iii

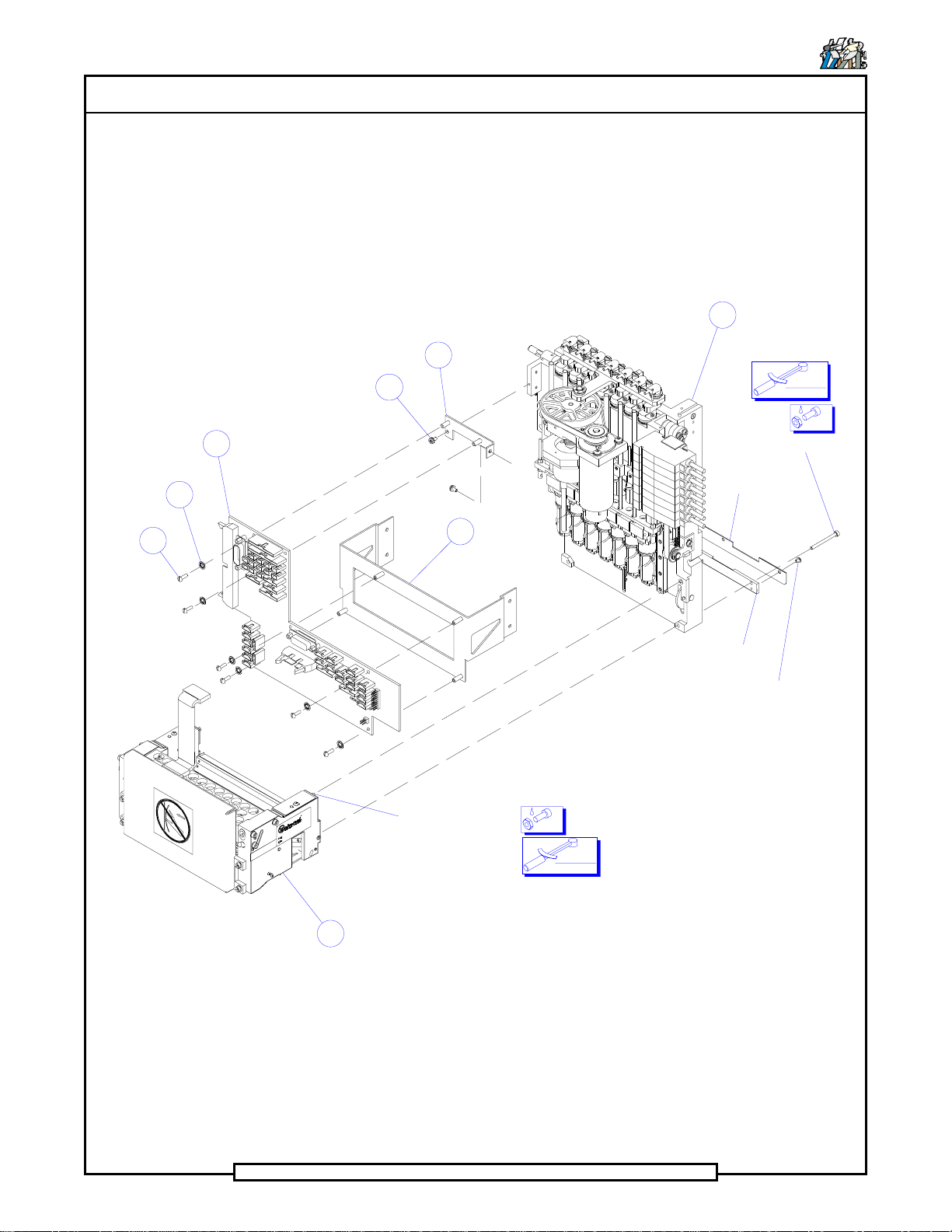

FlexJet Head Assembly T47541109 Rev. J

TECHNICAL PUBLICATIONS

This Document Supports Assembly 47541109 Rev. F

Install the New PCA FlexJet Control ....................................................................................................... 72

Install the Electrical Cabling .................................................................................................................... 73

Final Steps ................................................................................................................................................ 74

Advanced Support Information ................................................................................................................................... 76

Replacing the Stop Brake Belt........................................................................................................................... 76

Prerequisites ............................................................................................................................................. 76

Initial Steps............................................................................................................................................... 76

Remove the Damaged Belt....................................................................................................................... 77

Install the New Belt.................................................................................................................................. 77

Final Steps ................................................................................................................................................ 78

Replacing the Z Stop Brake Assembly .............................................................................................................. 79

Prerequisites ............................................................................................................................................. 79

Initial Steps............................................................................................................................................... 79

Remove the Faulty Stop Brake Assembly ............................................................................................... 79

Install the New Stop Brake Assembly...................................................................................................... 80

Final Steps ................................................................................................................................................ 81

Replacing a Spindle Touch-Down Sensor ......................................................................................................... 81

Prerequisites ............................................................................................................................................. 81

Initial Steps............................................................................................................................................... 81

Procedure.................................................................................................................................................. 82

Final Steps ................................................................................................................................................ 84

Replacing a Clutch............................................................................................................................................. 85

Prerequisites ............................................................................................................................................. 85

Initial Steps............................................................................................................................................... 85

Disassemble the Head .............................................................................................................................. 86

Install the New Clutch.............................................................................................................................. 89

Final Steps ................................................................................................................................................ 91

Replacing a Manifold Tubing ............................................................................................................................ 92

Prerequisite............................................................................................................................................... 92

Initial Steps............................................................................................................................................... 92

Procedure.................................................................................................................................................. 93

Final Steps ................................................................................................................................................ 94

Replacing the Manifold ..................................................................................................................................... 94

Prerequisites ............................................................................................................................................. 94

Initial Steps............................................................................................................................................... 95

Remove the Current Manifold ................................................................................................................. 95

Install the New Manifold.......................................................................................................................... 96

Final Steps ................................................................................................................................................ 98

Replacing a Fiber Optic Cable........................................................................................................................... 98

Prerequisites ............................................................................................................................................. 98

Initial Steps............................................................................................................................................... 98

Disassemble the FlexJet Head .................................................................................................................. 99

Install the New Fiber Optic Cable.......................................................................................................... 100

Install the PCA FlexJet Control ............................................................................................................. 100

Final Steps .............................................................................................................................................. 101

Replacing the Spindle Drive Belt .................................................................................................................... 102

Prerequisites ........................................................................................................................................... 102

Initial Steps............................................................................................................................................. 102

Change the Belt ...................................................................................................................................... 103

Final Steps .............................................................................................................................................. 103

Replacing a FlexJet Spindle Assembly............................................................................................................ 104

Prerequisites ........................................................................................................................................... 104

Initial Steps............................................................................................................................................. 104

Procedure................................................................................................................................................ 104

Disassemble the Head................................................................................................................... 105