2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Detection zone�����������������������������������������������������������������������������������������������5

4 Function���������������������������������������������������������������������������������������������������������������6

4�1 IO-Link �����������������������������������������������������������������������������������������������������������7

4�1�1 General information ������������������������������������������������������������������������������7

4�1�2 Functions only available via IO-Link communication����������������������������7

4�1�3 Set-up via IO-Link���������������������������������������������������������������������������������7

4�1�4 Process data via IO-Link ����������������������������������������������������������������������7

4�2 Defined state in case of a fault ����������������������������������������������������������������������8

4�3 Operating modes �������������������������������������������������������������������������������������������8

4�3�1 2-wire operation������������������������������������������������������������������������������������8

4�3�2 3-wire operation������������������������������������������������������������������������������������8

4�4 Analogue output���������������������������������������������������������������������������������������������8

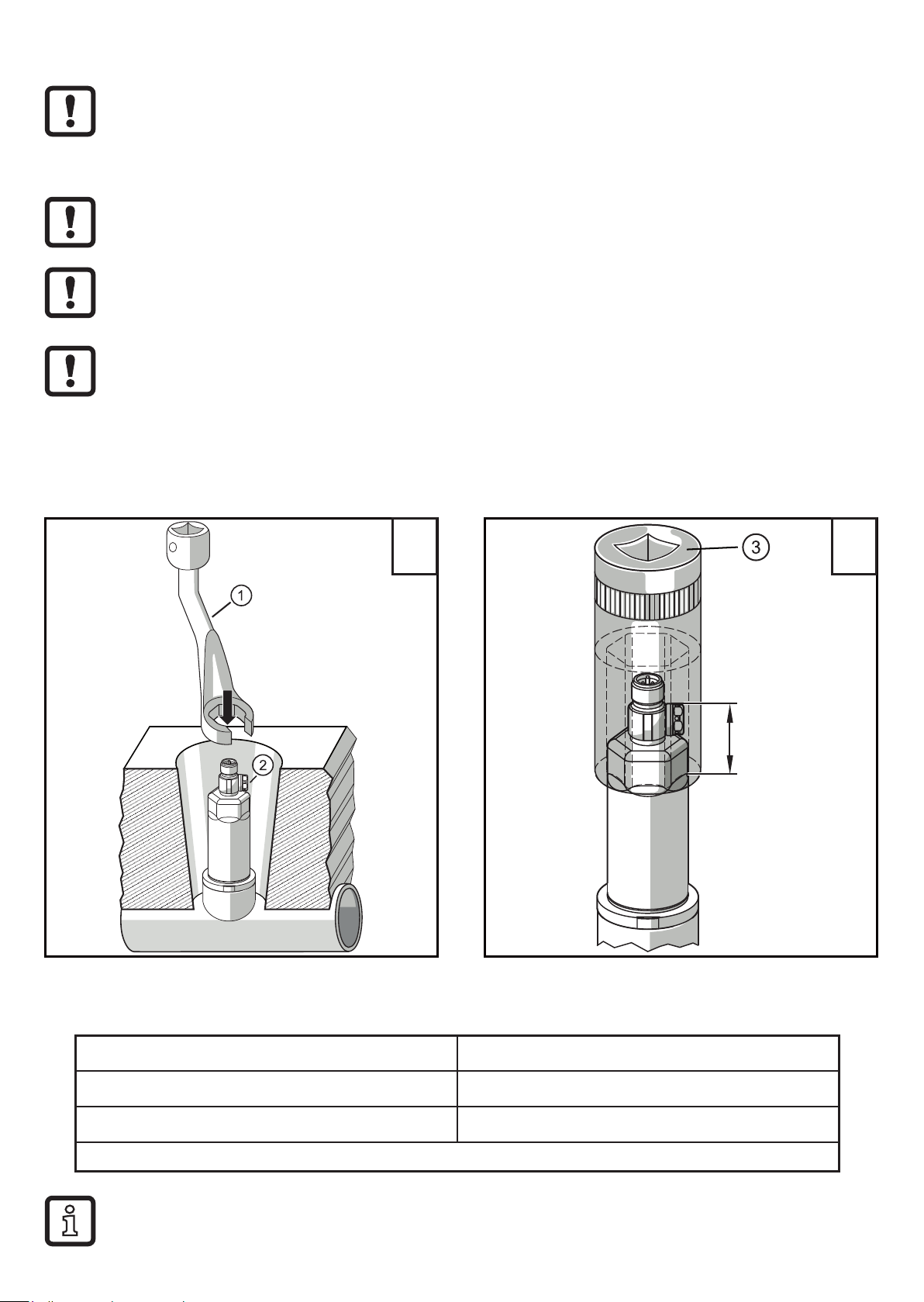

5 Installation����������������������������������������������������������������������������������������������������������10

5�1 G1A Aseptoflex Vario adaptation (PM17xx)������������������������������������������������� 11

5�2 Use in hygienic areas to 3-A������������������������������������������������������������������������12

5�3 Use in hygienic areas to EHEDG ����������������������������������������������������������������13

5�4 G1A sealing cone connection (PM16xx)������������������������������������������������������14

5�5 Protective cover�������������������������������������������������������������������������������������������15

5�5�1 Function ventilation diaphragm�����������������������������������������������������������15

5�5�2 Orientation of the filter cover ��������������������������������������������������������������15

5�6 Filter cover���������������������������������������������������������������������������������������������������16

6 Electrical connection������������������������������������������������������������������������������������������18

7 Parameter setting ����������������������������������������������������������������������������������������������19

7�1 Parameter setting via PC�����������������������������������������������������������������������������19

7�2 Parameter setting via the memory plug�������������������������������������������������������19

7�3 Teach offset with the teach button ���������������������������������������������������������������20

7�3�1 Scale analogue value �������������������������������������������������������������������������21

7�3�2 Select the standard unit of measurement (option)������������������������������21

7�4 User settings (optional)��������������������������������������������������������������������������������21