7

MANUAL - SOLVENT RECYCLERS - URS1600 SERIES, URS2000 SERIES & RI 80 Rev 2019-05

2) Install the Receiving Container, the Transfer Hoses and the air Supply

Receiving Container

• A 20 US Gal (80 liter) container must be used to receive the distilled solvent. Make sure the Solvent

Outlet Tube is properly inserted into the top opening of the Receiving Container by at least 1 inch (2.5

cm).

• When placing the Solvent Receiving Container, make sure the alligator clamp of the Grounding Strap

is fi rmly connected to the exposed metal surface of the container.

Air Supply

• These models are equipped with an air operated Dual Diaphragm pump and require a supply of clean,

dry air of at least 85 PSI (6 kg/cm2). A pre-set Pressure Regulator is included.

• Connect the air supply to the Air Inlet Fitting (1/4” NPT Female Threads) located at the right side of the

unit. Make sure that there are no leakages at the connection. Make sure that the air is free of dust, rust

and other contaminants. Use a Moisture Filter (not supplied), if necessary.

Hose Connections

• Place the drum/container with the dirty solvent to be distilled close to the unit.

• Connect the Solvent In Hose to the Solvent In port of the unit and insert the other end (with the Tank

Filler Suction Pipe) into the drum/container.

• Connect the alligator clamp at the end of the Ground Strap to the container with dirty solvent.

• Place the drum/container for the clean solvent close to the unit.

• Connect the Solvent Out Hose to the Solvent Out port of the unit and insert the other end with the

Outlet Tube into the drum/container. The Outlet Tube must extend below the rim of the pail to prevent

solvent spillage.

• If the pail is metal, connect the alligator clamp of the Ground wire to the rim of the drum/container.

3) Transfer Solvent to the Recycler Tank

• Turn the Handle of the Filler Valve counter-clockwise to open the fi lling passage.

• Turn the Filler Timer Knob clockwise fully. After a few seconds, dirty solvent will start fl owing into the

Distillation Tank.

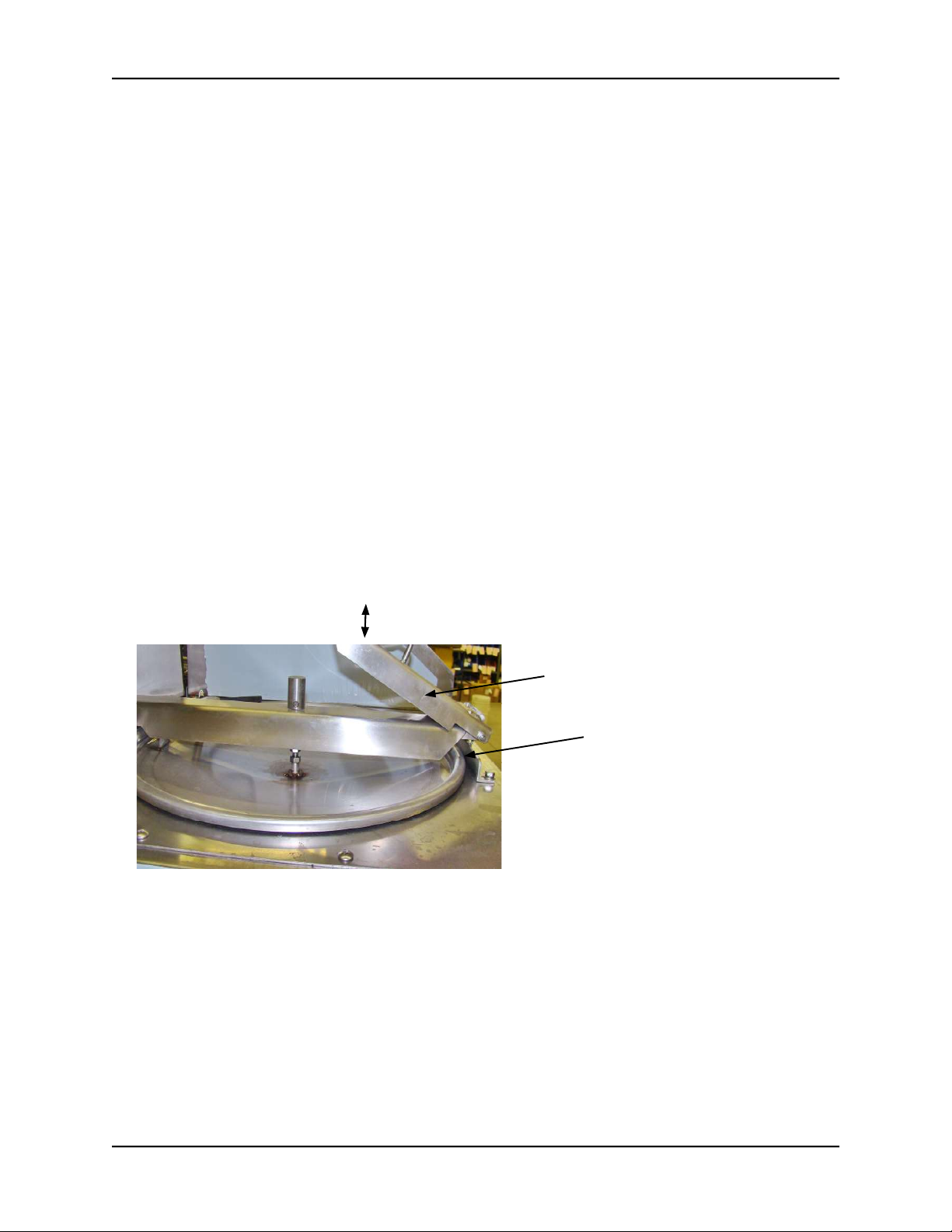

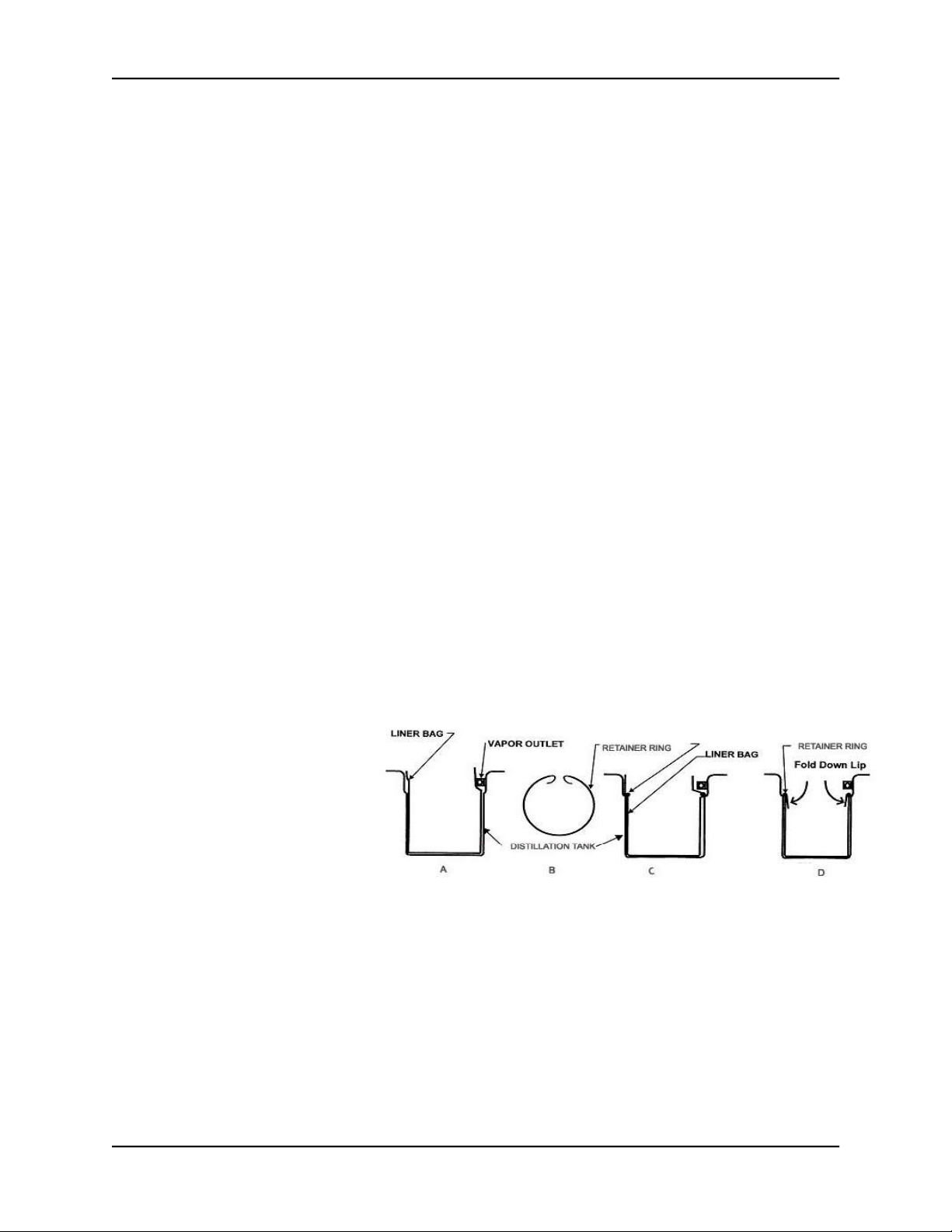

• Fill to 3” below retainer ring. After the fi lling process has been completed, turn the Handle of the

Filler Valve clockwise and close the Tank Lid. Make sure that the sealing area around the top of the

Tank is clean and damage free.

• Close the Distillation Tank Lid and secure with Lid Clamp. Make sure that the Lid is fi rmly seated to

avoid leakage.

• Close the Safety Cover.

4) Check distillation conditions and change, if necessary, using SETUP MODE.

Estimate Boiling Point

Add 40°C (100°F) to the boiling point of the pure solvent as shown on the MSDS (Material Safety Data

Sheet) or another reliable source.

Recycle more often

The boiling point of the waste solvent mixture increases as it gets dirtier. To reduce the boiling point,

recycle more often.

Minimize Temperature Set Point

After recycling there will be a small amount of solvent, about 1/8 US gal (500 ml), remaining in the distil-

lation tank due to condensation. Select the lowest Temperature Set Point that recycles the solvent to this

level.

If all the settings are acceptable, press START to begin distillation.

To change settings, enter Setup Mode