Turtle Tough: Total Suspend Solids Sensor Manual

Chapter 2. Digital Operation 8 Revised: 7 October 2022

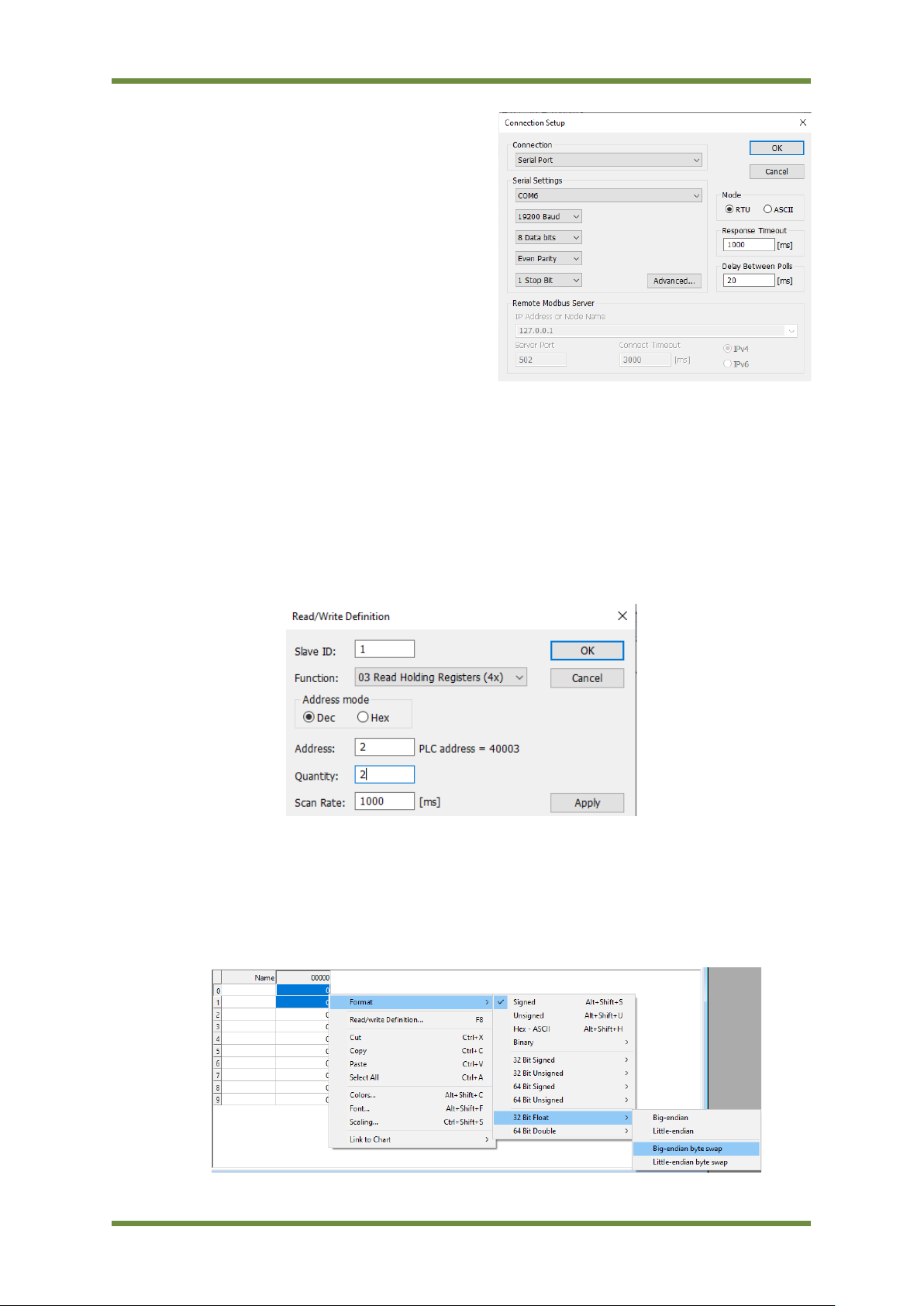

2.3.1 | Reading Values Using Modbus Poll:

The third-party program “Modbus Poll” can be used to

diagnose and set up the sensor. It is the simplest

method of communication to the Turbidity Sensor and

shall be used in this document for demonstration

purposes. To begin, connect the sensor to a PC using a

Turtle Tough Windows Interface Box. Once connected

open Modbus Poll and connect to the sensor using the

following settings: 19200 Baud Rate, 8 Data Bits, Even

Parity and 1 Stop Bits. Ensure the correct COM port is

selected.

2.3.2 | Reading the TSS value using Modbus Poll:

1) In the menu at the top of the application, select “Setup” then “Read/Write Definitions”.

2) In the menu set the following parameters:

•Slave Address = 1 (or whatever the slave address of your sensor is).

•Function = “03 Read Holding Registers”.

•Address = 2

•Quantity = 2.

3) This will read the first two holding registers on the sensor. These holding registers contain a

32-bit floating point representation of the TSS value stored in the IEEE754 format (see above).

To convert the IEEE754 to a single floating-point number, select the two registers then right-

click them and navigate to Format -> 32 Bit Float -> Little-endian byte swap. This will combine

the two registers and display the TSS value.