- 1 -

Multi-protocol decoder 73 510

in Mini-formatwith 6 way NEM 651 plug

For locomotives from Arnold, Bemo, Brava, Fleischmann, Kato, Roco, Tillig, Minitrix.

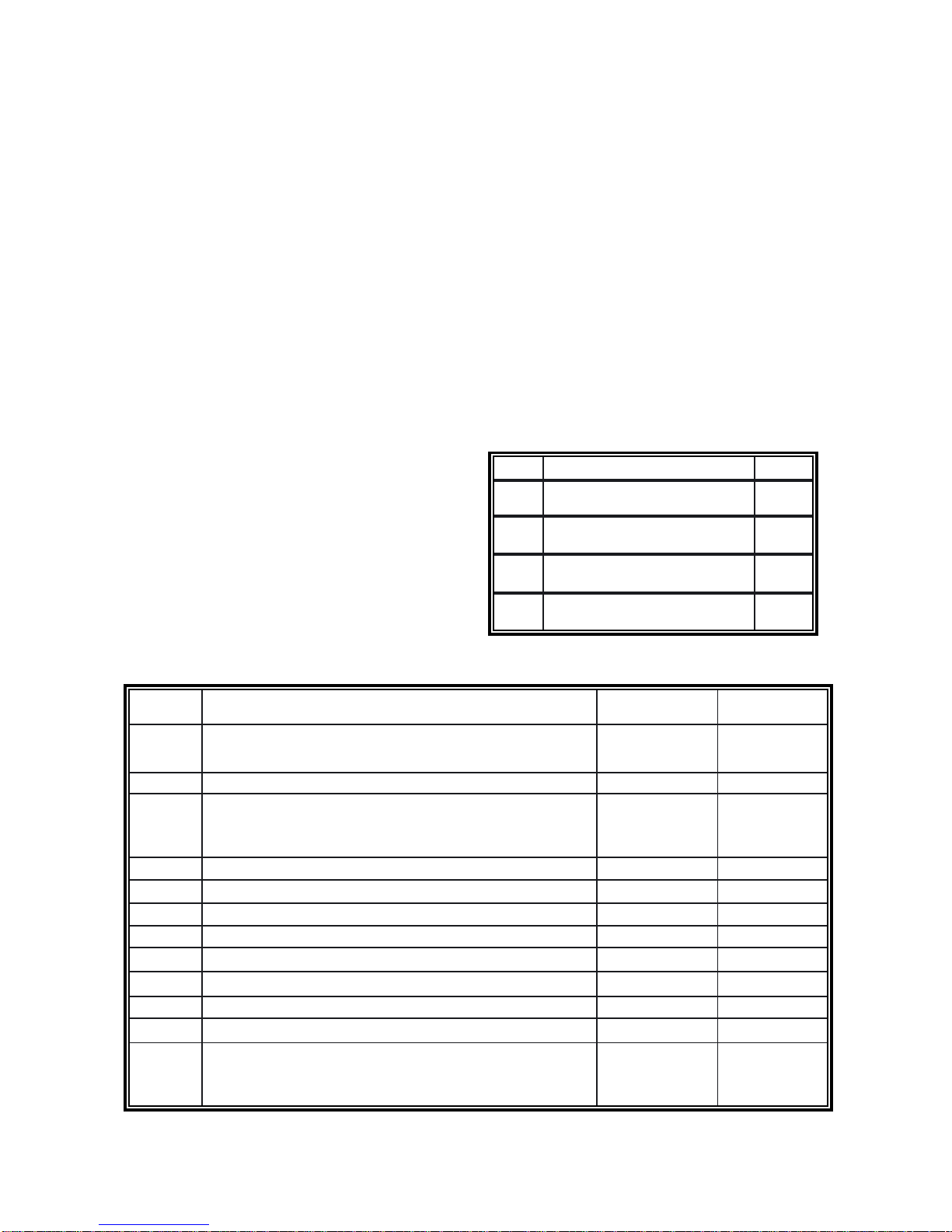

Features 73 510

•Regulated Multi-protocol decoder for DCC, Motorola and Selectrix

•Suitable for DC and Bell armature motors up to 500mA

•Quiet motor running with 18.75KHz control frequency

•14, 27, 28, 31 and 128 speed steps depending on the data format

•Short (1-127) and long (128-9999) addresses

•NMRA compatible

•Minimum, maximum and middle speeds adjustable

•Speed step table for 14, 28 and 31 speed steps

•Main line programming (DCC)

•Shunting speed (half speed) switched with F3

•Direction dependent, dimmable lighting switched via F0

•Reacts to DCC brake signal (e.g. from Power 3) or Selectrix “Brake diode” or braking section

in DC operation.

•Over heating protection

•All outputs have short circuit protection

•Conventional DC operation with automatic switching between DC and digital mode

•All CV’s programmable by digital devices with DCC, Motorola and Selectrix formats

•Programmable via register, direct CV or page mode in DCC operation

•Updatable using Flash memory

Description

Locomotive decoder 73 510 a very small multi-protocol decoder. It can be operated in DCC,

Motorola and Selectrix digital systems and also runs in DC analog mode.

The decoder operates with a frequency of 18.75KHz and is therefore well suited for DC and

especially for Bell armature motors (e.g. Faulhaber, Maxon, Escap) up to a maximum power

load of 500mA. Short burst start up currents are tolerated.

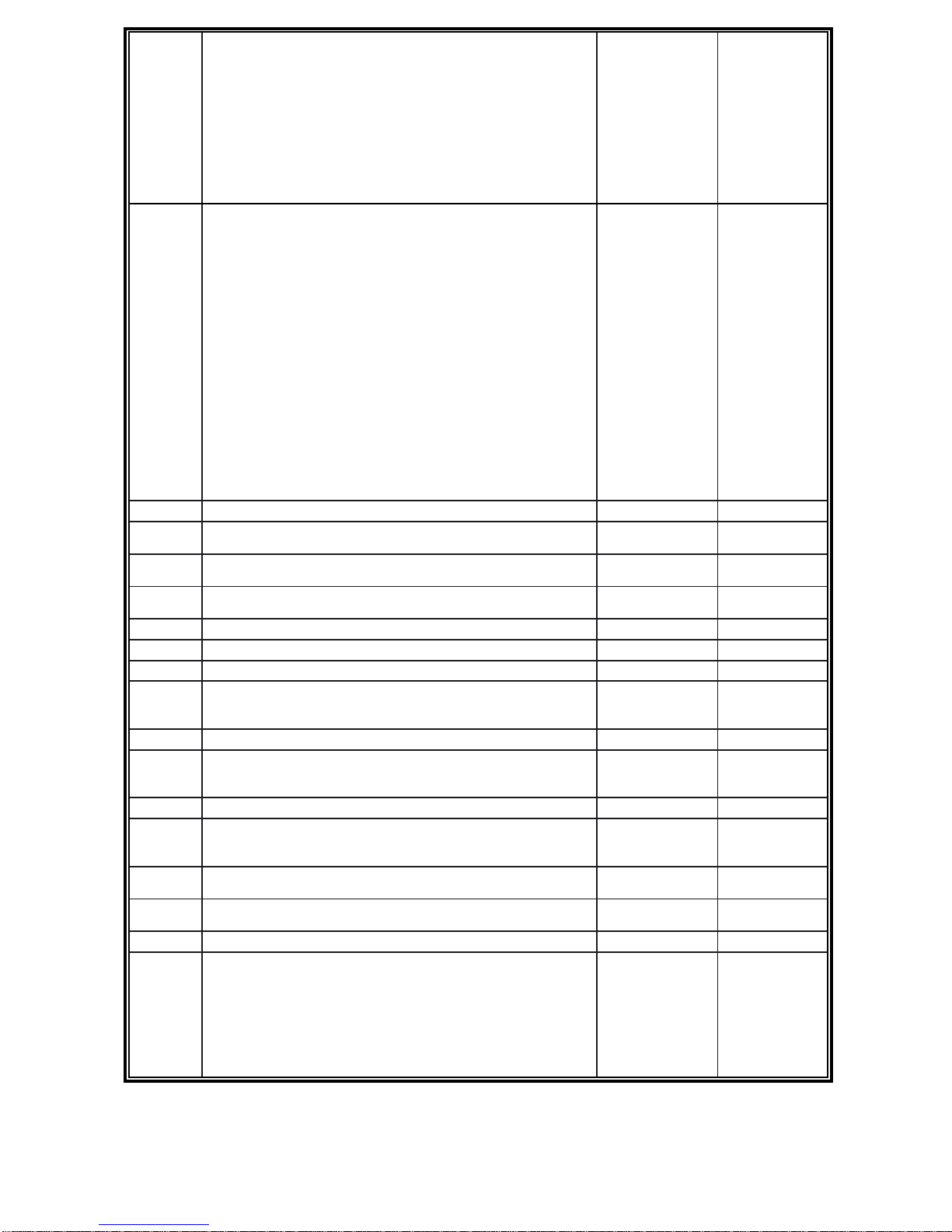

Motor characteristics can be controlled either by setting the minimum, maximum and middle

speeds or via various CV’s for individual speed steps.

Load regulation can be control via regulation parameters to a variety of individual motors.

The decoder provides two direction dependent lighting outputs. Using F3 and F4 a shunting

mode for slow speeds and Start/braking inertia can be activated.

The decoder can be programmed with the Intellibox, DCC, Märklin and Selectrix controllers and

Selectrix programming devices. CV’s can be programmed with all devices.

In factory default the decoder automatically recognizes DCC and Märklin data formats. On a

Selectrix layout the decoder must first its address programmed. The data format will then be

automatically be switched to “Selectrix only” (CV49, Bit 4 = 1). The decoder can then only be

switch to another data format by DCC programming.

If the decoder is to be used on a conventional DC layout the operating mode must be set up

with the configuration variable. If the decoder set to “analog mode” is placed on to a digital

layout it will automatically detects the digital signal and switches to digital mode.