Side 2 af 33

Turbovex A/S

Industrivej 45, DK –9600 Aars

Telefon: +45 96 98 14 62

e-mail: info@turbovex.dk –www.turbovex.dk

Contents

1.0 General information.....................................................................................................3

1.1 Foreword....................................................................................................................3

1.2 Field of application .....................................................................................................3

1.3 Scope of delivery........................................................................................................3

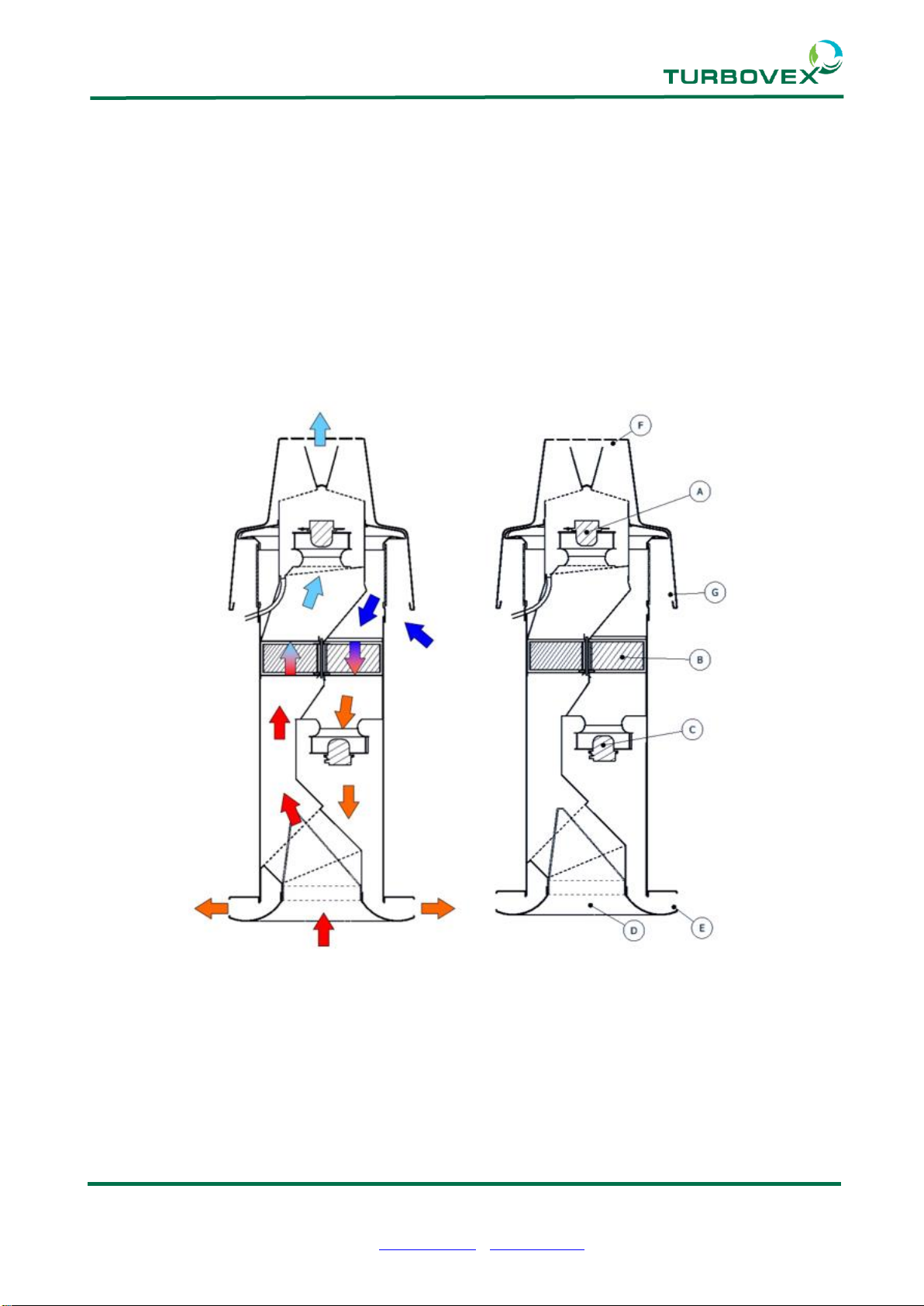

1.4 Function of the unit.....................................................................................................4

2.0 Installation....................................................................................................................5

2.1 Dimensions ................................................................................................................5

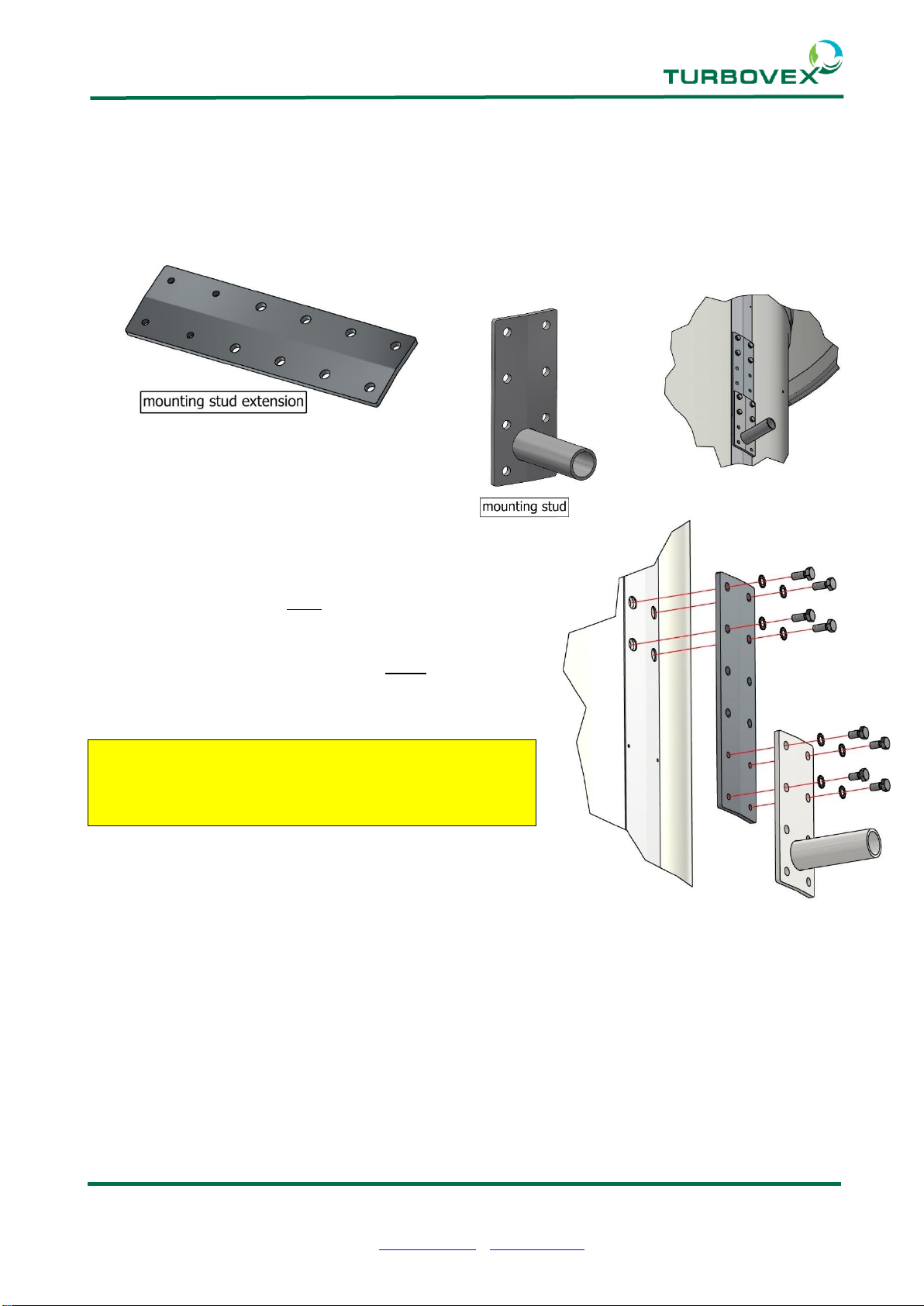

2.2 Mounting stud extensions...........................................................................................6

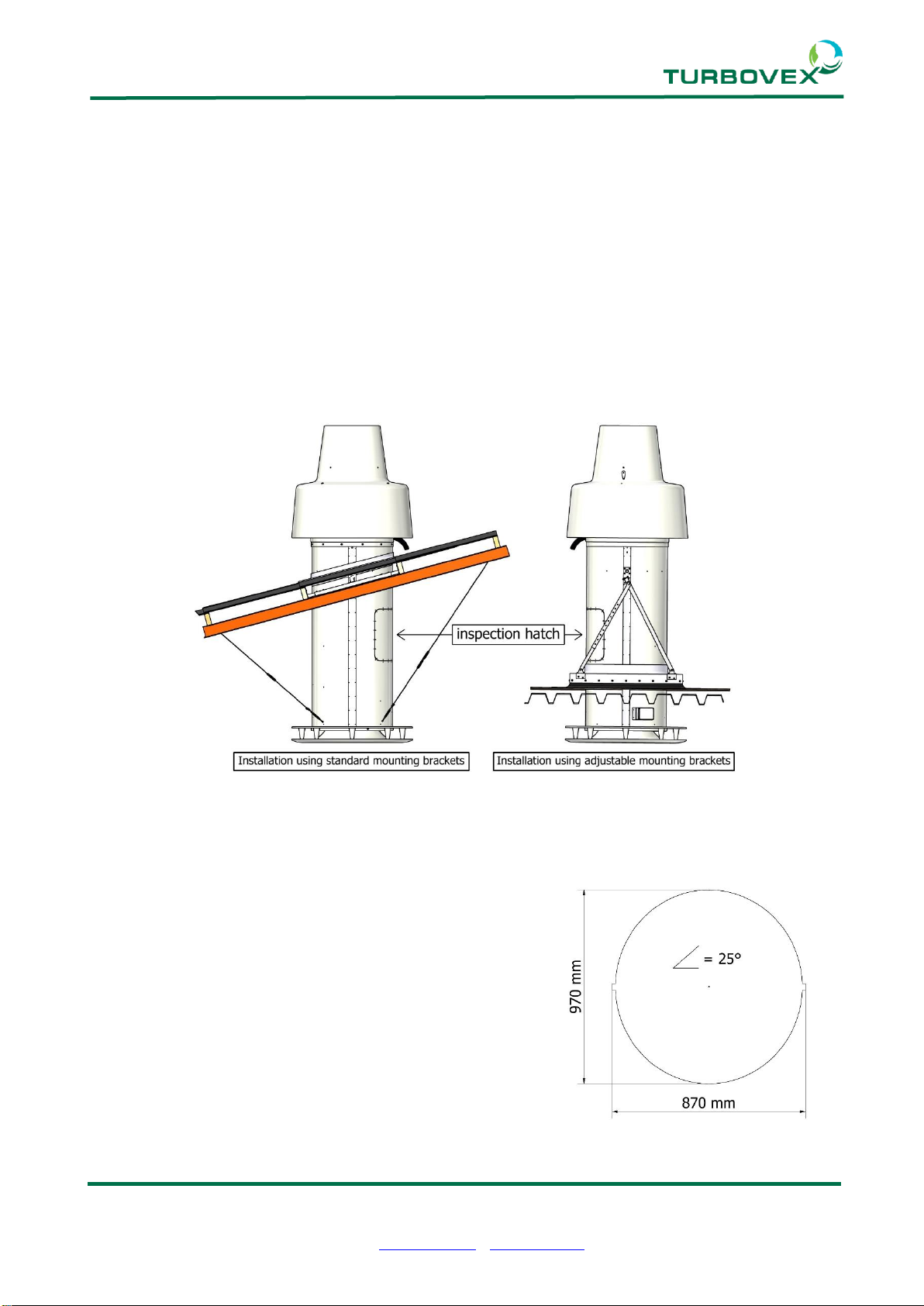

2.3 Placement..................................................................................................................7

2.4 Template....................................................................................................................7

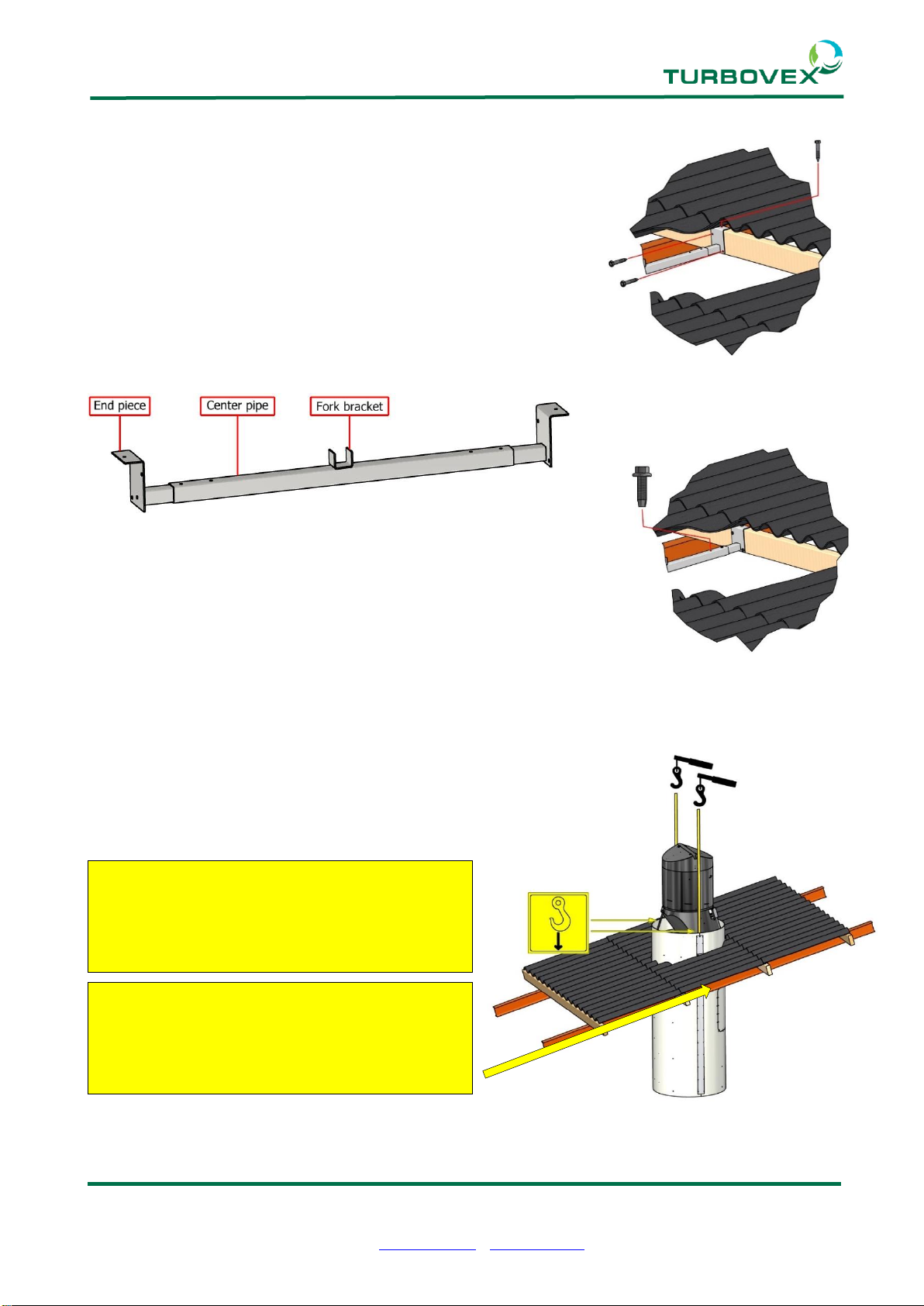

2.5 Installing the unit(standard mounting brackets)..........................................................8

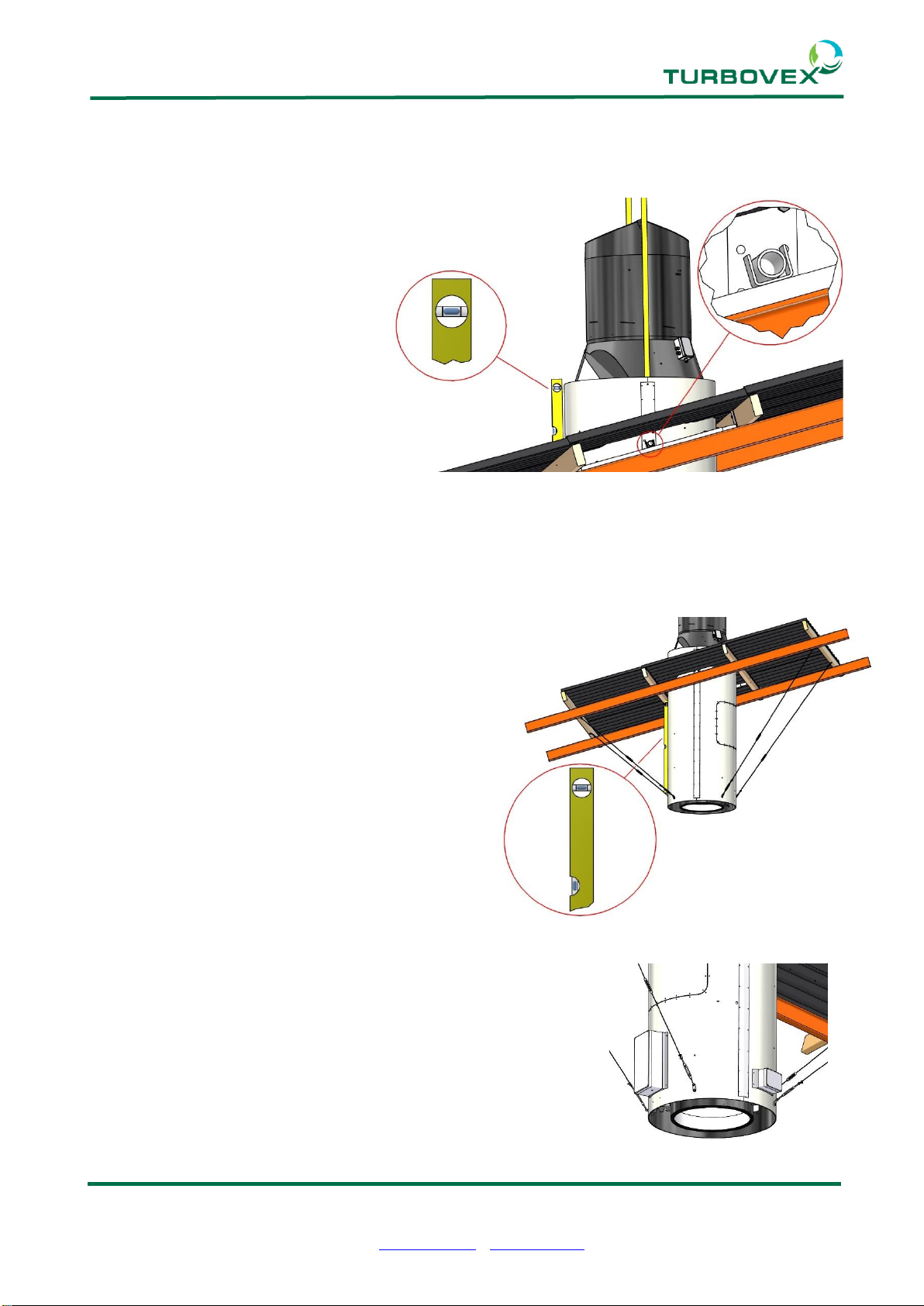

2.6 Installing the unit(adjustable mounting brackets) .....................................................14

2.7 Installation of bottom extension................................................................................20

2.8 Installation of top extension......................................................................................22

2.9 Thermal insulation against condensation and loss of energy...................................23

3.0 Technical specifications ...........................................................................................24

3.1 Unit...........................................................................................................................24

4.0 Electrical wiring diagrams ........................................................................................25

5.0 Service........................................................................................................................29

5.1 Maintenance inspections..........................................................................................29

5.2 Service Checklist......................................................................................................30

5.3 Filter change ............................................................................................................31

6.0 Declaration of conformity .........................................................................................33