2021 TAMARACK SOLAR - REVISION 5 FM SYSTEM MANUAL

3

Tamarack Ground Mount System Features

• Designed for mounting photovoltaic (PV) arrays on the ground.

• Top clamps and rail attachments require the use of a single standard 1/2-inch socket

• 5050 Clamp for both mid-clamp and end-clamp use simplies ordering and stocking parts.

• Module clamps are spring loaded to ease module placement.

• Built-in wire management for module and microinverter cables

Tamarack Product Summary

The Tamarack Solar Ground Mount system is a visually appealing photovoltaic (PV) module installation system

that signicantly lowers PV module installation cost by allowing the installation professional to stock fewer

parts and to complete the installation in less time.

Certied to meet local and International Building Codes and ASCE/SEI-7

when installed in accordance with this manual.

ETL Listed to UL 2307 for bonding and grounding when in¬stalled in

accordance with this manual.

Rails, clamps, splices, and mounting devices are UL2703 Listed for

mounting at-plate Photovoltaic Modules and Panels

• Conforms to STD UL 2703 (2015) Standard for Safety First Edition: Mounting Systems, Mounting Devices,

Clamping/Retention Devices, and Ground Lugs for Use with Flat-Plate Photovoltaic Modules and Panels.

• Certied to CSA STD LTR AE-001-2012 Photovoltaic Module Racking Systems.

• Max Overcurrent Protective Device (OCPD) Rating: 20A

• Max Module Size: 25.6 ft²

• System Level Allowable Design Load Rating: meets minimum requirements of the standard (10 PSF down-

ward, 5 PSF upward, 5 PSF lateral). Actual system structural capacity is dened by PE stamped certication

letters.

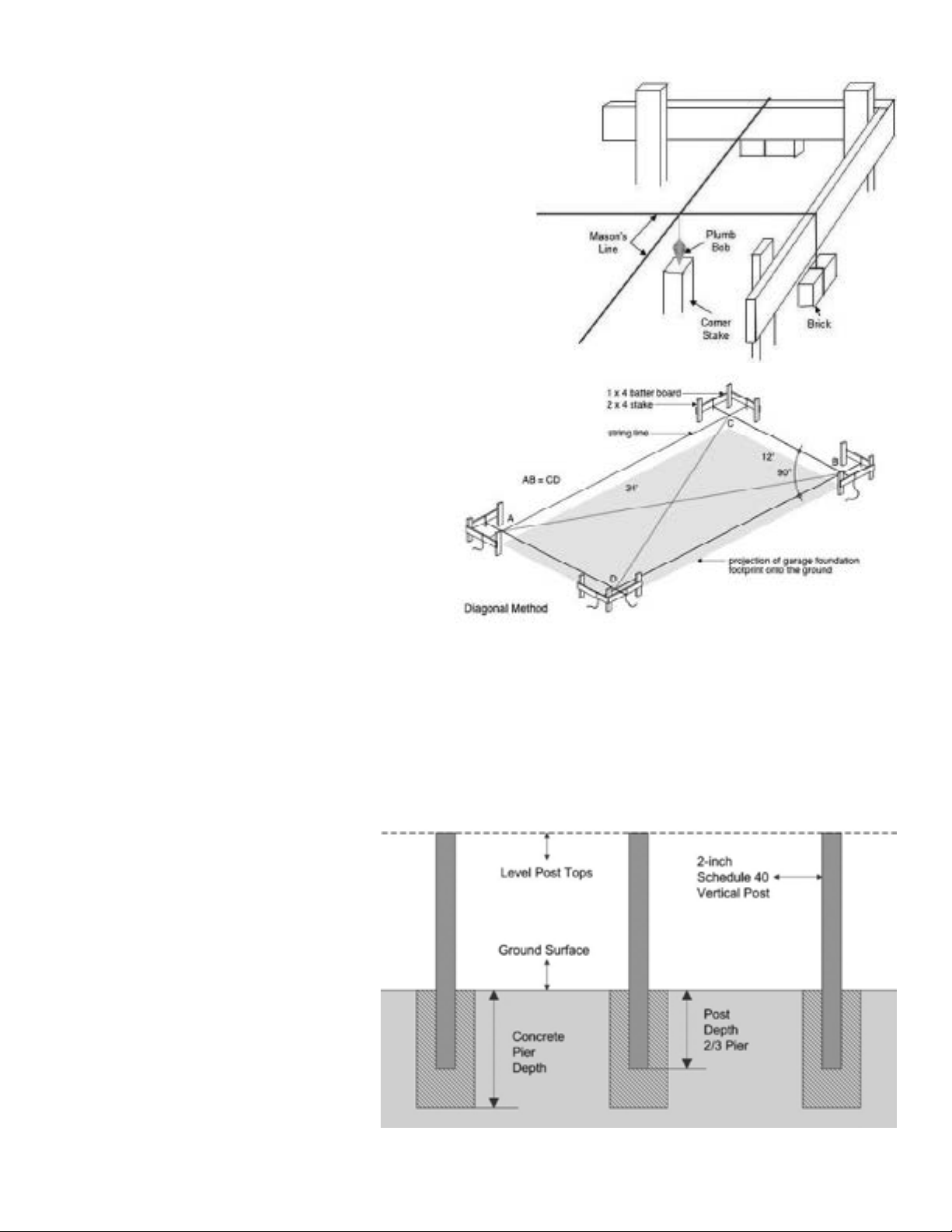

Tamarack Solar Ground Mounts use Hollaender® structural aluminum pipe ttings that combined with pipe

make stable, secure, corrosion-free mounting rack systems for both ground and roof mounted solar arrays. Hol-

laender’s Speed-Rail® ttings are ideal for this application because the aluminum-magnesium 535 alloy used

to manufacture them is the most corrosion resistant aluminum alloy available. It can be used with steel without

any concern for galvanic corrosion. Hollaender Speed-Rail® ttings are now approved as UL 2703 Recognized

Components under ETL Mark 5006568. The system uses set-screws that penetrate the surface of the pipe to

ensure that ttings are electrically bonded to pipe and bracing, thereby eliminating the need for added bonding

components such as jumpers to provide a grounding path.

This manual describes proper installation procedures and provides necessary standards required for product

reliability. Warranty details are available on our website. www.tamaracksolar.com

All installers must thoroughly read this manual and have a clear understanding of the installation procedures

prior to installation. Failure to follow these guidelines may result in property damage, bodily injury or even

death.

5014275