3

Care should be taken when handling components that are seen by the

homeowner, as surfaces may be scratched if not handled with care

(see p10). Choose a suitable area for unpacking the components

and always check them before fitting. Any claims for missing or

damaged parts are only accepted in line with our standard terms

and conditions of sale.

Health & safety

Site safety is particularly important. The installation company shall

be responsible for the safety of all of the fitting team, the customer

and members of the public. The Surveyor should have carried out

a risk assessment to reduce risk on site and this should have been

discussed with you prior to starting.

Please use safe working platforms and ladders that comply with

BS EN 131. Always use equipment in line with manufacturers

recommendations .Personal Protective Equipment - such as

goggles, mask and ear defenders - should be used when, for

example, grinding out for the flashing.

Careful consideration should be given to the safe disposal of

all packaging – Pergola packaging is predominantly made from

recycled materials and can be readily recycled.

Components

The kit is supplied with a quality control check list. Should you need

to re-order a part the component identification chart on p9 will be

helpful.

Sealing

It is important to use the correct sealant when sealing the roof use

low modulus neutral cure brand of silicone.

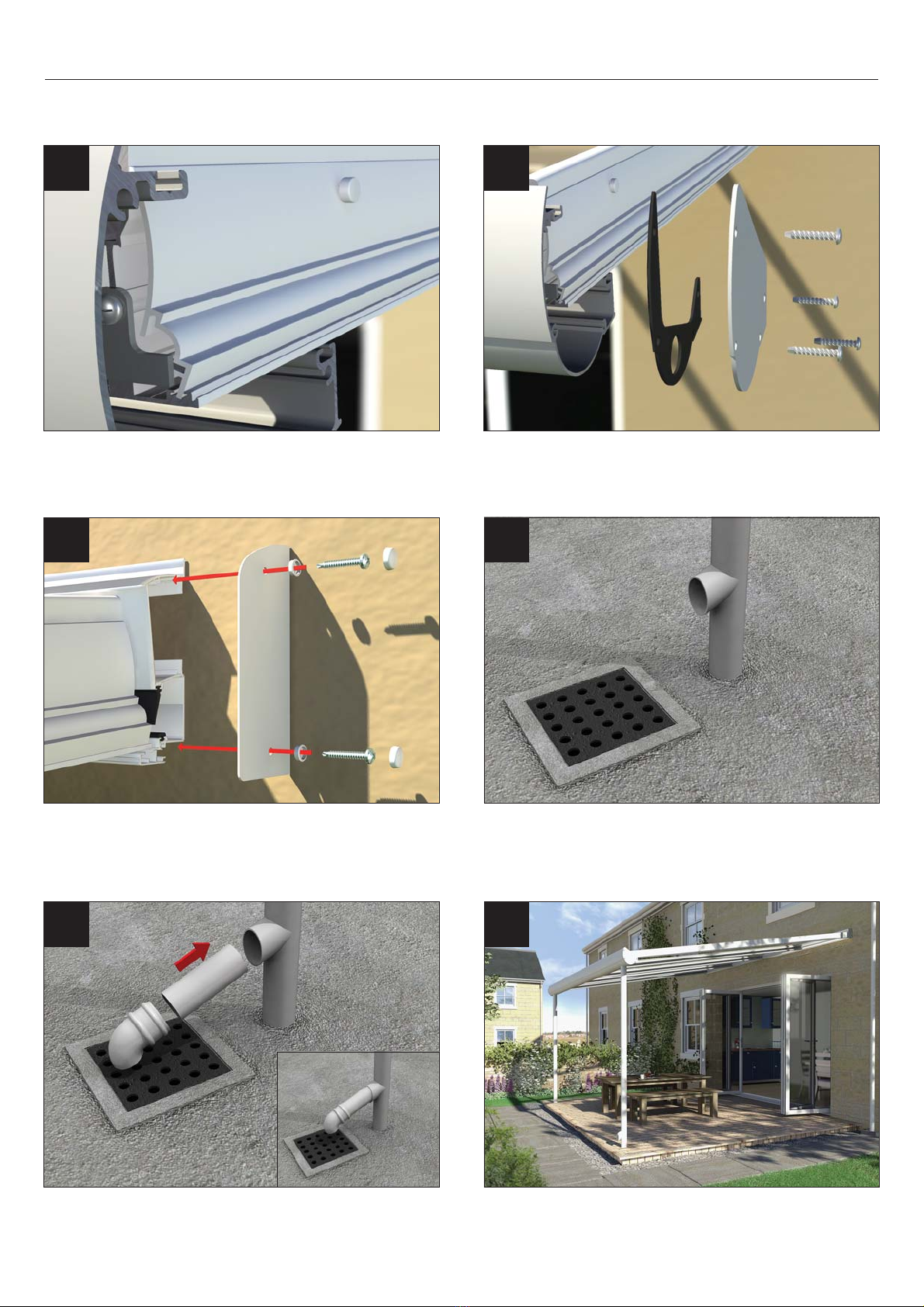

The Superstructure

Before starting to install the Pergola, please check the condition of

the host wall and whether it’s plumb – depending upon what you find,

these conditions can seriously affect the final integrity of the roof.

Technical Support

PAINTED ALUMINIUM PRODUCTS - PLEASE NOTE

All paints will ‘chalk’ to some extent and there will be a

reduction in gloss level over time. (See Cleaning and

Maintenance guidelines p14)

Quality expectations on installation.

- Appearance. This is assessed based on the selection

of the ‘significant’ (primary) surface. From a distance of 3m,

stand at an oblique angle of 60degree and then defects such

as blisters, runs, pin holes etc should NOT be seen.

- Colour and gloss. Viewed from 5m, the coating must

be of even colour and gloss with good coverage.

Pergola to host wall fixings not supplied.

8, 10, 13mm+

17mm Socket

Spanner

Deadblow

Hammer or White

Rubber Mallet

No. 2 Pozi-drive Bit Hack Saw Drill/Screwdriver Long nose pliars Gasket Shears/

Snips

4.5mm Drill Bit

10mm Drill Bit

Sealant Gun 17mm Open

Ended Spanner -

Tie Bars

Spirit Level Tape Measure Anglefinder Plumb bob

TOOLS OVERVIEW

Allen Keys

General Points

Screwdriver