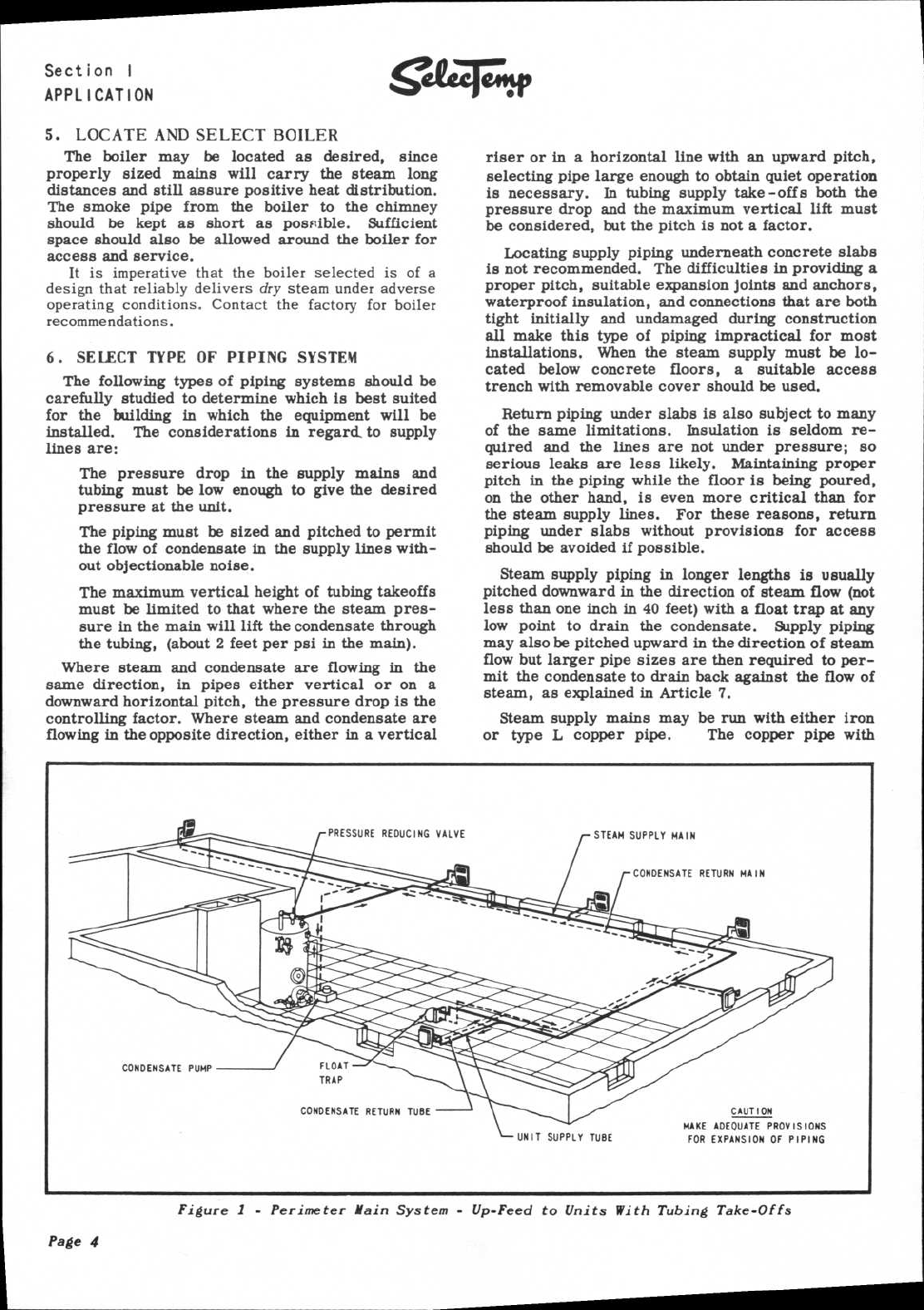

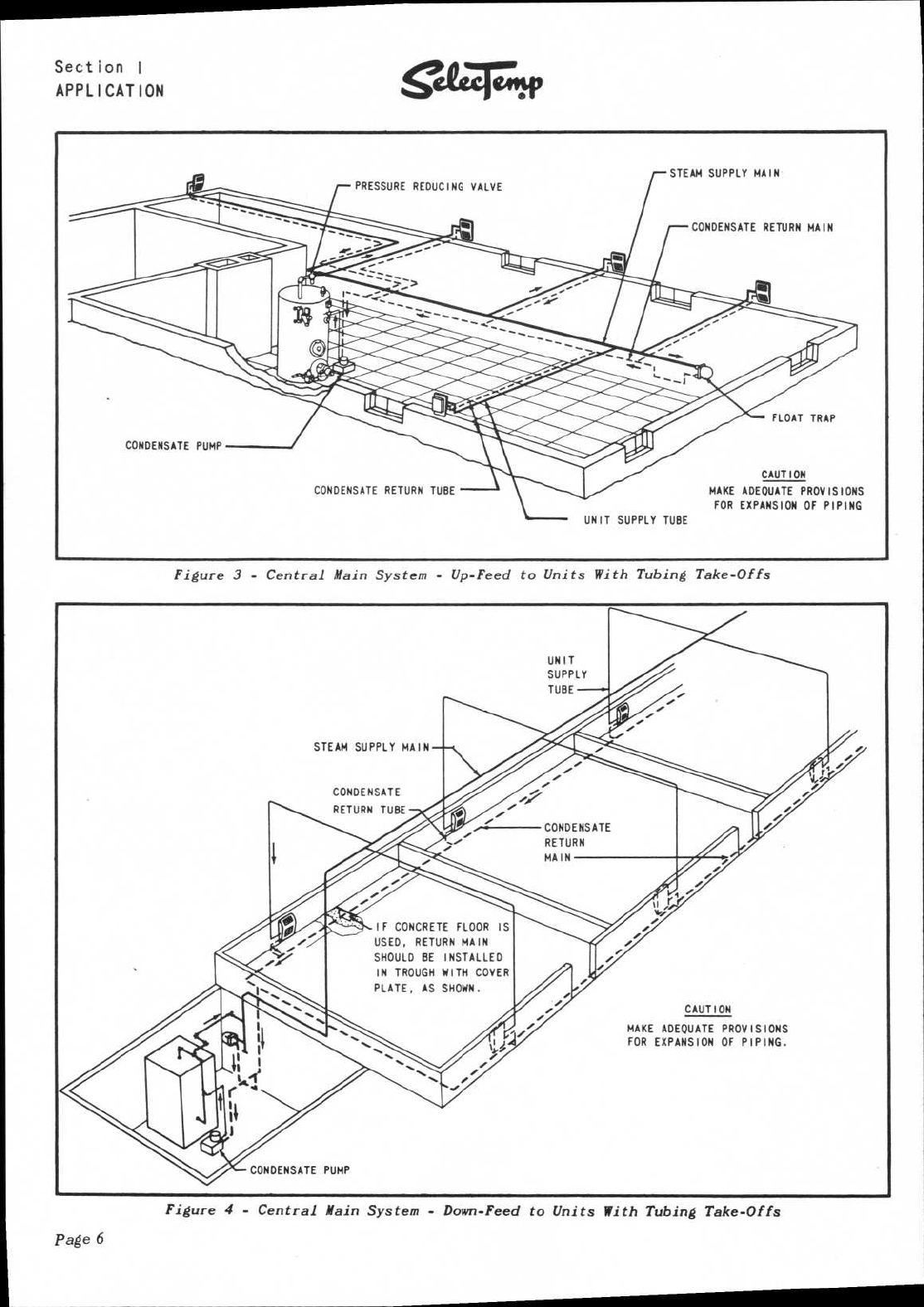

CAUTION

MAKE ADEQUATE PROVISIONS

FOR EXPANSION OF PIPING

CONDENSATE RETURN TUBE

UNIT SUPPLY TUBE

PRESSURE REDUCING VALVE

STEAM SUPPLY MAIN

CONDENSATE RETURN MAIN

CONDENSATE PUMP

FLOAT

TRAP

Section I

APPLICATION

Sualz.tx

5.

LOCATE AND SELECT BOILER

The boiler may be located as desired, since

properly sized mains will carry the steam long

distances and still assure positive heat distribution.

The smoke pipe from the boiler to the chimney

should be kept as short as possible. Sufficient

space should also be allowed around the boiler for

access and service.

It

is imperative that the boiler selected is of a

design that reliably delivers

dry

steam under adverse

operating conditions. Contact the factory for boiler

recommendations.

6.

SELECT TYPE OF PIPING SYSTEM

The following types of piping systems should be

carefully studied to determine which is best suited

for the building in which the equipment will be

installed. The considerations in regard, to supply

lines are:

The pressure drop in the supply mains and

tubing must be low enough to give the desired

pressure at the unit.

The piping must be sized and pitched to permit

the flow of condensate in the supply lines with-

out objectionable noise.

The maximum vertical height of tubing takeoffs

must be limited to that where the steam pres-

sure in the main will lift the condensate through

the tubing, (about 2 feet per psi in the main).

Where steam and condensate are flowing in the

same direction, in pipes either vertical or on a

downward horizontal pitch, the pressure drop is the

controlling factor. Where steam and condensate are

flowing in the opposite direction, either in a vertical

riser or in a horizontal line with an upward pitch,

selecting pipe large enough to obtain quiet operation

is necessary. In tubing supply take -offs both the

pressure drop and the maximum vertical lift must

be considered, but the pitch is not a factor.

Locating supply piping underneath concrete slabs

is not recommended. The difficulties in providing a

proper pitch, suitable expansion joints and anchors,

waterproof insulation, and connections that are both

tight initially and undamaged during construction

all make this type of piping impractical for most

installations. When the steam supply must be lo-

cated below concrete floors, a suitable access

trench with removable cover should be used.

Return piping under slabs is also subject to many

of the same limitations. Insulation is seldom re-

quired and the lines are not under pressure; so

serious leaks are less likely. Maintaining proper

pitch in the piping while the floor is being poured,

on the other hand, is even more critical than for

the steam supply lines. For these reasons, return

piping under slabs without provisions for access

should be avoided if possible.

Steam supply piping in longer lengths is usually

pitched downward in the direction of steam flow (not

less than one inch in 40 feet) with a float trap at any

low point to drain the condensate. Supply piping

may also be pitched upward in the direction of steam

flow but larger pipe sizes are then required to per-

mit the condensate to drain back against the flow of

steam, as explained in Article 7.

Steam supply mains may be run with either iron

or type L copper pipe.

The copper pipe with

Figure 1 - Perimeter Main System - Up-Feed to Units With Tubing Take-Offs

Page

4