UIM-90 (221)

UIM-90 (221/В)

UIM-90 (221/Р)

UIM-90 (221/ВР)

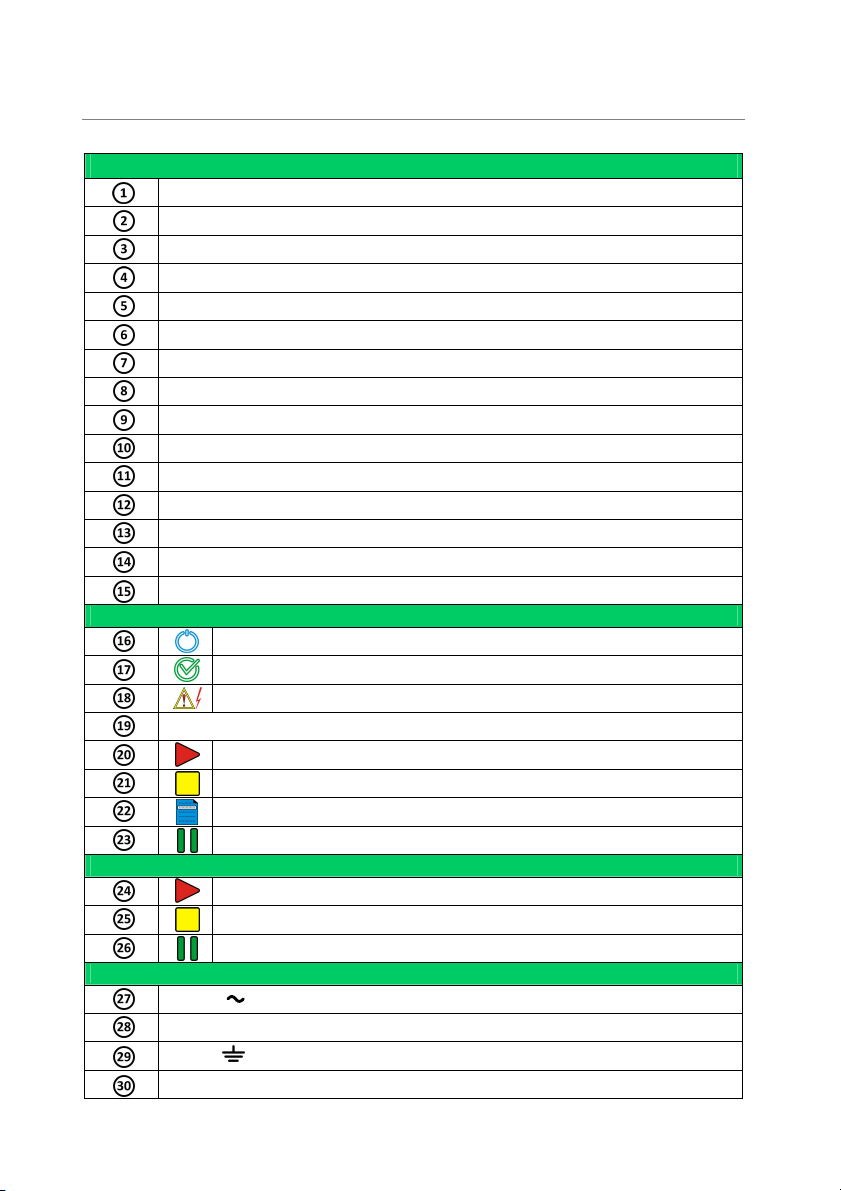

1.2 Technical specifications

1.2.1 The main technical characteristics of the Oil tester:

Type Value

1 Range of testing voltage (rms value), kV from 10 to 90

2 Relative voltage measurement error, % 3

3 Volume of measuring cell, cm3, min 400

4 Operating alternating voltage, V 220 10

5 Power supply frequency, Hz 50/60

6 Power consumption, kV×A, max 0,1

7 Weight, kg, max 28

8 Dimensions, mm, min 520×335×320

1.2.2 Duration of continuous work of the Oil tester is 8 hours.

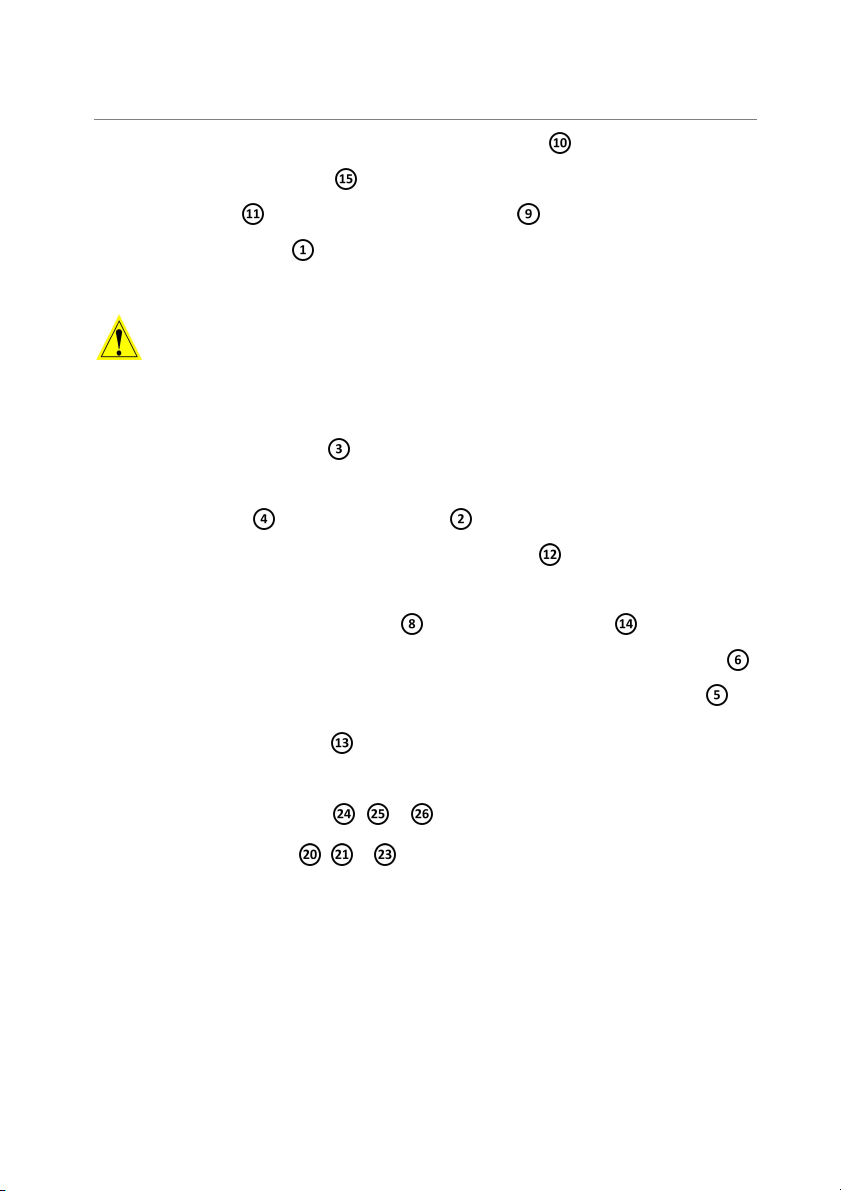

1.2.3 Oil tester operates, retaining its design and parameters during and af-

ter exposure to external influencing factors:

Extreme values of factors

Extreme conditions

External influencing factor Operating

conditions Transporta-

tion Storage

1 Ambient temperature, °C

– lower value

– upper value

+15

+30

–25*

+55

–25*

+55

2 Relative humidity, %

– lower value

– upper value

10

75

10

100

10

100

3 Atmospheric pressure, kPa

– lower value

– upper value

70

106

70

106

70

106

4 Shockproof on multiple shocks

– peak shock acceleration, m×sec-2

– duration of shock acceleration, ms

– quantity of shocks, pcs.

–

30

1

80-120

–

* Turning on the Oil tester after a long stay at a temperature below 5°C is allowed after pre-

exposure for 4 hours at a temperature from +15°C to +30°C