1.0 BAR

1.0 BAR

V= 230V

Ti= 35° C

Language

Pmax

Dp.start

P.dr.ru.

Pmax2

Dp.stop

P.Limit

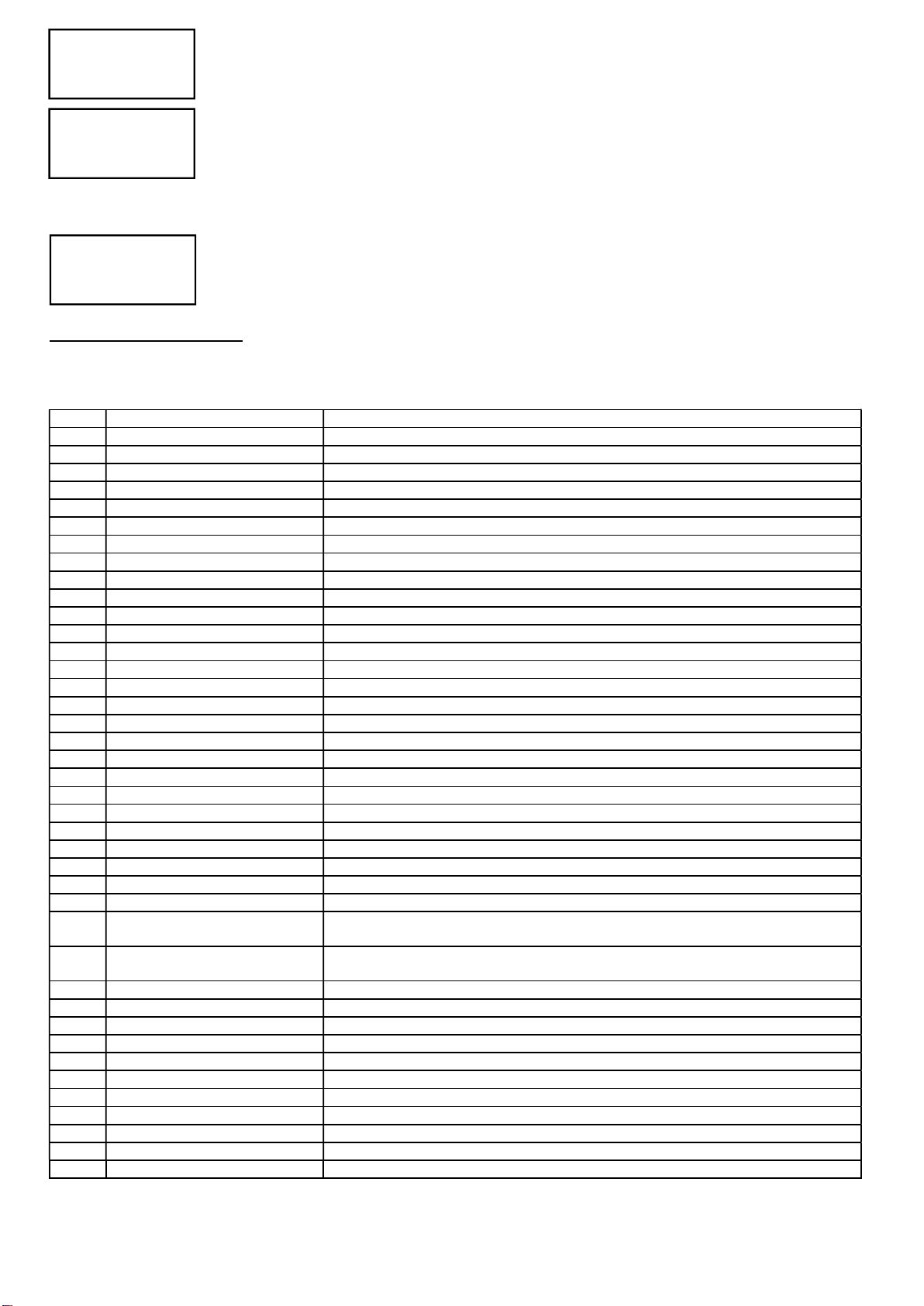

DESCRIPTION OF THE PARAMETERS AND SCREEN PAGES

MAIN MENU:

These screen pages are accessible when the device is on.

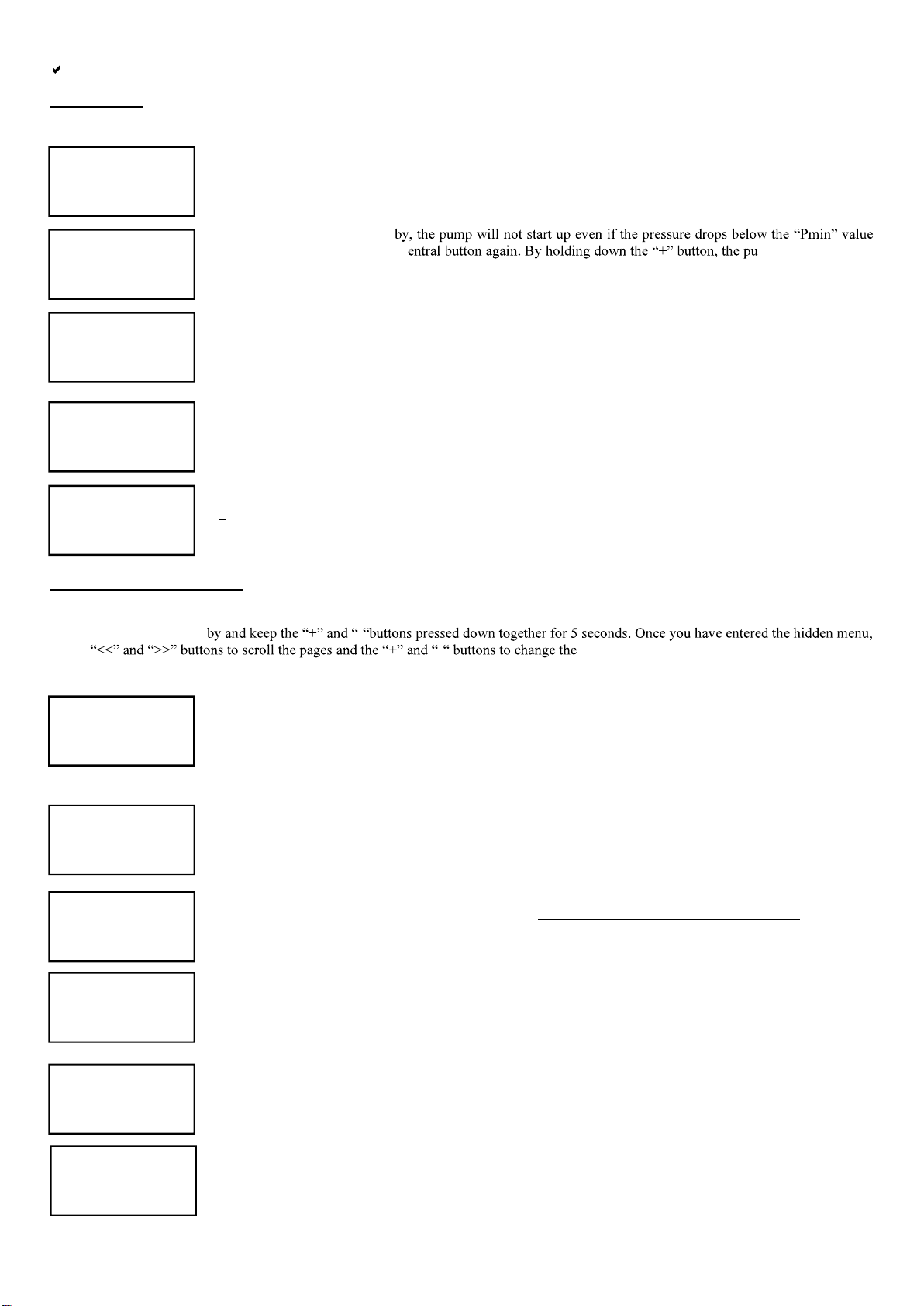

Main screen page: whenthe inverter is operating correctly, the first line of the display shows the instantaneous

pressure detected by the system; the second line shows the current frequency of the motor. From here, it is

possible to scroll through the main menu using the arrows, or put the system in "Stand-by" by pressing the

central "on-off" key

When the inverter is in stand-

set. To exit stand-by, press the c mp is brought up to

the maximum operating speed, overriding the dry running protection (use this function to fill the pump on initial

start-up).

Voltage and current screen: on this page of the menu it is possible to view the input voltage to the inverter and

the current absorbed by the motor. The value of the output current to the motor may differ from the value of the

input current as the inverter modulates both frequency and voltage.

Temperature screen: this displays the ambient temperatures inside the inverter and the IGBT power module.

The values of these temperatures contribute to the intelligent power management which limits the value of the

maximum frequency of the motor when the pre-alarm thresholds are reached.

Language: The language used for the menus and the alarm messages can be selected by the user. Use the + and

buttons to alter the parameter setting.

INSTALLER PARAMETERS:

These parameters can be found on hidden pages and usually they should only be changed in the installation phase. To access these pages

switch the device to Stand- -

use the - parameters. To return to the main page press the

button in the centre. Some parameters may not be displayed if the relative function is not enabled.

Pmax: this parameter enables entry of the set-point value of the device. It is a constant pressure value required

by the system (maximum pressure). During its operation the inveter regulates the revs of the electric pump to

adapt them to the actual required flow-rate, therefore maintaining the constant pressure of the system. When it is

necessary to set the Pmax to a value higher than the maximum pump head, motor shut down on valve closure is

only guaranteed if the flow switch is activated, as inverter switches off the pump when the flow of water

passing through it falls below the minimum values (approx. 2 litres/minute) irrespective of the pressure reached in the system.

Delta P start-up: this parameter sets the delta negative of pressure compared to Pmax for the start-up of the

pump. On opening of any type of utility, the pump will not start-up until the system pressure has fallen below

Pmax by a value equal to the delta set in this parameter. After the motor is started up, the operating rotation

speed is controlled to maintain the pressure value as close as possible to that set in the parameter Pmax. The

minimum differential settable between Pmax and Pmin is 0.3 Bar, with the recommended value being at least 0.5 Bar.

Dry-running pressure: this parameter only affects operation with the flow switch deactivated. Define the

minimum pressure value below which, with the motor at maximum frequency, the protection against dry-

running triggers.

Pressure limit: this parameter sets the threshold for the overpressure protection intervention.

The overpressure protection intervention stops the inverter until the user resets it.

Pmax2: this parameter enables entry of the secondary set-point of the device. When the auxiliary contact (or the

auxiliary I/O board input) is closed externally, the pressure value set in Pmax2 becomes the new set-point,

according to which inverter regulates the revs of the electric pump.

Delta P stop: this parameter sets the positive pressure delta compared to Pmax for immediate shutdown of the

pump. During normal operation, when the valves close, the pump stops after a time set in the parameter "stop

delay". In any case, if the system pressure exceeds the Pmax value of a delta greater than that set in this

parameter, the pump will stop immediately to avoid overpressure which may damage the system.