In order to improve the products in this catalogue the specications are subject to change without notice.

ASSEMBLY INSTRUCTIONS / MSD MG MOTOR SIDE DRIVE WITH A TIMING BELT

MOUNTING

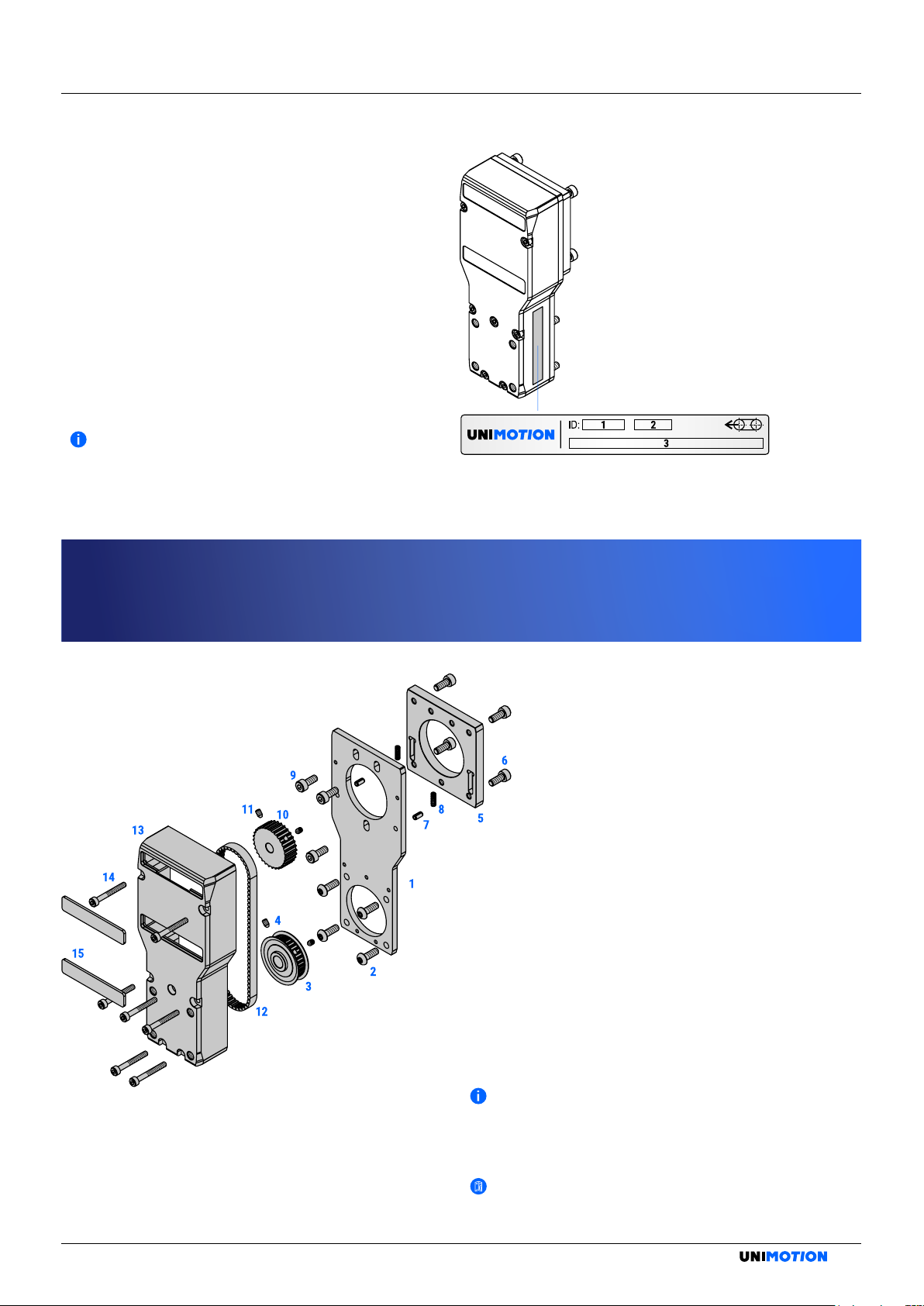

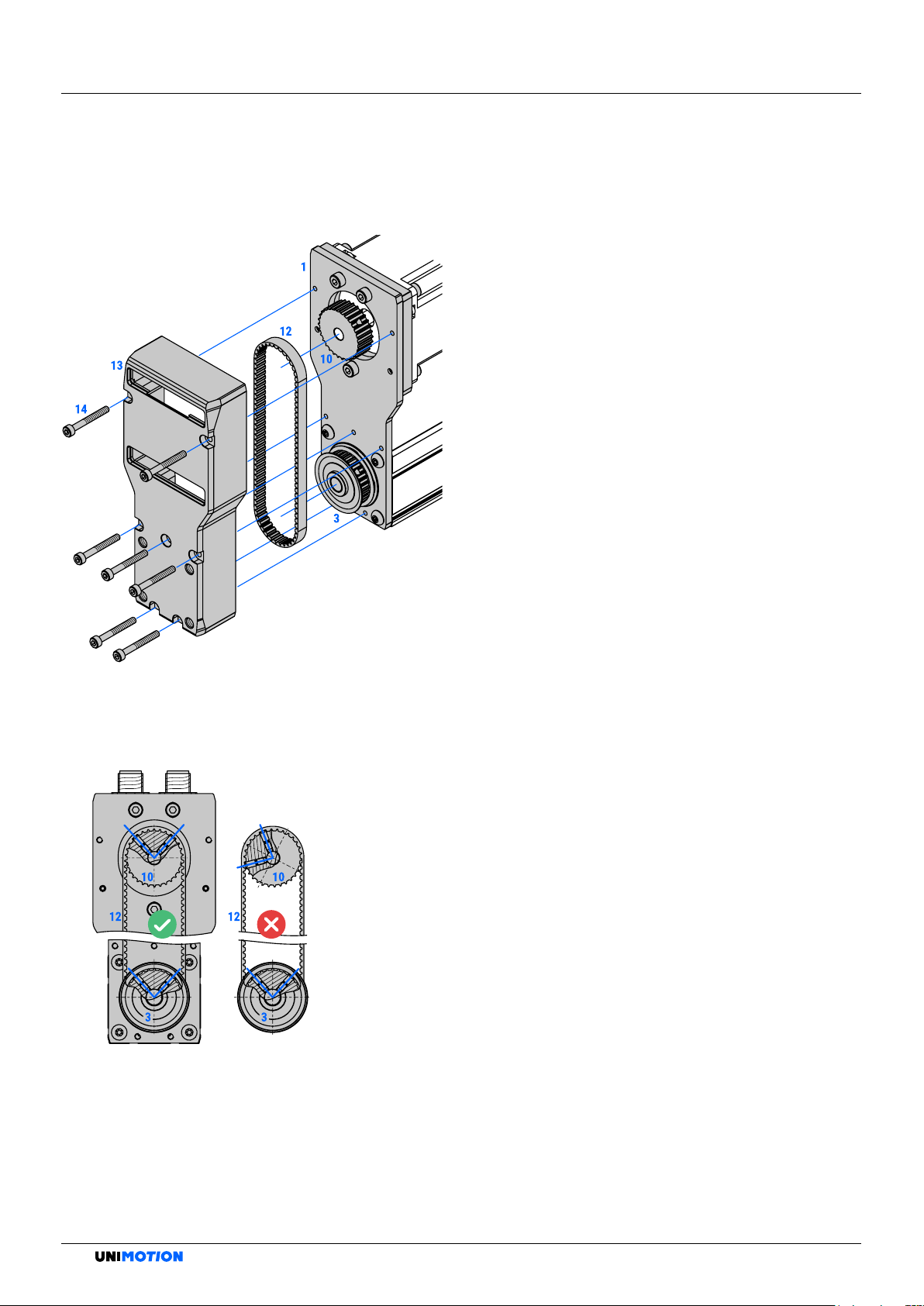

STEP 1 AND 2

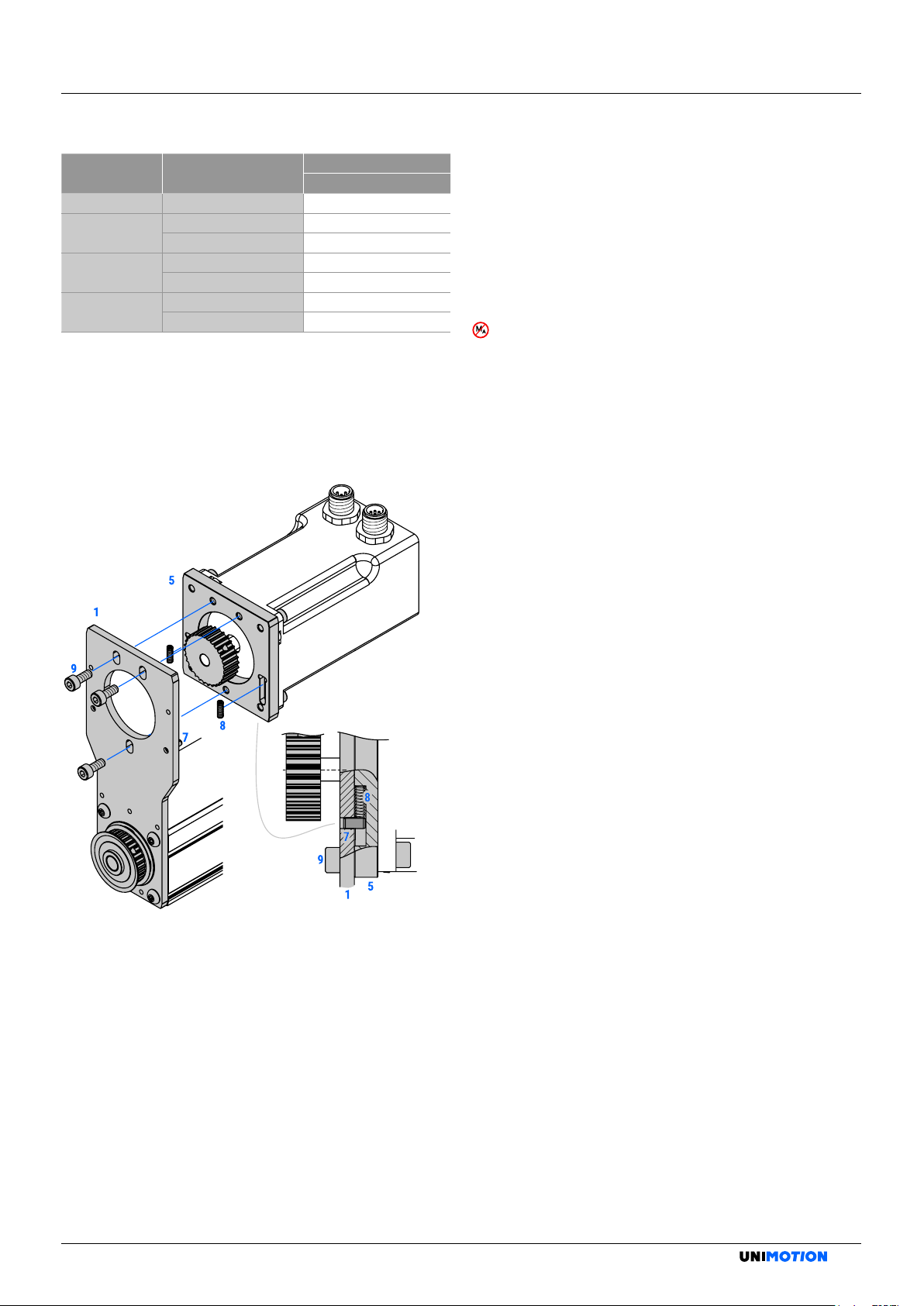

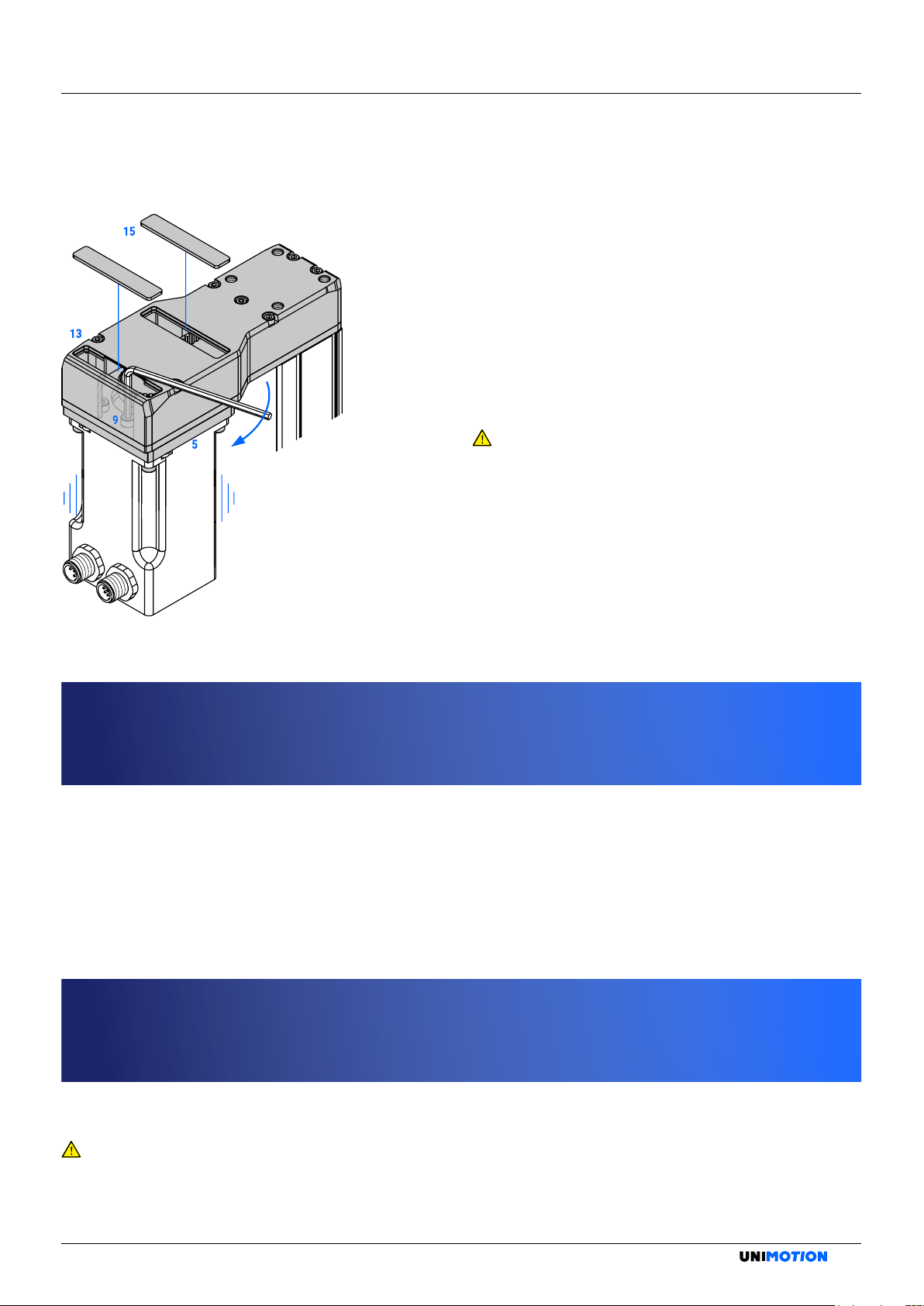

STEP 3 AND 4

Figure 3: Step 1 and 2.

Figure 4: Step 3 and 4.

MOUNTING

Requirements for personnel

The motor side drive may only be mounted by appropriately

qualied personnel. All qualied personnel must have

read and understood this assembly instructions.

Avoid from collision of the moving components and

the motor side drive (or the motor).

There must never be any collision of the mounted

motor side drive (or the motor) and the moving

components of the product or structure where the

product is installed, otherwise the product or motor

side drive may be damaged.

Risk of coming into contact with power conducting parts!

During the mounting procedure, the power supply should

be disconnected and secured against reconnection!

STEP 1: Mount the base plate 1on the product using

the base plate screws 2. The base plate 1

can be mounted in any orientation (facing up,

right, down or left).

Tighten the base plate screws 2.

STEP 2: Place the product belt pulley 3on the drive

shaft of the product. Ensure that the product

belt pulley 3is completely pushed on the drive

shaft of the product, please see the Figure 3.

Tighten the product belt pulley set screws 4

evenly.

STEP 3: Mount the tensioning plate 5onto the motor

(in desired motor orientation) with the motor

screws 6. Tighten the motor screws 6, as it is

presented in the Table 1.

There should be noted that the spring support pins

7are already mounted onto the base plate 1.

Make sure that the prepared slots for the springs

on the tensioning plate 5are placed on the

opposite side of the motor.

For the case of using the standard motor side

drive and the standard motor with the tapped

mounting holes, there are no motor screws 6. Place

the tensioning plate 5onto the motor without

tightening it.

Tighten the set screw 4with the tightening torque

as follows:

•set screw of size M3: 0,9 Nm,

•set screw of size M5: 5,8 Nm.

For the compatibility of the standard motor side

drives MSD MG with standard motors, please refer

to the product catalogue.

4