9.0 PRINTER:

SP-e series dot printer is a new type of Panel mounted front-loading paper micro Printer. It

is a kind of printing device, which can be easily mounted on any kind of instrument panel. It

is especially designed for the instrument's panel, that has micro Printer mounted on its

panel, and the instrument needs only a rectangle opening(l03mm*57mm) to mount the

micro printer on its panel. SP-E series micro Pinter has special structure of front loading

paper and print ribbon, that makes changing paper and ribbon very easily, without removing

whole printer, so avoid swinging inner cable, that will enhance the reliability of the

instrument it is mounted on..

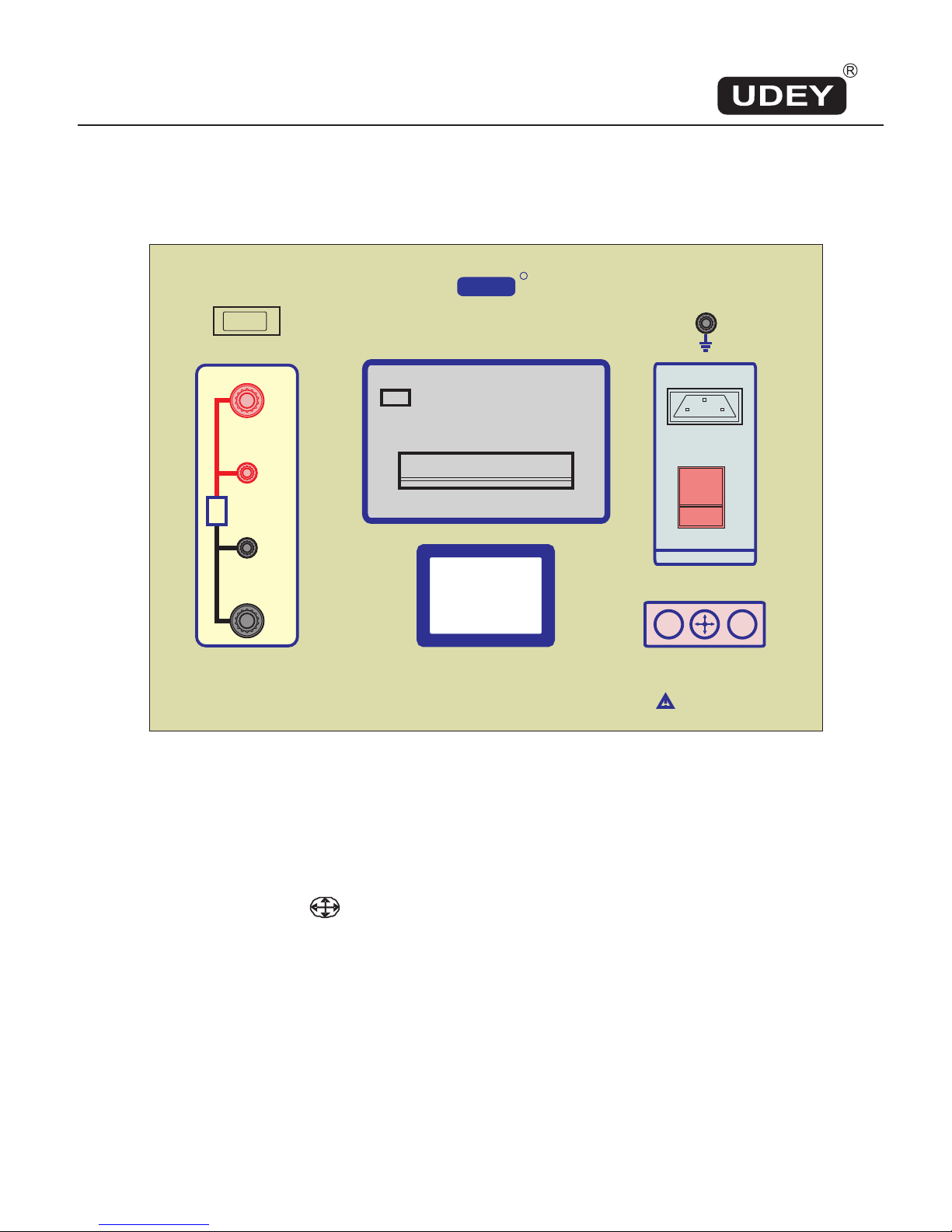

The printer is composed of turn able front cover, printer head, slide chassis, controlling

board, paper axle rod and fastening slides. Its front cover has a transparent window though

which print paper quantity can bee seen. On the lower side of the front cover's right, there

is a key of SEL, and SEL indicator. There is a long rectangle slot on the upper side of front

cover, with cutting paper saw on its upper edge. The printer head and paper roll are

mounted in the printer box, at back of the cover. The micro printer is fastened by the

fastening slides on inter side of the instrument's panel.

Mounting the printer

Insert the printer in to the opening of the instrument. The fastening slides should be put into

the holes on both sides of the printer box, then fasten the slides with screwdriver to screw

the printer tightly, the printer will cling the instrument firmly.

Loading paper-roll and feed paper

Pulling upper side of the front cover with 2 fingers pinching slightly to uncover the front

cover ,drag out ,with 2 fingers pinching the slide chassis clips ,the printer slides chassis

about 20 mm ,and then put the paper row axel rod on to the paper roll slots .Lastly ,push

the slide chassis back in to the box.. Connect the printer power .After the printer initialed,

the indicator will light up. Press the key, for 2 seconds the printer motor starts. Drag out the

tip of paper ,and cut paper tip in triangle, and feed the paper straight to printer head in slot

,when paper begins to come out of the exit slot a little ,press the key to stop the motor ,the

indicator will turn on ,indicating that the printer is ready for printing .Now ,push back the

front cover to shut up the printer box.

If the paper is not fed correctly, it may jam in the printer head, and cannot come out of the

exit slot Turn off the power, pull out the slide chassis, drag out the jammed paper, cut

twisted paper, push back the slide chassis, and reload the paper in the printer.

Change ribbon

After printing for some time, the printed character will not be clear because of ribbon fading.

Pulling upper side of the front cover with 2 fingers pinching slightly to uncover the front

cover, press the spring clips of the slide chassis and drag it out about 20mm, the ribbon will

appear, remove the old ribbon, replace a new one, and then push the slide chassis back,

cover the front cover.