MA

1.005.0

MTV Series MANUAL

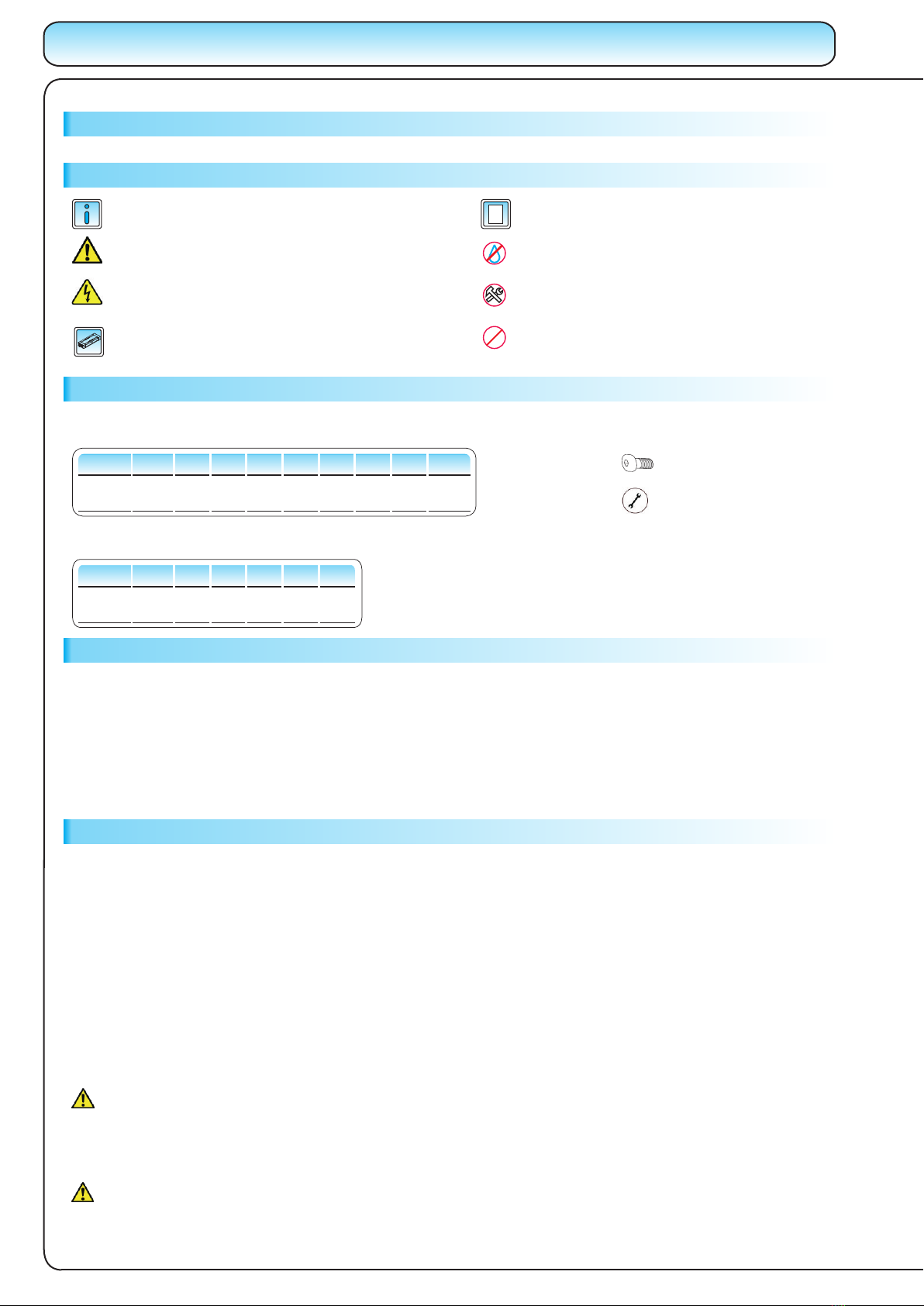

USED SYMBOLS

M2 M2,5 M3 M4 M5M6 M8 M10 M12

0.4 0.7 1.3 2.8 5.6 9.6 23 45 74

8.8

Mmax

[ Nm ]

Remark, note

Warning!

For more information see the catalogue

Linear Units

Linear Units

Linear Units

Linear Units

Linear Units

Caution!

Keep Linear Unit clean!

Cover it, if necessary!

TIGHTENING TORQUES

Following tightening torques are recommended for screws of strength class 8.8

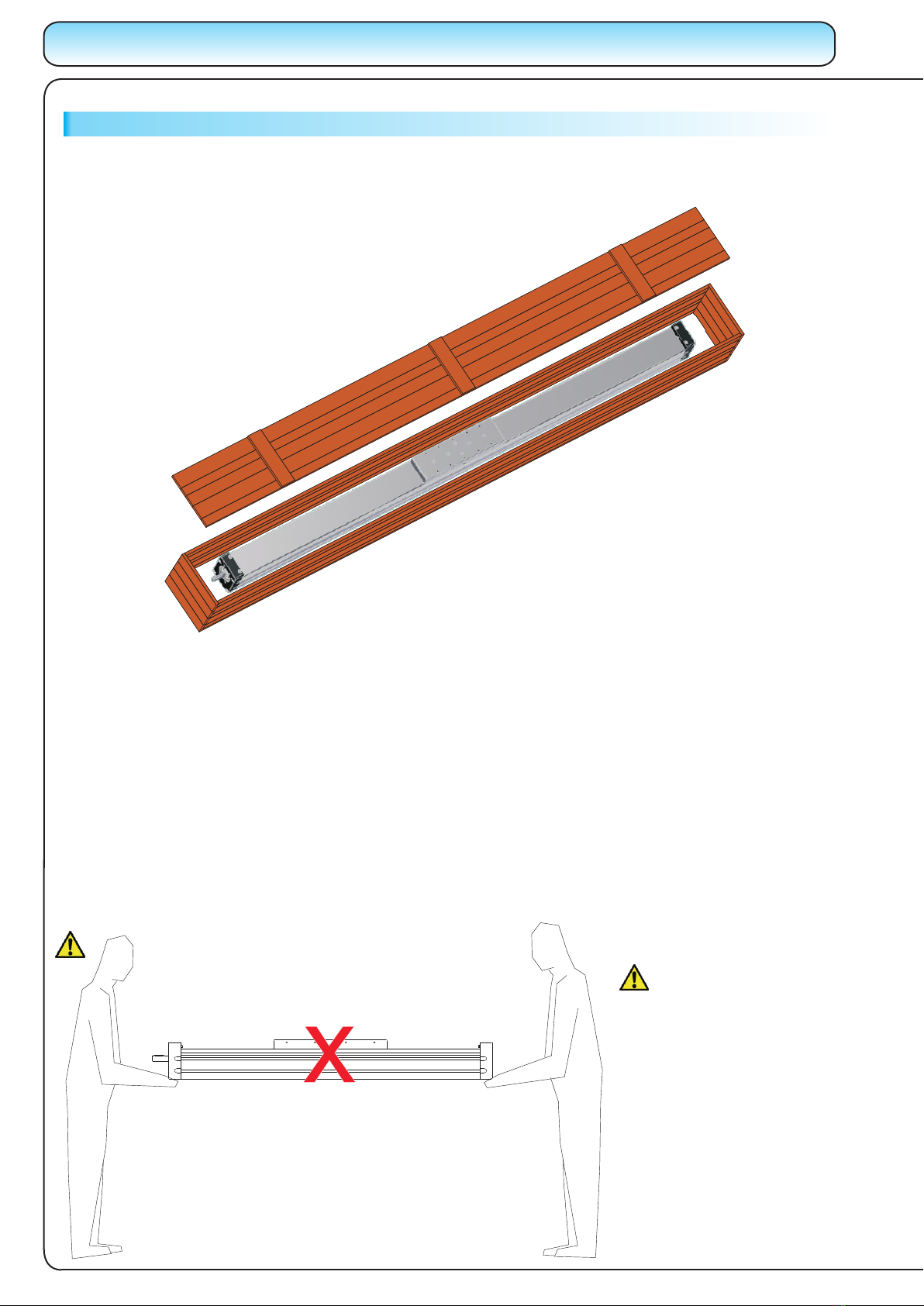

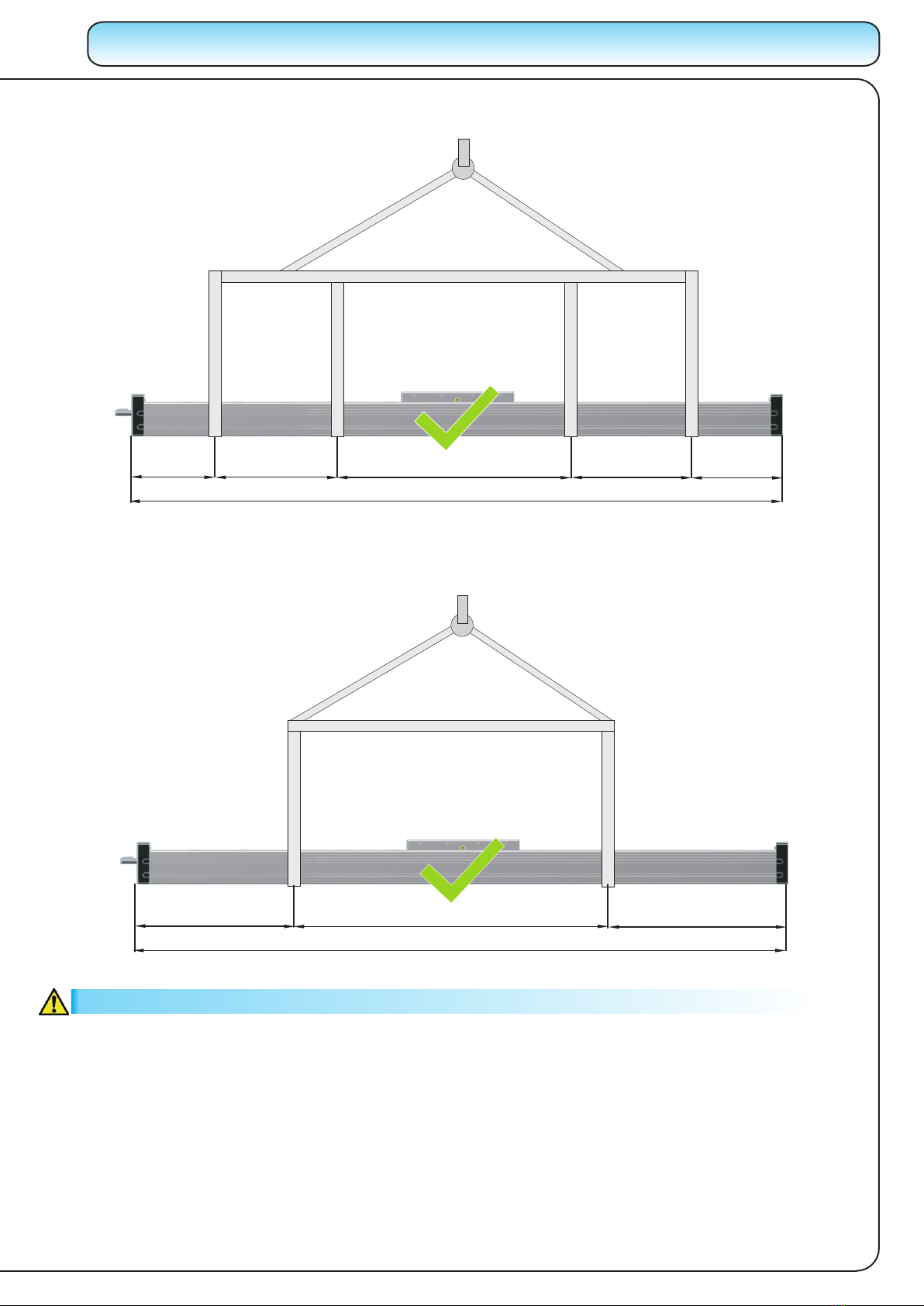

GENERAL SAFETY INSTURCTIONS

The linear unit must not be put into service until the final machinery into which it is installed has been

declared in confirmity with the provisions of the Machinery Directive, where appropriate.

Each operation of the Linear Unit that is not in compliance with its intended use can lead to the product being

damaged, accidents and at the same time stoppages in production. To ensure a safe operation please refer to this

Instruction Manual and the operating manual of other machinery where the Linear Unit is to be incorporated.

The linear unit satisfies the requirements of EC Machinery Directive 2006/42/EC according to the European or

national standards of Safety of machinery:

·EN ISO12100-1

·EN ISO 12100-2

The linear units may only be installed, operated, maintained, repaired or dismantled by appropriately qualified

personnel in accordance with specification User manual. All qualified personnel must have read and understood this

Instruction manual.

REGULATION OF USESAFE OPERATION

Requirements for personnel

Checking linear unit

In accordance with the EU Health and Safety Directive 89/655/EEC article 4a, the operating company must

subject the unit to thorough checking prior to putting it into operation, after carrying out repairs, and after

malfunctions have occurred.

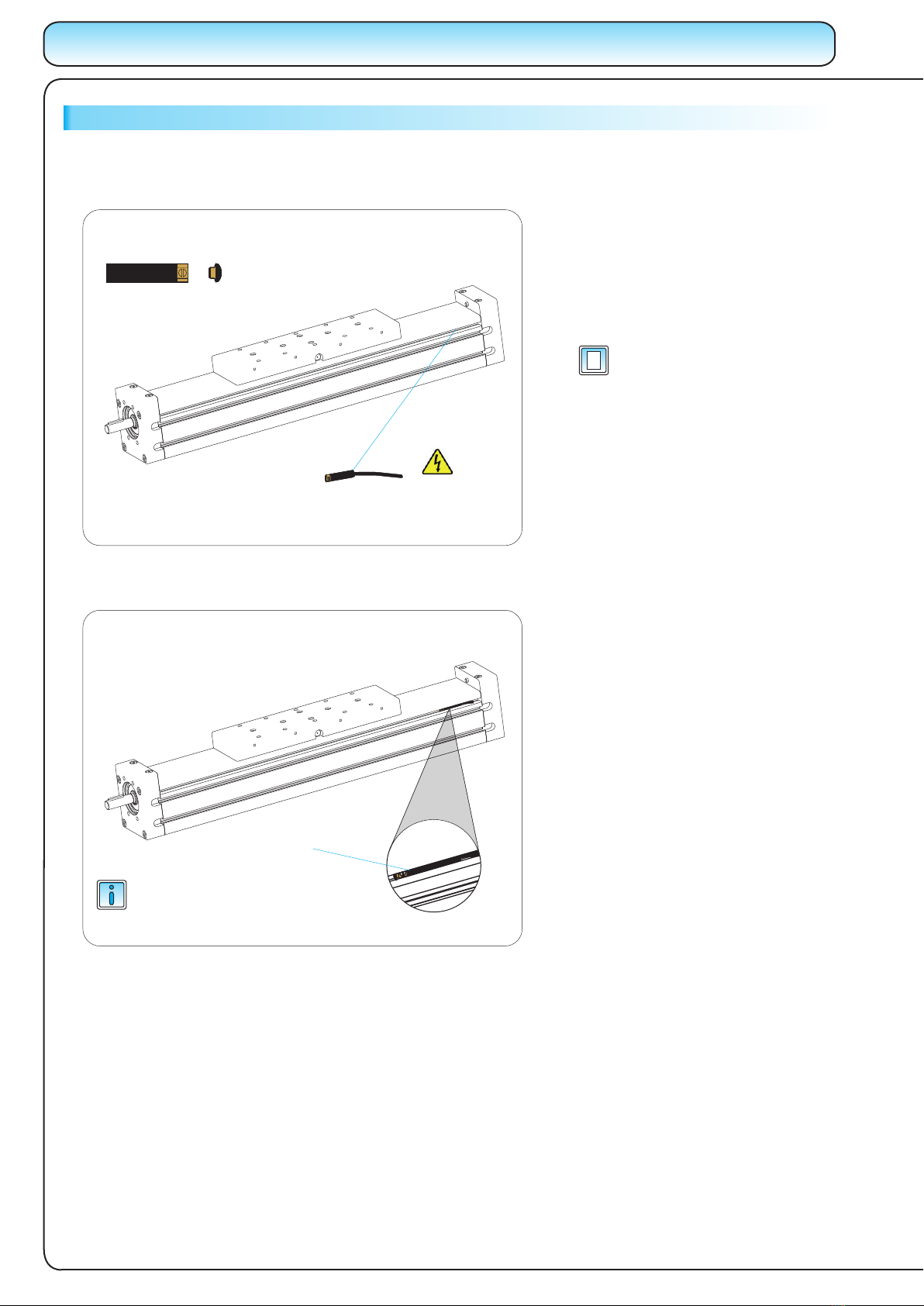

Danger!

Risk of coming into contact with power

conducting parts! Cut off power supply!

Screw

Tightening torque

To ensure the right functionality of the MTV Linear Unit, it must be handled with care. It is not allowed to put any

tools or any other items which can cause damage to the linear unit on the linear unit.

The Linear Unit must be proteceted against any liquid that can cause damage to it.

The MTV Linear unit must be placed in a dry, clean environment. For information on the conditions in which the

linear module can operate please contact us.

If the Linear Unit isn’t in use, place it in a dry, clean envrionment and cover it to prevent any damage.

GENERAL INFORMATION

Do not use glue in current step

Use dedicated tools for the current step

Use different tightening torque than in

the table on page 1.005.0

The specifications in order to improve the products in this catalogue are subject to change without notice.

M2,5 M3 M4 M5 M6M8

1.2 2.1 4.9 9.7 17 41

8.8

Mmax

[ Nm ]

Following tightening torques are recommended for screws of the self locking device