- 3 -

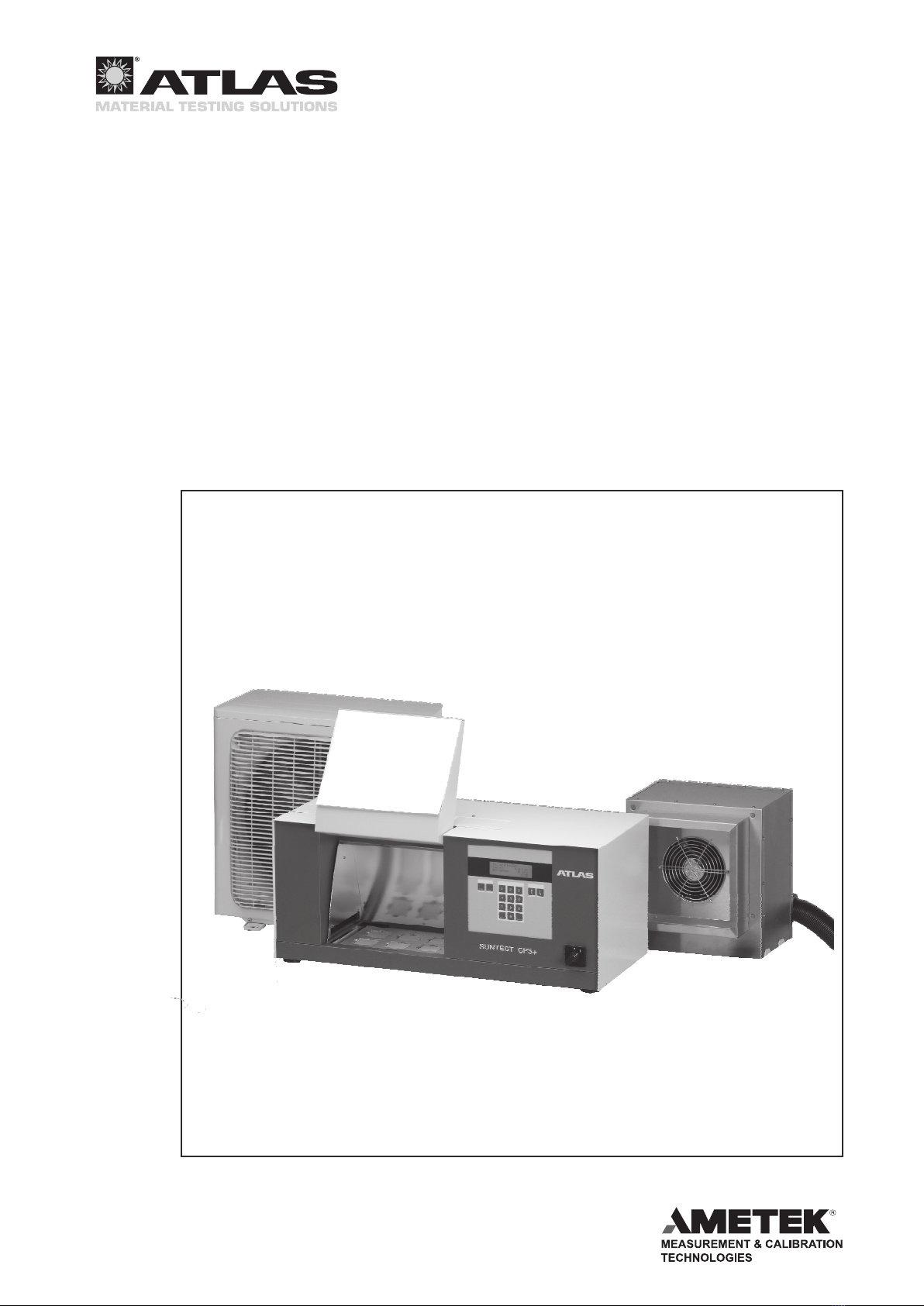

Operating Manual SunCool for SUNTEST® CPS+

Contents Page

1 Instructions for safe operation ...................................................................................................................... 5

1.1 Explanation of the symbols .......................................................................................................................... 7

1.2 General safety instructions ........................................................................................................................... 8

1.3 Safety instructions for coolants .................................................................................................................. 10

2 Delivery of the instrument ............................................................................................................................ 12

2.1 Packaging .................................................................................................................................................. 12

2.2 Scope of delivery ........................................................................................................................................ 12

3 Requirements for the installation site ......................................................................................................... 13

3.1 Room climate ............................................................................................................................................. 13

3.2 Room ventilation ........................................................................................................................................ 13

3.3 Installation .................................................................................................................................................. 13

3.4 Heat sources .............................................................................................................................................. 14

3.5 Transport .................................................................................................................................................... 14

3.6 Effects of vibration ...................................................................................................................................... 14

3.7 Installation and space requirements .......................................................................................................... 15

4 Description of the instrument ...................................................................................................................... 16

4.1 SunCool Components ................................................................................................................................ 16

5 Functional description .................................................................................................................................. 17

5.1 SunCool funktionality ................................................................................................................................. 17

5.2 Setting the test parameters ........................................................................................................................ 17

6 SunCool start up ........................................................................................................................................... 18

6.1 Preparatory measures ................................................................................................................................ 18

6.2 Starting for the rst time ............................................................................................................................. 19

6.3 Checking the instrument components ........................................................................................................ 19

6.4 Closing the coolant circuit .......................................................................................................................... 20

6.5 Indoor installation of the liqueer unit ......................................................................................................... 21

6.6 Outdoor installation of the liqueer unit ...................................................................................................... 22

6.7 Main power supply ..................................................................................................................................... 25

7 Operation ....................................................................................................................................................... 26

7.1 Menu structure of the device controller ...................................................................................................... 26

7.2 Setting the SunCool accessory .................................................................................................................. 26

7.3 Starting the cooling process ....................................................................................................................... 27

8 Taking out of operation ................................................................................................................................. 28

8.1 Switching off the instrument ....................................................................................................................... 28

8.2 Switching off the instrument in an emergency ........................................................................................... 28

8.3 Decommissioning of instrument ................................................................................................................. 28

9 Troubleshooting ............................................................................................................................................ 30

9.1 Error messages and troubleshooting ......................................................................................................... 30

10 Maintenance .................................................................................................................................................. 30

10.1 Inspection ................................................................................................................................................... 30

10.2 Repair ......................................................................................................................................................... 30

10.3 Maintenance ............................................................................................................................................... 31

10.4 Cleaning ..................................................................................................................................................... 31

11 Technical Data ............................................................................................................................................... 32

12 Accessories .................................................................................................................................................. 33

13 Declaration of conformity ............................................................................................................................ 34

14. Notes ............................................................................................................................................................. 35