www.ultraoptics.com page 2

breakage, the 44R system continuously monitors the quality of the wash water and alerts

the user when problems start to arise. This allows servicing the equipment before the

issue gets worse and the production yield goes down.

Measured UV light intensity –the coating applied to the lens will only properly cure if it

has received sufficient energy from the UV light source. It is well understood that the

intensity of the UV light source diminishes over time. The 44R actively monitors this

intensity level and will alert the user when the intensity is getting too low to produce

reliable curing of the coating.

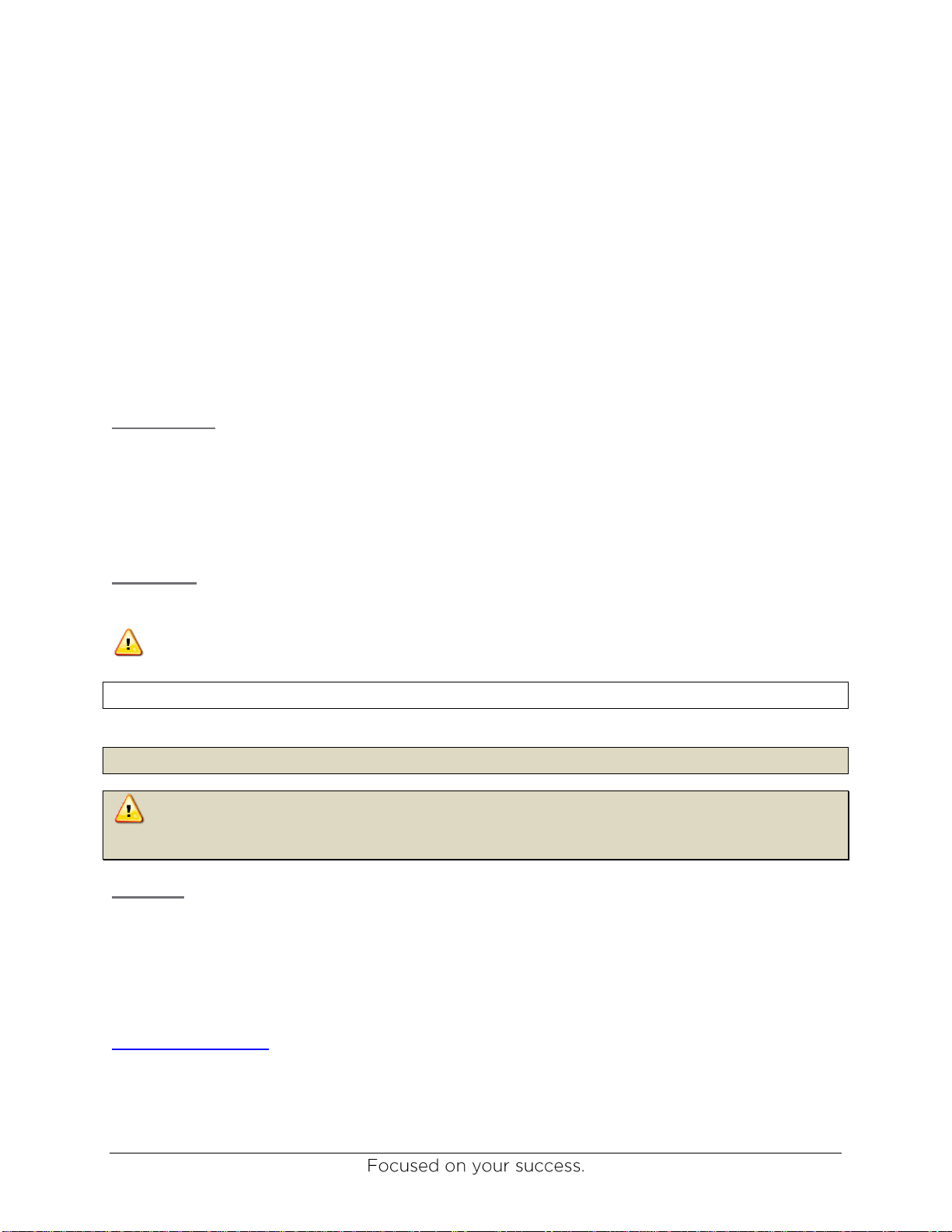

Enhanced compressed air filtration –a well cleaned lens can quickly be spoiled if it is

dried with contaminated air. In order to reduce lens breakage during the drying step of

the process, the 44R makes use of multi-stage air filtration to deliver ultra-clean air

during the drying of the lens.

Lens Conveyor

The front of the 44R machine contains a 6-foot long section of automated conveyor. This

section is designed to take incoming trays and feed them into the staging area of the machine.

A motor-driven belt I used to advance the trays across the front of the machine. There are

several stop locations for the trays to wait, and they are controlled by stop pins mounted

beneath the trays. These stop pins are controlled pneumatically by the system PLC.

Lens Load/Unload

Lenses are loaded and unloaded into the machine by making use of a robotic arm. The motion

of the arm is controlled by the robot’s controller, utilizing input communication from the main

system PLC. As the system’s PLC controls the over-all process, it sends commands to the

robot controller, which in turn manipulates the arm of the robot to the desired location and

action. The end-of-arm tooling on the robot has been designed to flip 180 degrees with proper

suction cups to facilitate picking and placing lenses into the processing portion of the machine

and the carrying trays. The robot will always load/unload lenses into the first, or front, station of

the processing portion of the machine. The machine’s arm assembly will transport the lens from

one processing station to the next (i.e. from the wash station to the dray station, etc) without any

action required from the robot. The lenses are processed directly from the tray, while still

mounted to the block. It is not necessary to de-block the lens prior to entry into the 44R

machine. The lenses are picked and held by use of vacuum pressure at each of the suction

cups.

While the lens is being processed, the suction cup is applying vacuum to the block, not the lens

directly, reducing the amount of stress on the lens during processing. Further, the mass of the

block provides heat dissipation during the curing stage, reducing the temperature of the lens

during curing. The benefit of these design considerations is significant reductions in lens

warping during processing.