V1.0 2 of 22 04/01/2009

General Description

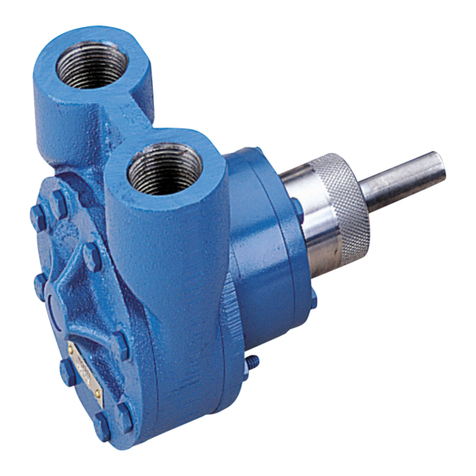

Model AC

Model AC pumps are available in six sizes, ranging in capacity from 2 to 84 gpm with

differential pressures to 100 psi. The maximum discharge pressure capability is 125 psi.

They have an integrally cast mounting foot and are supplied in four different mounting

styles. This pump is suitable for driving at direct motor speeds and will pump equally well

in either direction of rotation (unless supplied with an internal relief valve). It is equipped

with a sleeve bushing, aluminum packing and an adjustable packing gland.

Model C1G

Model C1G is similar to model AC except that it is equipped with spring loaded V type

leather packing. Model C1G pumps have the packing chamber vented to the suction side

of the pumping zone. Therefore, the pump must operate in the direction for which it is

assembled. Model C1G is available in six sizes, ranging in capacity from 2 to 84 gpm with

differential pressures to 100 psi. The maximum discharge pressure capability is 125 psi.

Like the model AC, these pumps are available in four different mounting styles.

Models C1E, C1EN, CIF and C1FA

Model C1E and C1F pumps are sleeve bushing lip seal units designed for direct drive

service. Model C1E has an integral foot mount. Model C1F is a flange mount pump. Model

C1FA pumps are similar to model C1F but are supplied without a seal. Model C1EN

pumps are sleeve and ball bearing units with a lip seal and integral mounting foot

designed for indirect (belt, chain, gear) drive.

The seal chamber on these pumps is vented to the suction side of the pumping zone.

Therefore, the pump must operate in the direction for which it is assembled.

All models are available in five sizes, ranging in capacity from 6 to 84 gpm with differential

pressures to 100 psi. The maximum discharge pressure capability is 100 psi.

Model C1B

Model C1B is a flange mount pump with two sleeve type bushings and a mechanical seal.

It is bi-rotational, unless equipped with an internal relief valve. This pump is available in

five sizes, with capacities from 6 to 84 gpm and differential pressures to 150 psi. The

maximum discharge pressure capability is 300 psi. A mounting foot is optional.

Model CKIB

Model CK1B pumps are equipped with a mechanical seal and incorporate heavy-duty

features, including special double bearing construction with an inboard double ball bearing

and an outboard roller bearing. This pump is available in five sizes, with capacities from 6

to 84 gpm and differential pressures to 250 psi. The maximum discharge pressure

capability is 300 psi. A mounting foot is optional.

The seal chamber is vented to the suction side. Therefore, the pump must operate in the

direction for which it is assembled.