Date: 10.07.2012 Page 3 of 28 user manual no. CRD 10617 FE

Structure

1. Safety instructions ............................................................................................................. 5

1.1 Scope of validity...........................................................................................................................5

1.2 Documentation.............................................................................................................................5

1.3 Proper use ...................................................................................................................................5

1.4 Commissioning ............................................................................................................................5

2 General ................................................................................................................................. 6

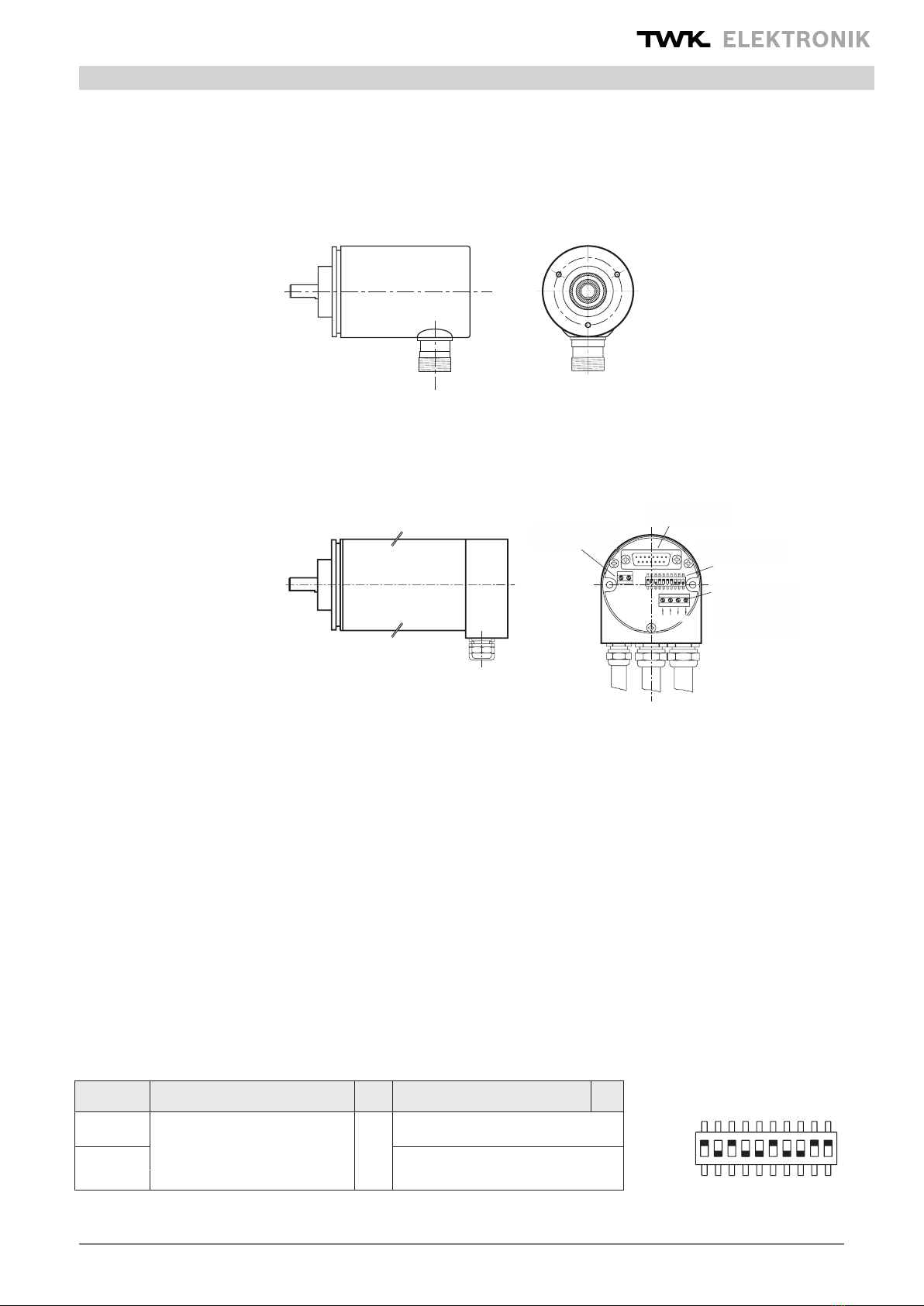

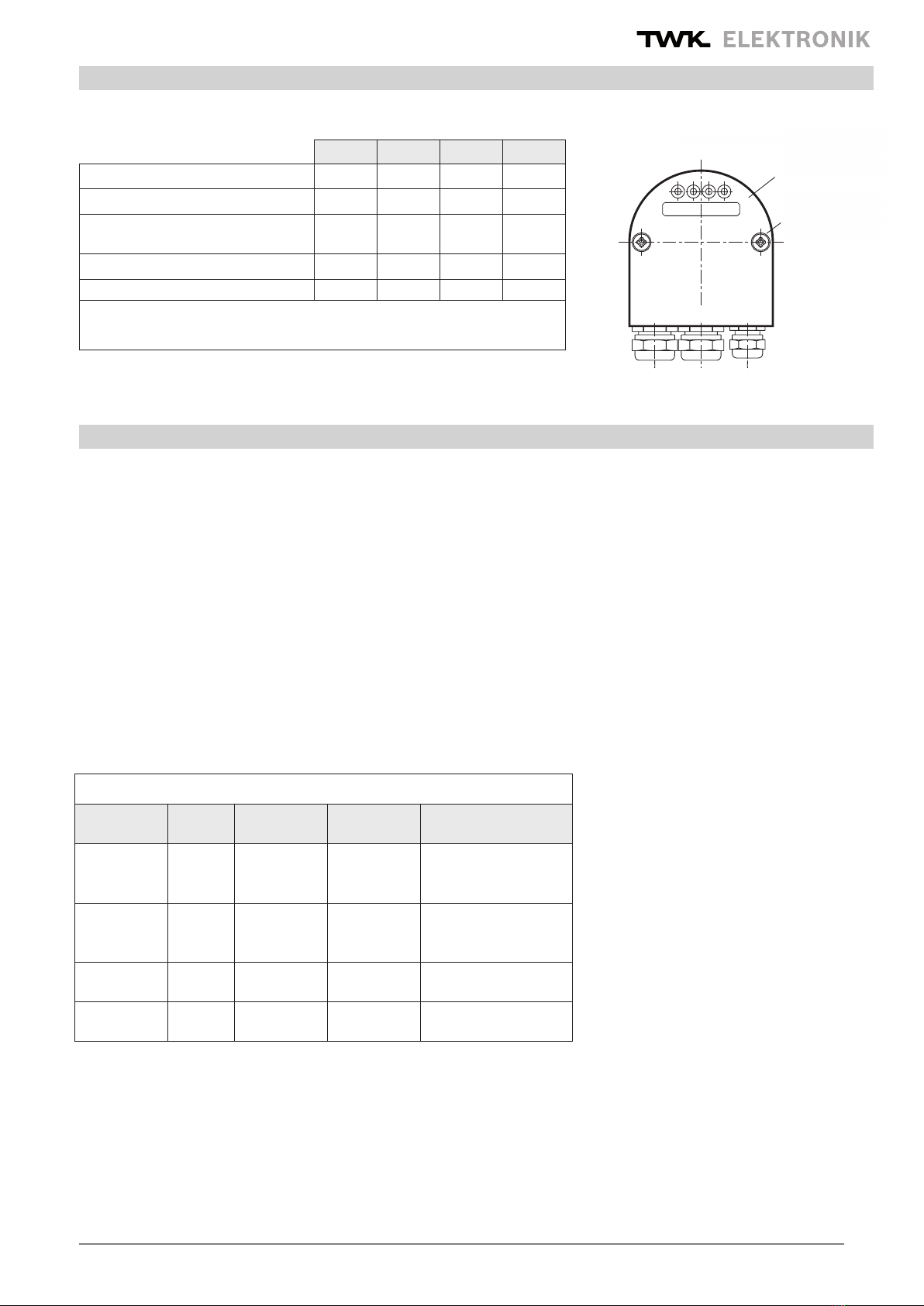

3. Installation instructions for PROFIBUS-DP - RS 485 ...................................................... 7

3.1 Connection of encoder with RS plug ...........................................................................................8

3.2 Connection of encoder with connecting cap ................................................................................8

4. Conguration function (DDLM_Chk_Cfg) ........................................................................ 9

5. Data exchange function (DDLM_Data_Exchange) ........................................................ 10

5.1 Actual position value ..................................................................................................................10

5.2 Set preset value.........................................................................................................................10

5.3 Example: Setting the preset value in 32 bit data format ............................................................ 11

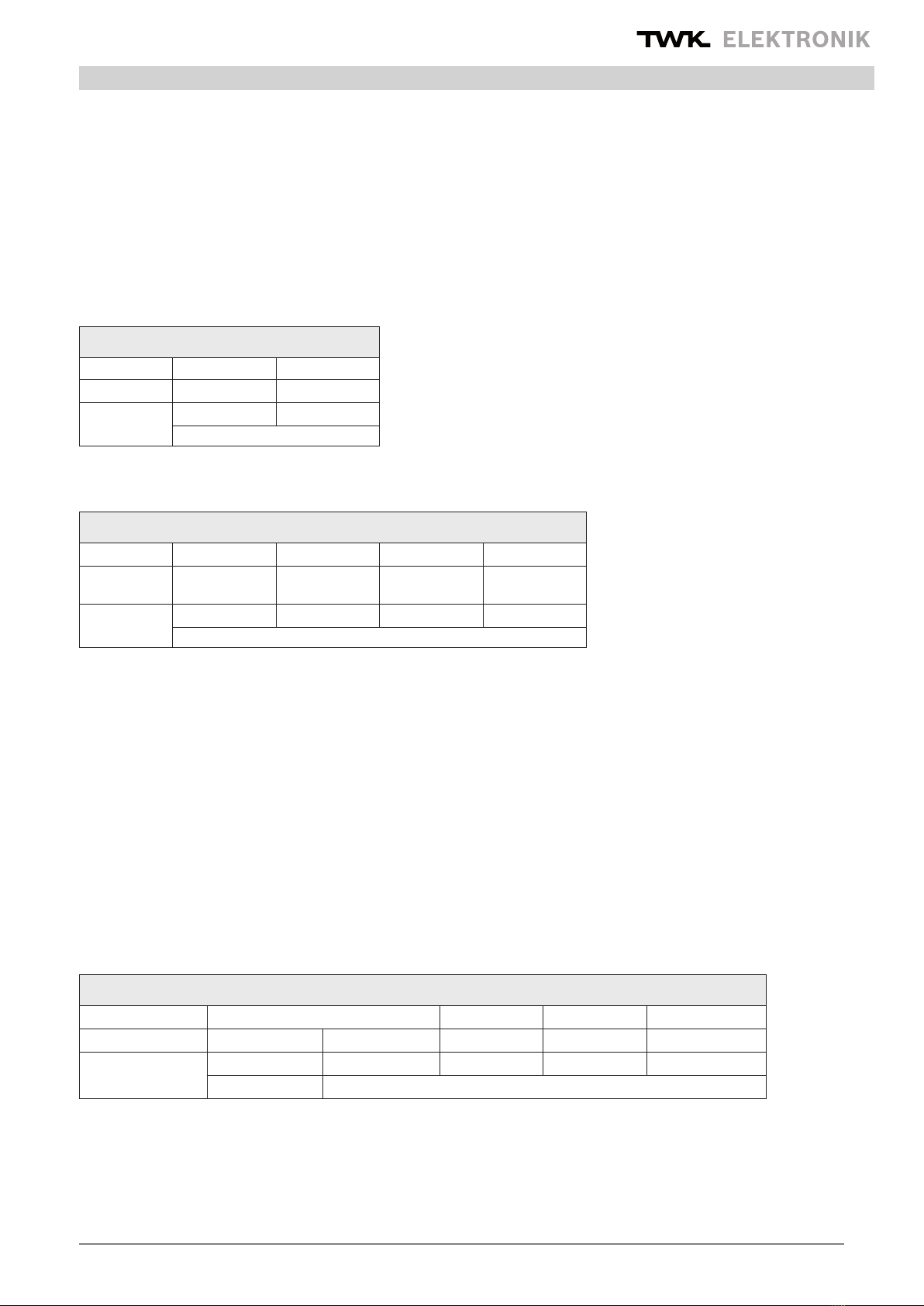

6. Programming parameters for class 1/2 encoder (DDLM_Set_Prm) /4/........................ 12

6.1 Denition of the programming parameters ................................................................................12

6.1.1 Operating mode ...................................................................................................................12

6.1.2 Measuring units per revolution (Octet 10-13).......................................................................13

6.1.3 Total measuring range in units (Octet 14-17).......................................................................13

6.2 Examples for parametration (User_Prm_Data) .........................................................................14

7. Diagnosis messages (DDLM_Slave_Diag)..................................................................... 15

7.1 Standard diagnosis information (Octet 1-6): ..............................................................................15

7.2 Device-related diagnosis ...........................................................................................................15

7.2.1 Extended header byte (Octet 7): .........................................................................................15

7.2.2 Alarm messages (Octet 8):...................................................................................................16

7.2.3 Operating mode (Octet 9) ....................................................................................................16

7.2.4 Encoder type (Octet 10).......................................................................................................16

7.2.5 Single turn resolution (Octet 11-14) .....................................................................................16

7.2.6 Measuring range (Octet 15, 16) ...........................................................................................16

7.2.7 Additional alarm messages (Octet 17) ................................................................................16

7.2.8 Supported alarm messages (Octet 18,19) ...........................................................................17

7.2.9 Warning messages (Octet 20,21) ........................................................................................17

7.2.10 Supported warnings (Octet 22,23) .....................................................................................17

7.2.11 Prole version (Octet 24,25)...............................................................................................17

7.2.12 Software version (Octet 26,27) ..........................................................................................17

7.2.13 Operating time (Octet 28-31) .............................................................................................17

7.2.14 Offset value (Octet 32-35)..................................................................................................17

7.2.15 Manufacturer offset value (Octet 36-39) ............................................................................17