User guide and technical documentation

Page 1 of 29

Contents

1

Introduction ...................................................................................................................................... 3

1.1

What is Unipi Patron?.............................................................................................................. 3

1.2

What can be Unipi Patron used for?........................................................................................ 3

1.3

Which Patron models are available? ....................................................................................... 3

1.4

Patron product line structure ................................................................................................... 4

1.5

Compliance with directives ...................................................................................................... 4

2

Installation and connection .............................................................................................................. 5

2.1

Basic instructions and safety information ................................................................................ 5

2.2

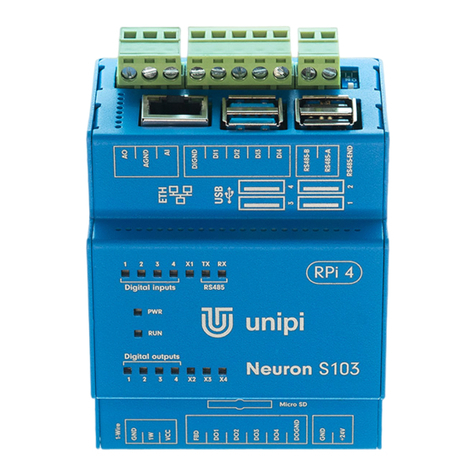

Basic unit description............................................................................................................... 5

2.3

Description of connectors and indication LEDs....................................................................... 6

2.3.1

LEDs indication................................................................................................................ 6

2.3.2

Connector description...................................................................................................... 7

2.4

Installation................................................................................................................................ 7

2.4.1

Mounting/Demounting...................................................................................................... 7

2.4.2

Connection....................................................................................................................... 9

2.4.3

Power supply connection................................................................................................. 9

2.4.4

Communication line connection....................................................................................... 9

2.4.5

Digital input connection – DI.......................................................................................... 10

2.4.6

Digital output connection – DO...................................................................................... 11

2.4.7

Analog input connection – AI......................................................................................... 11

2.4.8

Analog output connection – AO..................................................................................... 13

2.4.9

Relay output connection – RO....................................................................................... 14

3

Software......................................................................................................................................... 16

3.1

Default settings ...................................................................................................................... 16

3.1.1

Unipi Patron unit startup ................................................................................................ 16

3.1.2

Service mode................................................................................................................. 17

3.2

Overview of available APIs.................................................................................................... 18

3.2.1

EVOK............................................................................................................................. 18

3.2.2

Modbus TCP.................................................................................................................. 18

3.2.3

SysFS ............................................................................................................................ 18

3.3

Serial port maps..................................................................................................................... 20

3.3.1

RS485/RS232................................................................................................................ 20

3.3.2

USB................................................................................................................................ 20

3.4

Description of functions ......................................................................................................... 20

3.4.1

Digital inputs functions................................................................................................... 20

3.4.2

Digital outputs functions ................................................................................................ 21

3.4.3

Other setting and informative functions ......................................................................... 22