3. Installation

3.1 Location

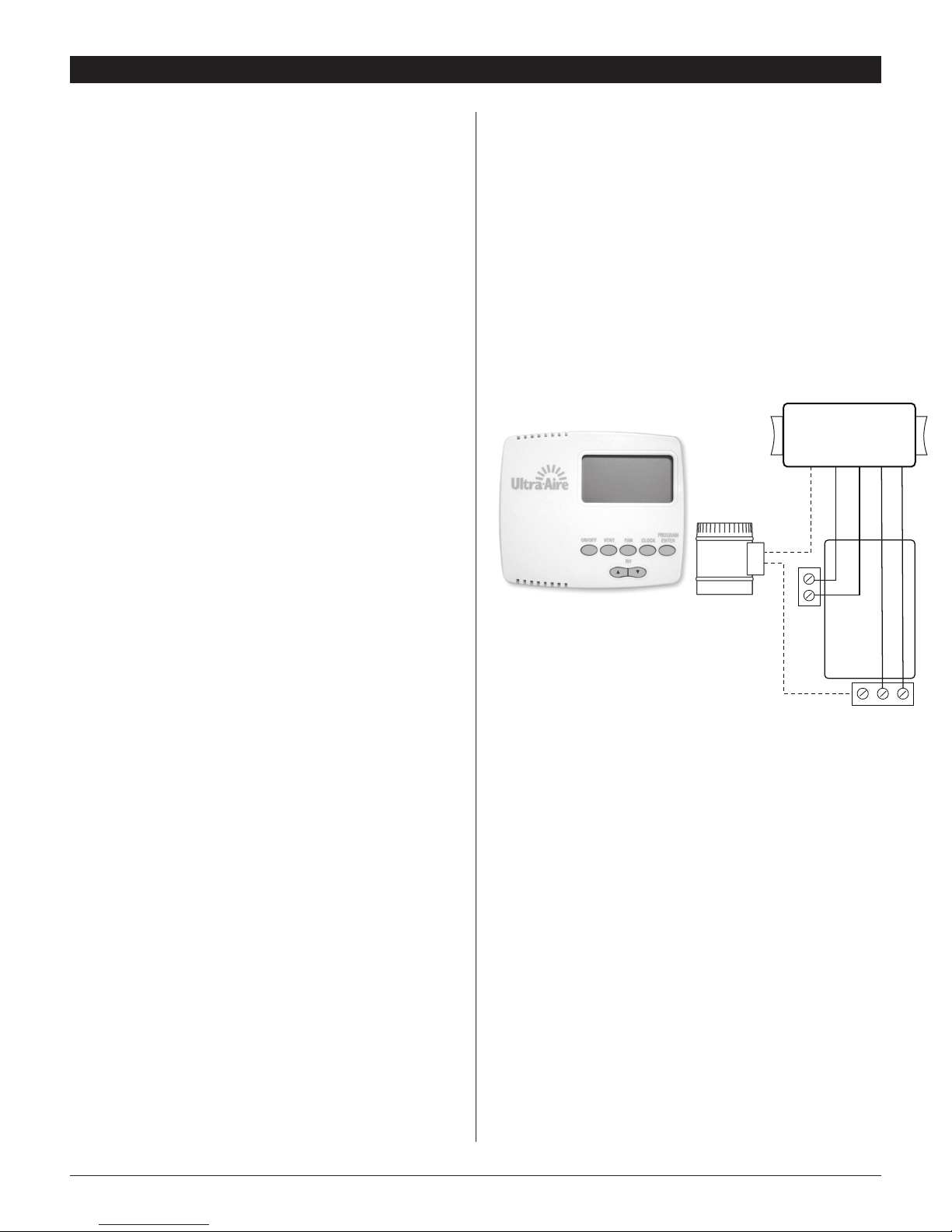

The Ultra-Aire should be located near the existing air handling system

to minimize the required ductwork for connecting the Ultra-Aire to

the existing air handling system.The controls for the Ultra-Aire are

remote from the unit and must be located in the space that is to be

conditioned. The controls are low voltage (24 volt) and should be

connected to the Ultra-Aire with low voltage thermostat cable.

If fresh air ventilation is desired, thought should be given to the

location for the fresh air ducting. A 6" round duct will have to be

installed on the Ultra-Aire and run to the outside of the structure to

bring in fresh air. Use an 8" insulated round duct for lengths of more

than 25' or if more than 100 CFM is needed.

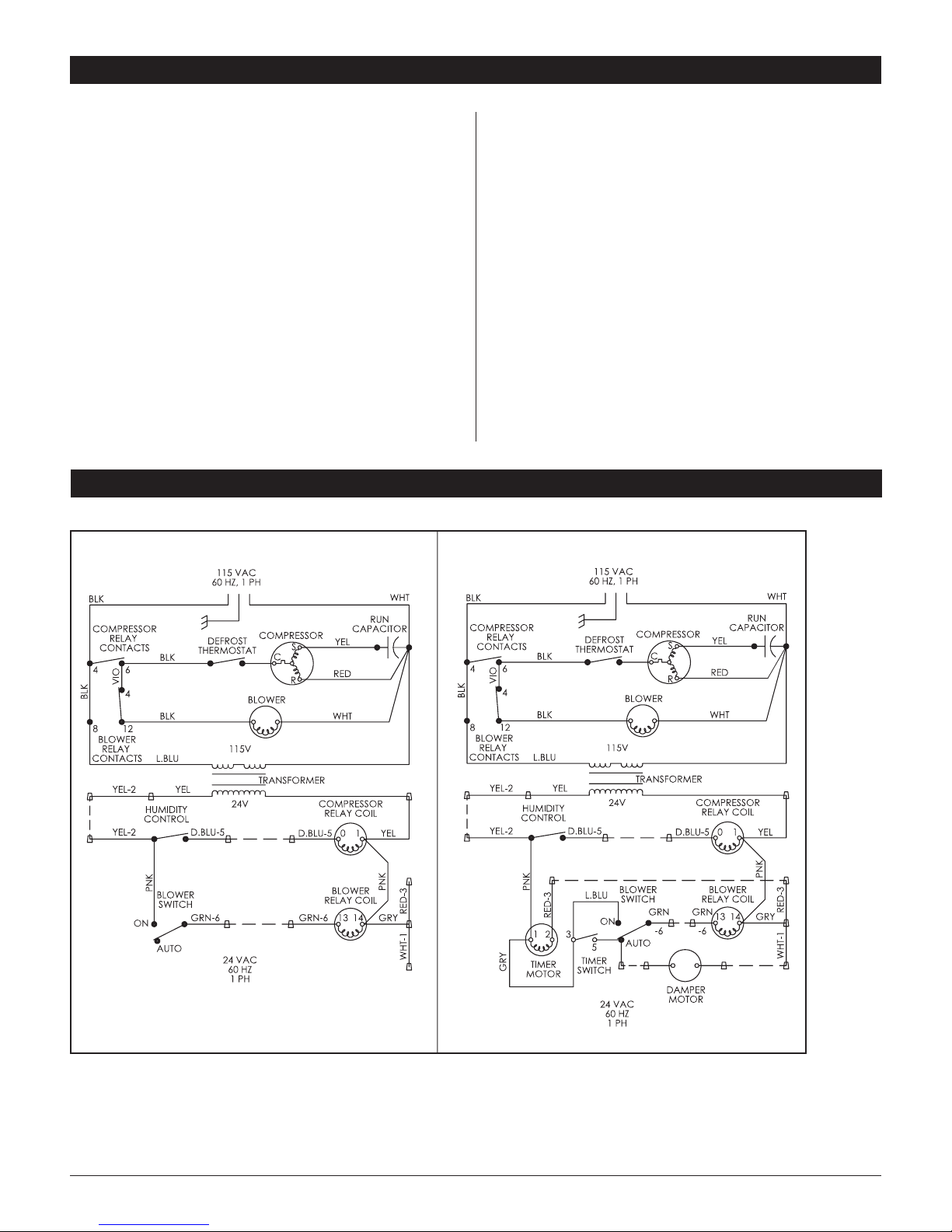

3.2 Electrical Requirements

The Ultra-Aire plugs into a common grounded outlet on a 15 Amp

circuit. It draws between 6 and 7 Amps under normal operating

conditions. If used in a wet area (pool, spa room, or basement prone

to flooding), a ground fault interrupter protected circuit is required.

The installer must supply the wiring between the Ultra-Aire and the

control panel. Be sure to safely route the control wires to prevent

damage during installation. Be careful not to cross the wires when

connecting the Ultra-Aire and the remote control panel or damage to

the transformer may result.

The remote controls of the Ultra-Aire are powered by a low voltage

circuit (24 Vac) and must NEVER contact or be connected to a high

voltage circuit. The control wires leaving the Ultra-Aire and the

remote control panels are color coded to prevent confusion. Some of

the control wires leaving the Ultra-Aire may not be used with certain

control panels and should be left safely disconnected with wire

nuts taped onto the stripped ends. Be sure to consult the electrical

schematic in this manual or on the front panel of the Ultra-Aire before

making the control connections.

WARNING! Do not allow the yellow lead

from the Ultra-Aire to contact the red lead or orange

lead from the Ultra-Aire or damage to the transformer

will result.

NOTE: Reset the ventilation timer before attempting to

program after initial installation. The timer may not ..

operate correctly until it is reset.

3.3 Condensate Removal

Condensate drains by gravity via the clear hose extending from the

unit. Route the hose to a floor drain. Use care to keep the hose as flat

to the floor as possible; excessive humps will prevent proper drainage.

We do not call for a trap since there is an internal trap with this unit.

If the Ultra-Aire is located too far from a floor drain for the attached

hose to reach, inexpensive 1⁄2" PVC pipe can be used to extend it. It is

commonly available in 10' lengths from building supply, plumbing and

hardware stores. It will slide tightly inside the end of the drain hose.

If more than one length of pipe is required, they can be joined with a

short piece cut from the end of the drain hose.

An optional condensate pump may be installed if a lift is required to

dispose of the condensate. The condensate pump kit can be ordered

direct from the factory. See item 27 on page 21.

3.4 Ducting

3.4A Installing Duct Collars

The Ultra-Aire is equipped with 8" and 6" round inlet collars and an

8" round white exhaust collar. The 8" and 6" round inlet collars are

designed with tabs that fold under the top of the Ultra-Aire. The 8"

round white exhaust collar is attached to the Ultra-Aire by (4) screws.

To install the inlet collars: Insert the tabs of the collar into the hole in

the top of the Ultra-Aire and fold the tabs up to attach to the Ultra-Aire.

To install the exhaust collar: Bend the (4) tabs toward the inside of

the collar 90°. Attach the collar to the Ultra-Aire cabinet using 1⁄2"

long #8 sheet metal screws. DO NOT use screws longer than 1⁄2" to

attach this collar or damage to the refrigeration system may result.

3.4B Ducting for Dehumidification

For the ideal installation, draw air from the central part of the home

and return it to the isolated areas of the home like the bedrooms,

den, utility room, or family room. The ductwork of the existing heating

system can be used to supply air to the home. If the existing supply

goes to isolated areas of the home, discharge the supply of the

Ultra-Aire into the supply of the existing heating system. If the existing

heating system incorporates a central supply, installation of a separate

supply duct from the Ultra-Aire to each isolated area is recommended.

DO NOT draw air directly from the kitchen, laundry, or basement. All

flexible ducting connected to the Ultra-Aire should be UL listed.

The inlet of the Ultra-Aire is the 8" diameter hole on top of the unit. An

8" round collar is supplied with the unit to attach to round duct. The

duct may be permanently attached to the collar. A 6" round collar is

provided with the unit to attach to the 6" hole in the top. The 6" collar

should be capped if fresh make-up air is not desired. If fresh make-up

air is desired see section 3.4C.

The outlet of the Ultra-Aire is located on the side of the unit. A second

8" round collar is supplied with the unit and can be attached using the

screws provided and the pre-punched holes in the cabinet side.

A length of 10 feet or more of acoustical flex ducting on the outlet of

the Ultra-Aire will reduce air noise from the blower. A length of flexible

ducting on all Ultra-Aire duct connections is recommended to reduce

noise and vibration transmitted to rigid ductwork in the structure.

Ducting the Ultra-Aire as mentioned in sections 3.4A-3.4G requires

consideration of the following points:

SAFETY PRECAUTIONS

3Ultra-Aire 100V Installer’s & Owner’s Manual