1392

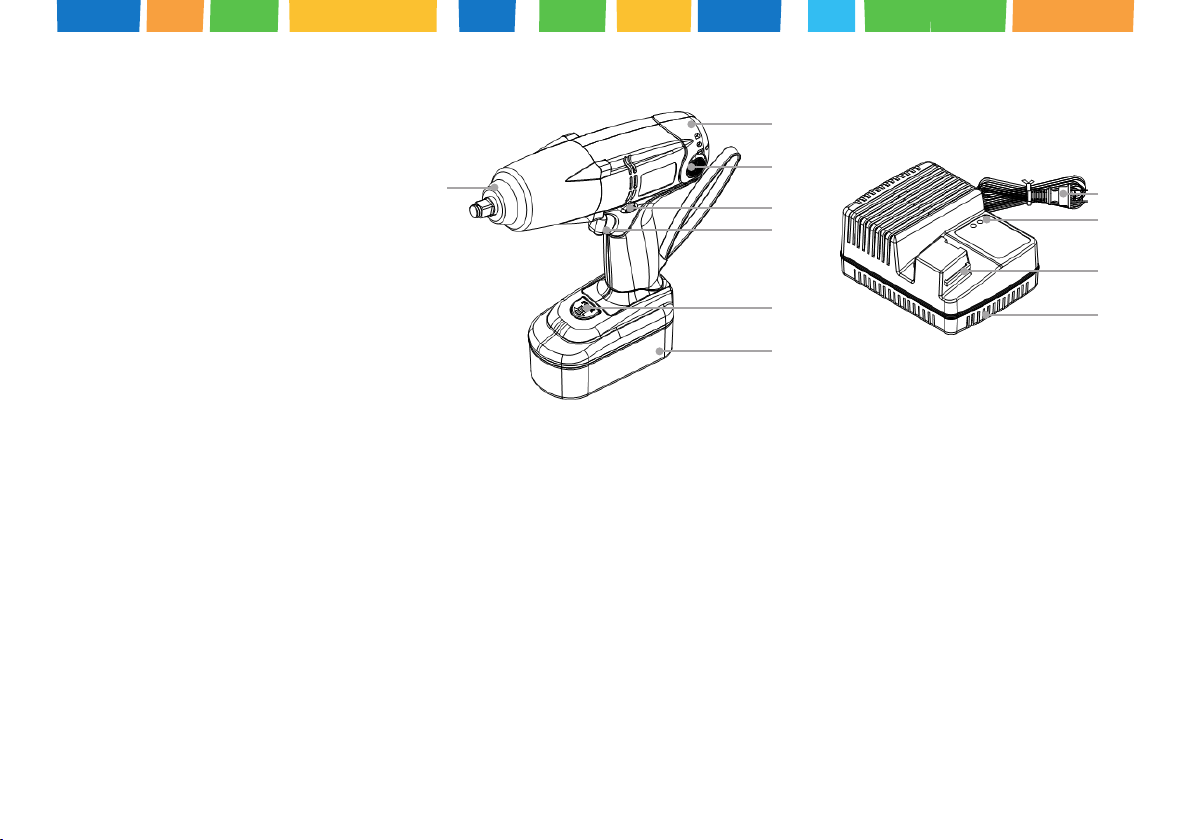

AKU screwdriver

EN

GENERAL WARNINGS

(1) For usage outside EU region, use corresponding adapter between charger cord and outlet

of your electrical network (2) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. (3) Keep bystanders, children and visitors away while

operating a power tool. (4) A battery operated tool with integral batteries or a separate battery pack

must be recharged only with the specified charger for the battery. A charger that may be suitable for one

type of battery may create a risk of fire when used with another battery. (5) Use battery operated tool

only with specifically designed battery pack. Use of any other batteries may create a risk of fire. (6)

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

tool while tired or under the influence of drugs, alcohol, or medication. (7) Do not wear loose clothing

or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose lathes, jewelry, or

long hair can be caught in moving parts. (8) Avoid accidental starting. Be sure switch is off position

before inserting battery. (9) Remove adjusting keys or wrenches before turning the tool on. (10) Use

safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions. (11) Do not use tool if switch does not turn it on

or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired. (12)

Disconnect battery pack from tool or place the switch in the locked or off position before making any ad-

justments, changing accessories, or storing the tools. Such preventive safety measures reduce the risk of

starting the tool accidentally. (13) Store idle tools out of reach of children and other untrained per-

sons. Tools are dangerous in the hands of untrained users. (14) When battery pack is not in use, keep

it away from other metal objects like: paper clips, coins, keys, nails, screws, or other small metal objects

that can make a connection from one terminal to another. Shorting the battery terminals together may

cause sparks, burns, or a fire. (15) Maintain tools with care. Keep cutting tools sharp and clean. Pro-

perly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

(16) Check for misalignment or binding of moving parts, breakage of parts, and any other condition that

may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are ca-

used by poorly maintained tools. (17) Use only accessories that are recommended by the manufac-

turer for your model. Accessories that may be suitable for one tool, may become hazardous when

used on another tool. (18) Tool service must be performed only by qualified repair personnel. Service

or maintenance performed by unqualified personnel could result in a risk of injury. (19) When servicing

a tool, use only identical replacement parts. Use of unauthorized parts or failure to follow Main-

tenance Instruction may create a risk of electric shock or injury. (20) NEVER disassemble the battery.

(21) NEVER incinerate the battery, even if it is damaged or is completely worn out.The battery can

explode in a fire. (22) NEVER short-circuit the battery. (23) NEVER insert any objects into the battery

charger’s air vents. Electric shock or damage to the battery charger may result. (24) NEVER charge

outdoors. Keep the battery away from direct sunlight and use only where there is low humidity and good

ventilation. (25) NEVER charge when the temperature is below 32°F (0°C) or above 104°F (40°C). (26)

NEVER connect two battery chargers together. (27) NEVER insert foreign objects into the hole for the

battery or the battery charger. (28) NEVER use a booster transformer when charging. (29) NEVER use

an engine generator or DC power to charge. (30) NEVER store the battery or battery charger in places

where the temperature may reach or exceed 104°F (40°C). (31) ALWAYS operate charger on standard

household electrical power (230 volts). Using the charger on any other voltage may overheat and

damage the charger. (32) ALWAYS wait at least 15 minutes between charges to avoid overheating the

charger. (33) ALWAYS disconnect the power cord from its receptacle when the charger is not use.

(34) Keep your work area and clean and well lit.