The Ecotype Covering System installation ...............................................12

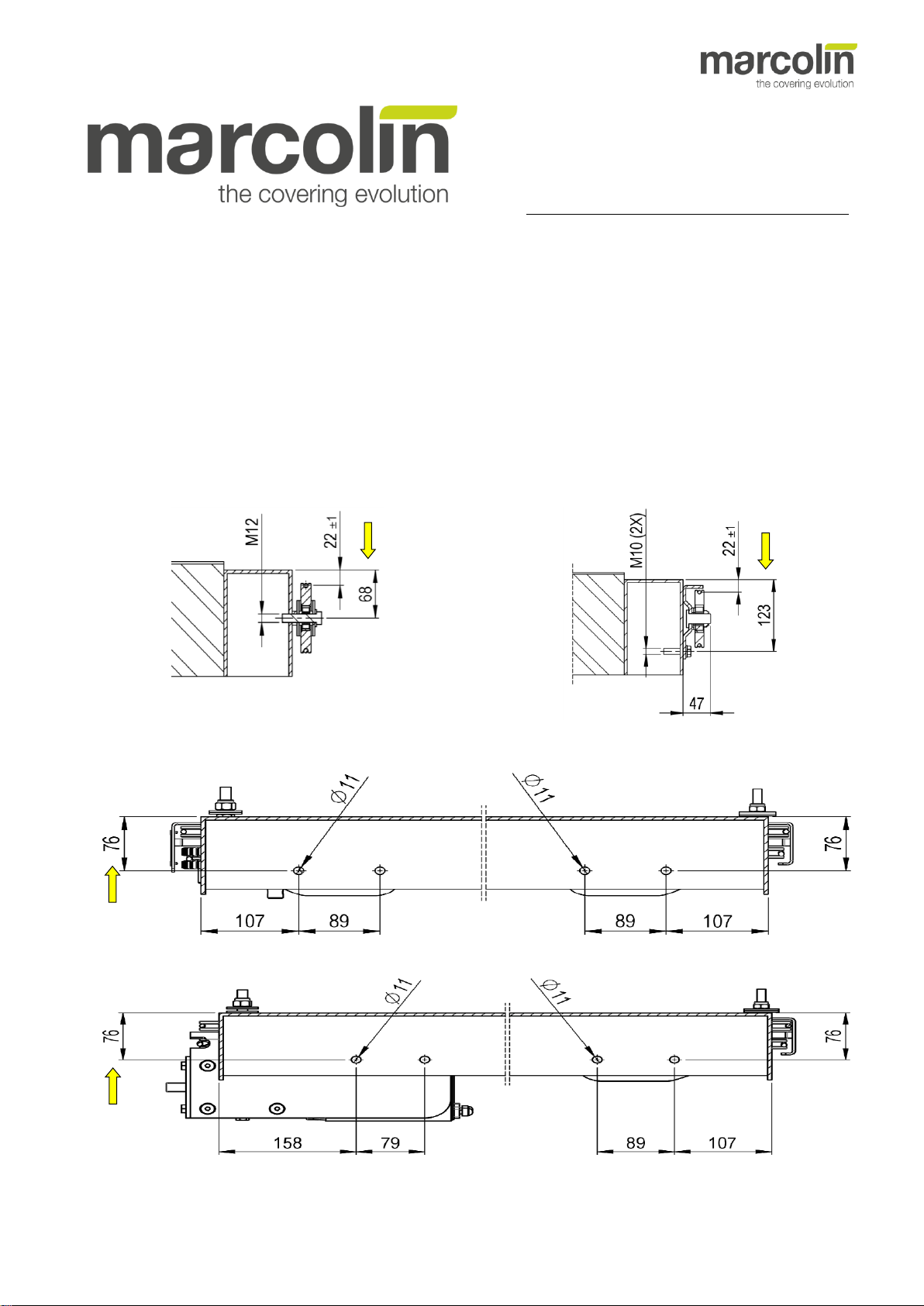

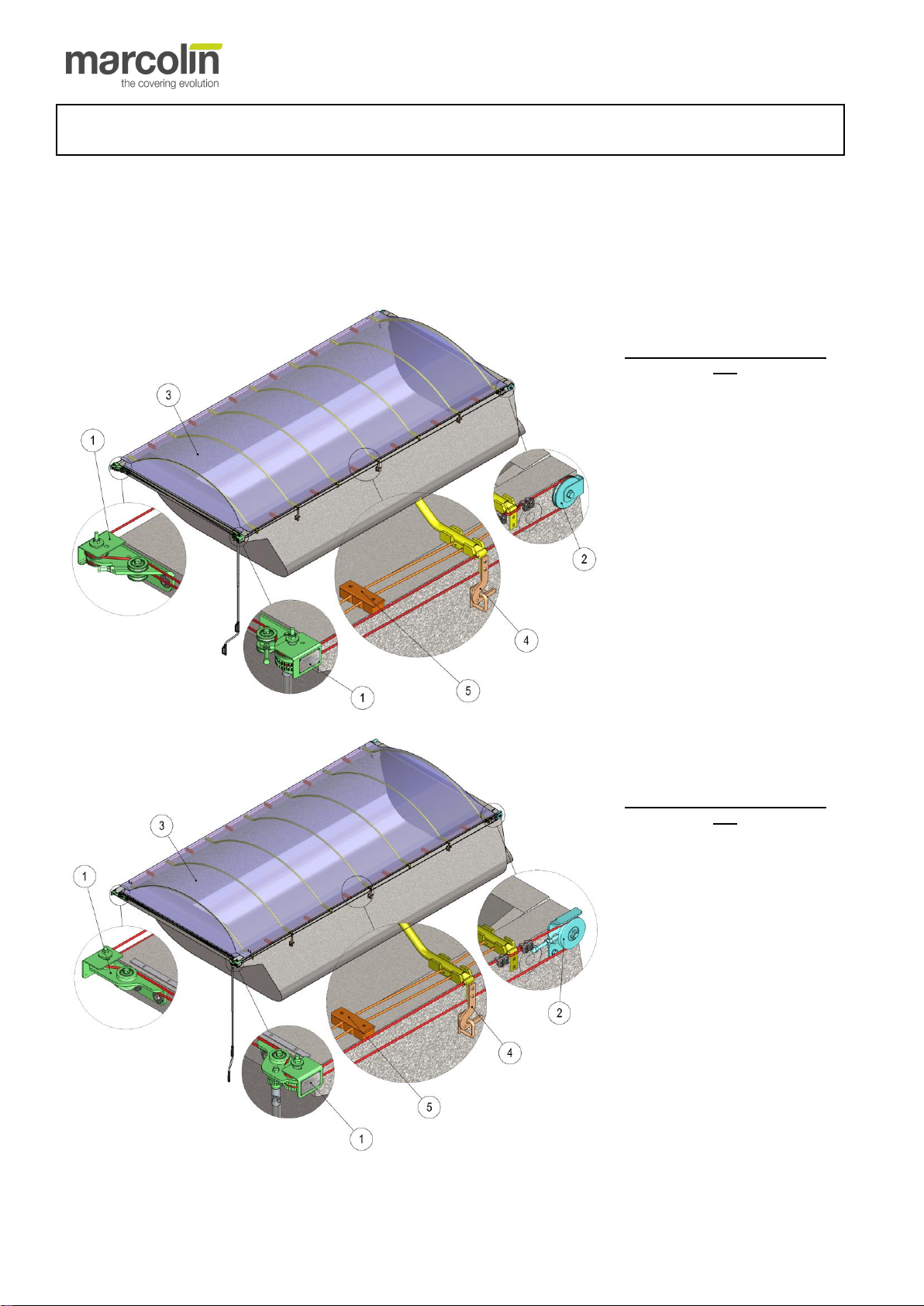

3.1 Fitting the rear pulleys - Hand-operated version for body < 8 m................................................................. 12

3.1.1 Fitting the rear pulleys in case of “STANDARD CABLE SYSTEM”......................................................................12

3.1.2 Fitting of the rear pulleys in case of “LOWERED CABLE SYSTEM” ...................................................................12

3.2 Installing the tensioning plates - Hand-operated version for body > 8 m and electrical version................. 13

3.2.1 Installation of the rear tensioning plates with the "NORMAL CABLE" option....................................................... 13

3.2.2 Installation of the rear tensioning plates with the "LOWERED CABLE" option....................................................13

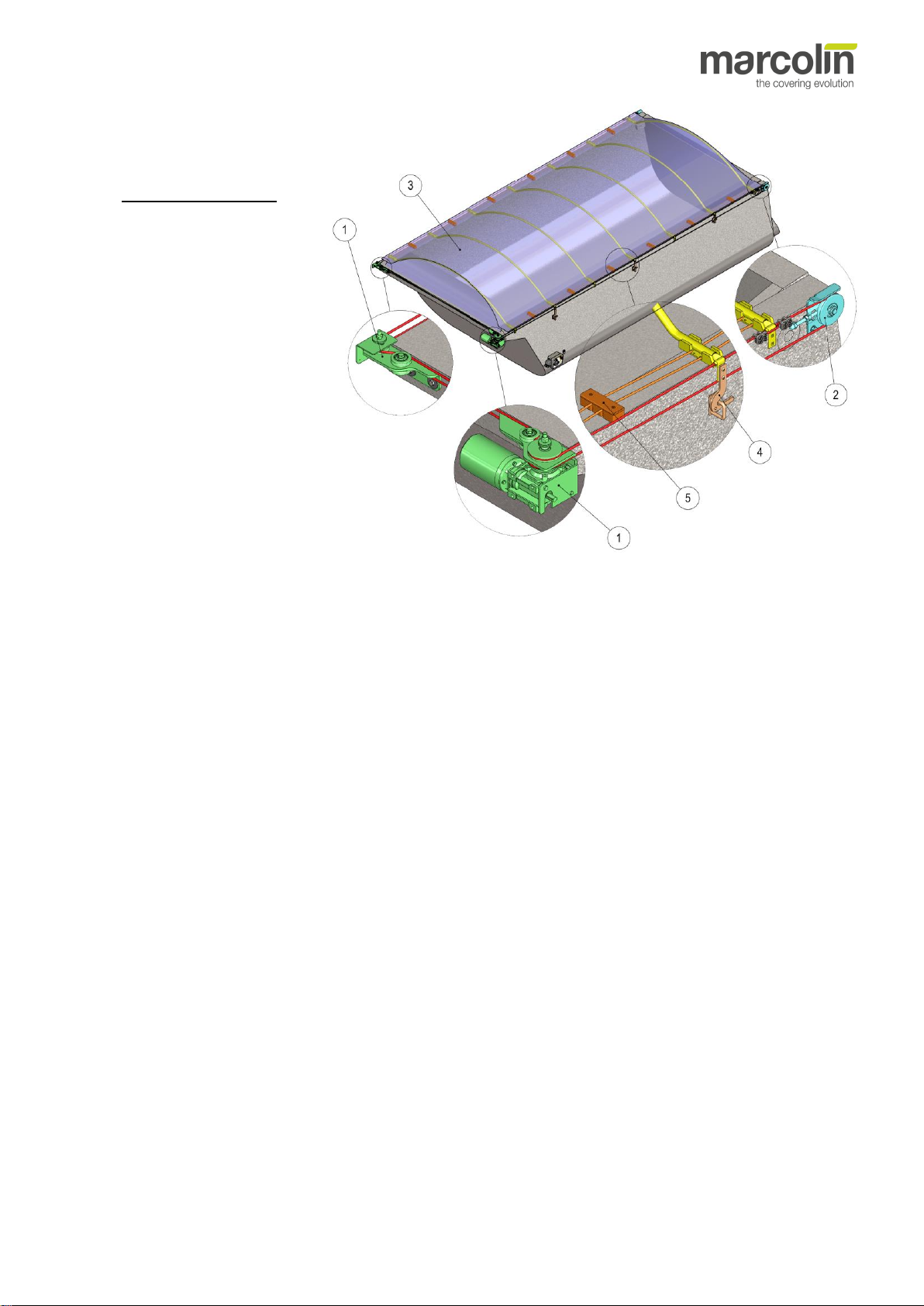

3.3 Driving system installation........................................................................................................................... 14

3.3.1 Versatility of the covering system........................................................................................................................ 14

3.3.2 Working and preparation of the cab guard with “STANDARD CABLES” .............................................................14

3.3.3 Working and preparation of the cab guard with “LOWERED CABLES”............................................................... 16

3.3.4 Supports fitting..................................................................................................................................................... 17

3.4 Installation of the steel cable ....................................................................................................................... 19

3.4.1 Run of the steel cable..........................................................................................................................................19

3.4.2 Cable fastening.................................................................................................................................................... 22

3.4.3 Clamping the pulling bow.....................................................................................................................................23

3.4.4

Steel cable tightening up .....................................................................................................................................24

3.5 Fastening the operating rod (hand-operated covering system)................................................................... 26

3.6 Tarpaulin fastening ...................................................................................................................................... 27

3.7 Lateral hooking system for the covering...................................................................................................... 28

3.7.1 Standard closure with automatic hooking............................................................................................................28

3.7.2 Hermetic closure with elastic strings.................................................................................................................... 30

3.8 Electrical wiring for Ecotype Covering System............................................................................................ 31

3.8.1 Control Box models description........................................................................................................................... 32

3.8.2 Installation of the electrical components..............................................................................................................33

3.9 Switch panel of the machine........................................................................................................................ 35

3.9.1 Description of the Control Box.............................................................................................................................35

3.9.2 Emergency pushbutton key, safety shutdown ..................................................................................................... 36

3.9.3 Control switches of the Control Box for operators ...............................................................................................36

3.9.4 Description of the radio control system................................................................................................................36

3.9.5 Reprogramming the "TX MARCOLIN" radio remote control................................................................................ 37

3.9.6 Unfold the Ecotype tarpaulin for covering the tipper body................................................................................... 37

3.9.7 Interruption of machine operations ...................................................................................................................... 37

3.9.8 How do you stop the machine in case of emergency? ........................................................................................37

3.9.9 Restoring of standard operative conditions.......................................................................................................... 38

3.9.10 Machine stop in safety conditions......................................................................................................................38

3.9.11 Retraction of the Ecotype tarpaulin for uncovering the tipper body ...................................................................38

3.9.12 How do you interrupt the machine operations? .................................................................................................38

3.9.13 How do you stop the machine in case of emergency? ......................................................................................38

3.9.14 Machine stop in safety conditions......................................................................................................................38

3.9.15 In case of empty tipper body.............................................................................................................................. 39

3.10 What is to be done, when the electric operated handling system doesn’t work?...................................... 40

3.10.1 Replacement of the internal fuse in emergency case........................................................................................40