Introduction

This manual contains information and recommendations for installing, operating, and servicing the Ultra

Air Refrigerated Dryer. Ultra Air Refrigerated Dryers are the highest quality dryers available. We back this

claim with one of the longest warranties available in the industry. All units are totally self-contained and

have been fully tested and inspected by Ultra Air before shipment from the factory.

The information, specifications, and illustrations in this manual are in accordance with the information in

effect at the time of printing. Ultra Air reserves the right to change design and specifications without notice

and without incurring obligation.

Please read this manual carefully before locating and installing your dryer. Any questions or problems not

covered herein may be directed to your Ultra-Air distributor or to Numatics Air Preparation Group, 3309

John Conley Drive, Lapeer, MI 48446, or by phone at (810)667-6800 or fax at (810)667-3902. Before call-

ing, be sure to have the model and serial numbers available. The manufacturer will not be responsible for

parts returned without proper authorization.

Warnings

Only persons experienced and licensed to work on electrical, refrigeration, and compressed air systems

should install or operate this equipment.

This entire manual should be read and understood before starting installation or operation of this dryer.

Before starting, installing, or performing maintenance procedures, the main power must be turned off and

the dryer must be depressurized to 0 PSIG.

Do not remove, repair, or replace any item on this dryer while it is under pressure and/or the power is

turned on. This dryer contains refrigerant R134A or R22. Service personnel must be certified to handle

R134A and R22 and comply to all local, state, and federal regulations concerning refrigerant when per-

forming maintenance or service on this dryer. Never operate this dryer above the maximum rated operat-

ing conditions. Operating above specified conditions will result in inferior performance and could damage

the unit and/or cause personal injury.

Ultra Air Products, Inc. will not be held responsible for removal, reinstallation, down time costs, or conse-

quential damages caused by the refrigerated air dryer even if the possibility of such incidental or conse-

quential damages has been made known to Ultra Air Products, Inc.

Receiving and Inspection

Upon arrival, remove all packaging materials and inspect dryer carefully. Inspect cabinets for dents, inlet

and outlet connections for damage, and skid for any oil due to refrigerant leaks. Inspect refrigerant

gauges; they should read at least 40 PSIG and not be damaged. If they do not read at least 40 PSIG, do

not start the dryer, instead, contact the factory immediately. If any damage is found, report it to the freight

company immediately.

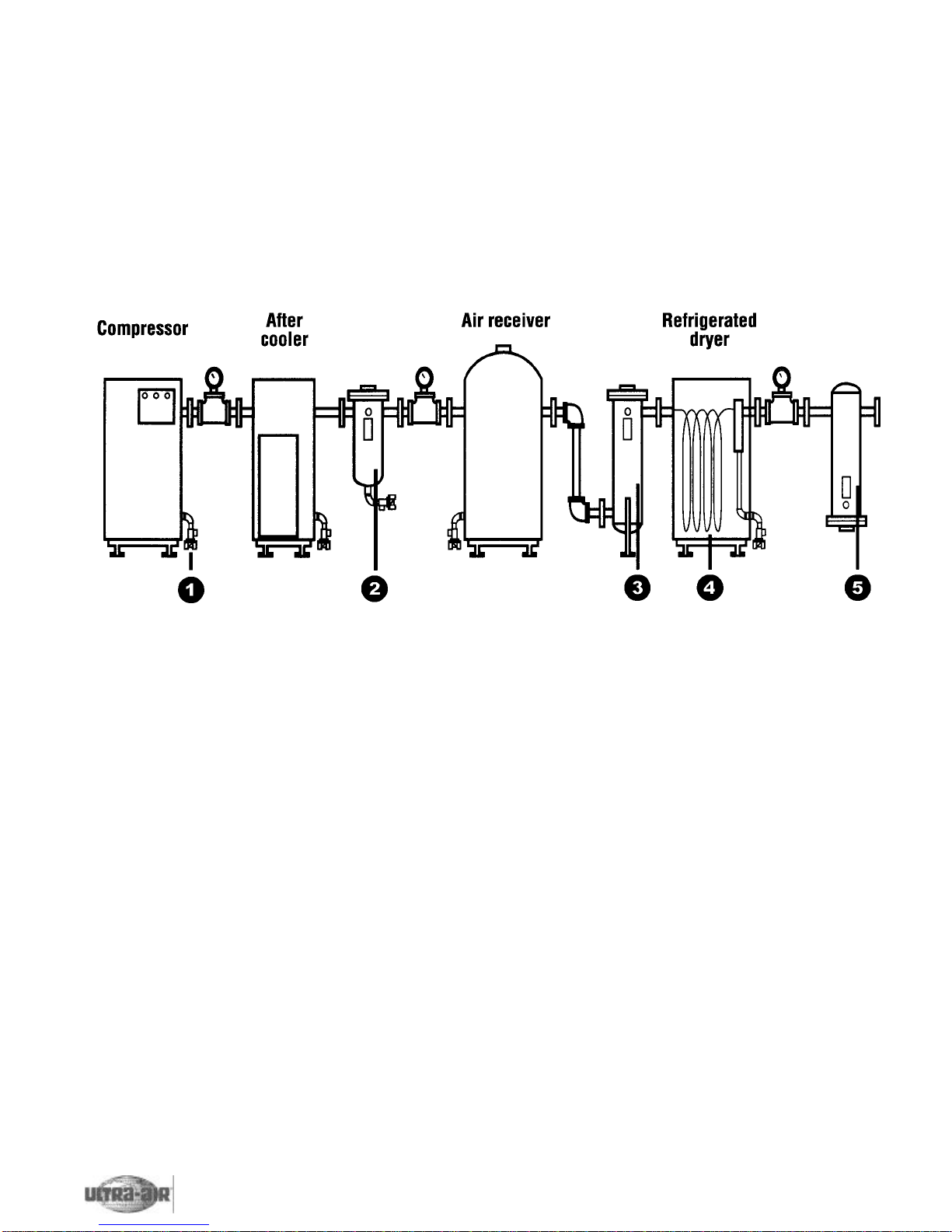

Installation

Allow three (3) feet on all sides of the dryer for service and proper air flow. The dryer should be installed

in ambients where temperatures do not drop below 40ºF or rise above 110ºF. Dryers are normally

installed downstream of the receiver tank to prevent undue surging. Unit should be sitting level. Always

select an installation site where ample with ventilation, particularly for air-cooled condenser units. An ade-

quate supply of outside air may be made available by using an exhaust system to avoid recirculation of

room air. An area with a high ambient temperature will affect the efficiency of an air-cooled (continued)

Ultra Air Refrigerated Dryers 201 Series Instruction Manual

1REFRIGERATED AIR DRYER INSTRUCTION MANUAL