UnionSpecial 39500N Series Instruction sheet

Other UnionSpecial Sewing Machine manuals

UnionSpecial

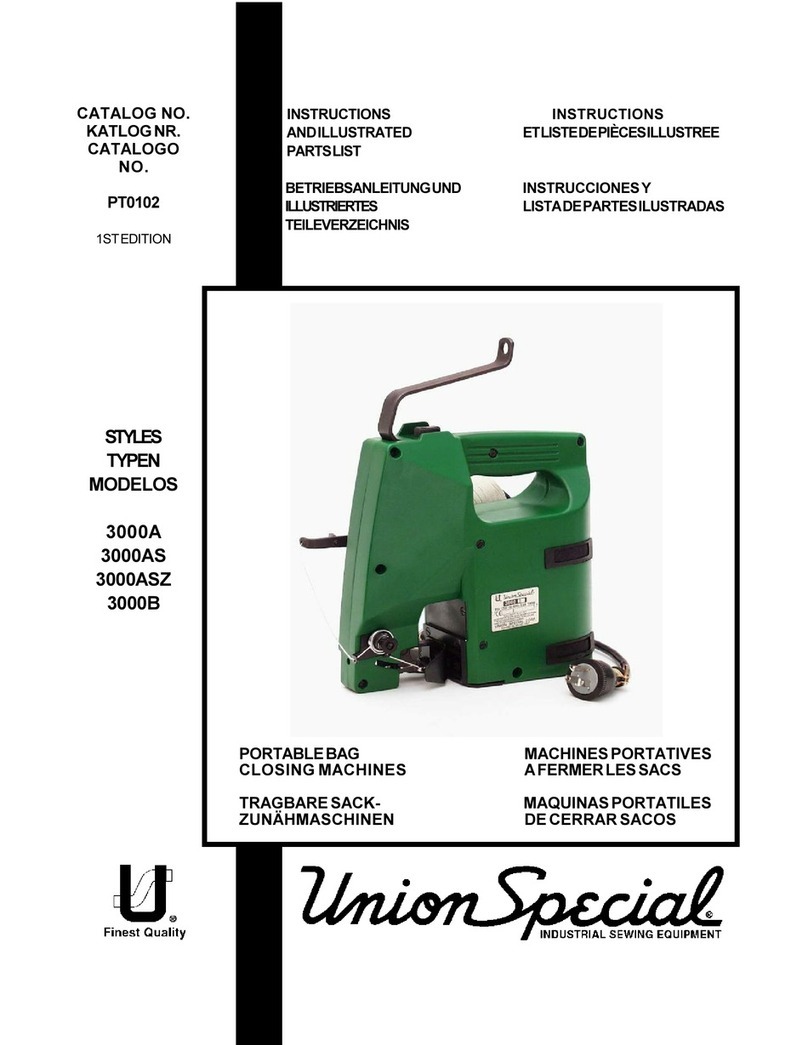

UnionSpecial 3000 Setup guide

UnionSpecial

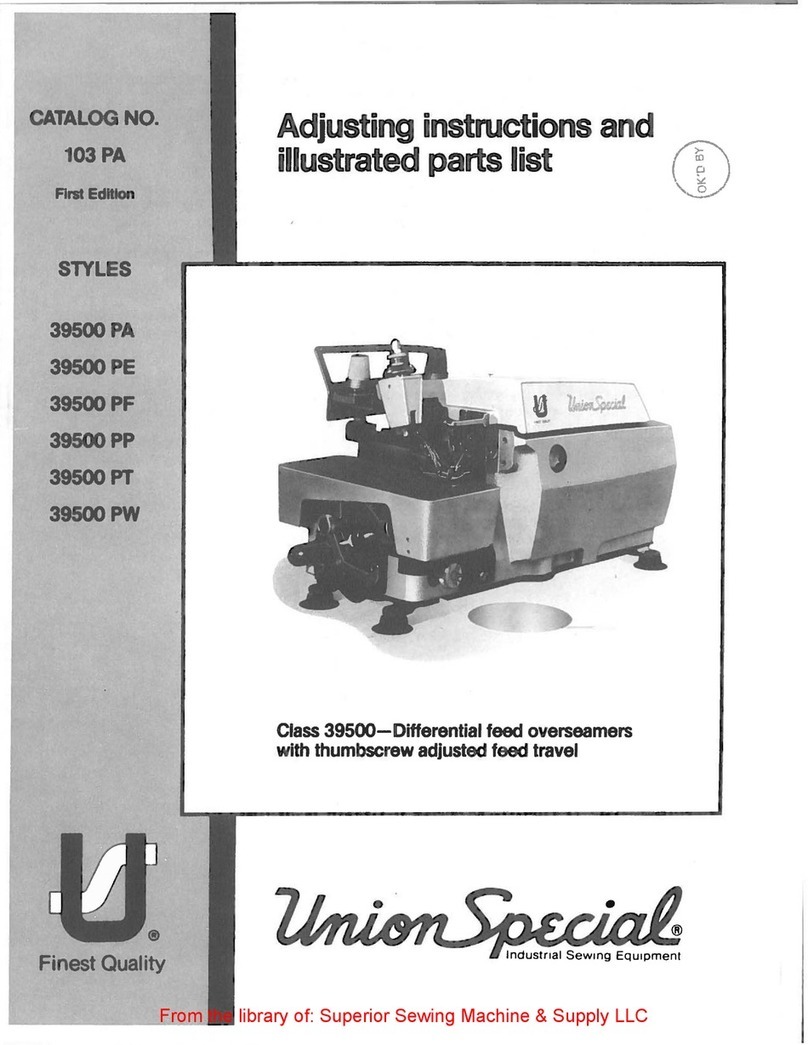

UnionSpecial 39500PA Setup guide

UnionSpecial

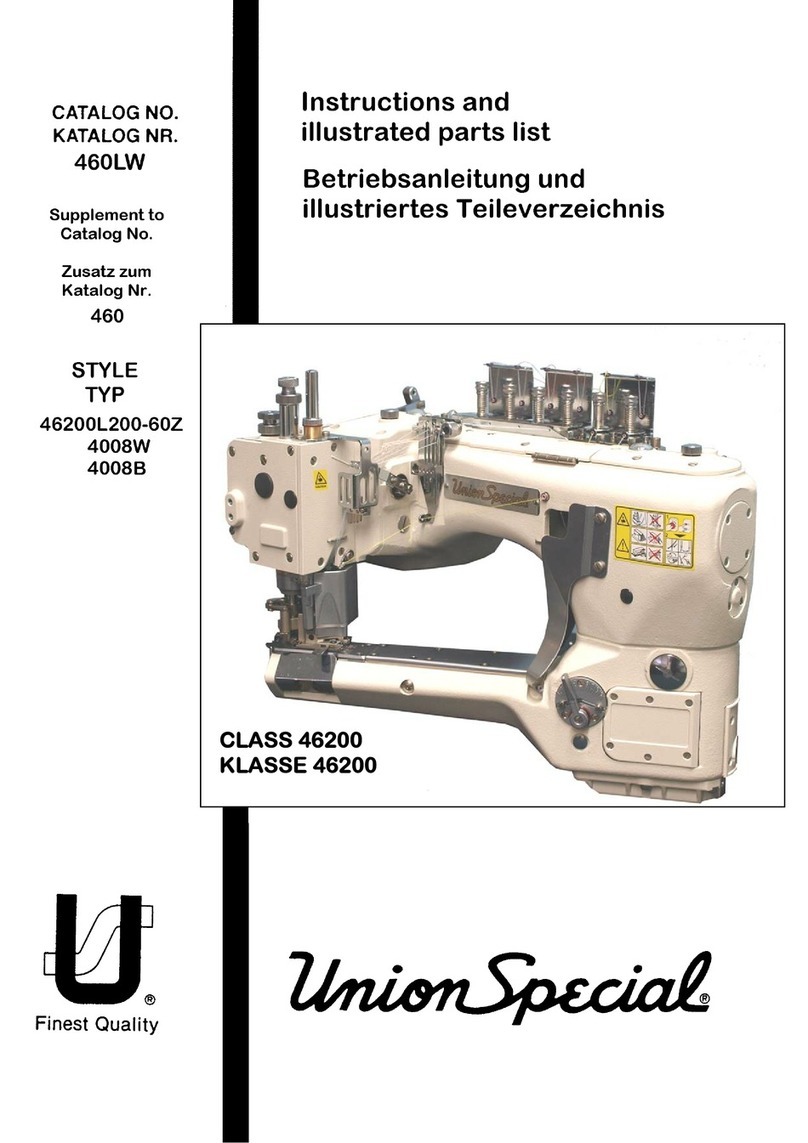

UnionSpecial 460LW Setup guide

UnionSpecial

UnionSpecial 81300 SERIES Technical reference manual

UnionSpecial

UnionSpecial 2200A User manual

UnionSpecial

UnionSpecial G230A-GR Setup guide

UnionSpecial

UnionSpecial 81300A Setup guide

UnionSpecial

UnionSpecial BC200 User manual

UnionSpecial

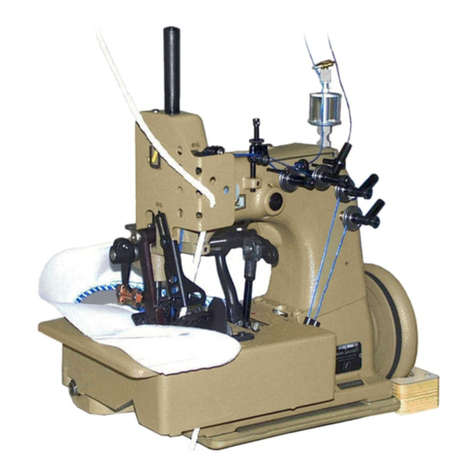

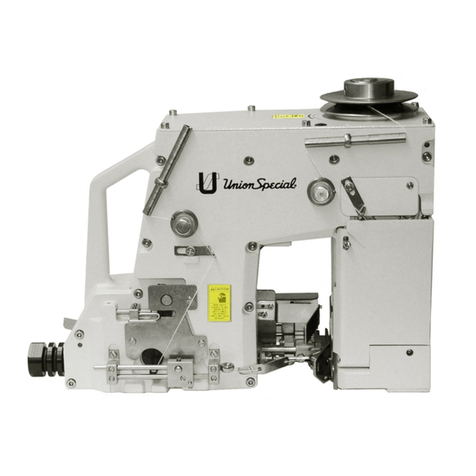

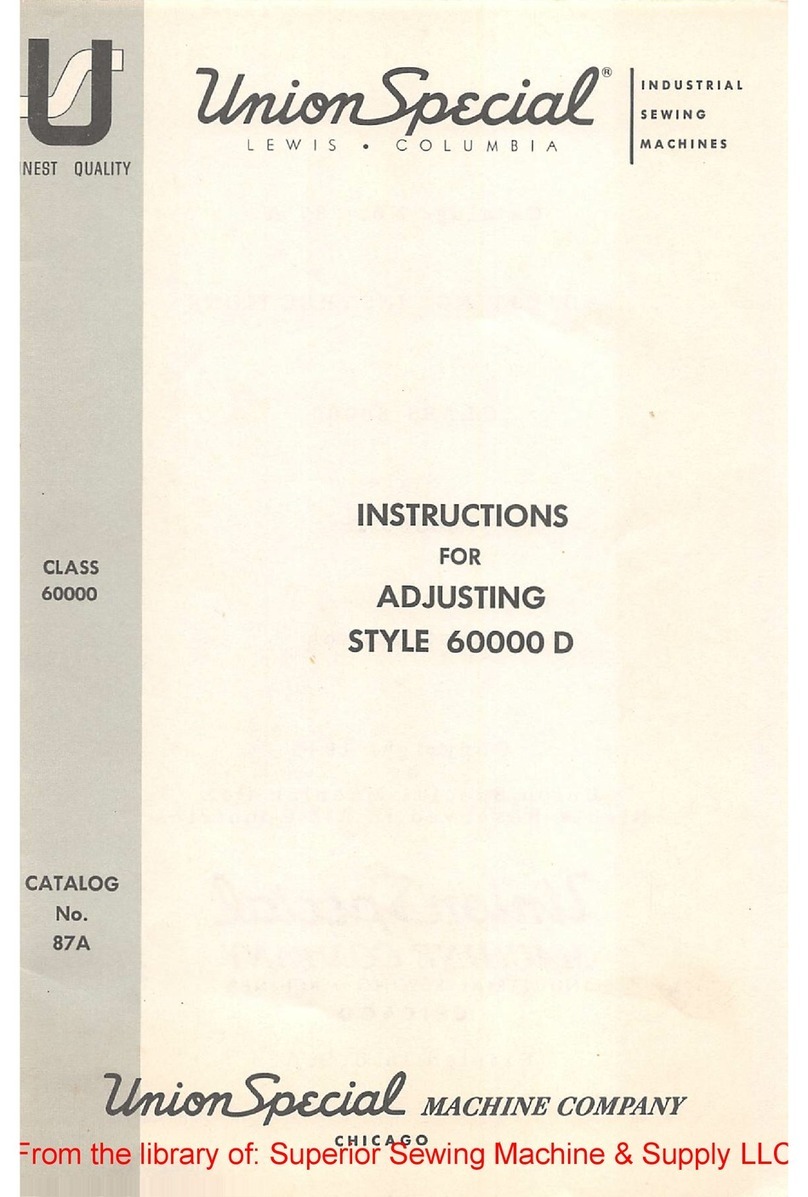

UnionSpecial 60000 D User manual

UnionSpecial

UnionSpecial LF612KlOOHB Setup guide

UnionSpecial

UnionSpecial 81500B2 Setup guide

UnionSpecial

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial CLASS 2200 User manual

UnionSpecial

UnionSpecial BC200 Setup guide

UnionSpecial

UnionSpecial BC100 User manual

UnionSpecial

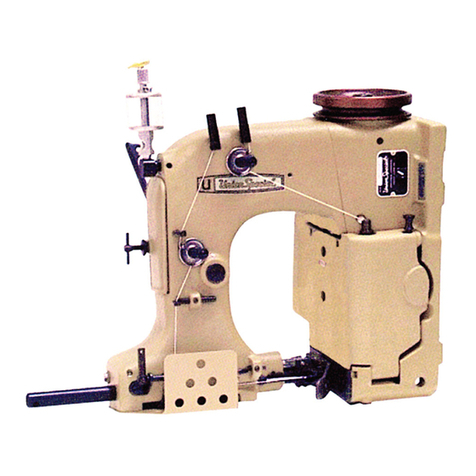

UnionSpecial PL 1096 User manual

UnionSpecial

UnionSpecial 80800 Setup guide

UnionSpecial

UnionSpecial 80800C User manual

UnionSpecial

UnionSpecial 39500FW Instruction sheet

UnionSpecial

UnionSpecial 4000 Series Setup guide