How to avoid trouble | 9

Flow rates

Outgassing from soil sample

Temperature influences

Ion specification

Outgassing from water

Water discharge

Different ion composition and concen-

tration of water and soil affect the

value of the measured conductivity.

Make sure the ion composition and con-

centration of water and soil are similar.

If necessary adjust by adding CaCl2.

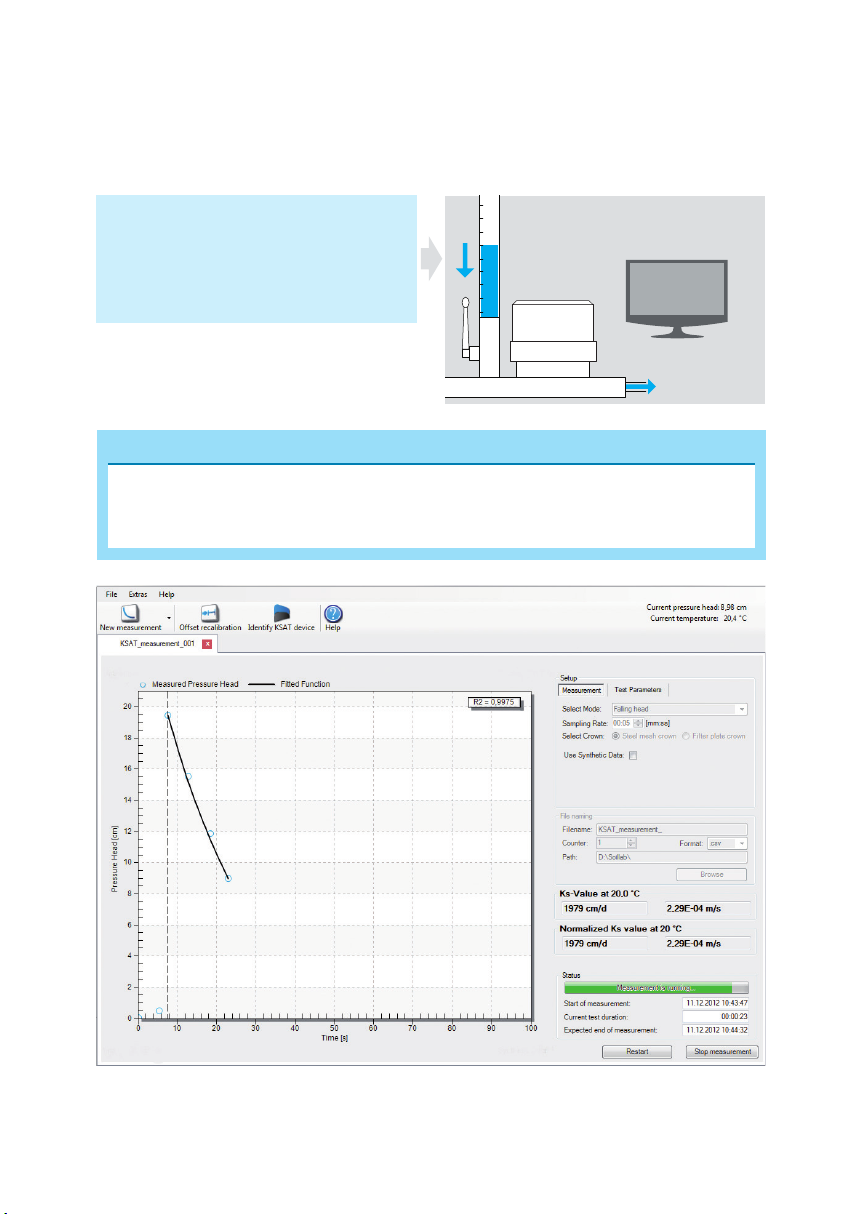

High flow rates erode the soil sample

and lead to wrong measuring results.

Air bubbles outgassing from the sample

reduce the conductivity.

Extremely high flow rates cause turbulent

flow and invalidate the methodology.

Keep the flow rates as low as possible.

The scientific literature recommends

an initial water column of 5 cm (2 in).

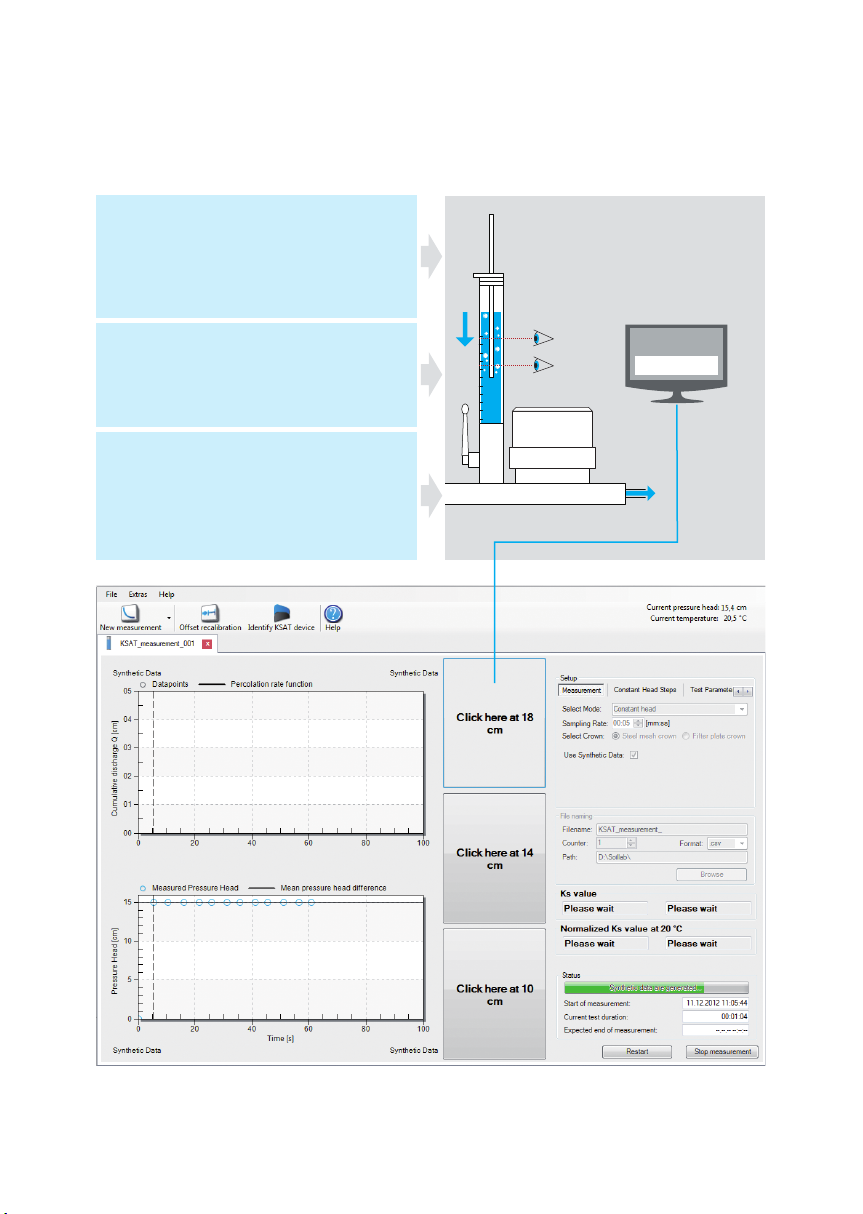

Soil samples can pass air bubbles that

form a film between the porous plate

and the soil sample. They reduce the

value of the measured conductivity.

Use degassed water. Saturate the soil

sample in vacuum.

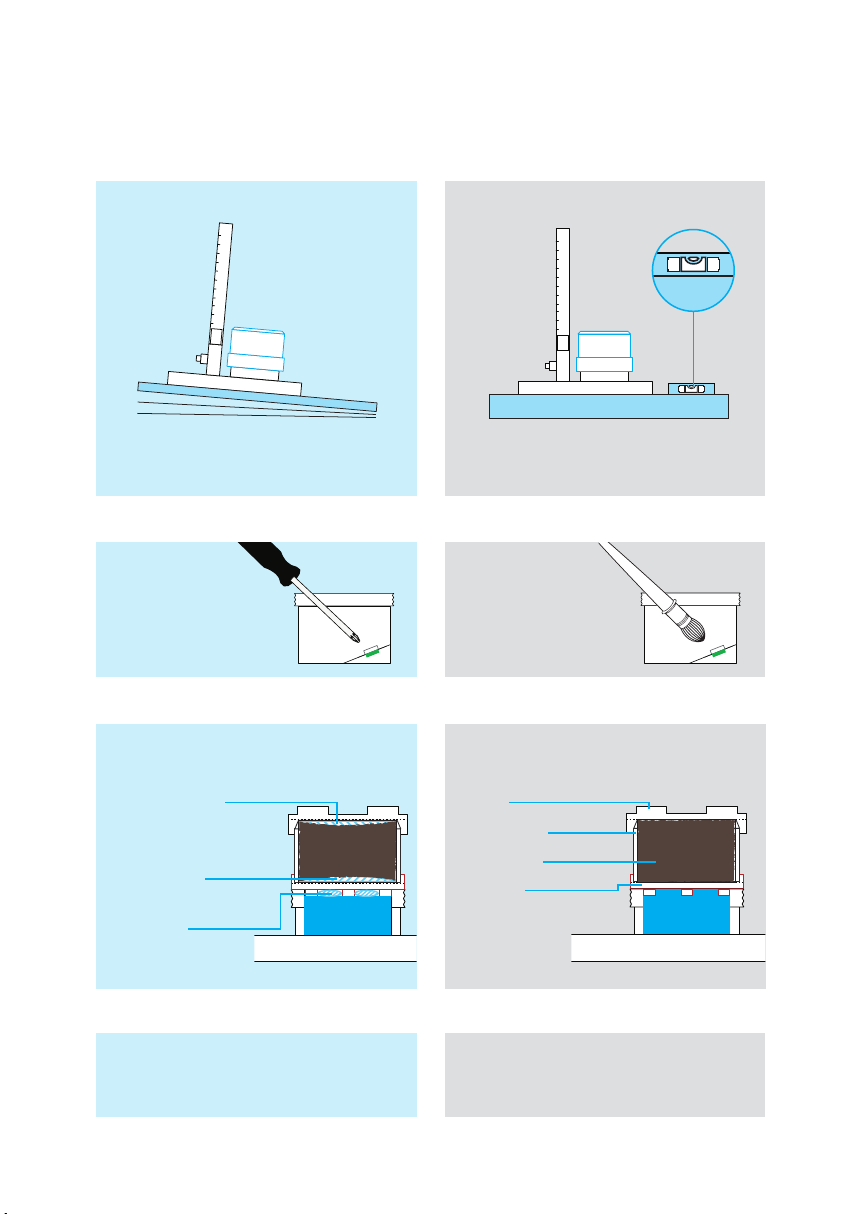

A temperature raise reduces the viscosity

of the measuring fluid.

E. g. increasing temperature from 20 to

23° C (68 to 73.4 F) causes a 18% change

of the measuring result.

Measuring device, environment and

water should have the same temperature.

Keep the temperature of your lab constant.

Dissolved gases outgas and form a

bubble film between the porous plate

and the soil sample. They reduce the

value of the measured conductivity.

Use degassed water

(Boiling before measuring is ok).

Eroded particles from instable materials

like sand may plug the discharge

channel of the device.

Clean the measuring dome, remove

particles and rinse thoroughly.