2

IMPORTANT!

•Do not make sharp bends or ”elbows” along the steam pipe.

•Do not direct the steam jet at a wall, seating or any other

object. There should be a free space of at least 70 cm (28")

in front of the steam nozzle.

•Do not allow sags or “water pockets” along the steam pipe

and/or the ventilation duct. IMPORTANT! There must not be

any type of obstruction along the steam line, such as a stop-

off valve or tap. The internal diameter of the steam pipe

must not be reduced.

•Ensure that steam rooms that are used continuously for

more than two hours at a time are ventilated by 10–20 cubic

metres of air per person and hour.

•The power supply to the steam generator via the feeder

cable must not be broken. For that reason, avoid switches,

etc., along the feeder cable.

•Make sure that the drainage pipe slopes all the way down to

the waste outlet.

•The ambient temperature outside the steam room and around

the steam generator must not exceed 35°C.

•Place the thermostat sensor as far away from the steam jet

as possible.

•De-scale the steam generator at regular intervals as

instructed. (Please read the section 'De-scaling' for further

details). In hard-water areas, where calcium levels exceed

5°dH, we recommend the installation of a water softener or

a Tylö automatic de-calcifier.

•Clean the steam room regularly. See the section on

“Cleaning the steam room” under Operating instructions.

•CAUTION! Stay at least 12" (30 cm) away from hot steam

escaping from steam outlet.

•IMPORTANT. The steam generator’s wastepipe must

always discharge into a drain outside the steam room itself.

The water is very hot.

General Information.

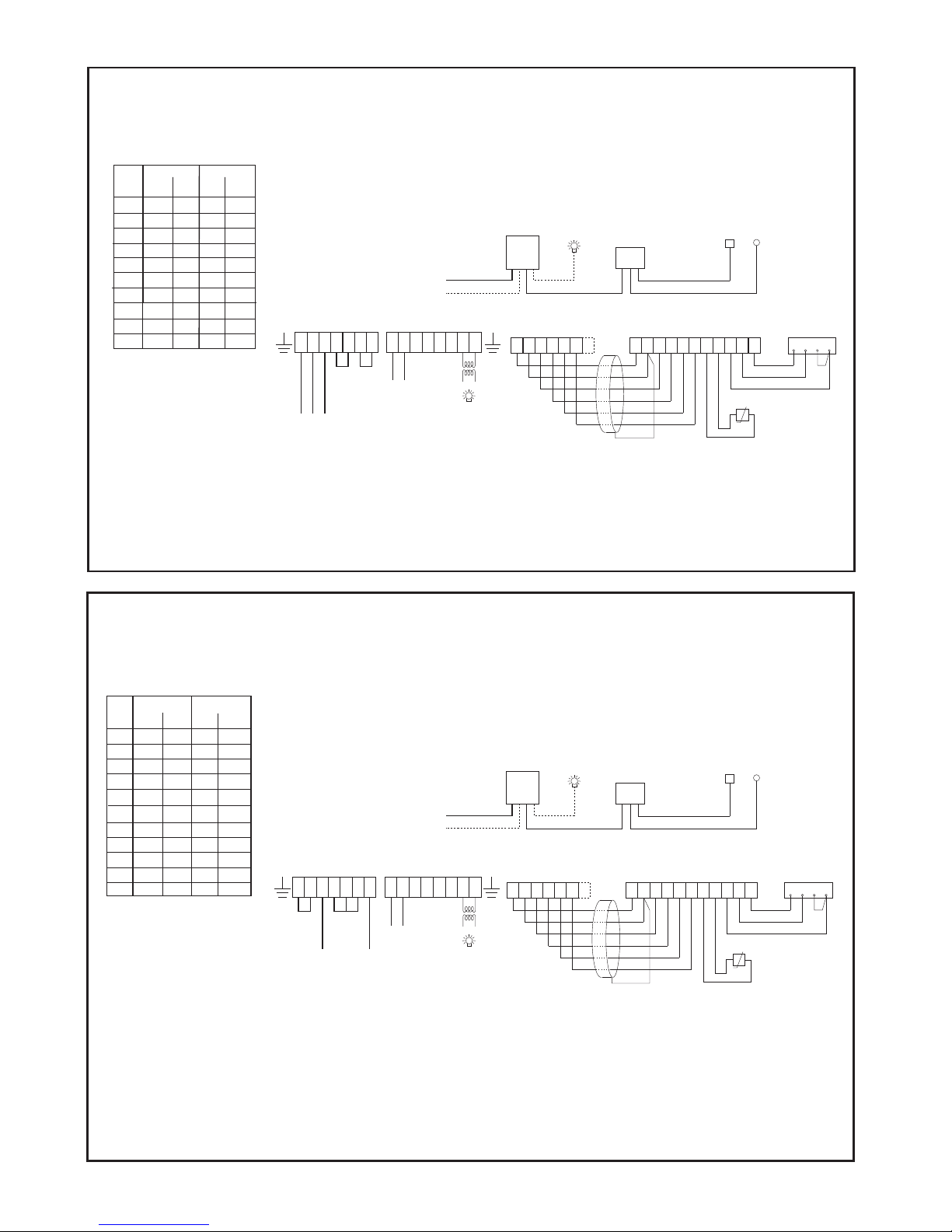

Fig. 1.

Examples of ventilation, electrical and plumbing

installation.

X = feeder cable from mains to steam generator. Do not

fit a switch along this cable. Where local regulations

require a switch to be fitted, this switch must always

be in the ON position. If the electrical supply is

interrupted before the automatic emptying and

flushing functions have occurred (approx. 80 min

after completion of bathing) these functions are

terminated without the reservoir being emptied. This

reduces the life expectancy of the steam generator.

Y = control cable from mains supply via control panel to

steam generator.

V = thermistor cable.

Z = cable to external on/off switch (if any).

D = steam pipe.

E = drainage pipe.

F = incoming water.

G = air inlet.

H = air outlet, leading out via a ventilation duct into the

open air.

The steam room.

The steam room should not have any other source of heat

than the steam generator. The ambient tempera-

ture around the steamroom and the steamgenerator

generator should not exceed 35°C (95°F). If there is a

sauna next to the steam room, the sauna must be well

insulated, and placed so as to give at least 10 cm (4")

free space between the outside walls of the sauna and

the steam room.

Location of the steam generator.

The steam generator must be installed by an authorised

electrician/plumber. The steam generator must be

permanently installed and secured against existing floor

or wall. It is to be located outside the steam room itself,

but as close to it as possible – no more than 15 m (50 ft)

away.

The steam generator must be placed in a dry and

ventilated space with a waste outlet, above, below or on

the same floor as the steam room, and concealed in a

cupboard, wardrobe, etc. (Never directly above a waste

outlet or in an aggressive environment).

The steam generator must be mounted horizontally, at a

suitable height above the floor to permit the drainage pipe

to slope towards the waste outlet. To achieve this, it may

sometimes be necessary to place the steam generator on

wall brackets, or a floorstand.

CC control panels.

Instructions: included with the control panel.

To be installed outside the steamroom, at any distance

from the steam room.

CC panels are electronically operated and are available in

the following models:

CC 10-3. Manual and automatic on/off. Maximum

3- hour running time, 10 hour pre-set.

CC 10-10. Manual and automatic on/off. Maximum

10- hour running time, 10 hour pre-set.

CC 50. Manual and automatic on/off. Maximum

3 or 12 hour running time, 10 hour pre-set.

CC 100. Manual and automatic on/off. Maximum

3 or 12 hour running time, 24 hour pre-set. Built-in weekly

timer.

CC 300. Manual and automatic on/off. Maximum

24 hour´s running time, 24 hour pre-set. Built-in weekly

timer.

Thermometer.

The thermometer in the steam room should be placed at

a height so that the temperature corresponds exactly to

the numbers in the names CC 50/ CC 100/ CC 300.

Temperature limit control.

Tylö steam generators are equipped with a built-in

temperature limit control. If the control is triggered off,

consult the checking and fault-finding list in this manual to

find the causes and a solution to the problem.

Note! The High temp limit control in a VA generator must

be reset by a Qualified electrician.

Main power switch.

On the bottom of the smaller steam generators is a power

switch, which should only be used if the unit is to be

disconnected for a long time.

The automatic emptying function ceases any time the

power is cut off.

Floors and drainage.

There must be a drain in the steam room, and the steam

room floor must slope towards the drain. The floor may be

covered with seamless vinyl flooring, quarry tiles, etc. The

requirements for sub-floor work, joining, etc., are the

same as for an ordinary shower.

PLEASE NOTE. Contact with steam and hot water may

cause plastic wallcovering/flooring close to the steam

head to become slightly discoloured.

Ventilation.

As a general rule, steam rooms which are in use for less

than two hours at a time require no special ventilation. In

order to ensure proper hygiene and trouble-free

operation, steam rooms which are in continuous use for

more than two hours at a time should be ventilated with

10–20 cubic metres of air per person and hour.

If there is a gap above the steam room, do not seal it. To

ventilate a cavity above the sauna, drill or cut at least one

ventilation hole (1000mm²) into the cavity through the wall

on which the sauna door is located.

The air inlet may be an opening placed low down on the

same wall as the door, or it may be a gap under the door.

The air outlet should be located high up on a wall or in

the ceiling, and as far away from the air inlet as possible.

However, the air outlet must not be located above the

door or directly above any of the seats. Connect the outlet

to a ventilation duct discharging into the open air. Use

existing ducting, if possible. The ventilation ducting must

be 100% steamtight and watertight, and made of

materials which will not deteriorate or corrode in the high

humidity. Do not allow the formation of “water pockets”,

caused by sags in the ducting, where condensed steam

may collect as water and cause a blockage. If a water

pocket is inevitable, install a trap to drain the condensed

water into the waste outlet.

The air outlet vent must be of sufficient size to allow the

evacuation of 10–20 cubic metres of air per person and

hour.

Mechanical ventilation. If the unassisted through-flow of

air is insufficient, due possibly to negative pressure in the

room supplying air to the steam room, a mechanical

exhaust fan must be installed and adjusted to extract a

minimum of 10 and a maximum of 20 cubic metres of air

per person and hour.

Steam generator functions.

All Tylö Model VA/VB Steam Generators incorporate

these features:

zStainless steel water reservoir zTubular heating

elements, resistant to rust and acid zAutomatic emptying

1 hour after the steam bath has been switched off

zAutomatic flush function rinses 4 times after emptying

z3-part output zElectronic water-level regulator

zElectronic water level control zSelf-cleaning, calcium-

repellent electrodes zContinuous steam production

zAlways the right output, regardless of quantity and

quality of water zBuilt-in safety valve zBuilt-in

temperature cut-off zBuilt-in filter zEquipped for remote-

control operation zAdjustable steam head zSplashproof

finish.

Automatic emptying.

This automatic function considerably reduces the build-up

of calcium carbonate and other deposits in the water

reservoir. Do not switch off any switches between the

mains supply and the steam generator until at least 80

minutes after the control panel timer has turned the

system off, because otherwise, the automatic emptying

and flushing of the water reservoir will not start.

WARNING. The water is very hot.

Automatic flushing with DIP

switch.

The steam generator is factory set to flush out part of the

water automatically after 4 hours. The steam generator

should, however, be emptied more frequently in areas

where the water is hard (5dH° or more than 100 ppm

calcium carbonate), or if it is used for more than four

hours per day. Set the required interval using the DIP

switches as shown (fig. 17).

WARNING. The water is very hot.

De-scaling.

Some of the limescale released from the water in the

steam generator is flushed out in the automatic emptying

and cleaning process; some, however, remains. The Tylö

Automatic De-calcifier (art no. 9090 7000) does not

remove limescale deposits as such, but modifies the ions

in such a way that more of the calcium is evacuated

during the flushing process. For this reason it is essential

to check that the automatic emptying function of the

steam generator has not been impaired by incorect

wiring. The reservoir must be emptied each time it has

been used.

To maximise serviceable life and reduce the need for the

manual removal of limescale deposits, we recommend

that steam generators for use in public facilities should be

connected to a water softener which removes calcium

from the water. This is particularly important if the

hardness of the water is greater than 5 degrees German.

(5 °dH, see table.)

The water softener must not generate any froth on the

water nor produce any harmful chemical reactions. If so,

the generator may indicate the wrong water level and

trigger the temperature cut-off. (Repeated activation may

result in the failure of the elements.)

The manual removal of limescale must be carried out at

regular intervals as specified in the table below.

For normal private use, there is little need for the manual

removal of limescale, unless the water is very hard. Even

so, it is advisable to de-scale the steam generator at least

once per year. This removes calcium and other deposits

that have become encrusted on the walls and elements of

the water reservoir.

Instructions for de-scaling Tylö Steam Generator

•Switch on the steam generator and let it run until the

water in the tank begins to boil.

•Switch the generator off and wait for approximately 5

minutes.

•Unscrew the capping nut from the 3-way connector on

top of the steam generator.

•Use a funnel to pour the de-scaling agent into the

tank via the 3-way connector.

•Screw the capping nut back in place on the 3-way

connector and leave the de-scaling agent to work.

•After approximately 1 hour the generator will

automatically empty and flush the tank. After this the

steam generator is once more ready for use.

Tylö Solvent is harmless, odourless, will not damage the

components in the steam generator and allows you to use

the steam generating function during the de-scaling

process. If you use any other type of de-scaling agent, do

not use the steam bath until after the de-scaling operation

has taken place.

As the table shows, how often manual de-scaling needs

to be done depends on the quality of the water, the output

of the steam generator and the total operating time.

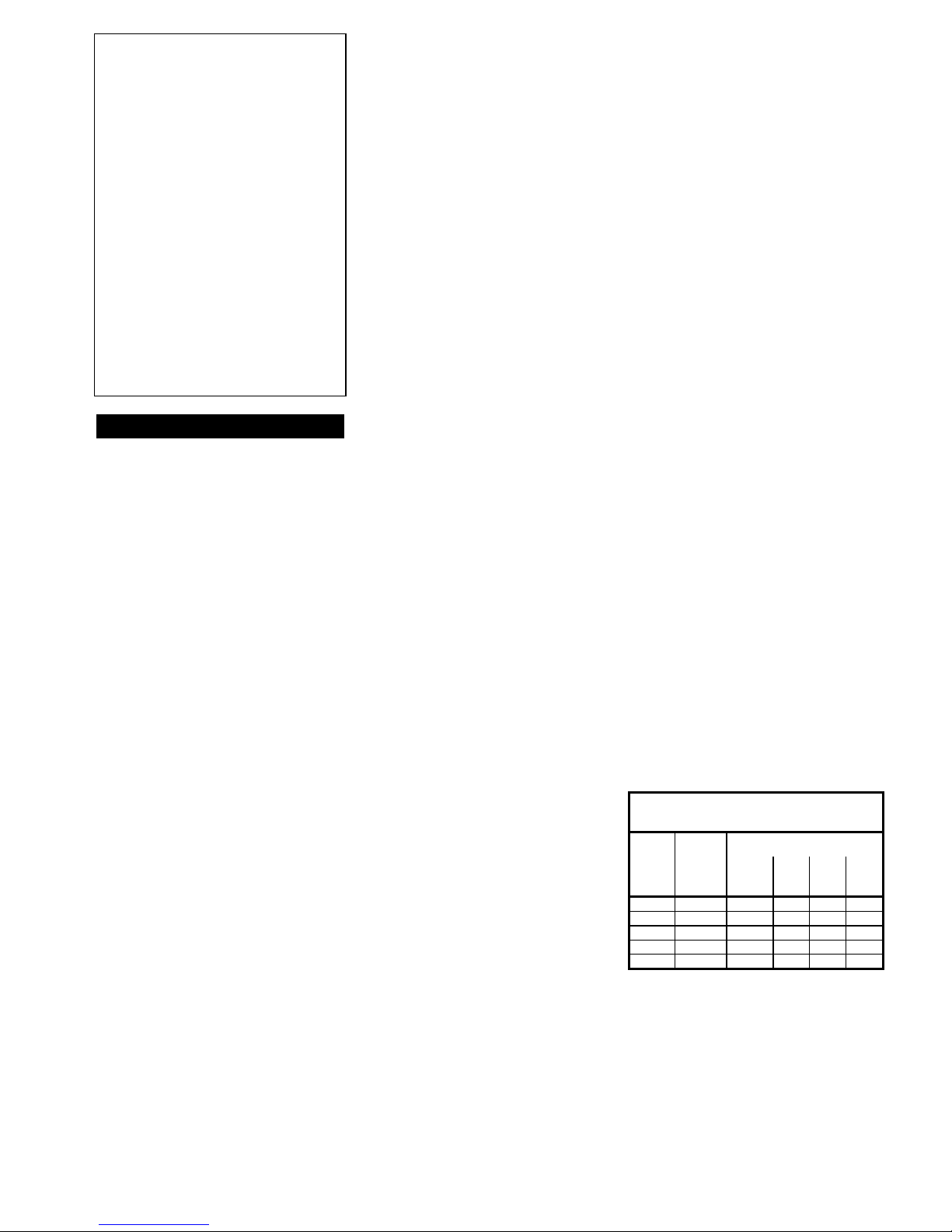

Operating time before de-scaling

(To reduce the need for manual removal of limescale we recommend

the use of softened water in public facilities)

Operating time for different water

hardnesses

Steam

generator

output kW

Amount of

de-scaling

agent

(1pack 80g)

Softened

0,01-1°dH

Soft

1-3°dH

Hard

3-8°dH

Very

hard

8-20°dH

2,0-2,5 2 pack 7000 2300 900 350

3,8-5 2 pack 3800 1300 500 190

5,6-7,5 2 pack 2600 900 300 130

7,5-9 2 pack 1700 600 200 90

10-13 2 pack 1300 400 160 70

(1-dH = 7.14 mg calcium / litre water)