Contents

1. Dev ce descr pt on...................................................................................................................................... 5

2. Cond t ons of safe operat on..................................................................................................................... 6

2.1. Warnings............................................................................................................................................... 6

2.2. Basic r les............................................................................................................................................ 6

2.3. Protection against electric shock.......................................................................................................... 7

2.4. Operation list after receiving the device................................................................................................7

2.5. Environmental conditions...................................................................................................................... 7

2.6. Recycle................................................................................................................................................. 7

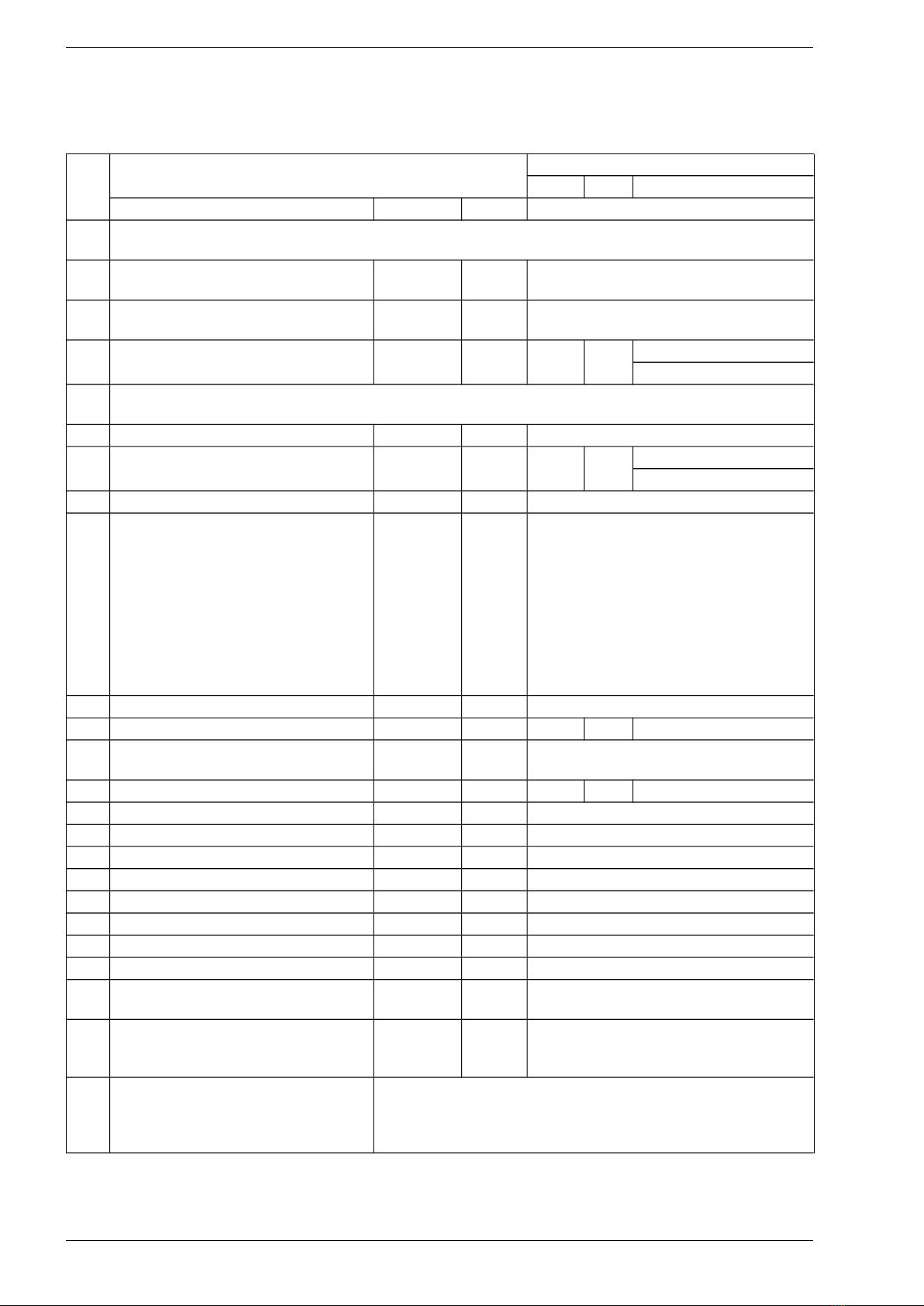

3. Spec f cat on............................................................................................................................................... 8

3.1. Technical data....................................................................................................................................... 8

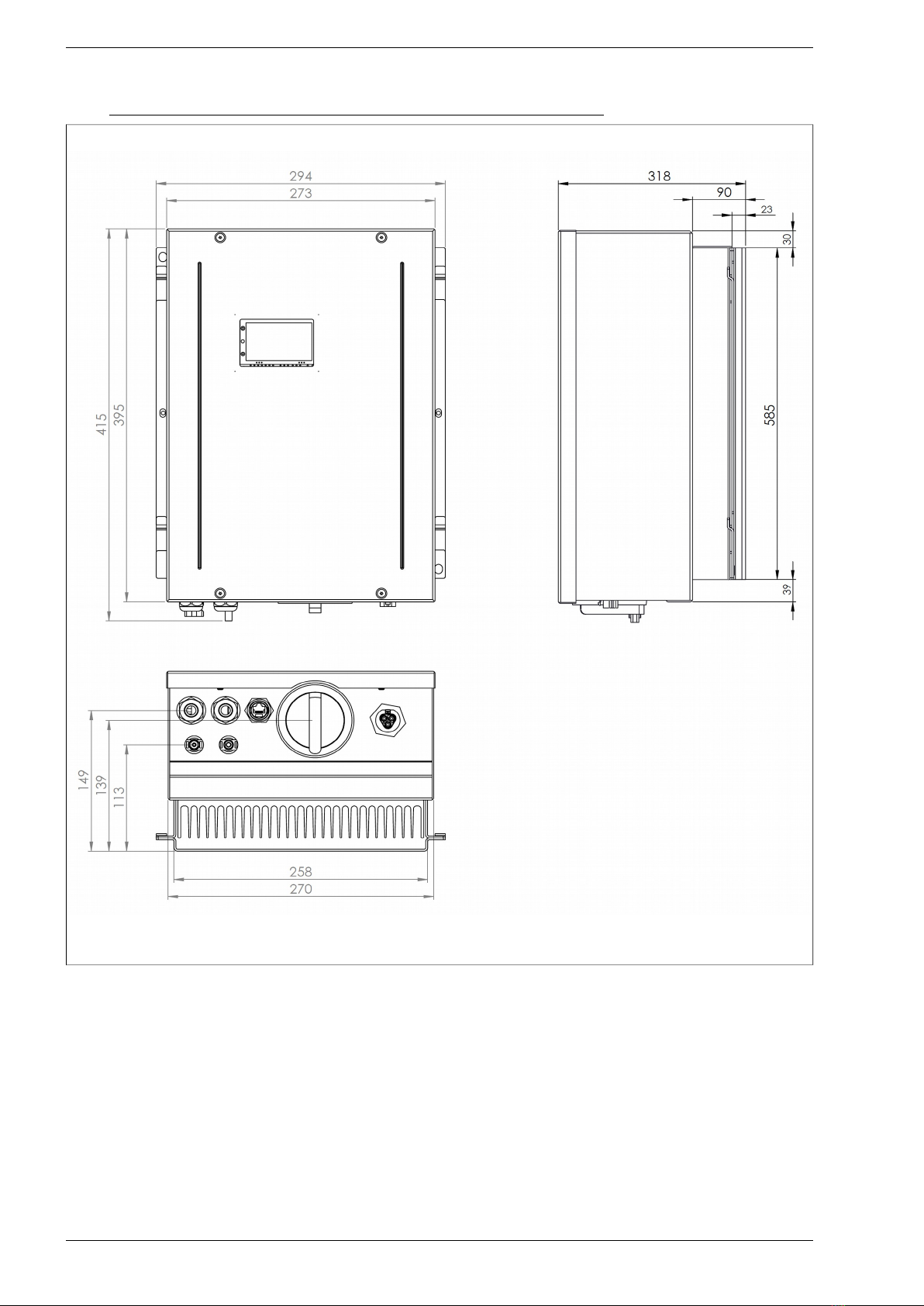

3.2. Mechanical dimensions and weight....................................................................................................10

3.2.1. PS100-WT/1kW, PS100-WT/3kW, PS100-PV/1kW, PS100-PV/3kW.........................................10

3.2.2. PS100-PV/5.5kW, PS100-WT/5.5kW, PS100-H/3kW, PS100-H/5.5 kW.....................................12

3.2.3. PS100-WT+BC/1kW, PS100-WT+BC/3kW, PS100-PV+BC/1kW, PS100-PV+BC/3kW.............14

3.2.4. PS100-WT+BC/5.5kW, PS100-PV+BC/5.5kW, PS100-H+BC/3kW, PS100-H+BC/5.5kW..........16

4. Prepar ng for nstallat on......................................................................................................................... 18

4.1. Inverter installation location................................................................................................................18

4.2. Environmental condition......................................................................................................................18

4.3. Cooling................................................................................................................................................ 18

4.4. Use of resid al c rrent devices........................................................................................................... 18

4.5. Power line connector.......................................................................................................................... 19

4.6. Installation position.............................................................................................................................21

4.7. Power circ it terminals........................................................................................................................22

5. ON-GRID nstallat on................................................................................................................................ 23

5.1. Inverter with WT generator inp t.........................................................................................................24

5.2. Inverter with PV inp t.......................................................................................................................... 25

5.3. Hybrid inverter with AC (PMSG) and DC (PV) inp ts..........................................................................26

6. OFF-GRID nstallat on............................................................................................................................... 27

6.1. Inverter with the WT generator inp t................................................................................................... 28

6.2. Inverter with PV photovoltaic panels inp t..........................................................................................29

6.3. Hybrid inverter with WT generator and PV photovoltaic panels inp ts................................................30

7. Bu lt- n control panel................................................................................................................................ 31

7.1. Information displayed on the operator panel witho t removing the inverter cover.............................32

7.2. Operating the control panel sing b ttons..........................................................................................33

7.3. Updating the Control panel software...................................................................................................35

8. The f rst run............................................................................................................................................... 37

8.1. Maxim m Power Point Tracking (MPPT) and Global Maxim m Power Point Tracking (GMPPT)......37

8.2. 16 point load characteristic of a synchrono s generator.....................................................................38

8.3. Start/Stop command........................................................................................................................... 38

8.4. D mp load resistors............................................................................................................................ 39

8.5. The internal process of switching ON the inverter in on-grid mode.....................................................39

8.6. The internal process of switching the inverter off-grid.........................................................................39

9. D g tal nputs and outputs........................................................................................................................ 40

9.1. Generator load control........................................................................................................................ 41

9.2. Anemometer....................................................................................................................................... 42

9.3. Storm Protection................................................................................................................................. 42

9.4. Remote O tp t Stop Order................................................................................................................. 42

10. Commun cat on parameters sett ng......................................................................................................43

10.1. Connecting the inverter to the Internet.............................................................................................44

10.2. Comm nication via Json file............................................................................................................44

PS100 – User’s man al 3