1

I. INTRODUCTION

Now you can breathe a lot easier… you and everyone

else who breathes the air cleaned electronically by

SMOKEETER/CRYSTAL-AIRE. Your new electronic air

cleaner is the most advanced product of its type on the

market today.As you begin its operation, we would like to

remind you of a few important facts.

First, we appreciate your business… and because we

appreciate your business, we have manufactured an

electronic air cleaner worthy of your consideration.

SMOKEETER/CRYSTAL-AIRE is designed and engine-

ered to rigid specifications incorporating the latest tech-

nological advances, and it is built using the highest

grade materials available. It is subject to rigorous

quality control checks before it leaves our factory. And,

your unit is backed by a factory warranty as described

on the back cover.

Second, like any piece of precision equipment,

SMOKEETER/CRYSTAL-AIRE needs periodic mainten-

ance. Properly cared for, it will operate at peak

efficiency for many years.

Finally, while we hope you never have any problems,

United Air Specialists, Inc. (UAS) is always ready to lend

assistance. We have factory-trained distributors world-

wide. Should you need information or service, contact

your local distributor or the Technical Support Dept. at

United Air Specialists, Inc., 4440 Creek Road, Cincinnati,

Ohio 45242, 1-800-252-4647.

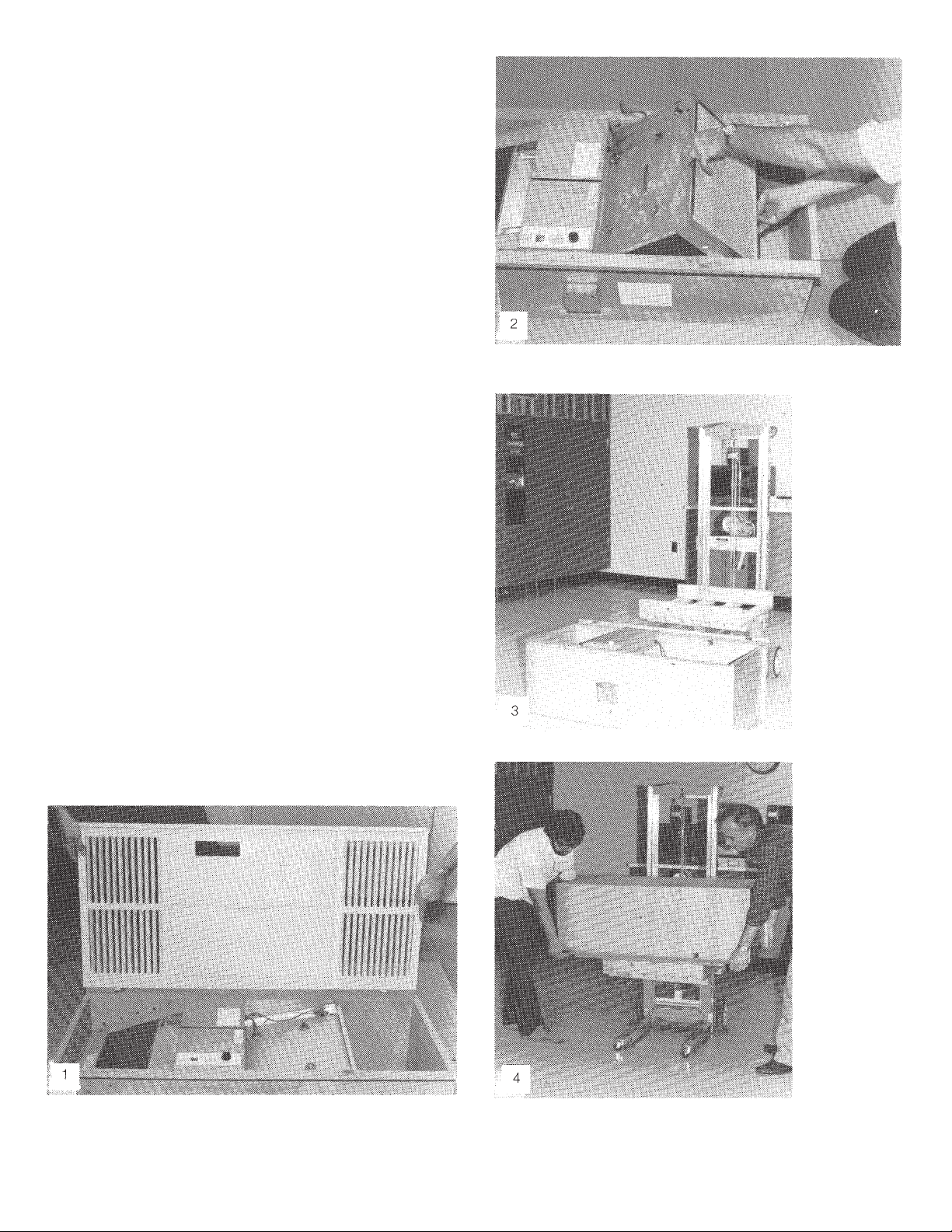

II. INSPECTION OF EQUIPMENT

Inspect for any shipping damage upon receipt of your

unit. A damaged carton indicates that the equipment

may have received possible internal damage. If any

damage is found, notify your delivery carrier and enter

a claim.

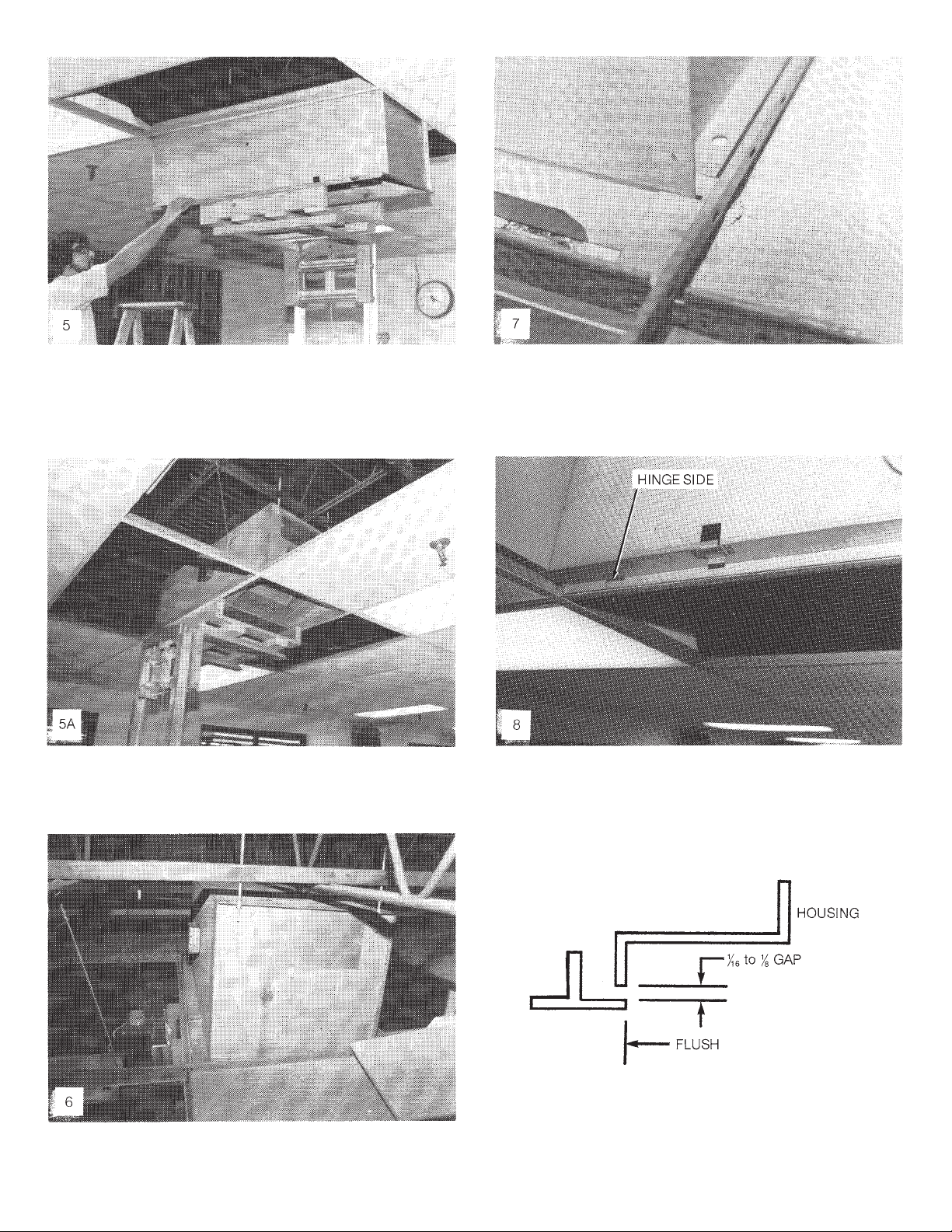

III. HOW YOUR SMOKEETER/

CRYSTAL-AIRE OPERATES

The motor/blower draws the contaminated air through

an aluminum mesh prefilter, trapping the larger par-

ticles. As the smaller particles enter the ionizer sec-

tion, they are given an intense positive charge. The

charged particles then pass through the oppositely

charged plates of the collection cell where they are re-

tained. Clean air is exhausted and redistributed by the

fixed louvers of the faceplate grille. The carbon after-

filter aids in controlling odor.