of Q2. These two currents are steered into and out of the

range capacitor by the diode gate IC10, under the control of the comparator output.

7

When the symmetry button is depressed the short across VR8 is removed and the total resistance

between Q1 and Q2 emitters is increased from R to 10R. This lowers the current through this

resistor chain by a factor of 10 and so the frequency is divided by 10. Rotating VR8 imbalances the

current through Q1 and Q2 to give a duty cycle of up to 1:19 or 19:1.

With the symmetry button out, the waveform symmetry is set by VR9 at the top of dial (5.0). At the

bottom of the dail, symmetry is determined by offsets on ICs 1-6 (refer to calibration procedure).

Current source IC8 tracks the I+ current source IC5 and IC9 mirrors this to become -2I+. The -2I+

current is used to clamp the waveform in the Trig and Gate modes. The ramp can only stop in the

upward direction. When the Q output

of IC14b is set low, D1 is off. If the voltage at Q5 emitter is 0V (= to 0o), the voltage on the range

capacitor will ramp up and stop at 0V. When clamped the I+ current from the diode bridge flows

through the diode between pins 4 and 3 into the -2I+ current sink. A current equivalent to I+ also

flows through the diode between pins 9 and 1 into the -2I+ current sink to total 2I+. IC7 and Q5

buffer the voltage on the Start/Stop Phase control VR11 to give a low impedance voltage source on

pin 9 of IC10. This voltage can be varied between approximately +/-1.2V by VR11 corresponding to

the triangle peaks, giving +/-90oof phase control. To release the clamp the Q output of IC14b is set

high which pulls the -2I+ current sink high via D1, reverse biasing the two clamp diodes.

Waveform Generation - range selection and triangle amplifier

Range selection is by seven push-button switches, which steer the current sources into the

appropriate multiplier capacitor. The lower four ranges use the same range capacitor C9; the lower

three ranges use a capacitance multiplier. The capacitance multiplier steals current from the range

capacitor via R36. The amount of current taken is determined by the gain setting resistors R28,

R30 or R31 for the x100, x10 and x1 ranges respectively. The triangle wave on C9 is connected to

the non-inverting inputs of IC11 and IC12. The triangle wave is amplified by IC11 which has a gain

of 3; this is trimmed by VR15 to set the overall gain of the capacitance multiplier. Q8 and Q9 buffer

the output of IC12.

The triangle buffer consists of a FET source follower Q10 with temperature compensation provided

by current source Q11, which is IDSS matched with Q10. Q13 and Q14 are emitter followers to

provide 2 low impedance outputs. Q12 is strapped as a diode and compensates for the VBEs of

Q13 and Q14. VR17 trims the DC offset in this stage.

8

Waveform Generation - Comparator and TTL output

IC13 operates as a window detector and determines the peak to peak amplitude of the triangle

wave on the range multiplier capacitor, which is approximately +/-1.2V. C17-C22 compensate for

comparator and loop delays ensuring that the triangle wave amplitude remains constant with

increase in frequency. The two internal NAND gates in IC13 are wired as a flip-flop to ensure

positive switching of the comparator. C23 provides a small amount of positive feedback to ensure

jitter free operation. Some comparators oscillate with the dial at 0.005; this can be prevented by

fitting C66.

One of the comparator outputs is routed via IC17a to parallel gates IC17 c and d which drive the

TTL output. Q15 level shifts IC13 output to be about ground to drive the diode gates. Q16 is a VBE

multiplier and its total voltage is just under two VBEs. R45, R46 and C16 improve triangle linearity

at 5MHz.

IC15a and level shifter Q17 are used to drive the squarewave shaper circuit. When the squarewave

button is out, pin 4 of IC15a is held low and so the squarewave is gated off at the source.

9

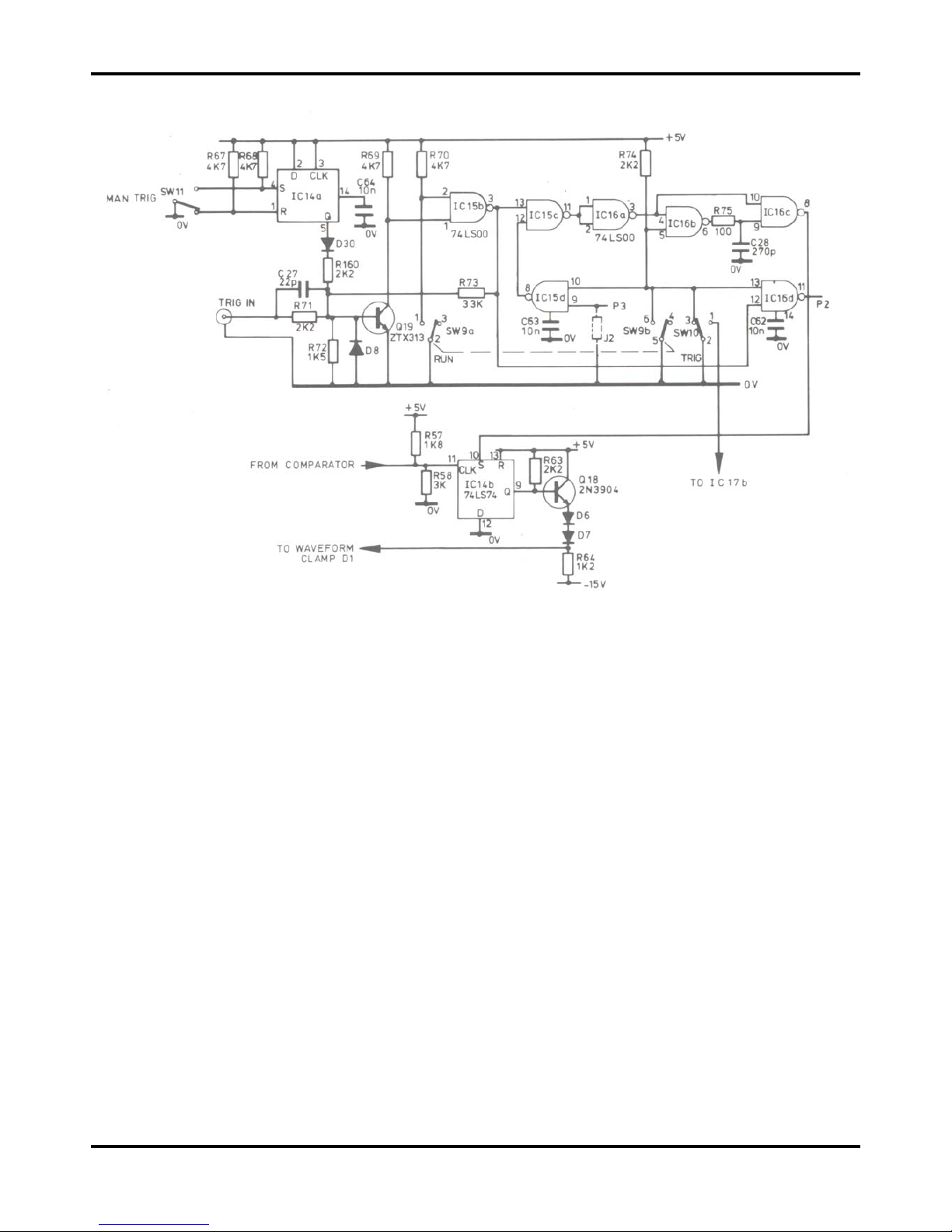

Waveform Generation - Trigger Circuit

In the Trig or Gate modes the waveform is clamped at the Start/Stop Phase point under control of

IC14b (described earlier).

Q19 and IC15b form a Schmitt trigger which ensures correct operation from DC to 5MHz. R71 and

R72 with C27 fix the input threshold at <1.5V over the whole frequency range.

In the trigger mode the output of IC15b is routed through IC15c and IC16a to the monostable

formed by IC16b and c. For every high going transition at the trigger input or depression of the

manual button a 50 nanosecond pulse at IC16c output is generated. This pulse goes from high to

low, and back to high after 50ns and is used to set the flip flop IC14b which releases the waveform

clamp. The flip flop now waits for a rising edge on its clock input; this occurs when the triangle wave

changes from a negative slope to a positive slope. This edge resets the flip flop and enables the

waveform clamp circuit which stops the waveform at a point determined by the Start/Stop Phase

control.

In the gate mode the monostable around IC16b and c is disabled and the signal bypasses IC16b.

When a high level signal is applied to Trig in, the output of IC16c goes low and releases the

waveform clamp. The generator now free runs until the Trig in signal goes low and IC16c output

goes high. IC14b flip flop now waits for a rising edge on its clock input as in trigger mode and stops.

In the run mode IC14b flip flop is permanently set by SW9b, disabling the waveform clamp so that

the generator free runs.

10

Waveform Generation - Waveform Shaping

The squarewave shaper is a diode bridge which steers current from either R89 or R90 into R91.

This provides a squarewave with controlled rise/fall times, and thus no overshoot and ringing, which

is symmetrical about ground. The drive signal comes from Q17.

The sine shaper comprises a monolithic transistor array IC18 which is driven by the triangle

amplifier. The circuit has two non linear stages. A pair of emitter followers round the peaks of the

triangle which are adjusted by VR18 for the bottom of the waveform and VR22 for the top of the

waveform. The output from this stage is impressed across R78 and R81 in series and applied to the

second stage. This comprises a long tailed pair driven almost into cut off and converts the clipped

triangle wave into a sinewave. VR19 adjusts the gain of the long tailed pair to bring them close to

cut off and therefore minimum sinewave distortion. VR23 adjusts the dc operating point of the

sinewave convertor to give symmetrical operation on both positive and negative halves of the

waveform. VR20 adjusts the dc output of the convertor and VR21 output amplitude.

Output Preamplifier

The selected waveform passes to the preamplifier. Q20 and Q21 form a long- tailed pair and are in

thermal contact with each other to reduce dc drift. Q22 and Q23 are two cascaded emitter

followers; feedback is via R98. The preamplifier is an inverting virtual earth type. DC offset is

trimmed by VR26. Sine, square and triangle waveform amplitudes are set for 10V peak to peak into

50 Ohm at the 50 Ohm output by VR21, VR24 and VR25 respectively.

11

Output Amplifier and DC Offset

The signal passes via the Amplitude control VR27 to the output amplifier. A simplified diagram is

shown in fig. 7 and the following circuit description refers to this.

The HF amplifier is made up of discrete components and is in principle an inverting operational

amplifier with a gain of -10 set by R109 and R115. This has offset voltages and currents which are

compensated for by IC19 and IC20. IC19 compensates for input bias currents. IC20 controls dc

offset and LF gain by driving the non-inverting input.

Refer now to fig. 8 for the description of the HF amplifier (simplified). Q24 and Q26 are

complementary emitter followers to provide low drive impedance to the complementary class A

amplifier stage Q28 and Q29. Level shifting is achieved by adjustable zener diodes, these are

formed by a zener diode and a VBE multiplier. Note incorrect setting of the level shifters will cause

excessive current to flow in the class A stage causing damage to these devices. Refer to the

calibration section for adjustment procedure. The output of the amplifier stage is buffered by

complementary emitter followers Q30 and Q31 to drive the 50 Ohm output, D17 and D18 provide

their bias.

The non-inverting input is effectively the emitters of the class A amplifier, D19 and D20 provide the

necessary level shifting.

12

Calibration

Equipment Required

Oscilloscope

Distortion meter

4.5 digit battery powered multimeter

Calibration should be carried out after the instrument has been on for 1 hour.

Note: If any work has been done to the output stage, VR32 and VR33 must be turned fully anti-

clockwise before switching on.

The available calibration points are:

Dial calibration, high frequency (5.0) end, 10k range - VR3

Dial calibration, low frequency end (.005) - VR2

Waveform symmetry, high frequency end of dial (5.0) - VR9

Waveform symmetry at the low frequency end of dial (.005) is affected by offset nulling of ICs 2 to 6,

see below.

Dial calibration 1M range - VC1

Dial calibration 100k range - VC2

Capacitance multiplier offset - VR16

Capacitance multiplier gain - VR15

DC offset of triangle amplifier - VR17

Sinewave distortion - VR18, VR19, VR22 and VR23

Sinewave dc offset - VR20

13

Sinewave amplitude - VR21

Squarewave amplitude - VR24

Triangle wave amplitude - VR25

DC offset of preamplifier - VR26

Output amplifier quiescent operating current - VR32 and VR33

Output amplifier dc offset - VR31

Output amplifier bias compensation - VR28

Output amplifier LF gain - VR30

+15Vrail - VR34

For best results the above adjustments should be carried out in the following manner:

After the instrument has warmed up the case upper is removed to make any adjustments, which

should be done in a draft free environment.

Adjust VR34 for +15.0V +/-100mV at TP12

Check -15V rail is within +/-2% of the +15V rail at TP18

Check +10V rail is +10.2 +/-400mV at TP19

Check -10V rail is within +/-2% of the +10V rail at TP21

Check +5V rail is 5.0V +/-0.25V

Check -5V rail is -5.0V +/-0.25V

Select: Run, 1k range, dial at 5.0, dc offset out, squarewave, 0dB

Offset nulling of ICs 1 to 6 is critical for correct operation of the instrument. Gold plated test pins are

provided and a gold plated 2 way header on the end of the leads to the DVM is recommended to

make a good connection and help to avoid thermal e.m.f.s.

IC TP Adjust DVM Reading

1 13 VR4 <40uV

2 1 VR5 <40uV

3 2 VR6 <40uV

4 3 VR7 <40uV

5 4 VR10 <40uV

6 5 VR12 <40uV

8 6 VR13 <100uV

9 7 VR14 <100uV

12 10 VR16 <100uV

Nulling of the triangle amplifier is achieved by shorting its input (TP11) and adjusting VR17 to give

<2mV at TP9.

To null the pre-amplifier, deselect the waveform output by releasing the 3 function buttons. Connect

a DVM to the right hand leg of the amplitude control (VR27) and adjust VR26 for <3mV.

Output stage adjustment must be carried out with great care to avoid circuit damage. Adjustment is

easiest with 2 voltmeters, one connected to TP15 and the other to TP14. With only one meter

available, alternately monitor the 2 test points. With no output waveform selected and the amplitude

control at minimum, slowly adjust VR32 and VR33 for 13.4V to 13.5V at the two test points. Note

14

that the voltage on these test points (TP14 and TP15) must not go below 13.3V otherwise Q28 and

Q29 will be damaged. VR32 and VR33 are interactive. Connect a DVM to TP16 and check that the

voltage on this point is <+/-1V. If not, slightly adjust VR32 or VR33 ensuring that the voltages on

TP14 and TP15 remain within 13.4V to 13.5V. Note that it may be necessary to add a low value

resistor in the meter lead close to TP14 and TP15 to prevent instability in the amplifier. Connect a

voltmeter to TP8 and adjust VR28 for <1mV. Connect a DVM to TP17 and adjust VR31 for <3mV.

Frequency multiplier to 100 range, squarewave, adjust VR30 for a flat top squarewave. Note that

the oscilloscope must be dc coupled for this adjustment.

Symmetry, select 1k range and adjust VR9 for equal mark: space ratio using the oscilloscope x10 X-

multiplier to increase resolution and the trigger slope switch.

Before commencing the vernier calibration procedure, turn the dial fully clockwise and check that

the 005 mark aligns with the mark on the front panel. If not, remove the cap in the centre of the

knob, using a knife blade and loosen the nut one to two turns. The knob can now be slid around on

its shaft to align the marks. Tighten the nut and check that the dial rotates freely against the front

panel. Refit the knob cap. On later instruments a PTFE thrust washer is fitted between the dial and

the front panel.

Dial Multiplier Adjust Reading

5.0 10k VR3 49.5 to 50.5 kHz

5.0 1M VC1 4.9 to 5.1 MHz

5.0 100k VC2 490 to 510 kHz

5.0 100 VR15 495 to 505 Hz

0.005 100k VR2 465 to 475 Hz

Sinewave distortion, select sinewave, 1k range, dial at 5.0. Display the distortion meter output on

CH2 of the oscilloscope. Position VR18 and VR22 fully clockwise. Adjust VR19 to give a flat

response between peaks and VR23 to give a symmetrical display. Note, this is not minimum on the

distortion meter, do not adjust these two presets to give minimum distortion at this stage.

15

Now slowly adjust VR18 and VR22 to remove these peaks. Check the distortion meter reading

which should now be less than 0.5%, typically 0.3%. If not, very slightly adjust the above 4 presets

to achieve this. (If the instrument fails to meet specification, check the following: amplitude, linearity

and symmetry of triangle wave at TP9; pre and output amplifiers.) Adjust VR20 to trim dc output of

the sinewave converter, measured on the oscilloscope or use a DVM connected to the 50 Ohm

output (TP17). Adjust VR21 to give 10.2V peak to peak into 50 Ohm.

Triangle amplitude, adjust VR25 to give 10.2V peak to peak into 50 Ohm.

Squarewave amplitude, ajust VR24 to give 10.2V peak to peak into 50 Ohm.

Servicing Notes

The white printing on the pcb also shows all the points which are top soldered. The circles

(teardrops) show track pins and the squares show which lead of a component is top soldered.

Insulating washers are fitted to IC22, Q32, Q34 and Q39. Heatsink compound is applied to

regulators IC22, Q32, Q34 and Q39 and between transistor pair Q20 and Q21.

To help with trouble shooting the power supply etc., an external current limited (500mA) power

supply of +/-17V can be used with its ground (0V) going to the TG501 ground (negative end of C50

or positive end of C51). The +17V supply is connected to the positive end of C50 and the -17V

supply is connected to the negative end of C51.

Typical current drain from the +/-17V supply with output at minimum is -200mA and +240mA.

Input power with 240V input, 90mA maximum.

This service manual specifically covers issue 5 pcbs. Pre issue 5 boards have the following

differences:

R35 100R was fitted in series with R36//C11 and not in the sinewave converter.

R142 was 4K7

pcb support brackets were not fitted.

16

Parts List

PCB Assembly - Main

Ref Description Part No

R1 10RJ W25 CF 23185-0100

R2 150KJ W25 CF 23185-4150

R3 43KJ W25 CF 23187-3430

R4 10KJ W25 CF 23185-3100

R5 39KJ W25 CF 23185-3390

R6 2K7F W25 MF 23202-2270

R7 2K7F W25 MF 23202-2270

R8 2K43F W25 MF 23202-2243

R9 1K37F W25 MF 23202-2137

R10 1K37F W25 MF 23202-2137

R11 2K32F W25 MF 23202-2232

R12 750RF W25 MF 23202-1750

R13 4K3J W25 CF 23187-2430

R14 4K3J W25 CF 23187-2430

R15 750RF W25 MF 23202-1750

R16 3K3J W25 CF 23185-2330

R17 47RJ W25 CF 23185-0470

R18 47RJ W25 CF 23185-0470

R19 2K7F W25 MF 23202-2270

R20 2K7F W25 MF 23202-2270

R21 47RJ W25 CF 23185-0470

R22 47RJ W25 CF 23185-0470

R23 374RF W25 MF 23202-1374

R24 1K5J W25 CF 23185-2150

R25 1K0J W25 CF 23185-2100

R26 100RJ W25 CF 23185-1100

R27 10RJ W25 CF 23185-0100

R28 10KF W25 MF 23202-3100

R29 22KJ W25 CF 23185-3220

R30 100KF W25 MF 23202-4100

R31 1M0F W25 MF 23202-5100

R32 10KJ W25 CF 23185-3100

R33 10RJ W25 CF 23185-0100

17

Ref Description Part No

R34 10RJ W25 CF 23185-0100

R35* 100RJ W25 CF 23185-1100

R36 1K0J W25 CF 23185-2100

R37 10KJ W25 CF 23185-3100

R38 470RJ W25 CF 23185-1470

R39 220RJ W25 CF 23185-1220

R40 1K5J W25 CF 23185-2150

R41 1K5J W25 CF 23185-2150

R42 820RJ W25 CF 23185-1820

R43 1K0J W25 CF 23185-2100

R44 1K2J W25 CF 23185-2120

R45 100RJ W25 CF 23185-1100

R46 330RJ W25 CF 23185-1330

R47 14K3F W25 MF 23202-3143

R48 220RF W25 CF 23185-1220

R49 681RF W25 MF 23202-1681

R50 124RF W25 MF 23202-1124

R51 124RF W25 MF 23202-1124

R52 681RF W25 MF 23202-1681

R53 220RF W25 MF 23202-1220

R54 14K3F W25 MF 23202-3143

R55 150RJ W25 CF 23185-1150

R56 1K0J W25 CF 23185-2100

R57 1K8J W25 CF 23185-2180

R58 3K0J W25 CF 23187-2300

R59 4K7J W25 CF 23185-2470

R60 1K8J W25 CF 23185-2180

R61 3K0J W25 CF 23187-2300

R62 2K2J W25 CF 23185-2220

R63 2K2J W25 CF 23185-2220

R64 1K2J W25 CF 23185-2120

R65 4K7J W25 CF 23185-2470

R66 4K7J W25 CF 23185-2470

R67 4K7J W25 CF 23185-2470

R68 4K7J W25 CF 23185-2470

18

Ref Description Part No

R69 4K7J W25 CF 23185-2470

R70 4K7J W25 CF 23185-2470

R71 2K2J W25 CF 23185-2220

R72 1K5J W25 CF 23185-2150

R73 33KJ W25 CF 23185-3330

R74 2K2J W25 CF 23185-2220

R75 100RJ W25 CF 23185-1100

R76 47RJ W25 CF 23185-0470

R77 7K5J W25 CF 23187-2750

R78 560RJ W25 CF 23185-1560

R79 100RJ W25 CF 23185-1100

R80 7K5J W25 CF 23187-2750

R81 91RJ W25 CF 23187-0910

R82 7K5J W25 CF 23187-2750

R83 7K5J W25 CF 23187-2750

R84 68RJ W25 CF 23185-0680

R85 7K5J W25 CF 23187-2750

R86 100RJ W25 CF 23185-1100

R87 47RJ W25 CF 23185-0470

R88 10KJ W25 CF 23185-3100

R89 5K6F W25 MF 23202-2560

R90 5K6F W25 MF 23202-2560

R91 220RJ W25 CF 23185-1220

R92 470RJ W25 CF 23185-1470

R93 1K8J W25 CF 23185-2180

R94 270KJ W25 CF 23185-4270

R95 150RJ W25 CF 23185-1150

R96 6K2J W25 CF 23187-2620

R97 6K2J W25 CF 23185-2620

R98 2K2J W25 CF 23185-2220

R99 3K6J W25 CF 23187-2360

R100 3K3J W25 CF 23185-2330

R101 680RJ W50 CF 23179-1680

R102 10RJ W25 CF 23185-0100

R103 22RJ W25 CF 23185-0220

19

Table of contents

Other TTI Inverter manuals

Popular Inverter manuals by other brands

TLS

TLS Omnia.9sg Preliminary manual

GÜDE

GÜDE GC 100 PM Translation of original operating instructions

MAER IDROPULITRICI

MAER IDROPULITRICI BYTURBO instruction manual

DieHard

DieHard 71496 owner's manual

Makita

Makita EG SERIES Instructions for use

Tamarack Solar

Tamarack Solar Ground Mount Kit installation manual