Programming Uhlenbrock DCC decoders

Uhlenbrock DCC decoders can be rogrammed with every DCC Command Station featuring

Register, CV (direct) or aged rogramming.

Programming DCC decoders with the Intellibox

The Intellibox features an easy to use menu for rogramming DCC decoders. This menu also

su orts the rogramming of long addresses without having to erform com licated com utations

by hand. In fact, one can directly ty e a long address and have the Intellibox automatically

erform the com utations needed in order to find out what values to write into CV #17 and CV

#18. The Intellibox shall also write those values into CV #17 and CV #18, as well as enabling long

addresses by setting Bit #5 of CV #29. Please refer to the corres onding cha ter of the Intellibox

manual for more information on this oint.

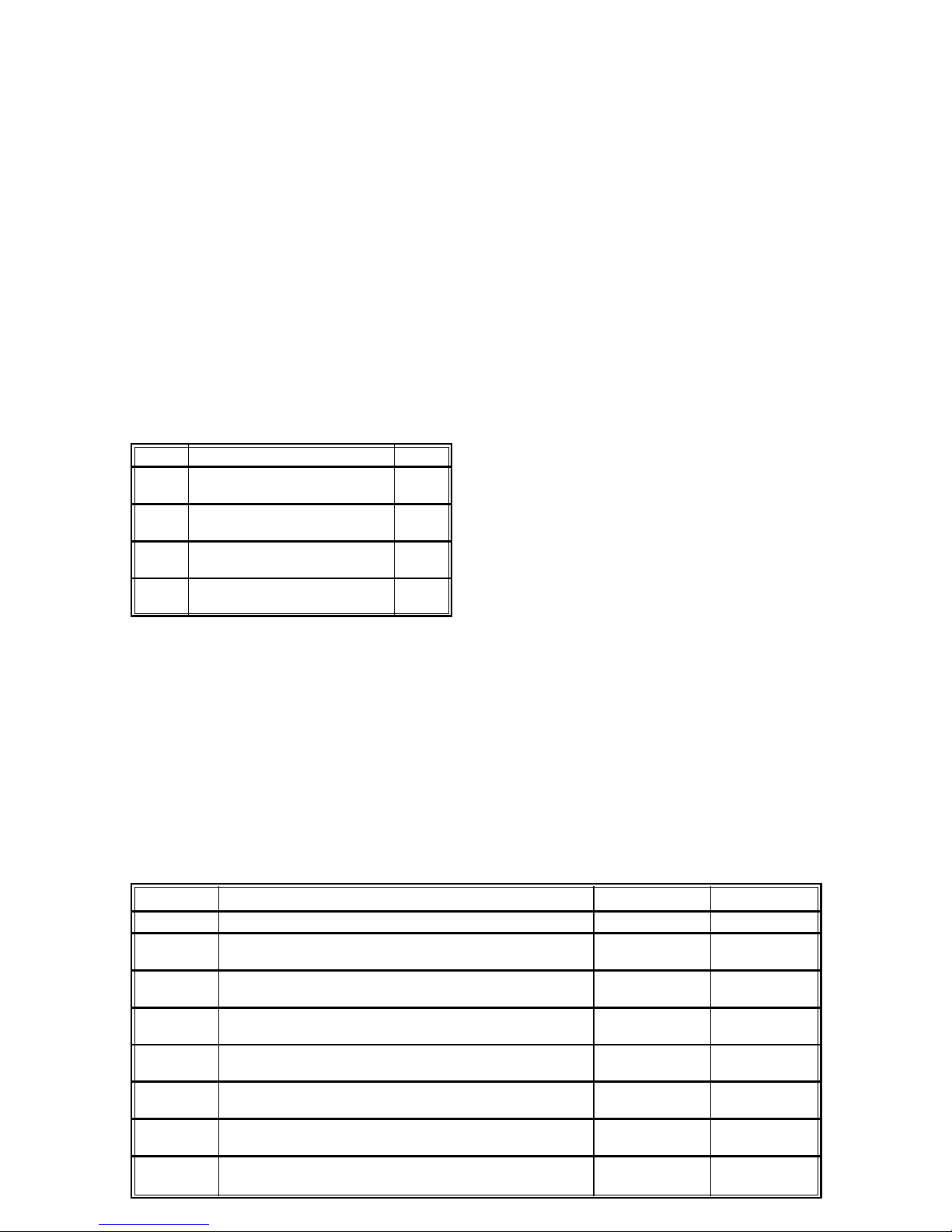

How to compute the value to be programmed into CV #29 (Register #5)

CV #29 (Register #5) is used to configure the decoder. One can for exam le invert the loco driving

direction (as well as its directional lights) or change the number of s eed ste s. It is ossible

to configure the decoder for digital-only o eration or for mixed (and automatic) analog/digital

o eration. Finally, one can tell the decoder to react to commands sent to either the short address

(CV #1) or to the long address (CV #17/18).

You can use the Value column of the following table in order to com ute by summation the value

to be written into CV #29 (or Register #5) in order to obtain the desired decoder configuration.

Example (if not using Bit programming):

Normal driving direction value =0

14 s eed ste s value =0

autom. analog/digital value =4

short adress value =0

The sum of all of these values gives 4.

This is the value to rogram into CV #29 (or

Register #5) - and, this value ha ens also to be

the factory default value for CV #29.

Function

Normal driving direction

opposite driving direction

14 / 27 speed levels

28 / 128 speed levels

Digital mode only

Automatic analog or digital operation

Short address (C #1, Register #1)

Long address (C #17 und C #18)

Value

0

1

0

2

0

4

0

32

BIT

0

1

2

5

Programming a long address without using a menu

If you have to rogram the decoder for o eration on a long address and you are not using a

Command Station which makes this rocess automatically, then you have to com ute what value

to write into CV #17 and CV #18. Well now show by exam le what to do using long address 2000.

Divide the choosen long address by 256 (here 2000/256 = 7 with a remainder of 208).

Take the integer quotient of that division (7 in our exam le) and add 192 to it.

Write the result of this addition (7+192 = 199) into CV #17.

Write the remainder of the division (208 in our exam le) into CV #18.

Important: make sure that Bit #5 of CV #29 is set to 1, so as to tell the decoder to react to

commands sent to its long address (CV #17/18) and not to commands sent to its short address.

Register Table

Description

Decoder (short) address

Minimum speed

at speedstep 2

Acceleration delay

1 = no delay, 255 = max. delay

Deceleration delay

1 = no delay, 255 = max. delay

Decoder configuration

Check chapter on decoder configuration/CV #29

Page Register

Used during paged programming

Maximum speed

at highest speedstep

Manufacturer id

for Uhlenbrock Elektronik GmbH

Register-Nr.

1

2

3

4

5

6

7

8

Allowed range

1-127

1-31

1-255

1-255

see C 29

-

1-95

-

Value

3

5

2

2

4

-

90

85