Contents

Contents

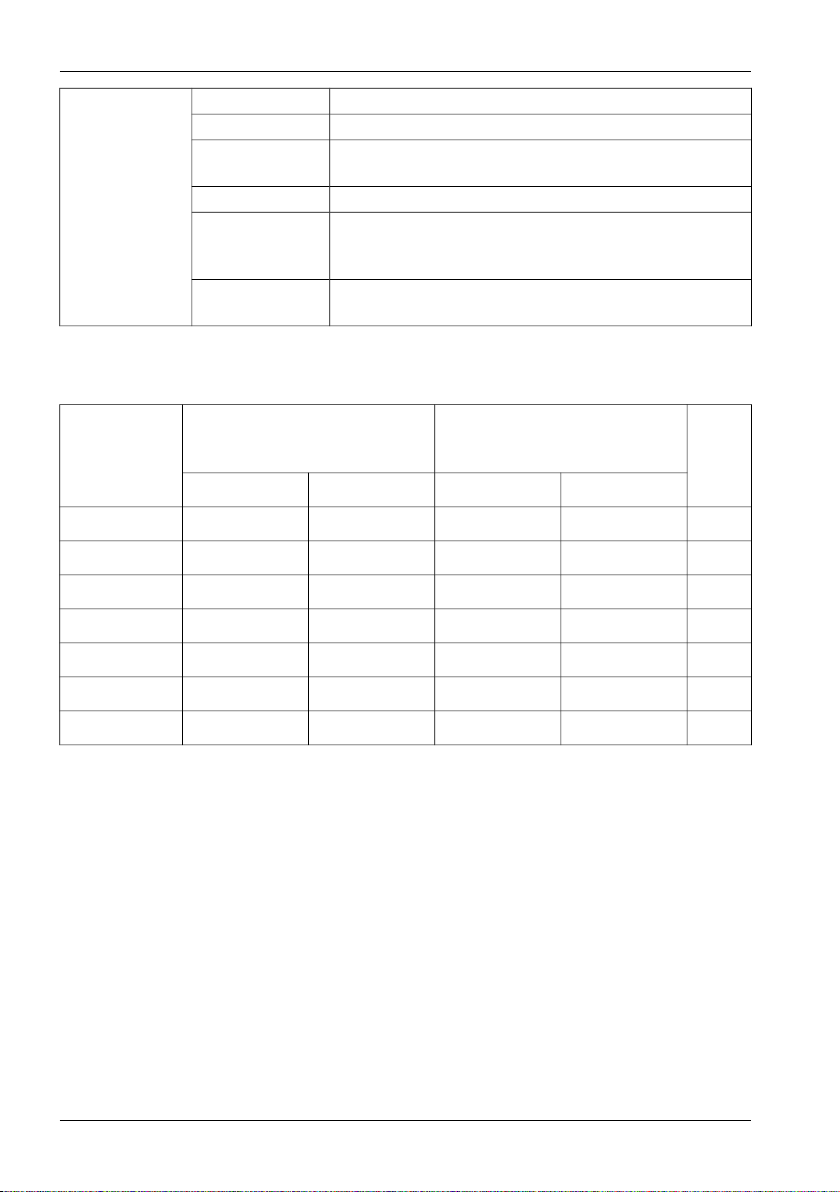

Technical data of frequency converters AFC2 .............................................7

1. Conditions of safe operation........................................................................9

1.1. Threats and warnings...........................................................................9

1.2. Basic rules.......................................................................................... 1

1.3. Operation list......................................................................................1

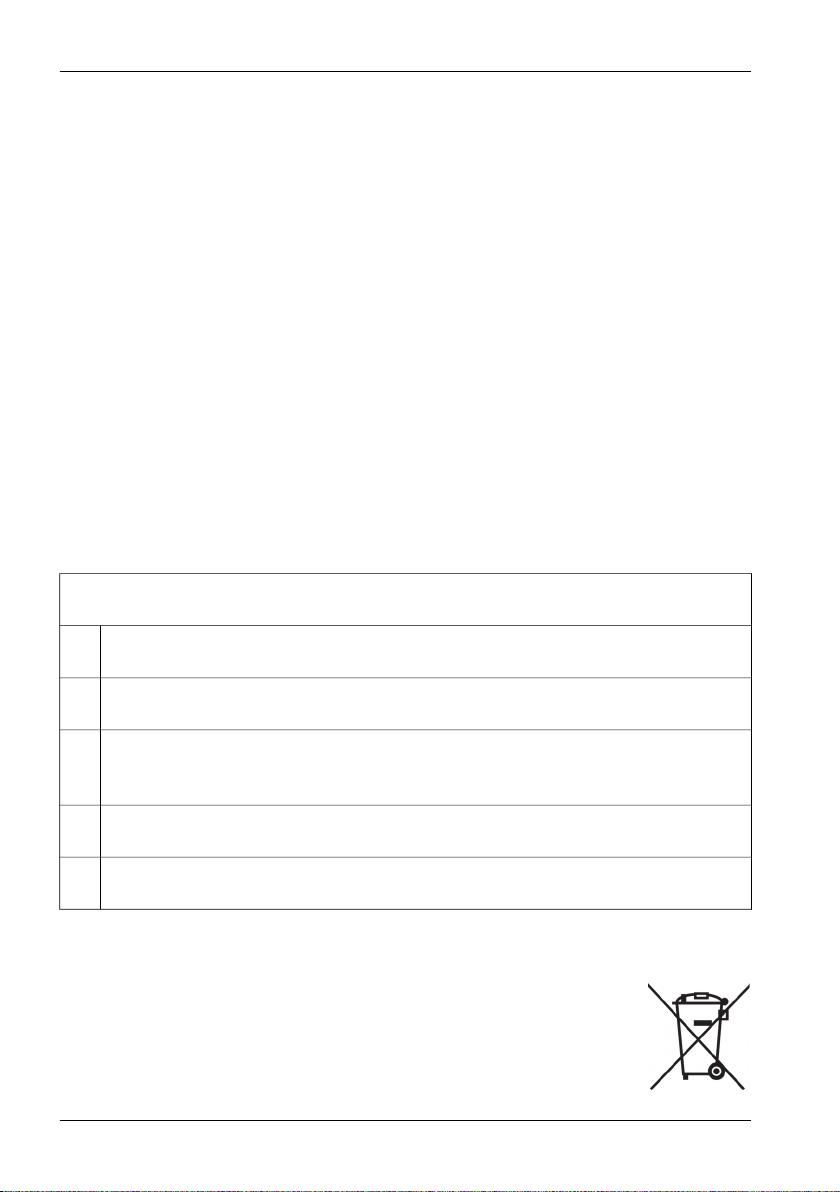

1.4. Disposal considerations.....................................................................1

1.5. Environmental conditions...................................................................11

1.6. Limits of responsibility........................................................................11

2. Installation of the frequency converter.......................................................12

2.1. Safety rules........................................................................................12

2.2. Assembly of the frequency converter.................................................14

2.3. Connecting the power circuit..............................................................16

2.4. Connection of control systems...........................................................17

2.5. Using contactors and circuit breakers at the frequency converter

output................................................................................................. 18

3. The control panel.......................................................................................19

4. The first start............................................................................................. 24

4.1. Power circuit connection....................................................................24

4.2. Entering nominal data........................................................................24

5. Configuration of the frequency converter..................................................25

5.1. Control from the control panel............................................................26

5.2. Control from the terminal block..........................................................26

5.3. Shaping the drive dynamics...............................................................29

5.4. Operation in U/f scalar modes............................................................29

5.5. Operation in vector mode...................................................................3

5.6. Analogue inputs.................................................................................31

5.7. Analog output.....................................................................................34

5.8. Constant speeds operation................................................................35

5.9. Motopotentiometer.............................................................................38

5.1 . Elimination of frequencies................................................................4

5.11. Electric motor rotation direction lock.................................................41

5.12. Thermal protections of the motor - Protection by I2t limit..................41

5.13. Operating at frequencies exceeding 5 Hz......................................43

6. PI controller...............................................................................................44

6.1. Turning on and configuration of the PI controller................................44

7. Frequency converter control via RS-485 communication link....................46

7.1. Parameters regarding communication via RS-485.............................47

7.2. Map of registers accessible through RS-485 link...............................48

7.3. Handling communication errors..........................................................51

8. Failures and warnings...............................................................................51

8.1. Messages on failures and warnings on the control panel...................51

8.2. Deleting failure message....................................................................52

TWERD Power Electronics 5