16. To ensure personal safety, please turn off the power switch after work

is completed. When not in use for an extended period, please unplug the

power cord.

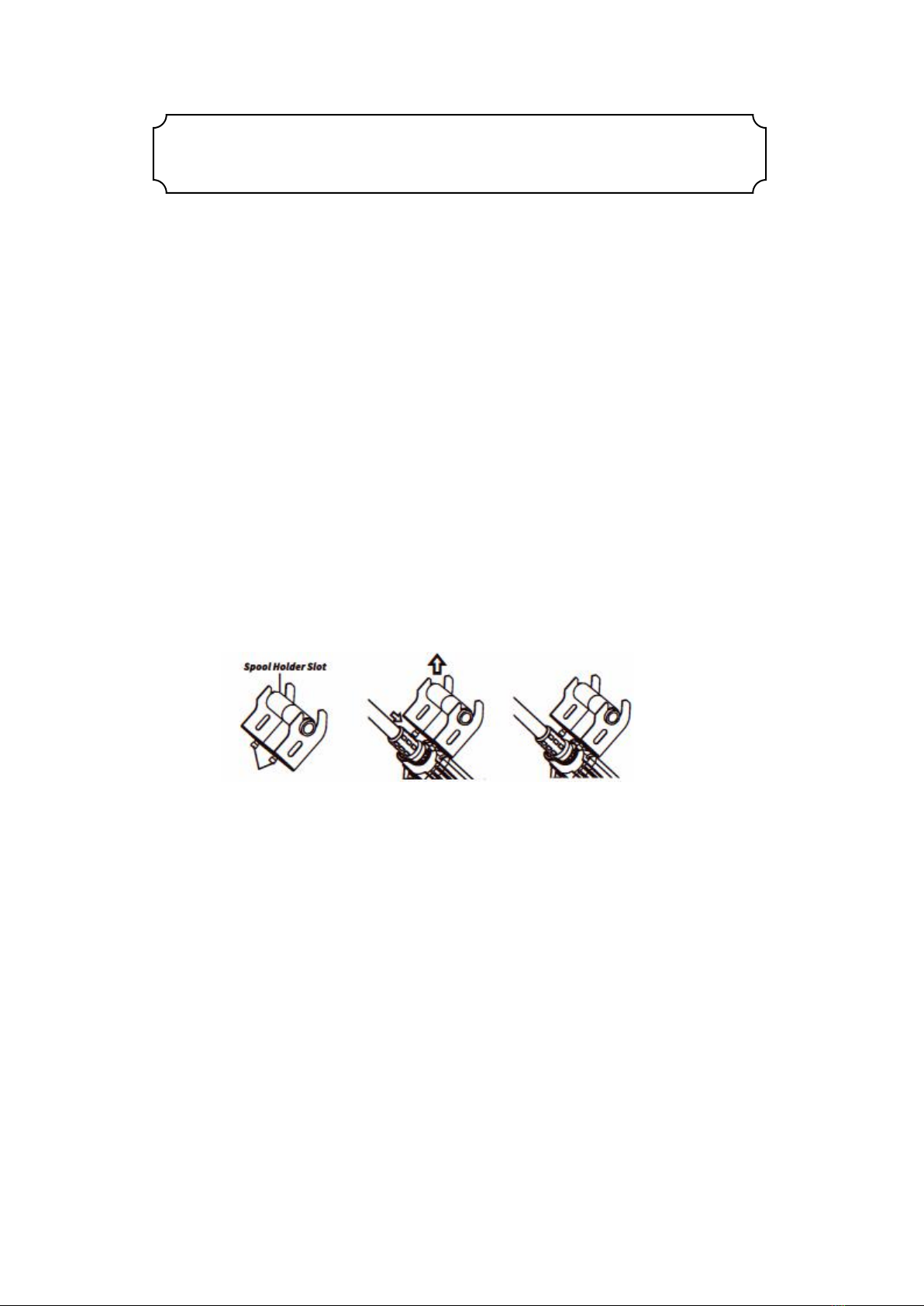

17. Do not install nozzle when the hot air gun is turned on. The heat pipe

and nozzle must be cooled before installing another nozzle.

18. Soldering produces fumes; ensure there is adequate ventilation.

19. After use, remember that when cooling the unit, the handle should be

placed on the handle holder.

20. Longer, detachable power-supply cords are available and may be used

if care is exercised in their use.

21. If a long, detachable power-supply cord is used:

1) The marked electrical rating of the detachable power-supply cord

or extension cord should be at least as great as the electrical rating of

the appliance;

2) The extension cord should be a grounding type3 wire;

3) The longer cord should be arranged so that it will not drape over

the countertop or tabletop, where it could be tripped over, snagged, or

pulled on unintentionally (especially by children).

22. A short power-supply cord (or short, detachable power-supply cord)

is provided to reduce the risks resulting from tripping or entanglement.