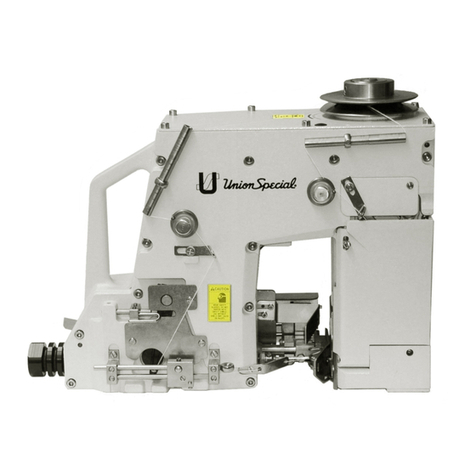

UnionSpecial PL 1096 User manual

Other UnionSpecial Sewing Machine manuals

UnionSpecial

UnionSpecial XF511B100MF User manual

UnionSpecial

UnionSpecial 80800R Setup guide

UnionSpecial

UnionSpecial BC200 User manual

UnionSpecial

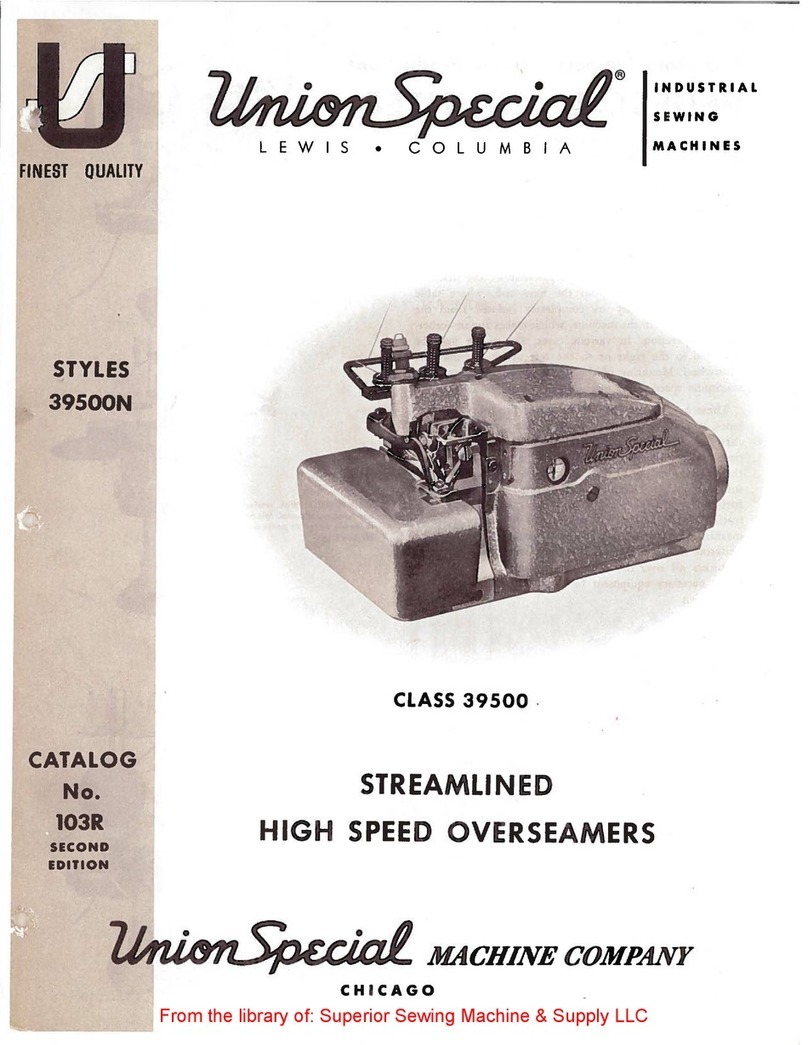

UnionSpecial 39500N Series Instruction sheet

UnionSpecial

UnionSpecial 80800 Setup guide

UnionSpecial

UnionSpecial 34 700 Series Setup guide

UnionSpecial

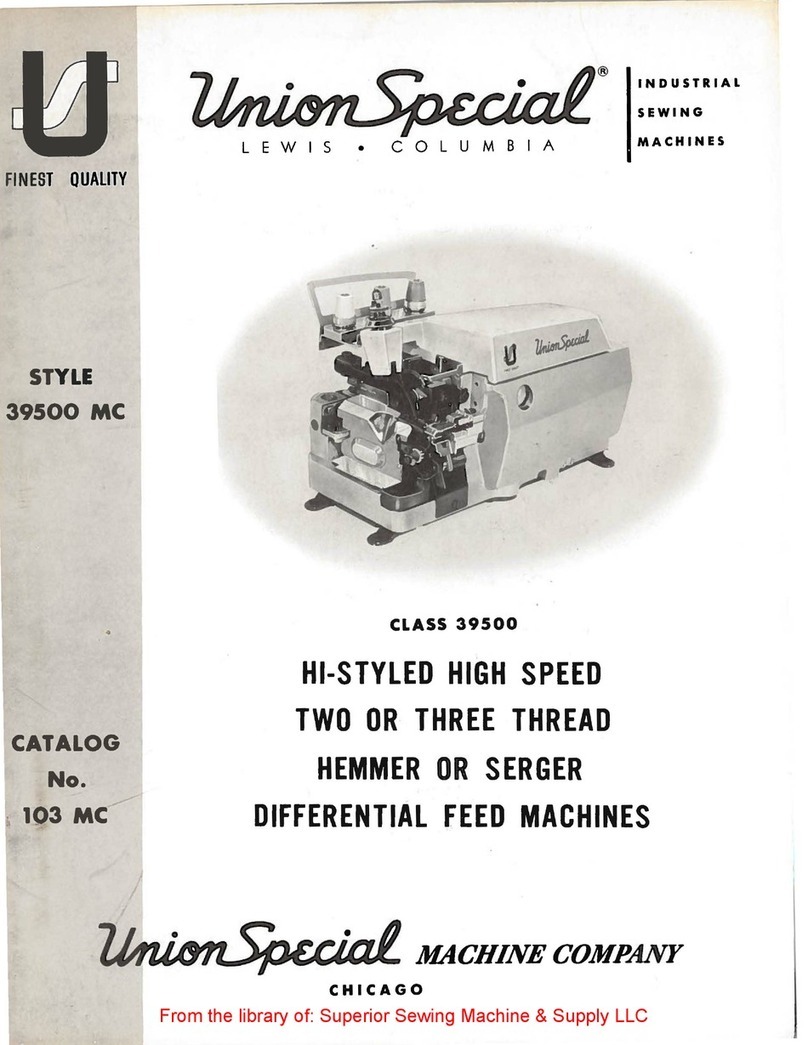

UnionSpecial 39500 MC Instruction sheet

UnionSpecial

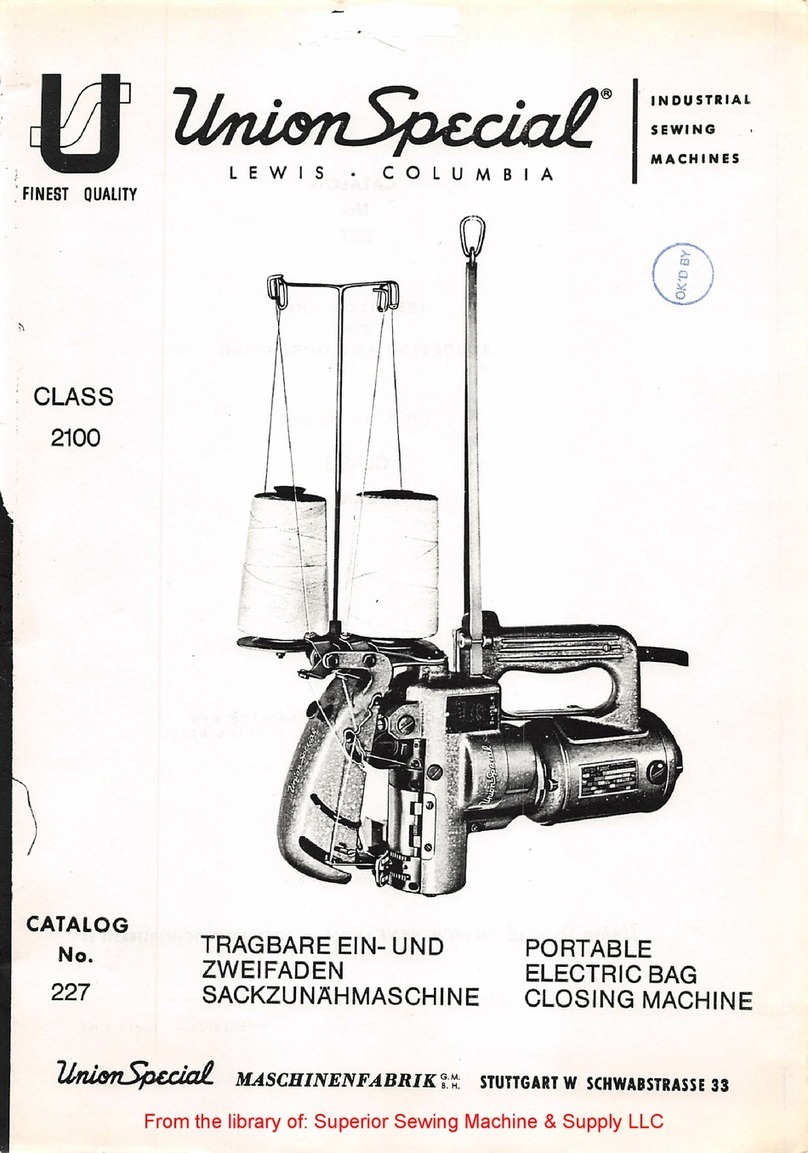

UnionSpecial CLASS 2100 Instruction sheet

UnionSpecial

UnionSpecial 61800C Parts list manual

UnionSpecial

UnionSpecial LF600 Series Setup guide

UnionSpecial

UnionSpecial 80800RN Setup guide

UnionSpecial

UnionSpecial 61800 Series Instruction sheet

UnionSpecial

UnionSpecial BC100 User manual

UnionSpecial

UnionSpecial TCP1 Original instructions

UnionSpecial

UnionSpecial 36200 Series Instruction sheet

UnionSpecial

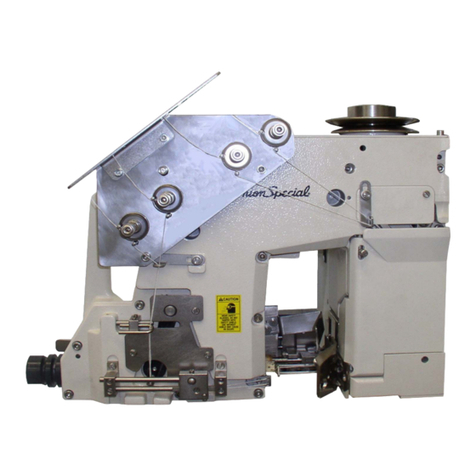

UnionSpecial P300-0 Series User manual

UnionSpecial

UnionSpecial BC200 User manual

UnionSpecial

UnionSpecial 81300 SERIES Technical reference manual

UnionSpecial

UnionSpecial 54200J-12-16 User manual

UnionSpecial

UnionSpecial 39500W Series Instruction sheet