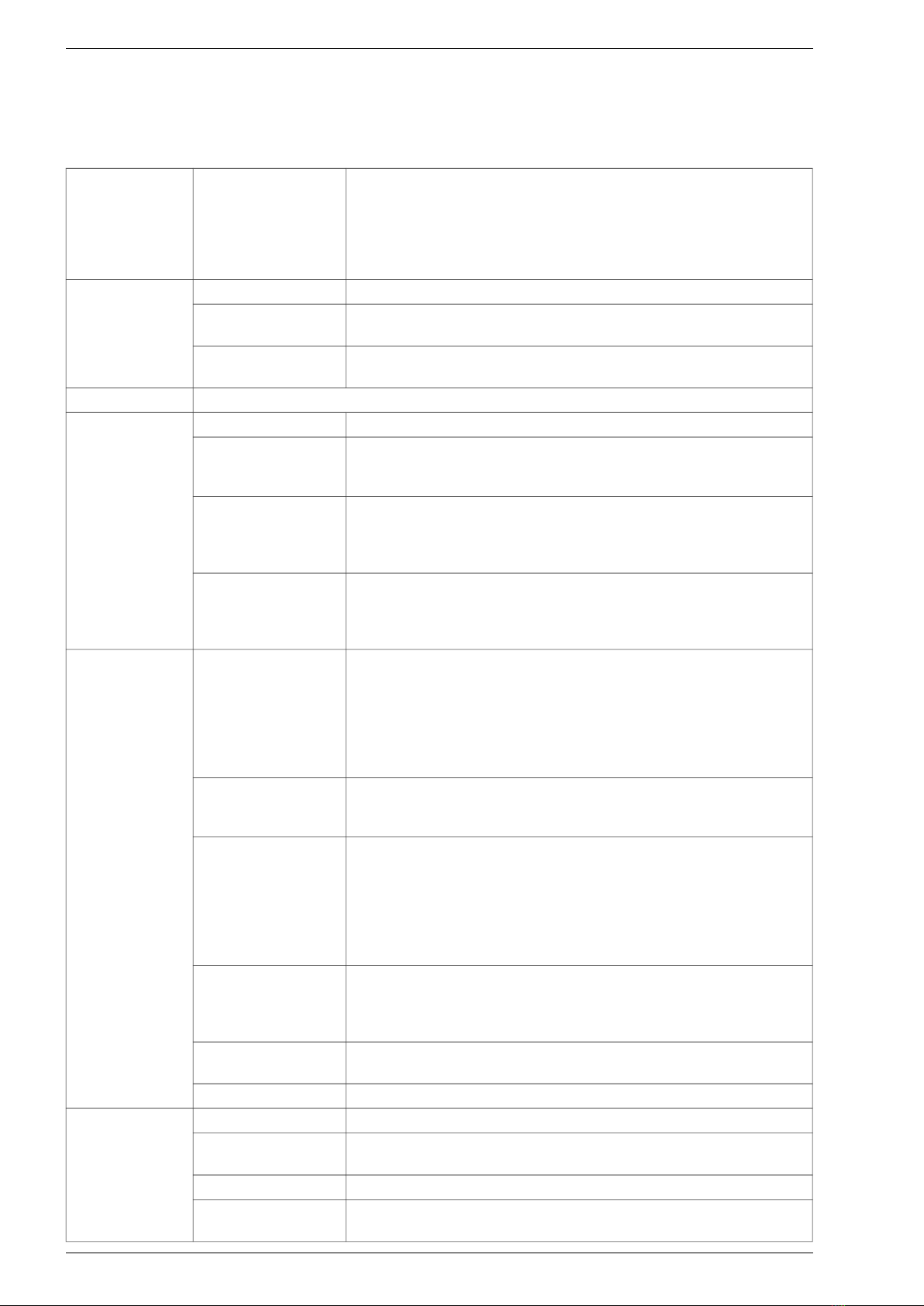

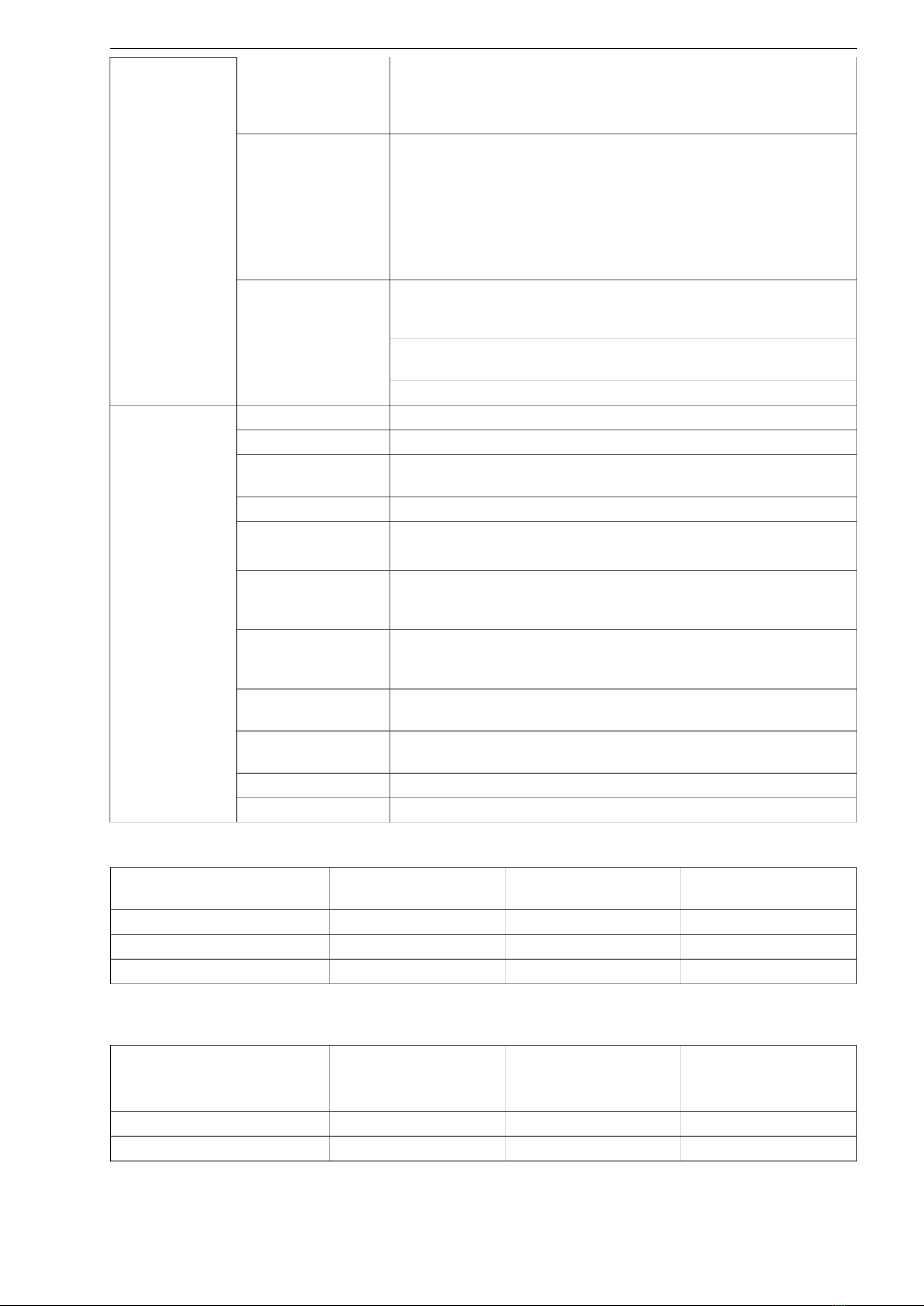

H.2. Technica data

Thi U er' manual refer to frequency converter MFC1000AcR. Table H.2.1 how the technical data.

Table H.2.1 – Technical data

Power supp y Voltage Uin / freq.

Three-pha e power:

3 x 400 V (-15%, +10%), 45..66Hz or

3 x 690 V (-15%, +10%), 45..66Hz

Note: depending on the type of ordered frequency converter

information contained the supply voltage is also placed on the

nameplate.

Output

Output voltage 0 ... Uіn [V]

Frequency 0,0 ... 400 Hz – U/f operation mode

0,0 ... 100 Hz – Vector operation mode

Frequency

re olution

0.01 Hz

Coo ing system Cooling i made by a forced ventilation from down to up

Contro system

Modulator SVPWM

Operation mode

U/f (linear, exponential),

Vector DTC-SVM without en or

Vector DTC-SVM with en or of the rotor po ition

Switching frequency

1 ... 8 kHz

Default: 2,5 kHz for nominal power when supply voltage is

3x400Vac and 2,0kHz for nominal power when supply voltage is

3x690V

Rotation peed

etting

Analog input , control panel, motopotentiometer, PID controller,

communication unit RS-485 and other po ibilitie .

Re olution of 0.1% for analog input or 0.1Hz / 1 rpm for the

control panel and RS.

Contro

inputs/outputs

Analog input

5 analog input (1 voltage mode, 4 voltage-current mode):

AI0: voltage mode 0(2) ... 10V, Rin ≥ 200kΩ;

AI1, AI2, AI3, AI4:

voltage mode 0(2) ... 10V, Rin ≥ 100kΩ;

current mode 0(4)...20mA, Rin = 250Ω,

Operation mode and polarity are cho en by parameter . Accuracy:

0.5 % of the full range.

Digital input

10 digital eparated input 0/(15...24)V, Rin ≥ 3kΩ.

The po ibility of obtaining up to 30 digital input on expan ion

card .

Analog output

2 analog output (voltage-current mode)

AO1, AO2:

Voltage mode 0(2)...10 V

Current mode 0(4)...20 mA

Configured by parameter , accuracy: 0.5%.

The po ibility of obtaining up to 10 digital input on expan ion

card (2 input on one each expan ion card).

Digital output

6 output relay K1 … K6 – breaking capacity: 250V/1A AC, 24V/1A

DC.

Fully programmable ignal ource. The po ibility of obtaining up

to 5 digital input on expan ion card .

Encoder interface Po ibility of direct connection of incremental encoder: 5V DC, line

driver (RS422), <250kHz. Recommended pul e rate: 1024-2048.

Temperature en or Pt100

Communication

Connector RS-485 x2, USB, Ethernet

Communication

protocol

MODBUS RTU. Function 3 (Read Regi ter), function 6 (Write

Regi ter), function 16 (Write Multiple Regi ter ).

Baud-rate 2400, 4800,9600, 19200, 38400, 57600, 115200 bit/

Application Remote control of unit operation and programming of all

parameter of the frequency converter.

8 MFC1000AcR, TWERD Power Electronic